Abstract

In the Industry 4.0 era, numerous manufacturing enterprises have tried to obtain a smart manufacturing system. A key component of a smart manufacturing system is data analytics to support optimal decision-making in production systems. Consequently, many IT service providers have developed data analytics services. However, many small- and medium-sized enterprises (SMEs) have very low penetration of data analytics services compared to large enterprises because of the low profitability for IT service providers. Mass-customizable data analytics (McDA) services, which can be applied to various manufacturing SMEs, can give IT service providers the opportunity to increase their sales and thus their profits by applying services to more companies at little extra cost. This paper proposes a conceptual development process of McDA services for manufacturing SMEs and suggests future research issues. We believe that this paper can contribute to the dissemination of a smart manufacturing system.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the Industry 4.0 era, numerous manufacturing enterprises have attempted to adopt smart manufacturing systems to enhance their competitiveness [1, 2]. Smart manufacturing systems support intelligent decision-making for quick responses to new situations using real-time data [1, 3]. A key component for realizing smart manufacturing systems is data analytics [4]. Data analytics for smart manufacturing systems supports optimal decision-making by facilitating diagnosis, optimization, and prognostics for many problems in production, such as scheduling and equipment maintenance, based on manufacturing data [1]. Consequently, many IT service providers have recently tried to develop data analytics services.

However, because of the low profitability for IT service providers, manufacturing SMEs have very low penetration of data analytics services compared to large enterprises. One of the reasons for the low profitability is that the way in which most IT service providers develop customized services on a one-to-one basis is very costly [5]. Mass-customizable data analytics (McDA) services, which is developed in a one-to-many manner, can give IT service providers the opportunity to increase their sales and thus their profits by applying services to more companies at little extra cost.

Despite the advantages of McDA services, they are difficult to systematically develop because there is no knowhow or guidance for IT service providers with little experience on their development. Therefore, we developed a conceptual development process model that can serve as a reference for McDA service development.

This paper proposes a conceptual development process of McDA services for manufacturing SMEs. The proposed development process was constructed by reviewing related literature and actual data analytics service development projects. We conducted research with various manufacturing SMEs and the Korean government (Ministry of Trade, Industry and Energy). This paper is organized as follows. Section 2 reviews the relevant studies to understand the proposed process. Section 3 describes the proposed conceptual development process of McDA services for manufacturing SMEs. Finally, Sect. 4 summarizes this paper and suggests future work.

2 Literature Review

This section reviews two studies to define the activities needed to develop McDA services: the common new service development (NSD) process [6] and cross-industry standard process for data mining (CRISP-DM) [7]. The NSD process is used to define activities for developing service concepts that are commonly needed for manufacturing SMEs. CRISP-DM is used to define activities for data analytics. The reviewed studies are considered basic knowledge in this paper.

2.1 Common New Service Development Process

Studies on the NSD process have organized activities for service development well. In particular, Kim and Meiren [6] formed a common NSD process based on six existing NSD processes. The common NSD process consists of five activities: opportunity identification, customer understanding, concept development, process design, and refinement and implementation [6]. Opportunity identification is recognizing opportunities for new services or improvements in existing services. Customer understanding is defining the target customers and identifying their needs. Concept design is generating the service concept based on the service opportunities and customer needs. Process design is developing the processes by which the service is produced and delivered. Refinement and implementation is testing and performing pilot runs of the service; after necessary enhancements and adjustments, a full-scale launch of the service is made, and a post-launch review is conducted.

2.2 Cross-Industry Standard Process for Data Mining

The following study of process model for data analytics is used to define data analytics activities. Among the many process models for data analytics, CRISP-DM is the most widely used because it works well in most data analytics [8]. CRISP-DM consists of six activities: business understanding, data understanding, data preparation, modeling, evaluation, and deployment [7]. Business understanding focuses on understanding the project objectives and requirements from a business perspective and then converting this knowledge into a definition of data analytics to design a preliminary project plan that achieves the objectives. Data understanding starts with an initial data collection and proceeds with activities in order to get familiar with the data, identify data quality problems, discover first insights into the data, or detect interesting subsets to form hypotheses for hidden information. Data preparation covers all activities to construct the final dataset from the initial raw data. For modeling, various modeling techniques are selected and applied, and their parameters are calibrated to optimal values. Evaluation involves determining if some important business issue has not been sufficiently considered. Deployment is an activity of deploying data analytics and giving the guidelines for using it.

3 Conceptual Development Process of Mass-customizable Data Analytics Services for Manufacturing SMEs

This section presents a conceptual development process of McDA services for manufacturing SMEs using IDEF0 representation. The development of the process was initiated by a literature review and our project of developing cloud services for situational analysis and decision-making based on manufacturing big data.

3.1 Overview of IDEF0

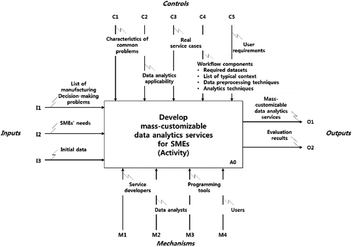

IDEF0 is an activity modeling method that is designed to describe activities and the relationships between them [9]. Activities in the IDEF0 model are influenced by inputs, controls, outputs, and mechanisms (ICOMs). Each activity receives certain inputs, is constrained by controls, and derives output by various mechanisms.

The IDEF0 model is hierarchically structured according to the detail level of the representation. Figure 1 shows A-0, which represents the most general level of McDA service development. Inputs are the items changed by the activity. In the McDA service development, manufacturing decision-making problems, SME needs, and the initial data correspond to the inputs. Controls are factors that trigger the activity and constrain its execution. Characteristics of common problems, data analytics applicability, real service cases, workflow components, and user requirements correspond to the controls. Outputs are the results of the activity. McDA services and evaluation results correspond to the outputs. Mechanisms are means used to perform the activity. Service developers, data analysts, programming tools, and users are the mechanisms in this case.

3.2 Level-1 Activities

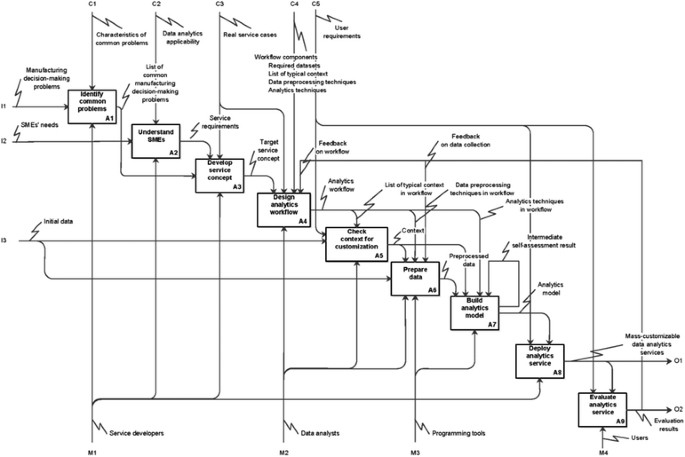

This section defines nine level-1 activities decomposed from A0 based on the reference processes mentioned in Sect. 2. Table 1 presents which activities of the reference processes are referenced in level-1 activities and what changes. The activities are semantically divided into two main phases: massification (A1–A4) and customization (A5–A9). In the massification phase, the service concepts that are commonly needed by many manufacturing SMEs are developed, and the analytics workflow is designed in advance. During the customization phase, the analytics service is customized to the manufacturing SMEs. A data analytics process that concentrates on the customization is costly and time-consuming because this has to be done separately for each manufacturing SME. Thus, in order to increase the efficiency, tasks should be conducted in the massification phase as much as possible, and only tasks for which customization is essential should be left in the customization phase.

3.3 Proposed Development Process

This section describes the proposed development process consisting of level-1 activities using IDEF0 representation. Figure 2 shows the conceptual development process of McDA services for manufacturing SMEs. Each activity is discussed below.

A1 Identify Common Problems.

Developing services for decision-making problems that occur only in the applicable company cannot be widely applied to other companies. This initial activity derives manufacturing decision-making problems that can be universally solved and widely occurring in various manufacturing industries and companies. Various manufacturing decision-making problems such as production scheduling, quality control, inventory management, and equipment maintenance can be collected based on a literature review and case studies. The service developer makes a list of common manufacturing decision-making problems by extracting problems with common characteristics from the collected problems. There are two criteria used to characterize common problems: industry-wide commonality and technically universal resolvability.

A2 Understand SMEs.

This activity identifies the needs of SMEs and derives the requirements of the data analytics service. It is necessary to collect the needs of SMEs by consulting with domain experts, focus groups of manufacturing SMEs, and case studies before this activity. Next, service developers review whether the collected needs are met through data analytics. Finally, the needs that can be met through data analytics are defined as the requirements of the service. An example of a service requirement may be a reduction in equipment maintenance costs.

A3 Develop Service Concept.

In this activity, the target service concept is generated on the basis of common problems that meet the service requirements of SMEs. The service objectives and data analytics goals are determined to satisfy the requirements. As an example of an abstract service concept, it can be defined as providing data analytics that diagnose equipment failures in real time to reduce maintenance costs. Service developers should refer to actual service cases to develop a concrete service concept.

A4 Design Analytics Workflow.

This activity involves designing the analytics workflow, which is the operational processes of the data analytics service. It begins with defining the required full dataset to solve the problem of the target service concept. Typical contexts, which are the cases that are typically considered in data analytics for a particular environment, are then defined. Next, the appropriate data preprocessing techniques and analytics techniques for each context are determined. Finally, the analytic workflow is designed by combining the techniques appropriate to each context at each analytic step, such as data preprocessing and modeling.

In practice, when data analytics services are being developed for diagnosing equipment conditions, typical required data are defined, such as vibrations, acoustic, pressure, moisture, humidity, temperature, and enviroment. Through interviews, case studies, and review papers, we can assume the following typical contexts: satisfying all requested data, no labeled data for equipment conditions, imbalanced data, etc. If there is no labeled data for equipment conditions, the unsupervised learning technique may be suitable for modeling. The analytics workflow is designed by combining the techniques suitable for each context.

The history of the workflow must be stored and managed in the system. Accumulated analytics workflow histories can help with automating all phases of data analytics in a variety of contexts. Even if a new context occurs, it can be customized with minor modifications.

A5 Check Context for Customization.

This activity, which is the first of the customization phase, checks the context of the application target. Data analysts compare the initial data and the user requirements with the typical context of the previously designed analytics workflow and select the most similar context among the defined contexts.

A6 Prepare Data.

This activity includes all tasks for constructing the initial data to match the required dataset in the analytics workflow as much as possible. Tasks in this activity are often performed multiple times, and the order is unspecified. Tasks include data collection, data cleaning, data integration, and data formatting.

A7 Build Analytics Model.

In this activity, the analytic techniques specified in the analytics workflow apply. The modeling techniques are applied to build the data analytics model, and their parameters are calibrated to optimal values. The best data analytics model with optimal hyperparameter settings can be found through self-validation.

A8 Deploy Analytics Service.

In this activity, the service providers deploy the data analytics service. Service providers transform the analytics model into a service that reflects the user’s service requirements. Finally, the McDA service is deployed to manufacturing enterprises.

A9 Evaluate Analytics Service.

In the final activity, service users review and evaluate the developed data analytics service based on user requirements and the performance of data analytics service. If the performance of the data analytics is insufficient, the cause is categorized as an insufficient dataset or incorrect workflow. If the poor performance is due to a deficient dataset, the service developer should go back to A6 to prepare a dataset that best meets the required dataset. If it is due to wrong workflow, the service developer should return to A6 to add the workflow for this context.

4 Conclusion and Future Work

McDA services can be applied to various manufacturing enterprises in a one-to-many manner. In this paper, we formalize activities and their relationships in our reference process model using IDEF0 for developing McDA services for manufacturing SMEs. Based on our reference process model, we expect IT service providers to be able to easily develop McDA services for manufacturing SMEs. Furthermore, this paper is expected to contribute to the proliferation of smart manufacturing systems in manufacturing SMEs.

Several future works are needed. First, the specific tasks and outcomes needed in each activity should be presented through an application of the proposed process to a wide variety of manufacturing SMEs. A relevant project is in progress, and the issues can be identified after all the activities are performed. Second, a system capable of providing McDA services should be developed. We are currently working on an architectural design for McDA services based on cloud services and service-oriented architecture [10]. Third, standardization is important for interoperation of the sensors and systems of various manufacturing SMEs with the data analytics service system.

References

Shin, S., Woo, J., Rachuri, S.: Predictive analytics model for power consumption in manufacturing. In: 21st CIRP Conference on Life Cycle Engineering, pp. 153–158. Elsevier, Amsterdam (2014)

Choi, S., Jun, C., Zhao, W.B., Noh, S.: Digital manufacturing in smart manufacturing systems: contribution, barriers, and future directions. In: Umeda, S., Nakano, M., Mizuyama, H., Hibino, H., Kiritsis, D., Cieminski, G. (eds.) APMS 2015. IAICT, vol. 460, pp. 21–29. Springer, Cham (2015). doi:10.1007/978-3-319-22759-7_3

Jung, K., Morris, K.C., Lyons, W.K., Leong, S., Cho, H.: Mapping strategic goals and operational performance metrics for smart manufacturing systems. In: 2015 Conference on Systems Engineering Research, pp. 184–193. Elsevier, Amsterdam (2015)

Manyika, J., Sinclair, J., Dobbs, R., Strube, G., Rassey, L., Mischke, J., Remes, J., Roxburgh, C., George, K., O’Halloran, D., Ramaswami, S.: Manufacturing the Future: The Next Era of Global Growth and Innovation. McKinsey Global Institute, Atlanta (2012)

Elgammal, A., Papazoglou, M., Kramer, B., Constantinescu, C.: Design for customization: a new paradigm for product-service system development. In: The 9th CIRP IPSS Conference on Circular Perspectives on Product/Service-Systems, pp. 345–350. Elsevier, Amsterdam (2017)

Kim, K., Meiren, T.: New service development process. In: Salvendy, G., Karwowski, W. (eds.) Introduction to Service Engineering, pp. 253–267. Wiley, Hoboken (2010)

Wirth, R., Hipp, J.: CRISP-DM: towards a standard model for data mining. In: Proceedings of the 4th International Conference on the Practical Applications of Knowledge Discovery and Data Mining, pp. 29–39. Association for the Advancement of Artificial Intelligence, Palo Alto (2000)

Mariscal, G., Marban, O., Fernandez, C.: A survey of data mining and knowledge discovery process models and methodologies. Knowl. Eng. Rev. 25, 137 (2010)

IEEE 1320.1: IEEE Standard for Functional Modeling Language – Syntax and Semantics for IDEF0. The Institute of Electrical and Electronics Engineers, New York (1998)

Delen, D., Demirkan, H.: Data, information and analytics as services. Decis. Support Syst. 55, 259–363 (2013)

Acknowledgment

This research was supported by Industry Core Technology Development Project funded by the Ministry of Trade, Industry and Energy (Project name: “Development of Cloud Service for Situational Analysis and Decision Making based on Manufacturing Big Data”, Project number: 10063369).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 IFIP International Federation for Information Processing

About this paper

Cite this paper

Park, H. et al. (2017). Conceptual Development Process of Mass-customizable Data Analytics Services for Manufacturing SMEs. In: Lödding, H., Riedel, R., Thoben, KD., von Cieminski, G., Kiritsis, D. (eds) Advances in Production Management Systems. The Path to Intelligent, Collaborative and Sustainable Manufacturing . APMS 2017. IFIP Advances in Information and Communication Technology, vol 513. Springer, Cham. https://doi.org/10.1007/978-3-319-66923-6_23

Download citation

DOI: https://doi.org/10.1007/978-3-319-66923-6_23

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-66922-9

Online ISBN: 978-3-319-66923-6

eBook Packages: Computer ScienceComputer Science (R0)