Abstract

The emergence of a pandemic affecting the respiratory system has resulted in a significant demand for face masks. Masks have always been mentioned as an effective tool against environmental threats. This includes the use of double masks by large sections of the public, as can be seen during the current global spread of COVID-19. However, there is limited knowledge available on the performance of the various commonly available double face masks used. In this study, we have compared the performance of single and double face configurations. Three types of 3-ply face mask (FM), three types of fabric face mask (CM) and nine configurations of these face masks were investigated based on morphology, filtration efficiencies, breathing resistance and carbon dioxide (CO2) content. The filtration efficiencies of the double face masks are enhanced when combined with a fabric mask, and were found to improve by 500% compared to those of a fabric mask. The lowest breathing resistance among the double masking was observed in the combination of FM1 and fabric face masks. From the results, it was found that all combinations of double face mask are suitable to use since the measurements indicate that the breathing resistance and CO2 contents are still lower than the acceptable value set by the Malaysian Standard (MS 2323:2010) and European Standard (EN 149:2001 + A1:2009). The performance of double masks is comparable with that of N95 respirators. The double masking combination can be used as an alternative method to reduce inhalation exposure to airborne contaminants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Coronavirus’s emergence and quickly spread around the world has resulted in a large epidemic and pandemic [1]. As a result, many countries have implemented numerous non-pharmaceutical solutions such as lockdowns, social distancing, and educational institution closures [2, 3]. Despite the ongoing global vaccination efforts against SARS-CoV-2, the public is recommended to maintain the use of face masks as the primary method of transmission control [4,5,6]. The face mask is critical in preventing transmission of coronavirus (SARS-CoV-2) infections. It has been found that face masks are useful in reducing the spread of the virus infection. Moreover, face masks can filter droplets containing the virus [7,8,9].

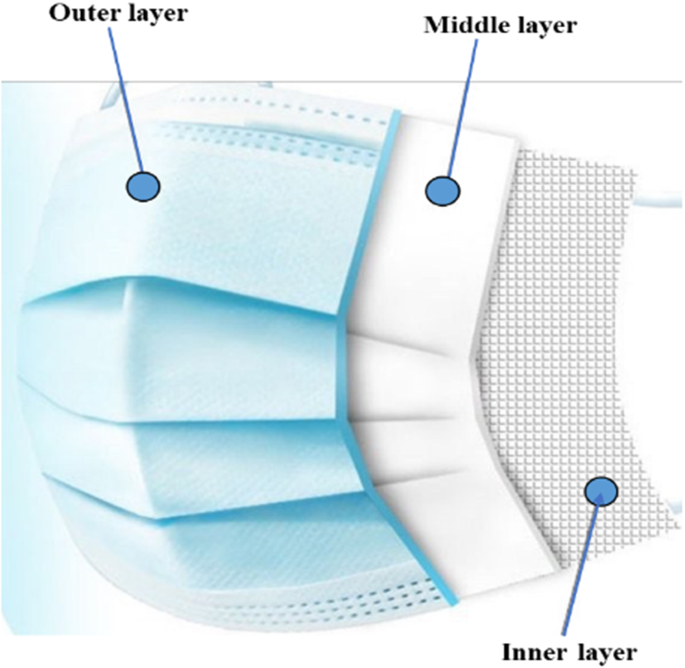

Various types of masks are being used by the public. These include 3-ply face masks, fabric masks, N95 masks, medical masks, and activated carbon masks [7, 10, 11]. It is observed that the 3-ply face mask is the most widely used mask in the COVID-19 pandemic. There are three layers in a 3-ply face mask (Fig. 1), where each layer has its own function. These layers are commonly composed of non-woven made from polypropylene (PP) fibres, known as the cover layer (outer layer), filter layer (middle layer) and shell layer (inner layer). The outer layer repels water and other liquids, while the middle melt-blown material layer serves as a filter, and the innermost layer’s material absorbs moisture from the user’s breath. The outer and innermost layers are spun-bond non-woven or hot-air non-woven with a fibre diameter of 15‒40 µm. The middle layer consists of melt-blown non-woven fabric with a diameter of 0.5–10 µm [12]. The size of the particulate that can be trapped is determined by the thickness of the fibres, the gaps between them, and the number of layers present [13]. On the other hand, fabric masks are preferred for use due to the low cost and can be used repeatedly. The use of a fabric mask will also reduce the non-biodegradable waste from the widespread use of disposable 3-ply face masks. However, the type of fabric used, number of layers and frequency of washings influence the efficacy of the barrier against droplets [14].

The N95 respirator is a particulate-filtering facepiece respirator that fits the US National Institute for Occupational Safety and Health (NIOSH) N95 classification of air filtration, in the sense that it filters at least 95% of airborne particles. N95 respirators, named for their ability to filter 95% or more of tiny 0.3-μm particles, are the mainstay of protection against airborne pathogens [15]. There are also several varieties of N95 respirators, such as surgical N95 respirators, which are more efficient than ordinary N95 respirators. From the inside to the outside, the N95 respirator is made up of three structural components: an inner layer, a filter layer, and an outer layer. In fact, the N95 respirator is a type of respiratory mask, which offers more protection than a 3-ply face mask and fabric mask. This is because it filters out both large and small particles when the wearer inhales. Since N95 respirators have been in short supply during the COVID-19 pandemic, they have been reserved for health care providers.

Recently, several variants of the new coronavirus have emerged throughout the world. Some of these variants can spread more easily between individuals. Based on the recent recommendation by the Centres for Disease Control and Prevention (CDC), some people opt to wear two face masks at a time to increase the overall filtration efficiency. According to scientists, layering up an additional layer of the mask not only offers strengthened protection but also helps lower infectivity and transmission by effectively curbing the pathogen from collecting. It can also do a better job in reducing the contagiousness of any infection [16, 17]. CDC refers to double masking as putting on a 3-ply face mask underneath a cloth mask that has multiple layers of fabric [18]. In other words, the double masking configuration is when the wearer layers one mask on top of another. Many types of masks do not fit perfectly on the wearer’s face. In fact, wearers have probably noticed that they can feel the air escaping through the sides of the face mask when they breathe in and out. This imperfect seal not only allows respiratory droplets containing the virus to escape from the face mask but can also allow them to penetrate inside the mask. When people are wearing double masks, the outer mask can apply gentle pressure to the edges of the inner mask. When this happens, the inner mask fits more closely against the skin and creates a better seal.

A summary of various research with filtration efficiencies with different layers of face masks is given in Table 1. Based on the previous works, lower filtration efficiencies were found in cotton face masks with a single layer. On the other hand, the performance of filtration efficiencies improves with the double layer face mask. Based on the findings by a study from Virginia Tech in Blacksburg, Virginia, it was estimated that the combination of a cloth mask and a medical procedure mask could achieve a better fit and reduce the wearer’s exposure by > 90%, specifically when a cloth mask is put over a medical procedure mask [4]. Meanwhile, CDC also conducted several experiments on medical procedure masks and cloth masks in January 2021. The combination of a cloth mask covering a medical procedure mask (double mask) blocked 85.4% of the cough particles with a standard deviation of 2.4 [1]. Double masking seems to be logical and can provide better protection to the wearer.

Although considerable research has been devoted to the filtration efficiency of single masks, rather less attention has been paid to the performance of double masking with a 3-ply face mask and fabric mask. A thorough literature review indicated that limited studies have reported on the performance of the double masking related to filtration efficiency, breathing resistance and CO2 content tests. The purpose of this investigation is to compare the performance of a single face mask and double masking configuration in terms of the filtration efficiency, breathing resistance and CO2 content. The results are compared among single and double masking configurations and the N95 respirator, which is established as having a higher efficiency performance. The derived results will give a scientific background on the improvement in the face mask protection to prevent COVID-19 infection.

2 Methodology

2.1 Face Mask

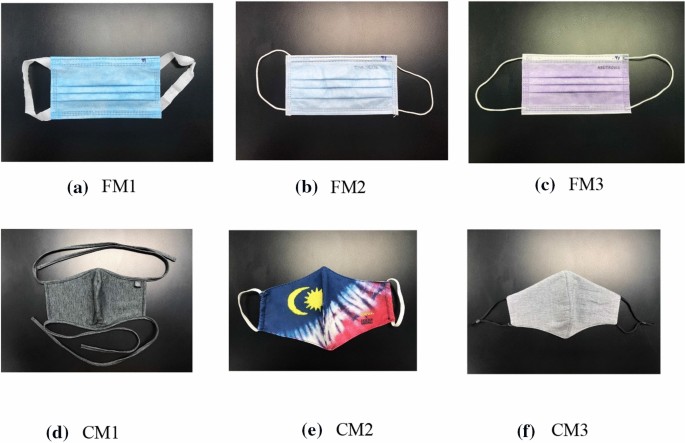

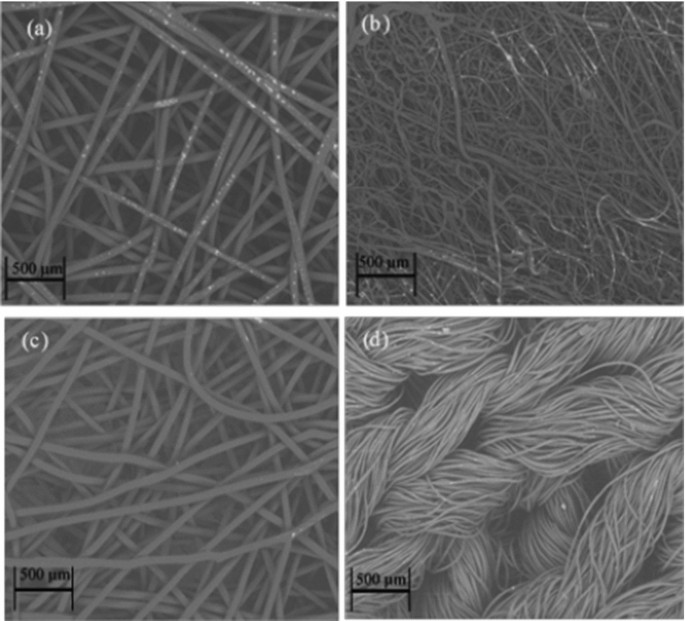

In the study, three 3-ply face mask models and three 3-ply fabric face masks were used and labelled as FM and CM, respectively (refer to Fig. 2). The combination of the three types of FM and three types of CM produced nine configurations of double masks which have been tested in this study; FM1CM1, FM1CM2, FM1CM3, FM2CM1, FM2CM2, FM2CM3, FM3CM1, FM3CM2, and FM3CM3.

2.2 Characterisation Methods

Four characterisation methods were used to evaluate the performance of the single and double face masks: face mask morphology, filtration efficiency, breathing resistance, and carbon dioxide content.

2.2.1 Face Mask Morphology

The surface morphology of the layers in the 3-ply face mask and fabric face mask was analysed using scanning electron microscopy (SEM), with a Hitachi TM3000 tabletop. The distribution of fibres in the face mask layers was observed from the microstructure.

2.2.2 Filtration Efficiency

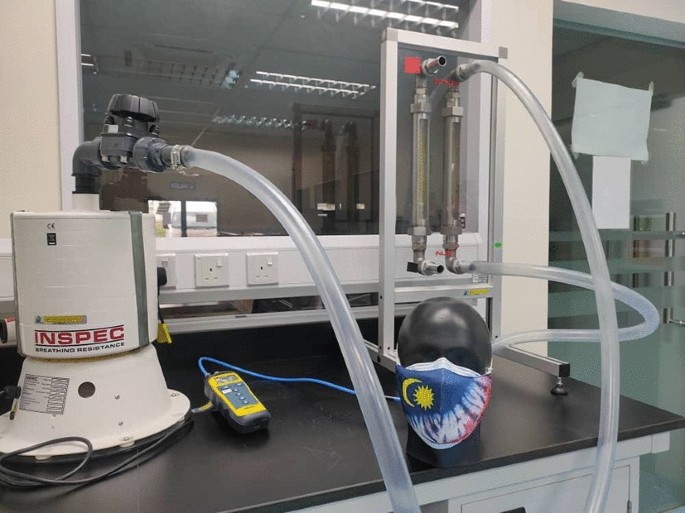

The particle filtration efficiency was measured using the penetration tester (as shown in Fig. 3). A TSI® Model 8130 Automated Filter Tester that is capable of efficiency measurements of up to 99.999% was utilised to measure the particle filtration efficiency. The NaCI aerosol airflow was set at approximately 28.3 L per minute (L/min). The effectiveness of the following mask configurations to block the aerosols and the average were reported.

2.2.3 Breathing Resistance

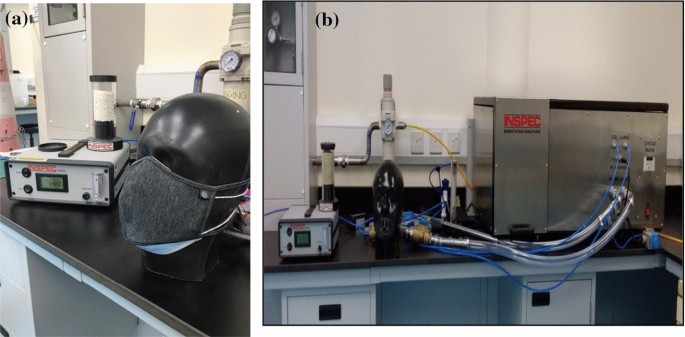

The breathing resistance test according to the EN149:2002 + A1:2009 standard was used to identify the performance of single and double face masks. A continuous inhalation flow of 30 L/min was used. The mask under test was fitted to a Breathing Resistance Machine (Sheffield dummy head) (shown in Fig. 4) and it was connected to a pump. Air was continuously inhaled and the breathing resistance was measured as an average of over 10 s at the mouth opening of the dummy head. According to the EN149:2002 + A1:2009 standard, the maximum permitted breathing resistance value is 0.7 mbar.

2.2.4 Carbon Dioxide Content Analyser

Carbon dioxide content was measured using the CO2 Contents Analyser (Fig. 5). The apparatus consists essentially of a breathing machine with solenoid valves controlled by the breathing machine, a connector, a CO2 flowmeter, and a CO2 analyser. The carbon dioxide content of the inhaled air is measured and recorded continuously. The test was performed until a constant carbon dioxide content in the inhaled air was achieved. The carbon dioxide content of the inhaled air (dead space) should not exceed an average of 1.0% (by volume).

3 Results and Discussion

3.1 Morphology of the Face Mask

Figure 6 shows the morphology of the outer, middle, and inner 3-ply face mask layers, which are composed of non-woven fibres. Based on the figure, it is observed that the fibre structure of the outer and inner layers is similar. Fibre diameters in the range of 20.4 to 21.5 µm were used for these two layers, and the arrangement is less dense compared to the middle layer (Fig. 6b). The middle layer consists of finer fibre with diameters of 2.6 to 3.0 µm. The presence of three layers, with the middle layer having a dense structure and small pores, shows that the 3-ply face mask is efficient in blocking the particulate matter. The morphology of the cotton fabric face mask is shown in Fig. 6d. The yarn sizes used to produce the fabric face mask are bigger than those of the fibres present in the three layers for the 3-ply face mask. This leads to large gaps between the warp and weft yarns. The arrangement of the yarns is totally different if compared with the randomly arranged microfibre in the nonwoven fibres in the 3-ply layers.

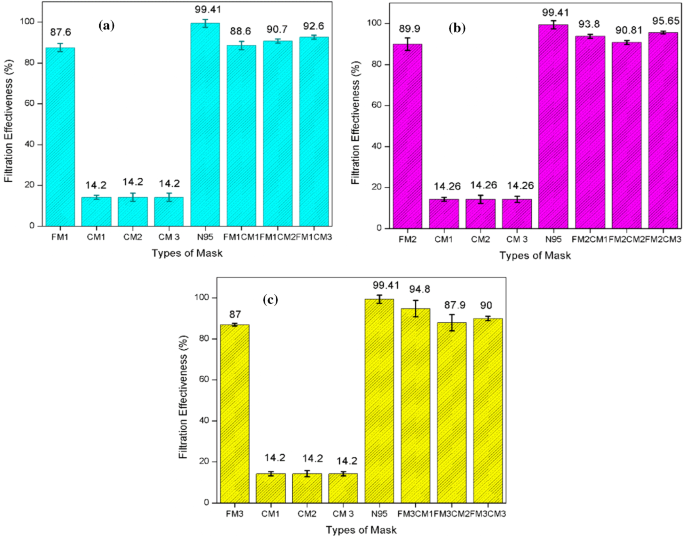

3.2 Filtration Efficiencies

Measurement of the filtration efficiencies was carried out to investigate the effect of different mask types and double masking, and the results are shown in Fig. 7. Among the single face mask tests, the 3-ply face mask was found to have vastly superior filtration efficiencies in the range of 87‒95.6% as compared to the fabric mask, which was in the range of only 7.5‒14.26%. This could be due to the big size of the voids existing in the woven structure of the fabric face mask, which provided less of a barrier to the aerosol particles. The randomly arranged nonwoven fibres present in the three layers of the 3-ply mask provide excellent filtration compared to the fabric mask.

The variation in the filtration efficiencies of the fabric face mask could be due to the differences in the tightness of the weave, which depends on the threads per inch of the fabric used for making the mask [22]. The result from single masking demonstrates that the fabric mask provides very little or no protection, especially in places where there is a high risk of infection. The combination of a fabric mask with a 3-ply mask in the double mask tests indicates a significant 500% improvement in filtration efficiencies. The reason for the improvement can be attributed to the better fit and compactness obtained after using the combination of the two face masks [10, 23]. The maximum filtration efficiency of 95.65% was obtained by double masking using FM2CM3, which is similar to that of the N95 respirator and shows that double masking is the easiest and low-cost alternative for medical professionals where there is a shortage of N95 respirators.

3.3 Breathing Resistance

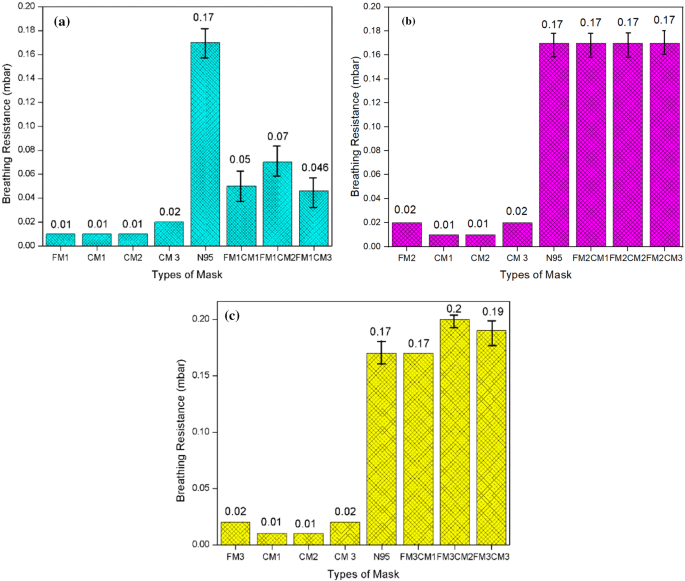

Breathing resistance is the measure of comfort properties, which affect the inhalation and exhalation of the wearer. The breathing resistance, which is measured by the pressure drop, is an important parameter that influences the filtration efficiency [24]. An increase in breathing resistance results in a greater physical effort to breathe through the face mask. In other words, the wearer’s lungs have to work harder in the breathing process. In order to keep the breathing resistance as low as possible, the face mask must be air-permeable on the one hand while still filtering particles on the other hand. Figure 8 shows the breathing resistance for single and different combinations of double face masks. The breathing resistance value shown by the N95 face mask is used as a comparison. As expected, the breathing resistance was found to be much higher for double masking as compared to the single mask, which indicates a tighter and leak-free fit in double masking.

Among the double masking variants, the lowest breathing resistance is observed in the combination of FM1 and fabric face masks (CM1, CM2, and CM3). This indicates that this combination is suitable and provides better breathing comfort for the wearer compared to the other FM2 and FM3 double maskings. The highest breathing resistance was found in the FM3 double masking, for example, FM3CM2, FM3CM3 and FM3CM, with breathing resistance values of 0.20, 0.19 and 0.17, respectively. A constant breathing resistance of 0.17 was found for all combinations of FM2 double masking, which demonstrated that the combination of different 3-ply face masks and fabric face masks does not have a significant effect on the breathing resistance. The breathing resistance test is congruent with the previous report by Vrielink and Meijer [25], in which they showed that increasing the number of layers will lead to an increase in the differential pressure. The values of breathing resistance less than 0.2 mbar shown by the double masks (Fig. 8) are comparable with the value measured for the N95 face mask.

As for breathing resistance, all of the double masks are at a tolerable level, where the results are comparable with the Malaysian Standard MS 2323:2010 and European Standard EN 149:2001 + A1:2009. According to both standards, the breathing resistance should not exceed 0.7 mbar. In this case, wearers will not have difficulty in breathing or feel suffocated when applying double masking. Besides, these findings are in line with the findings from a study conducted in previous work [26].

3.4 Carbon Dioxide Content

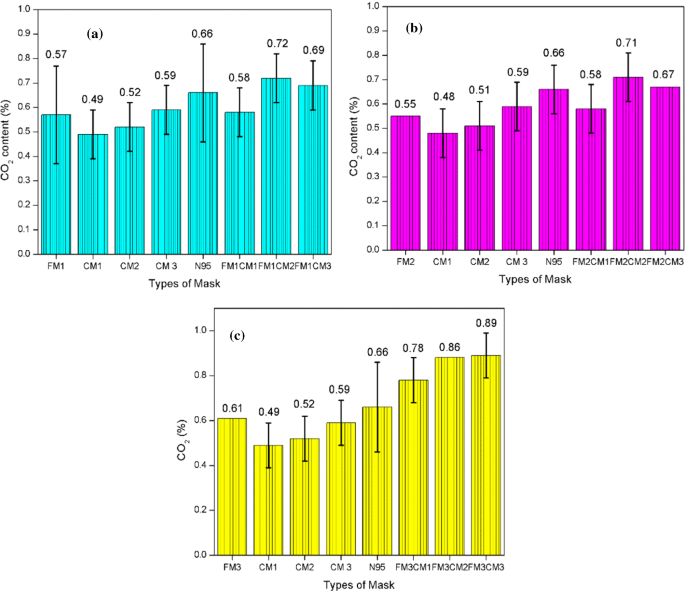

The carbon dioxide (CO2) content is crucial in defining the comfort properties of the mask. The accumulated CO2 has a detrimental effect on the wearer, especially in health care settings where the health professionals have to wear masks for prolonged periods. An ideal mask should release the CO2 gas exhaled by the wearer, but most of the mask accumulates the CO2 gas, which is further inhaled by the wearer, causing severe headaches, fatigue, and loss of content [27]. The CO2 content of various masks with double masking combinations was found and is plotted in Fig. 9. For the single mask test, the lowest CO2 content of 0.48 was found in a fabric mask (CM1), whereas the highest of 0.61was found for a 3-ply mask (FM1).

The fabric mask was found to retain less of the CO2, which could be due to the larger voids present between the weft and warp weave as compared to the compact packing of randomly arranged fibres in the case of the nonwoven filter layers present in 3-ply masks. The testing performed with double masking was found to retain a higher CO2 content, which was expected due to the presence of more barriers, which do not allow passage for exhaled air to leave in the atmosphere. Among all the results for double masking, the combinations of FM1CM1 and FM2CM1 produced the lowest CO2 content (0.58%), which indicates that these combinations are good to reduce the accumulation of CO2. The CO2 content of these double masking combinations was lower compared to that of N95, which showed a CO2 content of 0.68%. However, the highest CO2 content of 0.89% was obtained by the combination of FM3CM3, which is the result of the tight fit and higher barrier created by the combination of the two masks. Based on the results, it is found that all combinations of double face masks are acceptable, as the CO2 content is still lower than the maximum CO2 content, which is 1.0%. The results on carbon dioxide content shown by double face masks are at a tolerable level, < 0.90%. According to the Malaysian Standard MS 2323:2010 and European Standard EN 149:2001 + A1:2009, the maximum permitted average for CO2 content is no more than 1.0%. Although a significant increase in CO2 contents is noted routinely with just one face mask, the levels still remain within the standard limits.

4 Conclusions

In this work, the performance of single and double face masks relating to their filtration efficiency, carbon dioxide (CO2) content, and breathing resistance is evaluated. From the results, double masking will substantially reduce wearers’ exposure as the filtration efficiency was found to improve by 500%. The data indicate that the combination of a 3-ply face mask and fabric face mask increases the filtration effectiveness and is comparable with that of N95 respirators. The filtration efficiency of double masking was found to increase, which could be due to the tight fit and greater barrier compared to single masks. The CO2 content of the double masking combinations is lower compared to that of N95, and they show a CO2 content of 0.68%. All combinations of double face masks are suitable since the measurements indicate that the breathing resistance and CO2 contents are still lower than the required value set by the Malaysian Standard MS 2323:2010 and European Standard EN 149:2001 + A1:2009. Double masking is an efficient option to reduce the spread of the virus infection. The performance is comparable with that of the N95 respirators that are commonly used by health workers.

References

Marbouh, D.; Abbasi, T.; Maasmi, F.; Omar, I.A.; Debe, M.S.; Salah, K.; Jayaraman, R.; Ellahham, S.: Blockchain for COVID-19: review, opportunities, and a trusted tracking system. Arab. J. Sci. Eng. 1, 1–17 (2020)

Elachola, H.; Ebrahim, S.H.; Gozzer, E.: COVID-19: Face mask use prevalence in international airports in Asia, Europe and the Americas, March 2020. Travel Med. Infect. Dis. 35, 101637 (2020)

Zhang, Y.S.D.; Leslie, H.Y.; Sharafaddin-Zadeh, Y.; Noels, K.; Lou, N.M.: Public health messages about face masks early in the COVID-19 pandemic: perceptions of and impacts on canadians. J. Community Health 1, 1–10 (2021)

Ghaffari, H.; Tavakoli, A.; Moradi, A.; Tabarraei, A.; Bokharaei-Salim, F.; Zahmatkeshan, M., et al.: Inhibition of H1N1 influenza virus infection by zinc oxide nanoparticles: Another emerging application of nanomedicine. J. Biomed. Sci. 26, 70 (2019)

Chowdhury, M.A.; Shuvho, M.B.A.; Shahid, M.A.; Haque, A.K.M.M.; Kashem, M.A.; Lam, S.S., et al.: Prospect of biobased antiviral face mask to limit the coronavirus outbreak. Environ. Res. 192, 110294 (2021)

Karim, N.; Afroj, S.; Lloyd, K.; Oaten, L.C.; Andreeva, D.V.; Carr, C., et al.: Sustainable personal protective clothing for healthcare applications: A review. ACS Nano 14, 12313–12340 (2020)

Pullangott, G.; Kannan, U.: A comprehensive review on antimicrobial face masks: An emerging weapon in fighting pandemics. RSC Adv. 11, 6544–6576 (2021)

Skaria, S.D.; Smaldone, G.C.: Respiratory source Control using 3-ply masks with nanofiber media. Ann. Occup. Hyg. 58, 771–781 (2014)

Chua, M.H.; Cheng, W.; Goh, S.S.; Kong, J.; Li, B.; Lim, J.Y.C., et al.: Face Masks in the new COVID-19 normal: materials, testing, and perspectives. Research 2020, 1–40 (2020)

Asadi, S.; Cappa, C.D.; Barreda, S.; Wexler, A.S.; Bouvier, N.M.; Ristenpart, W.D.: Efficacy of masks and face coverings in controlling outward aerosol particle emission from expiratory activities. Sci Rep 10, 1–13 (2020)

Asadi, S.; Wexler, A.S.; Cappa, C.D.; Barreda, S.; Bouvier, N.M.; Ristenpart, W.D.: Effect of voicing and articulation manner on aerosol particle emission during human speech. PLoS ONE 15, e0227699 (2020)

Centers for Disease Control and Prevention. (2021). Improve How Your Mask Protects You.

Zhang, Z.; Ji, D.; He, H.; Ramakrishna, S.: Electrospun ultrafine fibers for advanced face masks. Mater. Sci. Eng. R: Rep. 143, 1094 (2021)

McDiarmid, M.; Harrison, R.; Nicas, M.: N95 respirators vs medical masks in outpatient settings. JAMA J. Am. Med. Assoc. 323(8), 789 (2020)

Centers for Disease Control and Prevention. Coronavirus (COVID-19). Accessed December 21, 2021. https://www.cdc.gov/coronavirus/2019-ncov/index.html

Boraey, M.A.: An analytical model for the effective filtration efficiency of single and multiple face masks considering leakage. Chaos Solit. Fractals 152, 111466 (2021)

Brooks, J.T.; Beezhold, D.H.; Noti, J.D.; Coyle, J.P.; Derk, R.C.; Blachere, F.M.; Lindsley, W.G.: Maximizing fit for cloth and medical procedure masks to improve performance and reduce SARS-CoV-2 transmission and exposure, 2021. Morb. Mortal. Wkly Rep. 70(7), 254 (2021)

Oude Vrielink, T.J.C.; Meijer, J.H.: Using 3-ply wrapping material for the fabrication of respirator masks. PLoS ONE 15, e0236239 (2020). https://doi.org/10.1371/journal.pone.0236239

Konda, A.; Prakash, A.; Moss, G.A.; Schmoldt, M.; Grant, G.D.; Guha, S.: Aerosol filtration efficiency of common fabrics used in respiratory cloth masks. ACS Nano 14, 6339–6347 (2020)

Shen, H.; Zhou, Z.; Wang, H.; Zhang, M.; Han, M.; Durkin, D.P., et al.: Development of Electrospun Nanofibrous Filters for Controlling Coronavirus Aerosols. Environ. Sci. Technol. Lett. 1, 1 (2021)

Hao, W.; Parasch, A.; Williams, S.; Li, J.; Ma, H.; Burken, J., et al.: Filtration performances of non-medical materials as candidates for manufacturing face masks and respirators. Int. J. Hyg. Environ. Health 229, 1182 (2020)

Clase, C.M.; Fu, E.L.; Ashur, A.; Beale, R.C.L.; Clase, I.A.; Dolovich, M.B., et al.: Forgotten technology in the COVID-19 pandemic: filtration properties of cloth and cloth masks—a narrative review. Mayo Clin. Proc. 95, 2204–2224 (2020)

Rengasamy, S.; Shaffer, R.; Williams, B.; Smit, S.: A comparison of face mask and respirator filtration test methods. J. Occup. Environ. Hyg. 14, 92–103 (2017)

Dhanraj, D.I.A.; Choudhary, S.; Jammalamadaka, U.; Ballard, D.H.; Kumfer, B.M.; Dang, A.J., et al.: Size-dependent filtration efficiency of alternative face mask filter materials. Mater. (Basel) 14, 1868 (2021)

Oude, T.J.C.V.; Meijer, JH.: Using 3-ply wrapping material for the fabrication of respirator masks (2020).

Brooks, J.T.; Beezhold, D.H.; Noti, J.D., et al.: Maximizing Fit for cloth and medical procedure masks to improve performance and reduce SARS-CoV-2 transmission and exposure, 2021. MMWR Morb. Mort. Wkly. Rep. 70, 254–257 (2021)

Geiss, O.: Effect of wearing face masks on the carbon dioxide concentration in the breathing zone. Aerosol. Air Qual. Res. 21, 1–7 (2021)

Acknowledgements

The authors would like to acknowledge the contribution received from Universiti Sains Malaysia (USM) and the National Institute of Occupational Safety and Health (NIOSH) Malaysia.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors on this manuscript have no conflicts of interest or financial disclosures to report.

Rights and permissions

About this article

Cite this article

Htwe, Y.Z.N., Mamat, H., Osman, B. et al. Performance Comparison of Single and Double Masks: Filtration Efficiencies, Breathing Resistance and CO2 Content. Arab J Sci Eng 48, 8349–8357 (2023). https://doi.org/10.1007/s13369-022-06801-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06801-w