Abstract

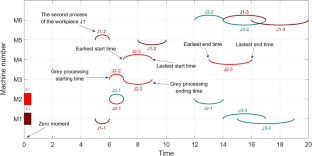

With the complexity of industrial products, the processing time of products is affected by many factors, and it is difficult to give a concrete time estimate. Therefore, it is significant to study the flexible job shop scheduling problem (FJSP) with uncertain processing time. This paper defines the uncertain processing time as the interval grey processing time (IGPT). Also, an FJSP model with IGPT (G-FJSP) is formulated to minimize the interval grey maximum completion time, and the mathematical operation rules of IGPT are improved. Based on this, a step-size adaptive discrete particle swarm algorithm with load balancing (LS-DPSO) is put forward to solve the G-FJSP model. The experimental analysis on six classical test cases indicates that LS-DPSO outperforms four algorithms proposed in recent literature in terms of speed and solution quality. Taking IMK05 as an example, the minimum and the average values of LS-DPSO IGPT are 1.8% and 2.2% smaller than the optimal results of other four algorithms. Also, the resulting grey Gantt chart has better processing time flexibility to guide practical production.

Similar content being viewed by others

References

Chu Y, You F, Wassick J M et al (2015) Integrated planning and scheduling under production uncertainties: bi-level model formulation and hybrid solution method. Comput Chem Eng 72:255–272. https://doi.org/10.1016/j.compchemeng.2014.02.023

Johnson S M (1954) Optimal two- and three-stage production schedules with setup times included. Nav Res Logist Q 1(1):61–68. https://doi.org/10.1002/nav.3800010110

Giffler B, Thompson GL (1960) Algorithms for solving production-scheduling problems. Oper Res 8(4):487–503. https://doi.org/10.1287/opre.8.4.487https://doi.org/10.1287/opre.8.4.487

Cook SA (1971) The complexity of theorem-proving procedures. In: Proceedings of the third annual ACM symposium on Theory of computing - STOC ’71, ACM Press. https://doi.org/10.1145/800157.805047https://doi.org/10.1145/800157.805047

Aarts EHL, van Laarhoven PJM, Lenstra JK et al (1994) A computational study of local search algorithms for job shop scheduling. ORSA J Comput 6(2):118–125. https://doi.org/10.1287/ijoc.6.2.118https://doi.org/10.1287/ijoc.6.2.118

Laguna M, Barnes J W, Glover F W (1991) Tabu search methods for a single machine scheduling problem. J Intell Manuf 2(2):63–73. https://doi.org/10.1007/bf01471219

Nakano R, Yamada T (1991) Conventional genetic algorithm for job shop problems. In: Proceedings of the 4th international conference on genetic algorithms (ICGA), pp 474–479

Brucker P, Schlie R (1990) Job-shop scheduling with multi-purpose machines. Computing 45 (4):369–375. https://doi.org/10.1007/bf02238804https://doi.org/10.1007/bf02238804

Wang C, Li Y, Li X (2021) Solving flexible job shop scheduling problem by a multi-swarm collaborative genetic algorithm. J Syst Eng Electron 32(2):261–271. https://doi.org/10.23919/jsee.2021.000023https://doi.org/10.23919/jsee.2021.000023

Ding H, Gu X (2020) Improved particle swarm optimization algorithm based novel encoding and decoding schemes for flexible job shop scheduling problem. Comput Oper Res 121:104,951. https://doi.org/10.1016/j.cor.2020.104951

Zadeh MS, Katebi Y, Doniavi A (2018) A heuristic model for dynamic flexible job shop scheduling problem considering variable processing times. Int J Prod Res 57(10):3020–3035. https://doi.org/10.1080/00207543.2018.1524165

Wu X, Peng J, Xie Z, et al. (2021) An improved multi-objective optimization algorithm for solving flexible job shop scheduling problem with variable batches. J Syst Eng Electron 32(2):272–285. https://doi.org/10.23919/jsee.2021.000024

Chen XZ (2018) Process planning technology of mechanical machining system for generalized energy efficiency. PhD thesis Chongqing University, Chongqing, China

Ishii H, Tada M (1995) Single machine scheduling problem with fuzzy precedence relation. Eur J Oper Res 87(2):284–288. https://doi.org/10.1016/0377-2217(94)00162-6

Sakawa M, Mori T (1999) An efficient genetic algorithm for job-shop scheduling problems with fuzzy processing time and fuzzy duedate. Comput Ind Eng 36(2):325–341. https://doi.org/10.1016/s0360-8352(99)00135-7https://doi.org/10.1016/s0360-8352(99)00135-7

Gao KZ, Suganthan PN, Pan QK et al (2016) An improved artificial bee colony algorithm for flexible job-shop scheduling problem with fuzzy processing time. Expert Syst Appl 65:52–67. https://doi.org/10.1016/j.eswa.2016.07.046

Palacios JJ, Gonzȧlez-rodríguez I, Vela CR et al (2017) Robust multiobjective optimisation for fuzzy job shop problems. Appl Soft Comput 56:604–616. https://doi.org/10.1016/j.asoc.2016.07.004https://doi.org/10.1016/j.asoc.2016.07.004

Gen M, Lin L, Ohwada H (2021) Advances in hybrid evolutionary algorithms for fuzzy flexible job-shop scheduling: state-of-the-art survey. In: Proceedings of the 13th international conference on agents and artificial intelligence. SCITEPRESS - science and technology publications. https://doi.org/10.5220/0010429605620573

Xie N, Chen N (2018) Flexible job shop scheduling problem with interval grey processing time. Appl Soft Comput 70:513–524. https://doi.org/10.1016/j.asoc.2018.06.004

Deng JL (1982) Control problems of grey systems. Syst Control Lett 1 (5):288–294. https://doi.org/10.1016/s0167-6911(82)80025-xhttps://doi.org/10.1016/s0167-6911(82)80025-x

Zeng B, Liu S, Xie N (2010) Prediction model of interval grey number based on DGM(1,1). J Syst Eng Electron 21(4):598–603. https://doi.org/10.3969/j.issn.1004-4132.2010.04.011

Garcez TV, Cavalcanti HT, de Almeida AT (2021) A hybrid decision support model using grey relational analysis and the additive-veto model for solving multicriteria decision-making problems: an approach to supplier selection. Ann Oper Res 304(1-2):199–231. https://doi.org/10.1007/s10479-021-04103-2

Tirkolaee EB, Torkayesh AE (2022) A cluster-based stratified hybrid decision support model under uncertainty: sustainable healthcare landfill location selection. Appl Intell. https://doi.org/10.1007/s10489-022-03335-4

Li B, Gu X (2006) Grey chance constrained programming for finite intermediate storage flow shop scheduling under uncertainty. In: 2006 6th world congress on intelligent control and automation, IEEE. https://doi.org/10.1109/wcica.2006.1713269

Zhu Z, Zhou X (2020) Flexible job-shop scheduling problem with job precedence constraints and interval grey processing time. Comput Ind Eng 149:106,781. https://doi.org/10.1016/j.cie.2020.106781https://doi.org/10.1016/j.cie.2020.106781

Brandimarte P (1993) Routing and scheduling in a flexible job shop by tabu search. Ann Oper Res 41(3):157–183. https://doi.org/10.1007/bf02023073https://doi.org/10.1007/bf02023073

Shi DL, Zhang BB, Li Y (2020) A multi-objective flexible job-shop scheduling model based on fuzzy theory and immune genetic algorithm. Int J Simul Model 19(1):123–133. https://doi.org/10.2507/ijsimm19-1-co1

Li J q, Zm Liu, Li C, et al. (2021) Improved artificial immune system algorithm for type-2 fuzzy flexible job shop scheduling problem. IEEE Trans Fuzzy Syst 29(11):3234–3248. https://doi.org/10.1109/tfuzz.2020.3016225

Pan Z, Lei D, Wang L (2022) A bi-population evolutionary algorithm with feedback for energy-efficient fuzzy flexible job shop scheduling. IEEE Trans Syst Man Cybern Syst 52(8):5295–5307. https://doi.org/10.1109/tsmc.2021.3120702

Li R, Gong W, Lu C (2022) A reinforcement learning based RMOEA/D for bi-objective fuzzy flexible job shop scheduling. Expert Syst Appl 203:117,380. https://doi.org/10.1016/j.eswa.2022.117380https://doi.org/10.1016/j.eswa.2022.117380

Zhu Z, Zhou X (2021) A multi-objective multi-micro-swarm leadership hierarchy-based optimizer for uncertain flexible job shop scheduling problem with job precedence constraints. Expert Syst Appl 182:115,214. https://doi.org/10.1016/j.eswa.2021.115214

Jamrus T, Chien C F, Gen M et al (2018) Hybrid particle swarm optimization combined with genetic operators for flexible job-shop scheduling under uncertain processing time for semiconductor manufacturing. IEEE Trans Semicond Manuf 31(1):32–41. https://doi.org/10.1109/tsm.2017.2758380

Yao L, Liu Y, Zhao H et al (2019) An improved UKPK-PSO algorithm inspired from block chain technology for flexible job shop scheduling problem. In: 2019 Chinese control conference (CCC). https://doi.org/10.23919/chicc.2019.8866111https://doi.org/10.23919/chicc.2019.8866111. IEEE, China, pp 2260–2265

Zhang Y, Zhu H, Tang D (2020) An improved hybrid particle swarm optimization for multi-objective flexible job-shop scheduling problem. Kybernetes 49(12):2873–2892. https://doi.org/10.1108/k-06-2019-0430https://doi.org/10.1108/k-06-2019-0430

Zhang GH (2009) Research on methods for flexible job shop scheduling problems. PhD thesis. Huazhong University of Science and Technology, China

Xu WX, Wang Q, Bian WB et al (2017) Improved GA and global random machine selection based on key operation to solve FJSP. CIESC Journal 68(3):1073–1080. https://doi.org/10.11949/j.issn.0438-1157.20161625https://doi.org/10.11949/j.issn.0438-1157.20161625

Pan QK, Wang WH, Zhu JY et al (2007) Hybrid heuristics based on particle swarm optimization and variable neighborhood search for job shop scheduling. Comput Integr Manuf 2:323–328. https://doi.org/10.13196/j.cims.2007.02.117.panqk.019

Sudholt D, Witt C (2010) Runtime analysis of a binary particle swarm optimizer. Theor Comput Sci 411(21):2084–2100. https://doi.org/10.1016/j.tcs.2010.03.002

Cui W, Li X, Zhou S et al (2007) Investigation on process parameters of electrospinning system through orthogonal experimental design. J Appl Polym Sci 103(5):3105–3112. https://doi.org/10.1002/app.25464https://doi.org/10.1002/app.25464

Cheng BW, Chang CL (2007) A study on flowshop scheduling problem combining taguchi experimental design and genetic algorithm. Expert Syst Appl 32(2):415–421. https://doi.org/10.1016/j.eswa.2005.12.002https://doi.org/10.1016/j.eswa.2005.12.002

Gao KZ, Suganthan PN, Pan QK et al (2014) Discrete harmony search algorithm for flexible job shop scheduling problem with multiple objectives. J Intell Manuf 27(2):363–374. https://doi.org/10.1007/s10845-014-0869-8

Acknowledgements

This study was supported by the Scientific Research Program of Beijing Municipal Commission of Education-Natural Science Foundation of Beijing (KZ202210017024) and the Interdisciplinary Research Exploration Program of Beijing Institute of Petrochemical Technology (BIPTCSF-008); the General Project of Scientific Research and Technology Program of Beijing Municipal Education Commission (KM201810017006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, W., Wu, W., Wang, Y. et al. Flexible job-shop scheduling method based on interval grey processing time. Appl Intell 53, 14876–14891 (2023). https://doi.org/10.1007/s10489-022-04213-9

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10489-022-04213-9