Abstract

The exploitation of condensation room-temperature vulcanized silicone rubber (C-RTV) with excellent mechanical properties and thermal stability is of great practical significance in the preparation of insulation materials and rubber products with high performance. In this work, novel silicone rubber was fabricated successfully by adding white carbon black (WCB) and different percentages of methyl MQ (MMQ) silicone resin to C-RTV silicone mold rubbers (C-RTV/WMMQ). The mechanical properties, dimensional thermal stabilities, and thermal decomposing temperatures of the as-prepared samples were investigated in detail. Compared to the primitive C-RTV, the tensile strength of the sample with the WCB adding an amount of 15% increased from 0.44 MPa to 3.9 MPa. When the 1% MMQ was introduced, the tensile strength further increased to 4.4 MPa, suggesting a 12.8% reinforcement rate in addition to the improvements in the dimensional thermal stabilities and decomposing temperature. Based on the experimental results, a feasible synergistic effect and compatibility mechanism was proposed that hydrogen bond formed on the interface between MMQ resin and C-RTV in addition to the rigid structure of WCB, and thus led to a dense crosslinking network structure in the polymer matrix.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

In recent years, silicone mold rubber has become one of the most important rubbers for making molds due to its excellent properties, such as better reproduction, easier demolding, higher flexibility, stronger impact resistance, and shorter molding time [1, 2]. Like all silicone rubber products, C-RTV has weak physical and mechanical properties without reinforcement, which limits the range of application. Therefore, how to reinforce it effectively to meet the application requirements is one of the research hotspots. The reinforcement of mold rubber that contains the improved tensile strength, thermal decomposing temperature, and dimensional stability is of great importance to the practical application, which can be realized by the addition of assistant agents [3, 4]. Functional fillers, such as WCB [5], inorganic nanoparticles [6], clays [7], and polymers [8], are the primary assistant agents to improve the performance of silicone mold rubber. For example, Ou [9] improved the thermal conductivity and dielectric properties of liquid silicone rubber using the co-filled addition of AlN and BN.

As a traditional reinforcing agent, WCB has a unique surface structure, which is rich in hydroxyl and easy to form a 3D cross-linking network with rubber, thus enhancing the mechanical properties of rubber effectively. However, the great surface energy generated by the hydroxyl groups that could make the WCB particles form a compact aggregate, which would lead to the uneven dispersion and incompatibility of filler in the non-polar rubber system and unconducive to subsequent processing [10â12].

MQ silicone resin is a kind of organic/inorganic hybrid polysiloxane. It is composed of monofunctional SiâO units (R3SiO1/4, M) and tetrafunctional SiâO units (SiO4/2, Q), where R could be hydrogen, vinyl, methyl, aryl, and other related organic or inorganic groups [13, 14]. MQ can be well compatible with the polydimethylsiloxane (PDMS) because of its unique organic/inorganic structure. The organic group R mainly improves the compatibility of MQ with other components and acts as a viscosity effect, and the SiO4/2 link mainly strengthens the composite material and acts as the reinforcing effect. Besides, it has high-temperature resistance, good electrical insulation, moisture resistance, fire resistance, corrosion resistance, and so on. Even though the cost is much higher than that of WCB, MQ has still been served as an excellent reinforcing agent and applied widely in the synthesis of silicone rubber products [15â18]. For instance, Wu and his co-authors [19] reported an efficient approach to enhance the tracking and erosion resistance of silicone rubber by incorporating the ureido-containing MQ silicone resin into addition-cure liquid silicone rubber. It is generally believed that there are two aspects to illustrate the reinforcing mechanism of RTV modified by MQ. One is the reinforcement by relying on the strength of MQ silicone resin itself. The other is the crosslinking reaction of the functional groups between MQ silicone resin and RTV rubber. For example, the hanging SiâOH of the methyl MQ (MMQ) silicone resin forms hydrogen bonds or chemically reacts with the hydroxyl of the C-RTV silicone rubber, and further crosslinks with the curing agent to form a 3D network structure. While the vinyl in MQ (VMQ) silicone resin first reacts with the curing agent by hydrosilylation and then the addition-compound crosslinks with C-RTV silicone rubber to enhance the modification effect [20â22].

In this work, WCB and MMQ co-modified C-RTV composite silicone rubbers were prepared by a facile approach of mechanical blending combined with cross-linking curing. To the best of our knowledge, there are few reports that the synergistic effect derived from WCB and MMQ has been employed for the mechanical property improvement of C-RTV silicone rubber, as well as the thermal stability. The tensile strength, thermal expansion coefficient, thermal decomposition temperature, and microtopography, were systematically investigated. It is expected to obtain a C-RTV silicone rubber composite material with excellent mechanical and low cost, and to further extend its application range.

2. Experimental

2.1. Materials

MMQ resin was obtained from Junchao Chemical Industry Company (Shanghai, China). Silicone oil of industrial grade was supplied by Bluestar Silicones Company (Shanghai, China). Hydroxyl base rubber (H(OSi(CH3)2)nOH, with the number-average molar mass of 60 000), alkoxy silane ((C2H5O)4Si), and tin dibutyl lauric were provided by Guyuan Ren Stone Company (Shanghai, China). Toluene of analytical purity was obtained from Guoyao Agent Company (Shanghai, China).

2.2. Preparation of C-RTV/W and C-RTV/WMMQ silicone mold rubber

C-RTV/W was synthesized by the reaction of two components, namely component A (hydroxyl-based rubber, H(OSi(CH3)2)nOH with the number average molar mass of 60 000) and component B (alkoxysilane crosslinker, (C2H5O)4Si) with a molar ratio of 100:1, and tin dibutyl lauric acid was used as curing catalyst. WCB with a mass percentage of 15% (15% is relative to the C-RTV mass) was added to the system under vigorous stirring.

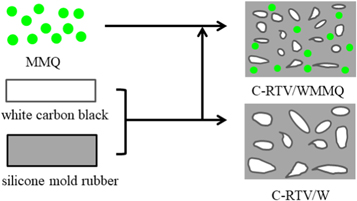

C-RTV/WMMQ silicone mold rubber was synthesized as follows (figure 1): Firstly, different amounts of MMQ resin (mass percentage s were set at 0, 1, 3, 5, and 7%, respectively) were dissolved in toluene and then mixed with 100 g of C-RTV/W through vigorous stirring. After three hours, toluene was removed via rotary evaporation. The prepolymer reacted with 1 g of alkoxysilane crosslinking under the catalysis of tin dibutyl lauric acid and kept stirring for another 10 min. Next, the as-prepared mixture was put into a mold to be solidified at 60 °C. Then the product was obtained and named using the convention C-RTV/WMMQ-x%, where x% is the mass percentage of MMQ relative to the C-RTV/W composite.

Figure 1. Preparation process of C-RTV/WMMQ mold rubber.

Download figure:

Standard image High-resolution image2.3. Characterization

The samples for the tensile and tear tests were prepared in the forms of dumbbell shape and perpendicular types, respectively. All the samples were repeatedly measured five times by using a tensile testing machine (AI-7000MN, High-speed Rail, China) at a crosshead speed of 500 mm · minâ1, then the median was taken as the final result. The thermal stability was measured using a thermal analyzer (TG, PT1600, LINSEIS, Germany), where each sample was heated from room temperature to 700 °C at a scanning rate of 20 °C · minâ1 under a nitrogen atmosphere. Dimensional thermal stability was measured using a thermal-mechanical analyzer (TMA, Q400EM, TA, America) from room temperature to 200 °C with a crosshead speed of 1 °C minâ1. The samples for TMA testing were prepared in standard dimensions of (10 ± 0.5) mm × (12 ± 0.5) mm × (1.8â¼2.2) mm. Hardness was measured using Shore Hardness Tester (XY-1, Shanghai Chemical Machinery Plant No. 4). Three pieces of the same sample were superimposed, and the hardness was measured three times to take the average value. The morphologies of the samples were measured using field-emission scanning electron microscopy (SEM, SU8020, Hitachi, Japan).

3. Results and discussion

3.1. Mechanical properties

As one of the important means to measure the performances of composite materials, mechanical properties have been used as a basic index to evaluate the effectiveness of silicone rubber modified by reinforcing agents [23, 24]. However, too much or too little of reinforcing agent addition is not good for the mechanical properties of silicone rubber [25â27].

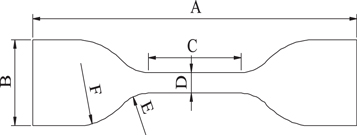

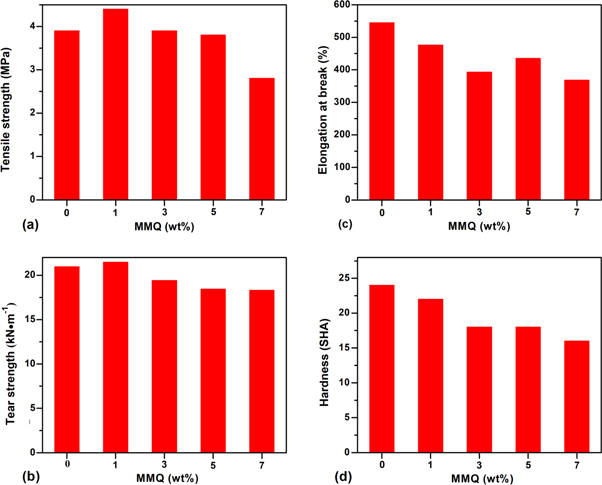

The detailed dimensions of the sample for mechanical testing and the digital photo after tensile testing were shown in figures 2 and 3, respectively. Figure 4 shows the tensile strength, tear strength, elongation at break, and hardness of composite materials with different WMMQ content. When the amount of WCB was 15%, the tensile strength of the composite material reached 3.9 MPa, which was 3.5 MPa higher than that of primitive C-RTV with 0.44 MPa [28] (figure 4(a)). With the addition of MMQ, there has been a marked improvement in the tensile strength of the composite material. When the content of MMQ was 1%, the tensile strength reached the maximum value of 4.4 MPa, and the improvement was nearly 12.8% compared with that of C-RTV/W. However, more than 1% addition of MMQ resin would result in a slight decrease in tensile strength, suggesting the optimum addition content of 1%. The different results of the 5 repeats were listed in table S1 (available online at stacks.iop.org/MRX/8/035201/mmedia) (supporting information). A similar trend with increase first and then decrease can also be observed in the tearing strength, where it reached the maximum value of 21.47 kN · mâ1 when the MMQ addition was 1% (figure 4(b)).

Figure 2. Size of the sample for tensile testing: Sample size GB528-82. (A overall length: 115mm, B end width: 25 ± 1 mm, C length of the narrow parallel part: 33 ± 2 mm, D width of the narrow parallel part: 6.0 ± 1mm, E small radius: 14 ± 1mm, F big radius: 25 ± 2mm thickness: 2 ± 0.2 mm).

Download figure:

Standard image High-resolution imageFigure 3. The digital photograph of the sample after tensile testing.

Download figure:

Standard image High-resolution imageFigure 4. Mechanical properties of C-RTV/WMMQ mold rubber: (a) tensile strength, (b) tear strength, (c) elongation at break, (d) hardness.

Download figure:

Standard image High-resolution imageThe enhanced tensile strength and tearing strength of the composite materials can be ascribed to the reinforcement effect of WCB rigid core. Moreover, the SiâOH in the molecular of MMQ reacted with the hydroxyl group on C-RTV to generate hydrogen bonds, forming a 'centralized crosslinking point'. Subsequently, a stable 3D network structure was obtained by a crosslinking reaction of the precursor with the curing agent. When the composite material was subjected to external force, the stress can be dispersed to the molecular chain network structure more uniformly through these crosslinking points, so the tensile strength and tearing strength were improved. However, they would be decreased when the amount of MMQ was increased further. This phenomenon can be ascribed to the excessive crosslinking density leading to an uneven distribution of 'concentrated crosslinking points', where stress concentration was easy to occur under the action of external forces.

Meanwhile, the elongation at break of composite material showed a downtrend when the MMQ was added, implying that the 3D crosslinked network structure hindered the free motion of the C-RTV/W molecular chain (figure 4(c)). The change trend of the hardness was showed in figure 4(d). It suggested that the addition of MMQ can reduce the hardness of the materials, which is benefit to the reinforcement anti-seismic property to some extent.

Â

3.2. Thermogravimetric analysis

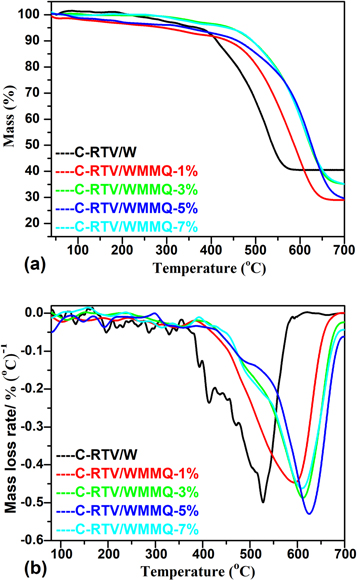

Generally, silicon rubber works for a long time in the temperature range of â60 °Câ¼200 °C. However, higher requirements have been put forward for the heat-resistant aging performance of silicone rubber with the development of modern industry, and it is even required to work for a long time above 300 °C in some particular fields. The thermal stabilities of the composite materials modified with different MMQ silicone contents were measured strictly using a thermal analyzer. There is only one thermogrgravity platform to be observed in the TG curve figure 5(a), as well as the peak temperature in the DTG curve figure 5(b). It is suggested that MMQ silicone resin has good compatibility with the C-RTV/W matrix and further forms a crosslinking network structure with C-RTV/W through the centralized crosslinking points. The maximum thermal decomposition temperatures (Tmax) of the materials were obtained according to the TG curves and the peak temperature in the DTG curves (table 1). When the addition amount of WCB was 15%, Tmax of the composite materials increased gradually with the increase of the MMQ silicone content, which increased from 526 °C of C-RTV/W to 626 °C of the C-RTV/WMMQ-5%. It suggested that the heat-resistance ability of the C-RTV/W matrix was improved by the introduction of MMQ silicone resin. As the MMQ content continued to increase to 7%, Tmax decreased slightly. It was because the SiâOH groups on the MMQ molecular chain could react with the âOH groups of RTV, resulting in the excessive curing agent. Under the high temperature, the residual small molecule curing agent would accelerate the fracture and the thermal cracking reaction of the crosslinked network chains, leading to a slight decrease in Tmax. Besides, the excessive MMQ would induce the aggregation and self-cross-linking of MMQ, which resulted in an insufficient number of active sites to react with SiâOH groups of the polysiloxane, causing the increase of the free flexible chains and acceleration of the degradation rate [29, 30]. The mechanical property and thermal stability of C-RTV/WMMQ in our study were compared with other RTV composites in recent works of literature (table 2), which exhibited superior performances to any other known RTV materials significantly. The mass loss percentages of the samples at various decomposition temperatures were calculated and presented in table S2 (supporting information).

Figure 5. Thermal properties of C-RTV/WMMQ mold rubber: (a) TG curve, (b) DTG curve.

Download figure:

Standard image High-resolution imageTable 1. Thermal decomposition parameters of C-RTV/W with various MMQ amounts.

| MQ content/% | Onset decomposition temperature/°C | Center decomposition temperature/°C | End decomposition temperature/°C |

|---|---|---|---|

| 0 | 424 | 526 | 555 |

| 1 | 488 | 596 | 630 |

| 3 | 498 | 611 | 653 |

| 5 | 546 | 626 | 659 |

| 7 | 519 | 613 | 654 |

Table 2. Comparison of mechanical property and thermal stability of C-RTV/WMMQ and other RTV composites.

| Name | Reinforcing agent content/% | Tensile Strength/MPa | Elongation at break/% | Decomposition temperature/°C | References |

|---|---|---|---|---|---|

| RTV/nano-CaCO3 | 44.4% | 2.6 | 475 | / | [31] |

| RTV/ APA-APTES | 15% | 1.45 | 283 | 560 (center) | [32] |

| RTV/OMMT | 40% | 0.78 | 912 | / | [33] |

| RTV/GO | 0.6% | 0.425 | 264 | 489 (onset) | [29] |

| RTV/SiO2-coated GO | 2% | 1.6 | 325 | 451 (onset) | [34] |

| RTV/DPCP-TPOSS | 3% | 4.5 | 335 | 546.5 (center) | [35] |

| RTV/TPOSS | 3% | 3.86 | 364.07 | 572.8 (center) | [36] |

| RTV /rosin | 15% | 1.25 | 355 | 605 (center) | [37] |

| C-RTV/WMMQ | 15% WCB and 1% MQ | 4.4 | 476 | 596 (center) | This work |

3.3. Dimensional thermal stability properties

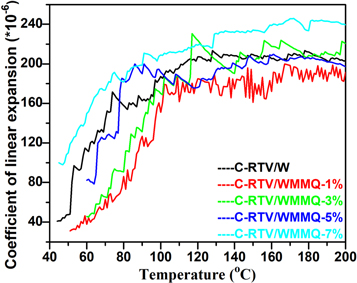

Figure 6 shows the TMA curves of C-RTV/W and C-RTV/WMMQ mold rubbers, where a multi-step degradation can be observed. The C-RTV/W initially displayed a thermal expansion coefficient between 4.08 × 10â5 Kâ1â¼4.78 × 10â5 Kâ1 at lower temperatures of 44 °Câ¼51 °C. Then the thermal expansion coefficient increased rapidly as the temperature rose until the temperature exceeded 110 °C, which reached a platform with a value of 1.99 × 10â4 Kâ1. However, the C-RTV/WMMQ mold rubbers exhibited higher dimensional thermal stability compared with C-RTV/W. When the dosage of MMQ resin was 1%, the thermal expansion coefficient lay between 3.70 × 10â5 Kâ1 and 1.98 × 10â4 Kâ1 at 60 °Câ¼170 °C, which was about 5%â¼67% lower than that of C-RTV/W. But the coefficient of thermal expansion slightly increased with the increase of MMQ addition, suggesting that the optimum dosage of MMQ was 1%.

Figure 6. Coefficient of linear expansion curves of C-RTV/MQ mold rubber.

Download figure:

Standard image High-resolution image3.4. Morphologies analysis

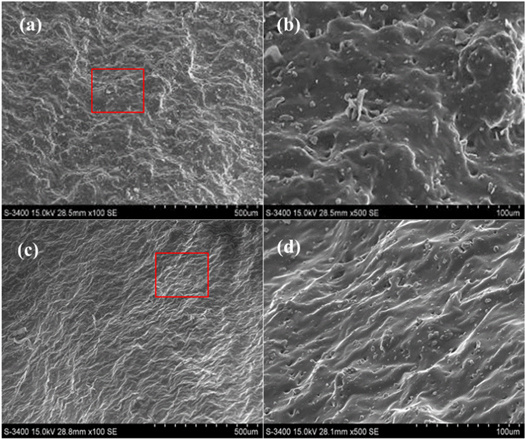

Based on the above performance test results, the tensile fracture morphologies of C-RTV/W and C-RTV/WMMQ-1% composites were measured (figure 7). The particles sizes of WCB in C-RTV/WMMQ-1% (about 5â¼10 μm) are smaller and dispersed more uniformly than those in C-RTV (about 5â¼20 μm), which can be embedded well in the polymer matrix, then generating a well-integrated interface between WCB and the matrix. We speculated that the addition of toluene in the rubber synthesis reduced the viscosity of the system then the WCB particles were repeatedly dispersed in the composite material under vigorous stirring. Besides, much denser 'crosslinking-ladder structures' are formed on the fracture section of C-RTV/WMMQ-1%. Such unique structures can effectively absorb energy during the destruction process by external forces, thus maintaining more for the mechanical properties of the composite material, which is consistent with the results of WCB and MMQ influencing the mechanical properties of the rubber [34, 38]. The morphologies of the surfaces have also been measured, suggesting few adverse effects on the surface roughness by the added particles, as shown in figure S1.

Figure 7. SEM images of the fracture section: (a) C-RTV/W, (b) magnified red mark of C-RTV/W, (c) C-RTV/WMMQ-1%, (d) magnified red mark of C-RTV/WMMQ-1%.

Download figure:

Standard image High-resolution image3.5. Compatibility-improving mechanism of the mold rubber composites

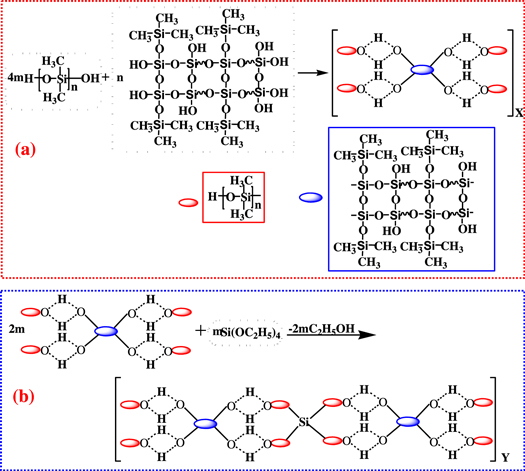

As described above, a possible mechanism of the compatibility improvement is demonstrated in figure 8. Under vigorous stirring, the MMQ resin that dissolved in toluene can be uniformly dispersed in the C-RTV/W matrix and reacted with C-RTV to generate intermolecular hydrogen bond, as shown in figure 8(a). Meanwhile, the aggregation of WCB particles was efficiently weakened because toluene could reduce the viscosity of the C-RTV/W system. Therefore, WCB was dispersed in the polymer matrix with fine particles, forming a large number of even 'crosslinking points'. After the removal of toluene, the pre-polymer was further polycondensed with the curing agent ethyl orthosilicate to generate a small molecule of C2H5OH, and the whole system was solidified (figure 8(b)). Besides, a multitude of hydroxyl groups introduced to the molecular chains of MQ resins, plus the released heat due to polycondensation, as well as the Coulomb repulsion between MQ and C-RTV molecules that further improved the compatibility of the components [39, 40].

Figure 8. Compatibility-improving mechanism of C-RTV/WMMQ mold rubber: (a) hydrogen bonding reaction, (b) condensation polymerization.

Download figure:

Standard image High-resolution image4. Conclusions

In conclusion, we demonstrated that the C-RTV silicone mold rubbers co-modified with 15% WCB and 1% MMQ exhibited outstanding mechanical properties, thermal stabilities, and dimensional thermal stabilities. This effect was mainly due to the excellent combination of the WCB particles and polymer matrix, the strong physicochemical force between MMQ and C-RTV, coupled with the unique 'ladder structure' of the composite. These results suggest that C-RTV/WMMQ offers a practical and economical approach for tailor-made structural design for composite silicone mold rubbers.

Acknowledgments

This job was financially supported by Educational Commission of Xinjiang [XJEDU2017S051, XJEDU2019Y052]. This research was also financially supported by the National Natural Science Foundation of China [52000011, 21663002].

Data availability statement

All data that support the findings of this study are included within the article (and any supplementary files).