Abstract

One core concept of Industry 4.0 is establishing highly autonomous manufacturing environments. In the vision of Industry 4.0, the product leads its way autonomously through the shopfloor by communicating with the production assets. Therefore, a common vocabulary and an understanding of the domain’s structure are mandatory, so foundations in the form of knowledge bases that enable autonomous communication have to be present. Here, ontologies are applicable since they define all assets, their properties, and their interconnection of a specific domain in a standardized manner. Reusing and enlarging existing ontologies instead of building new ontologies facilitates cross-domain and cross-company communication. However, the demand for reusing or enlarging existing ontologies of the manufacturing domain is challenging as no comprehensive review of present manufacturing domain ontologies is available. In this contribution, we provide a holistic review of 65 manufacturing ontologies and their classification into different categories. Based on the results, we introduce a priority guideline and a framework to support engineers in finding and reusing existent ontologies of a specific subdomain in manufacturing. Furthermore, we present 16 supporting ontologies to be considered in the ontology development process and eight catalogs that contain ontologies and vocabulary services.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the rise of Industry 4.0, data, information, and knowledge are central drivers for an intelligent manufacturing environment since they provide the foundation for autonomous production and decision support. The benefits of autonomous production and decision support for manufacturers include relieving labour from non-creative tasks or providing robust decisions for production planning and scheduling. (Ustundag & Cevikcan, 2018; Dashkovskiy et al., 2006) Transferring intelligent manufacturing environments into reality needs a standardized and general description of the manufacturing domain and the interconnections of the assets within this domain (da Rocha et al., 2020). Due to the advent of Industry 4.0, the term asset becomes prominent for declaring either a physical or virtual thing that has a value for the company. (Reference Architecture Model Industrie, 2016; Asset management, 2017) Thus, examples of assets within the manufacturing domain could be products, materials, machinery, or models and documents such as bills of materials and technical drawings. A standardized description is made by elements and their enhancement with semantic meta-data, e.g., units or the data type. Therefore, ontologies have been introduced that support unambiguous descriptions of elements and their relations. Initially established in the field of Philosophy, ontologies are used for knowledge engineering and information science (Peng & Man, 2013). Gruber defines an ontology as "a specification of a conceptualisation" that contains cross-linked relationships between single classes (Gruber, 1993). Thus, ontologies describe domains formally and explicitly by listing their terms, roles, properties, and possible constraints (Noy & Mcguinness, 2001; Peng & Man, 2013). These ontologies then can be used in knowledge graphs to reason about the semantic meaning of the defined terms (Hogan et al., 2021). While ontologies describe abstract classes and properties, knowledge graphs (KG) represent real-world entities (Paulheim, 2017). Hence, a KG is an instance of an ontology that comprises specific information, while the ontology acts as a schema for the overlying KG (Zhou et al., 2021; Ehrlinger & Wöß, 2016).

Ideally, one defines the domain’s elements once and then reuses them for other purposes, e.g., as a basis for optimization models. Reusing ontologies reduces the effort for remodelling the same elements again and enables cross-domain and cross-company communication, as every element has the same semantic foundation enabling interoperability. (Noy & Mcguinness, 2001; Institute of Data Science - Maastricht University, 2020; Zhou et al., 2021) Hence, ontologies ensure and improve a flexible, reusable, and extensible exchange of data (Peng & Man, 2013; Georgieva-Trifonova & Galabov, 2021).

Today, ontologies of the manufacturing domain are rarely implemented. One reason is that, as domain experts, production engineers are typically unaware of semantic web technologies. As building ontologies is a highly specialized task, qualified personnel in information technology with enhanced semantic web skills are required to support the production engineers in this task. In addition, manufacturing domain ontologies were often built without considering wider applications or reusing existing ontologies, which makes them not interoperable (Karray et al., 2021). Furthermore, adequate tools and best practices for building ontologies are rare. Finally, a dedicated register that contains ontologies for the manufacturing domain is absent, so existing manufacturing ontologies are spread in different scientific publications (Gangemi & Presutti, 2009; Psarommatis et al., 2022; Vigo et al., 2014; Ameri et al., 2022).

To overcome the absence of a register for manufacturing ontologies, we contribute ontology architects and manufacturing domain experts with a comprehensive register of manufacturing domain ontologies. We summarize every ontology’s scope and classify its application, e.g., products, resources, and maintenance. Besides the contribution an ontology originates from, we link directly to the ontology files and the respective communities where available. Additionally, we provide an overview of existing vocabulary service catalogs, giving ontology architects and manufacturing domain experts a starting point for their research. Our work accelerates the finding and reusing of pre-existing ontologies for specific purposes, making the process of semantic engineering faster and, hence, more efficient.

The remainder of our contribution is as follows: After the introduction, we introduce semantic models in the form of ontologies as a basis for knowledge representation in Section 2. In Section 3, we present related work, and subsequently our methodology in Section 4. Section 5 contains the review of the manufacturing ontologies, while Section 6 provide catalogs of ontologies and vocabulary services and ends with a conclusion and further work in Section 7.

Semantic models as a basis for knowledge representation

This chapter introduces the concept of semantic web technologies, in particular, the role of ontologies for knowledge management, to provide a brief understanding of knowledge management and their benefits for Industry 4.0 under consideration of an example of the manufacturing domain.

Use of ontologies

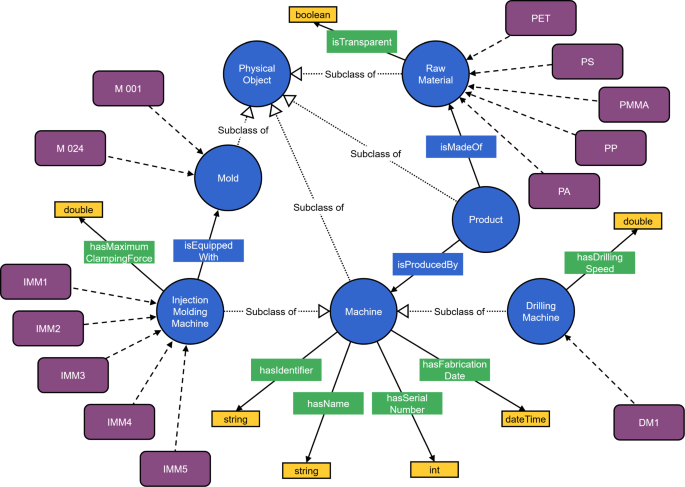

Figure 1 introduces an exemplary, basic shopfloor ontology that represents the general role of a product within the manufacturing domain. Moreover, domain-specific classes and instances from the injection molding and milling domain were added to demonstrate that ontologies can be nested at different levels.

Within this ontology, the Physical Object, Product, Machine, Raw Material, Mold, Drilling Machine, and Injection Molding Machine are classes (represented by blue circles). A class, also called a concept, comprises all objects that share the same properties. For example, every Machine has a name, an identifier, a serial number, and a fabrication date. In an ontology, properties of a class are modelled as Data Properties (green rectangles). Data Properties can be enhanced with a data type, e.g., integer (int) as the data type for the serial number (orange rectangles). The connection between two classes is realized by Object Properties (blue rectangles). A Product, for example, (isMadeOf) Raw Material. Classes can be nested, so sub-classes inherit their properties from their super-classes. The sub-classes are specifications of one super-class, e.g., an Injection Molding Machine or a Drilling Machine is a specification of a general Machine. Both machines share the same properties that are inherited from the class Machine. In addition, each class comprises further properties that are only appropriate and valid for the sub-class elements, e.g., an Injection Molding Machine has a property maximum clamping force but no property drilling speed as it belongs to a drilling machine. While classes describe the general features of a class element, an instance derived from this class is an exactly defined specification of this class element. In Figure 1, the purple rectangles stand for the instances, i.e., IMM1 is an Injection Molding Machine that have maximum clamping force of 500 kN.

As introduced before, relationships between classes are visible using Object Properties. In Figure 1, Product is linked to Machine through the relation isProducedBy. Thus, it can be explicitly expressed that

Vice versa, a Machine produces a Product. Since this relation is not explicitly formulated, it contains the same information implicitly. Hence, retrieving efficient and valid information about statements is valuable since it offers the generation of new knowledge of the domain, even if single relations are not expressed directly. This can be realized with inference or reasoner tools applied within ontologies. With the help of these tools, generating predictions and providing decision support is feasible since domain knowledge can be built. (Noy & Mcguinness, 2001; Psarommatis et al., 2022) Further literature in which ontologies are examined in more detail are Staab and Studer (Staab & Studer, 2004) or Sicilia (Sicilia, 2014).

Hierarchy of ontologies

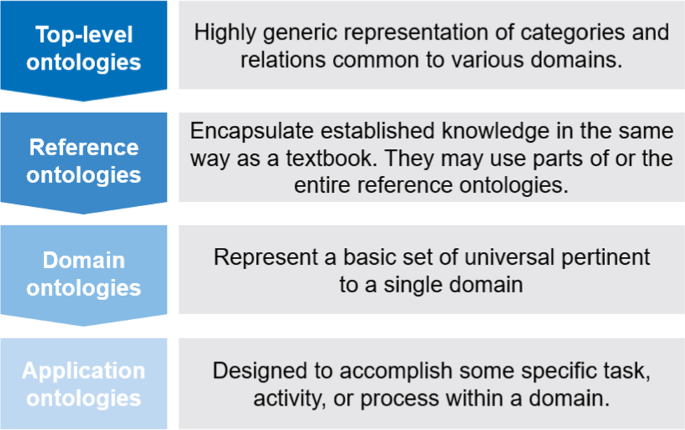

It is important to consider that ontologies, depending on their level of detail, can be classified into different hierarchy levels (Ramis Ferrer et al., 2021). Figure 2 introduces the four different levels ontologies can be grouped in.

Based on Arp Arp et al. (2015) and Lastra Martinez Lastra et al. (2010), Ocker et al. Ocker et al. (2019) comprehensively classifies ontologies into top-level, reference, application, and domain ontologies. Top-level ontologies include the most generic concepts applicable to all underlying domains since they are independent of any domain. Thus, the top-level ontologies’ classes are valid for all underlying levels. One example is the Basic Formal Ontology (BFO) that defines general classes for physical entities (e.g., objects) or the execution of processes Arp et al. (2015). On the next level, reference ontologies are used to provide a common understanding of a specific domain. An example of such type of ontology is the Supply Chain Reference Ontology describing general concepts in the supply chain domain. On the third level, domain ontologies defining properties of a specific domain in a generic manner, e.g., the general properties of machinery or plants of the manufacturing domain. The most detailed ontologies are application ontologies since they represent a particular task within this considered domain, e.g., an injection molding process. Due to standardization and modularization, domain applications should use the classes from the overlying ontologies by inheriting predefined properties Wache et al. (2001).

Related work

Wlazlak et al. (2020) review 13 ontologies and integrate them into a developed classification framework comprising five categories. Besides the conceptual product life cycle category, the other four categories focus the on the product and production process. They differ between the equipment and the assembly process as also the focus of these ontologies, i.e., conceptual and real-life cases. Further differentiation is not given. Negri et al. (2016) comprehensively point out and review conceptual and semantic languages and their features for building semantic models for the manufacturing domain (e.g., UML, RDF, and OWL). Since they focus on modelling languages, a review of existent manufacturing ontologies was not the scope of this contribution. Also, Fraga et al. (2020) conduct a systematic literature review to present the most relevant elements one must consider when building ontology-based solutions and their transfer into the industrial environment. This comprises, among others, the used libraries and tools or considered standards within the ontology-based development process. Hence, a review of manufacturing ontologies regarding their content was not processed. In contrast, Strzelczak (2015) reviews ontologies from the supply chain operations management and the manufacturing operations management by formulating short descriptions. Besides, Zahri et al. (2023) review ontologies for new product development. El Kadiri and Kiritsis (2015) perform literature research that facilitates ontologies for product lifecycle management. Their review is embedded in a study regarding the general roles, challenges, and needs of ontologies within the manufacturing domain. The authors mentioned before do not cluster the reviewed ontologies into pre-defined categories, so a comparison of those ontologies regarding their focus was not made. In Wache et al. (2001), the integration of ontologies was discussed. They presented three major approaches to identify how ontologies are used: 1) Single ontology, which provides a single, global ontology that shares the terminology with multiple information sources as one unified vocabulary, 2) Multiple ontologies, where each information source is connected to a separate ontology independently, and 3) Hybrid, which is a combination of the previous two approaches, where the global ontology is connected to the local ontologies that again serves as independent vocabulary supplier for the single information sources. Considering those three approaches, the hybrid approach is preferred, as it enables the easy addition of new sources without modifying the mapping between ontologies and simultaneously supports the extension and modification of ontologies Peng and Man (2013).

The Industrial Ontologies Foundries (IOF) is a noteworthy initiative striving to develop a core and openly accessible set of ontologies for the manufacturing domain, fostering data interoperability (OAGi. Industrial Ontologies Foundry 2023; Karray et al. 2021). They propose an ontological suite, including core, supply chain, and maintenance ontologiesFootnote 1, accompanied by technical principles, guidelines, and additional resources to support the creation of interoperable ontologies. In the work by Smith et al. Smith et al. (2019), the authors articulate a formal representation using first-order logic for the IOF’s axioms and definitions, with the Basic Formal Ontology (BFO) serving as the foundational framework. Another initiative, the Ontology-driven data documentation for Industry Commons (OntoCommons) (Ontocommons.eu. OntoCommons 2024), aims to compile information on existing ontologies in different domains. In their resulting report (Le Franc, 2022), they present (among others) the technical features of ontologies (e.g., usage of inverse properties) and calculate key performance indicators for ontologies, such as axiom count.

Furthermore, reviews of ontologies covering a specific manufacturing subdomain are available, e.g., for sensors(Schlenoff et al., 2013; Cao & Zanni-Merk, 2019), concepts related to the Web of Things (Li et al., 2019), different levels of simulations (May et al., 2022), and ontologies for process automation, including Process control (PLC-Level) Lepuschitz et al. (2022). Similarly, Nagy et al. (2021) introduces an overview of ontologies for building Industry 4.0 applications.

Existing related work shows that a holistic register of manufacturing ontologies is absent. To close this gap, we provide a comprehensive register including a short summary and classification of manufacturing ontologies, so ontology architects require less effort in establishing an intelligent manufacturing.

Methodology

We performed descriptive and qualitative research based on an analysis of literature describing ontologies relevant to the Internet of Production (IoP). Figure 3 shows the steps included in our methodology.

First, we reviewed relevant literature by selecting research papers targeting the following keywords: product ontology, i4.0 ontologies, manufacturing ontologies. Next, we used a snowballing research approach Streeton et al. (2004) by consulting the referenced papers to extract more information about the ontologies. Subsequently, we grouped the ontologies based on their coverage (upper and middle ontologies, domain ontologies, and supporting ontologies). After that, we determined the focus described by the ontologies by establishing relevant, manufacturing-related categories. In parallel, we filter ontologies that are not closely related to our domain of interest, e.g., business administration, finance, linguistics, or philosophical ontologies and concept papers. In addition, we considered ontologies related to the manufacturing domain in a broader sense, for instance, ontologies describing sensor or engineering processes, since sensors become increasingly crucial for monitoring and engineering directly influences the manufacturing process. As for supporting ontologies, we selected cross-domain ontologies, which can be valuable for complementing the knowledge from the manufacturing and production domains.

Additionally, we provide a compilation of catalogs, their characterization, and their field of application to facilitate the search for existing ontologies and vocabularies. To build the catalog, we searched for existing archives in papers and referenced websites, such as projects and initiatives related to ontologies.

Review

Our goal is to support Domain Experts (DEs) and Knowledge Experts (KEs) by providing a comprehensive list of ontology resources to aid the reusability and interoperability of newly created ontologies. Therefore, we built a comprehensive register containing vocabulary service catalogs and manufacturing domain ontologies. We revised and evaluated existing ontologies and vocabularies based on their scope and coverage.

Different coverage levels are necessary to design an architecture for ontology construction. In this sense, upper ontologies constitute the structural base of such architecture, followed by domain-specific ontologies and vocabularies. On top of that, one has to model the new concepts specific to the new ontology. To complement, one can add cross-domain ontologies to support the overall architecture and, in this way, extend the interoperability and reuse of the new ontology further by reusing already defined concepts in other ontologies.

Upper ontologies

Upper ontologies cover foundational concepts that one should consider when creating ontologies. Based on our analysis, we present in Table 1 the resulting list in this category to serve as a basis for new ontologies in the Internet of Production, and indicate in the column ONL the corresponding ontology file which is available online. Further reviews focusing more on upper and middle ontologies exist, e.g., in Guinard (2021); Mascardi et al. (2008).

The most preferred upper ontology used in the manufacturing domain is the BFO ontology, which allows the representation of concepts in several fields.

Application and domain ontologies

Several application and domain-specific ontologies focusing on different assets and aspects of the manufacturing and production domain exist. Furthermore, we can also consider ontologies not exclusively targeting the production and manufacturing domain but widely used in our field of interest, such as those covering simulations and sensors knowledge. Therefore, in Table 2 we describe the application and domain ontologies covering production and manufacturing processes, including those within the IOF ontological suite, specifically the IOF Core, MaintRefOnto, and SCRO ontology.

Then in Table 3 we classify the main ontologies (O) and semantic models (SM) into subcategories of the manufacturing domain. A semantic model is an abstraction of the real world in which one conceptually expresses objects, their properties and relationships, allowing a common understanding of the modelled concepts by adding the necessary context (semantics) regarding their characteristics and environment. On the other hand, ontologies are formal specifications describing general or specific domains, in the form of terms, relations and constraints, as we explained in Chapter 2.1.

The application and domain ontologies we list here cover elements related to several categories. We determine these categories based on assets listed in the IEC 62264 series of standards that provide enterprise-control system integration, i.e., by specifying relevant models and terminology GmbH (2014). We cluster the ontologies into the categories as follows: Products (PROD), Processes (PROC), Resources (RES), Scheduling (SHED), Maintenance (MAINT), Sensors (SENS), Robotics (ROBT), Engineering (ENG), Batch processing (BATCH), Measurements (MSMT), Standards (STD), and Simulation (SIM). We indicate the coverage of each ontology by adding a (\(\times \)) in the corresponding column of the covered feature. To the best of our knowledge and our research, we provide references to the corresponding ontology file in column ONL, while column COMM leads to the community that maintains the ontology. In column REF, we reference the source research paper.

Table 3 consists of application and domain ontologies in the manufacturing domain and provides stakeholders with resources to explore more in-depth and decide which ones to use.

In summary, we present 65 domain-specific ontologies. The majority of the ontologies in Table 3 cover resources (52) and processes (52), followed by 38 ontologies describing products. The high number of these categories was expected, as they represent fundamental components within the manufacturing sector. In combination with the summary from Table 2, ontology architects can identify which resources, processes, and products the ontology covers, i.e., in a general manner or dependent on the underlying manufacturing domain. Additional common topics covered by some of the listed ontologies are scheduling monitoring (19), maintenance (19), sensors (17), robotics (5), engineering (11), batches (6), and six concepts related to simulations. Furthermore, 30 ontologies include measurements and 15 consider standards.

Priority guideline and framework for reusing manufacturing ontologies

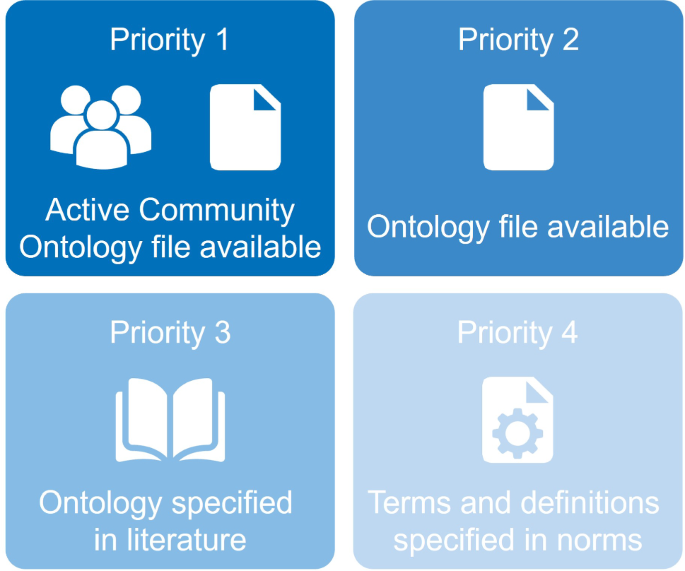

Based on the reviewed ontologies, we establish a guideline and a framework to guide ontology engineers and domain experts, enabling them to reuse existing ontologies. This accelerates the creation process and fosters a shared knowledge base. Figure 4 illustrates the guideline.

Before building new ontologies from scratch, (partly) reusing, referring, or merging ontologies should be aspired as recommended in ISO/IEC 21823-3 (Interoperability for IoT systems—Part 3: Semantic interoperability) Internet of Things (2021) or in different literature, e.g., in Katsumi and Grüninger (2016), as reusing existing ontologies fosters interoperability Zhdanova (2006); Sabou et al. (2016). In addition, reusing ontologies can utilize established, community-proven concepts, saving time and resources compared to developing new ontologies from scratch. This efficiency also extends to ontology maintenance, as the wider community can contribute updates.

We recommend prioritizing the reuse of ontologies that have an active community. A central advantage is that ontology engineers and domain experts can engage in a collaborative process that has the potential to contribute to and benefit from collective expertise and amendments. This collaborative approach allows for improving and refining the ontology itself, thus better serving the scientific community. Moreover, support may be much faster and easier if an active community is acting in the background. Zhdanova (2006) Additionally, consideration should be given to those endorsed by initiatives such as OntoCommons and the IOF, which have undertaken comprehensive studies and analyses of ontologies across diverse facets within the industrial domain. If no community maintains the ontology but the ontology is available as a file, they should be considered second priority. Usually, active communities also provide the ontology in a file format. Before reusing a file, it should be checked if the newest version of an ontology is used or if a successor exists. The third priority encompasses ontologies that neither have an active community nor are available as files but are already specified in the literature, so already defined concepts can be transferred to a file, enabling machine readability.

If requisite elements remain unavailable, we recommend exploring established standards and guidelines that have already formulated terminology for a specific domain as a fourth priority. Standards are crucial in building ontologies as they provide a common framework and vocabulary, ensuring consistency and interoperability across diverse systems. Adhering to established standards enhances the quality and usability of ontologies, facilitating effective communication and integration of information in various applications and domains. Oemig and Snelick (2016); Domingue et al. (2011) However, only 23 % of the ontologies we reviewed integrated or considered standards. An illustrative instance of such standardized domain terminology is DIN EN 62264, which delineates terms within the manufacturing domain Enterprise-control system integration (2014, 2016). Transferring these terms into a machine-readable ontology preserves the standardized and acknowledged elements, allowing for potential enrichment with semantics. In scenarios where the domain lacks a comprehensive description, it is recommended to establish a cross-company working group to create a standardized and universally accepted comprehension of the domain. Ideally, the outcomes should subsequently be codified into a standard, enabling other users to leverage this effort for their purposes. A comprehensive guideline covering essential ontology and semantic model development aspects is outlined in Molinas Comet (2022). The OAGI organization, addressing interoperability issues in software systems, also provides a list of helpful materials regarding ontologies and summarises some technical principles OAGI Organization (2023).

Our review pointed out that only six of the reviewed ontologies have both a community that supports their maintenance and a file. Similarly, most ontologies are unavailable online in a machine-readable format to ease ontology reuse. More specifically, only 20 ontologies out of 65 are available. Based on this result, we provide a framework in Table 4 that recommends suitable ontologies.

In the upper section, the framework lists all ontologies with both a file and an active community. Those ontologies should be considered with priority. In the lower section, all ontologies available as a file but with no community are located. Within these two sections, we sort the contents in descending order, depending on the number of covered domains. If the number of covered domains remains consistent, we have arranged the ontologies alphabetically.

Ideally, one ontology directly covers multiple domains. This simplifies the creation process since fewer resources have to be handled. Nonetheless, a potential drawback of ontologies covering a broad range of domains may arise from the risk of overly generalized modeling of elements. Hence, we recommend incorporating ontologies that concentrate on highly specific domains into the design deliberation process. The probability that these ontologies provide significantly more detailed domain specifications is notably increased.

The decision to reuse or create a new ontology should be carefully considered based on the specific needs and context of the project. Creating a new ontology may be justified if the existing ones do not adequately address the semantic nuances required for a particular domain or if they are overly complex for the intended use. Simperl (2009)

In summary, our framework is the first starting point for ontology engineers and domain experts. In general, (partly) reusing ontologies strongly depends on the creators’ purpose. Our work can help accelerate the process of finding suitable ontologies for implementing intelligent manufacturing.

Supporting ontologies

Another type of ontology to consider when developing a new ontology is cross-domain supporting ontologies, which adds value by describing traversal concepts to use in more than one domain. In the particular case of our study, complement the definition of concepts in the production and manufacturing domain. This type describes knowledge about measurements, institutional organisation and structures, data storage organisation, etc. One consideration here is that terms describing measurements are usually covered also in the application or domain ontologies. However, based on best practices, such concepts should be reused from the supporting ontologies instead of redefining them in the domain ones.

We list ontologies in this category in Table 5. It is important to note that some resources are defined as Vocabulary (V), while others are considered Ontologies (O). Even though there is no clear distinction between those two terms, as both refer to a structured collection of terms, usually those classified as vocabulary are organized less strictly or formally than ontologies and tend to be less complex. Some of the cross-domain ontologies we consider to support the construction of domain-specific ontologies are SKOS, Time, QUDT and OM.

Catalogs

In ontology development, it is also relevant to consider a list of catalog services that DEs or KEs in the IoP can access to retrieve details regarding ontologies and vocabularies. It is necessary to provide such a list, as information about domain-specific ontologies is only available in scientific publications, which hinders them from being discovered and reused.

Another important consideration is that WikidataFootnote 3 is a knowledge base in which concepts related to several domains exist, including the manufacturing domain. Then, one can also use such a resource for the disambiguation of concepts in a new ontology.

In Table 6, we summarise available ontology services and repositories, including access links and a short description of how to use them. We excluded unavailable services, those with outdated content, or those not relevant to our purpose of providing information on ontologies and vocabularies for building models in the IoP. Also, we filter out those country-specific and those focusing on domain-specific ontologies not relevant to our field of interest, e.g., BioPortal and AberOWL.

Conclusion and outlook

In this contribution, we provide a comprehensive review and classification of existing ontologies of the manufacturing domain resulting in a register of 65 ontologies. These range from general concepts independent of the manufacturing process to specific ontologies modeled for a particular manufacturing domain.

We summarized and clustered the reviewed ontologies into 12 different categories that characterize typical assets and aspects of the manufacturing domain, such as products and sensors or the engineering and scheduling process. A majority of ontologies cover products, processes, resources, and measurements. In addition to providing the source publication of the ontology, we include a link to the ontology file and community, if available. This allows engineers to directly access and use these ontologies as needed. Ultimately, the register we have constructed facilitates a faster semantic engineering process, providing relief to ontology architects and manufacturing domain experts from the task of searching for ontologies and identifying their scope. Moreover, our contribution supports the reuse of ontologies, sparing developers from starting from scratch as they now have a comprehensive register at their disposal. We have intentionally focused on classifying the reviewed ontologies and refrained from conducting evaluations. In addition, we provide a priority guideline and a framework that supports developers with recommendations for reuse existing ontologies. This approach empowers developers to decide which ontology or combination thereof is most suitable for their specific use case. Also, we reviewed relevant supporting ontologies that help to complement the domain knowledge and catalogs, which contain ontologies and vocabularies.

Our work facilitates the implementation of autonomous asset communication in an Industry 4.0 environment, since (partly) reusing ontologies strives for a common communication basis enabling cross-domain and cross-company communication. However, one important consideration is that most ontologies in the manufacturing domain are still only available on paper, which difficult their reuse. Hence, engineers who build new ontologies should always publish their developed files and make them accessible for subsequent use or reuse.

Further work we identify is the alignment of the reviewed ontologies within their subdomains. As, for example, ontologies that define resources are widely present, the definition of those resources often is made differently. Hence, Uniform Resource Identifier (URI) for the single terms to follow the unique persistent and resolvable identifiers should be introduced. Additionally, suitable ontologies from different subdomains should be merged together to receive an overall and common ontology for the manufacturing domain. Solving this complex and challenging task can be done by building norms and guidelines that comprise the terms in a standardized manner. Lastly, application and domain ontologies should be reproducible and available for its reuse, via the ontologies catalogs, instead of only being included in the literature.

Moreover, further work in the context of the current trend of Large Language Models (LLM) is to identify the advantages of using them to support domain experts in the development of manufacturing ontologies, together with Wikidata for the disambiguation of concepts in such ontologies.

Notes

URL expired (access attempt on 01.05.2024)

References

Ameri, F., & Dutta, D. (2007). 26th Computers and Information in Engineering Conference (ASME, New York, USA. Proceedings of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, 2006, 651–661. https://doi.org/10.1115/DETC2006-99600

Ameri, F., Sormaz, D., Psarommatis, F., & Kiritsis, D. (2022). Industrial ontologies for interoperability in agile and resilient manufacturing. International Journal of Production Research, 60(2), 420–441. https://doi.org/10.1080/00207543.2021.1987553

Arp, R., Smith, B., & Spear, A. D. (2015). Building ontologies with basic formal ontology. The MIT Press, Cambridge. https://mitpress.mit.edu/9780262527811/building-ontologies-with-basic-formal-ontology/

Asset management - Overview, principles and terminology. (2017). Standard, Beuth Verlag GmbH.

Ayinla, K., Vakaj, E., Cheung, F., & Tawil, A.R.H. (2021). Proceedings of the Second International Workshop on Semantic Digital Twins co-located with the 18th Extended Semantic Web Conference (ESWC 2021) (Hersonissos, Greece, 2021). http://ceur-ws.org/Vol-2887/

Beden, S., Cao, Q., & Beckmann, A. (2021). SCRO: A domain ontology for describing steel cold rolling processes towards industry 4.0. Information. https://doi.org/10.3390/info12080304

Bendadouche, R., Roussey, C., De Sousa, G., Chanet, J.P., & Hou, K. M. (2012). Proceedings of the 5th International Conference on Semantic Sensor Networks - Volume 904 (CEUR-WS.org, Boston, USA, 2012), SSN’12, p. 49–64. https://doi.org/10.5555/2887689.2887693

Bodenbenner, M., Sanders, M.P., Montavon, B., & Schmitt, R. H. (2021). in Production at the leading edge of technology, ed. by B.A. Behrens, A. Brosius, W. Hintze, S. Ihlenfeldt, J.P. Wulfsberg, Lecture Notes in Production Engineering (SPRINGER, Berlin and Heidelberg, 2021), pp. 448–456. https://doi.org/10.1007/978-3-662-62138-7_45.

Borgo, S., & Leitão, P. (2004). CoopIS, DOA, and ODBASE, Lecture Notes in Computer Science, vol. 3290, ed. by D. Hutchison, pp. 670–688. Springer. https://doi.org/10.1007/978-3-540-30468-5_43

Brickley, D., & Miller, L. (2024). Foaf vocabulary specification 0.99 (2014). Retrieved April 21, 2023, from https://xmlns.com/foaf/spec/

Cao, Q., Giustozzi, F., Zanni-Merk, C., de Bertrand de Beuvron, F., & Reich, C. (2019). Smart condition monitoring for industry 4.0 manufacturing processes: An ontology-based approach. Cybernetics and Systems, 50(2), 82–96.

Cao, Q., Samet, A., Zanni-Merk, C., de BertranddeBeuvron, F., & Reich, C. (2020). Combining chronicle mining and semantics for predictive maintenance in manufacturing processes. Semantic Web, 11(6), 927–948.

Cao, Q., & Zanni-Merk, C. (2019). C. Reich. In D. Dao, R. J. Howlett, R. Setchi, & L. Vlacic (Eds.), Sustainable design and manufacturing 2018 (pp. 61–70). Springer.

Cheng, H., Xue, L., Wang, P., Zeng, P., & Yu, H. (2017). 2017 IEEE International Conference on Industrial Technology (ICIT) (Toronto, Canada, 2017), pp. 1393–1396. https://doi.org/10.1109/ICIT.2017.7915568

Cho, S., & Hildebrand-Ehrhardt, M. (2020). Strategies and predictive maintenance models wrapped around physical systems for zero-unexpected-breakdowns and increased operating life of factories (z-bre4k): Work package 3 - enhanced semantic modelling based on the feedback from validation. https://www.z-bre4k.eu/wp-content/uploads/2020/12/Z-BRE4K-semantic-modelling.pdf

Cho, S., Hildebrand-Ehrhardt, M., May, G., & Kiritsis, D. (2020). Ontology for strategies and predictive maintenance models. IFAC-PapersOnLine, 53(3), 257–264. https://doi.org/10.1016/j.ifacol.2020.11.042

COMPOSITION Consortium. D6.8 Collaborative Manufacturing Services Ontology and Language II (2021). https://www.composition-project.eu/wp-content/uploads/2019/03/D6.8_Collaborative_Manufacturing_Services_Ontology_and_Language_II.pdf, Last accessed on 2023-04-21

Compton, M., Barnaghi, P., Bermudez, L., García-Castro, R., Corcho, O., Cox, S., Graybeal, J., Hauswirth, M., Henson, C., Herzog, A., Huang, V., Janowicz, K., Kelsey, W. D., Le Phuoc, D., Lefort, L., Leggieri, M., Neuhaus, H., Nikolov, A., Page, Sheth, A., & Taylor, K. (2012). The ssn ontology of the w3c semantic sensor network incubator group. Journal of Web Semantics,17, 25–32. https://doi.org/10.1016/j.websem.2012.05.003. https://www.sciencedirect.com/science/article/pii/S1570826812000571

Correia, A., Stokic, D., Siafaka, R., & Scholze, S. (2017). 2017 International Conference on Engineering, Technology and Innovation (ICE/ITMC) (Madeira Island, Portugal, 2017), pp. 1173–1180. https://doi.org/10.1109/ICE.2017.8280014

da Rocha, H., Espirito-Santo, A., & Abrishambaf, R. (2020). IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society. (pp. 5243–5248). Singapore. https://doi.org/10.1109/IECON43393.2020.9254274

Dashkovskiy, S., Wirth, F., & Jagalski, T. (2006) Manufacturing, modelling, management and control, ed. by G. Chryssolouris, D. Mourtzis (p. 7). Elsevier https://citeseerx.ist.psu.edu/document?repid=rep1 &type=pdf &doi=ebc2ab27772e2f6d2fd2b2d73206bebb7eeb5334

DCMI. Dcmi metadata terms (2022). Retrieved April 21, 2023, from https://www.dublincore.org/specifications/dublin-core/dcmi-terms/

Domingue, J., Fensel, D., & Hendler, J.A. (2011). (eds.), Handbook of Semantic Web Technologies. SpringerLink Bücher (Springer-Verlag Berlin Heidelberg, Berlin, Heidelberg, 2011).https://doi.org/10.1007/978-3-540-92913-0

Ehrlinger, L., & Wöß, W. (2016). Joint Proceedings of the Posters and Demos Track of the 12th International Conference on Semantic Systems—SEMANTiCS2016 and the 1st International Workshop on Semantic Change & Evolving Semantics (SuCCESS’16), CEUR-WS, vol. 1695 (Leipzig, Germany, 2016). https://ceur-ws.org/Vol-1695/paper4.pdf

El Kadiri, S., & Kiritsis, D. (2015). Ontologies in the context of product lifecycle management: State of the art literature review. International Journal of Production Research, 53(18), 5657–5668. https://doi.org/10.1080/00207543.2015.1052155

El Asmar, B., Chelly, S., & Färber, M. (2020). AWARE: An ontology for situational awareness of autonomous vehicles in manufacturing.

Enterprise-control system integration - Part 2: Objects and attributes for enterprise-control system integration. Standard, Beuth Verlag GmbH, Berlin (2014)

Enterprise-control system integration - Part 4 (2016). Object model attributes for manufacturing operations management integration. Standard, Beuth Verlag GmbH, Berlin.

Fraga, A. L., Vegetti, M., & Leone, H. P. (2020). Ontology-based solutions for interoperability among product lifecycle management systems: A systematic literature review. Journal of Industrial Information Integration, 20, 100176. https://doi.org/10.1016/j.jii.2020.100176

Gangemi, A., & Presutti, V. (2009). Ontology design patterns (pp. 221–243). Springer. https://doi.org/10.1007/978-3-540-92673-3_10

Garetti, M., & Fumagalli, L. (2012). P-pso ontology for manufacturing systems. IFAC Proceedings Volumes, 45(6), 449–456. https://doi.org/10.3182/20120523-3-RO-2023.00222

Georgieva-Trifonova, T., & Galabov, M. (2021). Semantic web technologies for big data modeling from analytics perspective: A systematic literature review. Baltic Journal of Modern Computing., 9(4), 377–402.

Ghedini, L. (2022). Development of orma+ ontology towards zero defect manufacturing in the digital twin framework. Master thesis, Politecnico di Milano, Milano. https://www.politesi.polimi.it/bitstream/10589/195722/3/2022_10_Ghedini.pdf

GmbH, B. V. (2014). Enterprise-control system integration—Part 1: Models and terminology. Standard, Beuth Verlag GmbH. https://www.iso.org/standard/35480.html

Grangel-Gonzalez, I., Baptista, P., Halilaj, L., Lohmann, S., Vidal, M.E., Mader, C., & Auer, S. (2017). 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA) (IEEE, Limassol, Cyprus, 2017), pp. 1–8. https://doi.org/10.1109/ETFA.2017.8247584

Gruber, T. R. (1993). A translation approach to portable ontology specifications. Knowledge Acquisition, 5, 199–220.

Guinard, A. (2021). A survey of Top-Level Ontologies 1.0.0. Retrieved April 21, 2023, from https://digitaltwinhub.co.uk/files/file/90-a-survey-of-top-level-ontologies.

Gyrard, A., Datta, S. K., Bonnet, C., & Boudaoud, K. (2015). 2015 17th Asia-Pacific Network Operations and Management Symposium (APNOMS) (pp. 364–367). Busan, Korea: IEEE.

Harcuba, O., & Vrba, P. (2015). 2015 IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA) (pp. 1–8). IEEE

Helbig, T., Erler, S., Westkämper, E., & Hoos, J. (2016). Modelling dependencies to improve the cross-domain collaboration in the engineering process of special purpose machinery. Procedia CIRP, 41, 393–398. https://doi.org/10.1016/j.procir.2015.12.123

Herre, H. (2010). Theory and applications of ontology: Computer applications (pp. 297–345). Springer.

Hildebrandt, C., Scholz, A., Fay, A., Schroder, T., Hadlich, T., Diedrich, C., Dubovy, M., Eck, C., & Wiegand, R. (2017). 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA) (IEEE, Limassol, Cyprus, 2017), pp. 1–8. https://doi.org/10.1109/ETFA.2017.8247585.

Hitzler, P., Haller, A., Janowicz, K., Cox, S. J., Lefrançois, M., Taylor, K., Le Phuoc, D., Lieberman, J., García-Castro, R., Atkinson, R., & Stadler, C. (2019). The modular ssn ontology: A joint w3c and ogc standard specifying the semantics of sensors, observations, sampling, and actuation. Semantic Web, 10(1), 9–32. https://doi.org/10.3233/SW-180320

Hogan, A., Blomqvist, E., Cochez, M., D’amato, C., Melo, G. D., Gutierrez, C., Kirrane, S., Gayo, J. E. L., Navigli, R., Neumaier, S., Ngomo, A. C. N., Polleres, A., Rashid, S. M., Rula, A., Schmelzeisen, L., Sequeda, J., Staab, S., & Zimmermann, A. (2021). Knowledge graphs. ACM Computing Surveys. https://doi.org/10.1145/3447772

Huang, M., Fan, B., Chen, L., Pan, Y., & Qin, Y. (2023). Selection of additive manufacturing machines via ontology-supported multi-attribute three-way decisions. Applied Sciences, 13(5), 2926. https://doi.org/10.3390/app13052926

Hu, X., Lu, J., Zheng, X., Arista, R., Sorvari, J., Lentes, J., & Ubis, F. (2022). D. Kiritsis. In J. Chen, T. Hashimoto, X. Tang, & J. Wu (Eds.), Knowledge and Systems Sciences (pp. 83–98). Springer.

Institute of Data Science—Maastricht University. Using Ontologies (2020). Retrieved Last April 21, 2023, from https://maastrichtu-ids.github.io/best-practices/docs/using-ontologies/

Internet of Things. (2021). (IoT)—Interoperability for IoT systems—Part 3: Semantic interoperability. Standard, International Organization for Standardization, Geneva, CH

IOFundry. (2022). The Maintenance Reference Ontology. Retrieved January 10, 2024, from, https://github.com/iofoundry/ontology/tree/202301/maintenance

Järvenpää, E., Siltala, N., Hylli, O., & Lanz, M. (2019). The development of an ontology for describing the capabilities of manufacturing resources. Journal of Intelligent Manufacturing, 30(2), 959–978.

Karray, M., Otte, N., Rai, R., Ameri, F., Kulvatunyou, B., Smith, B., Kiritsis, D., Will, C., & Arista, R. (2021). Industrial Ontology Foundry (IOF)—achieving data interoperability Workshop, International Conference on Interoperability for Enterprise Systems and Applications, Tarbes. https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=925879

Karray, M. H., Ameri, F., Hodkiewicz, M., & Louge, T. (2019). ROMAIN: Towards a BFO Compliant Reference Ontology for Industrial Maintenance. Applied Ontology, 14(2), 155–177. https://doi.org/10.3233/AO-190208

Karray, M. H., Chebel-Morello, B., & Zerhouni, N. (2012). A formal ontology for industrial maintenance. Applied Ontology, 7(3), 269–310. https://doi.org/10.3233/AO-2012-0112

Katsumi, M., & Grüninger, M. (2016). Formal ontology in information systems, ed. by R. Ferrario, W. Kuhn, Frontiers in artificial intelligence and applications (IOS Press, Amsterdam, 2016), pp. 9–22. https://doi.org/10.3233/978-1-61499-660-6-9

Kjellberg, T., von Euler-Chelpin, A., Hedlind, M., Lundgren, M., Sivard, G., & Chen, D. (2009). The machine tool model—A core part of the digital factory. CIRP Annals, 58(1), 425–428.

Knutilla, A., Schlenoff, C.I., & Ivester, R.W. (1998). Proceedings of the 2nd International Conference on Engineering Design and Automation, ed. by Ole Madsen, Rune Larsen, Niels Jacobsen, Carsten Bro, Lars Overgaard, Ingvar Hafsteinsson (Maui, Hawaii, 1998)

Kovalenko, O., Grangel-González, I., Sabou, M., Lüder, A., Biffl, S., Auer, S., & Vidal, M. E. (2018). Automationml ontology: Modeling cyber-physical systems for industry 4.0. IOS Press Journal, 1, 1–5.

Kulvatunyou, B., Drobnjakovic, M., Ameri, F., Will, C., & Smith, B. (2022). Formal Ontologies Meet Industry (FOMI) 2022 (Tarbes, FR, 2022). https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=935068

Le Franc, Y. (2022). Ontocommons D3.2 - report on existing domain ontologies in identified domains. Zenodo. https://doi.org/10.5281/ZENODO.6504553

Lemaignan, S., Siadat, A., Dantan, J.Y., & Semenenko, A. (2006). IEEE Workshop on Distributed Intelligent Systems: Collective Intelligence and Its Applications (DIS’06) (pp. 195–200). https://doi.org/10.1109/DIS.2006.48. IEEE

Lepuschitz, W., Lobato-Jimenez, A., Axinia, E., & Merdan, M. (2015). International Conference on Industrial Applications of Holonic and Multi-Agent Systems (Springer) (pp. 22–32)

Li, W., Tropea, G., Abid, A., Detti, A., & Le Gall, F. (2019). 2019 Global IoT Summit (GIoTS) (pp. 1–6). IEEE.

Li, X., Zhuang, P., & Yin, C. (2019). A metadata based manufacturing resource ontology modeling in cloud manufacturing systems. Journal of Ambient Intelligence and Humanized Computing, 10(3), 1039–1047. https://doi.org/10.1007/s12652-018-0964-3

Lu, Y., Wang, H., & Xu, X. (2019). Manuservice ontology: A product data model for service-oriented business interactions in a cloud manufacturing environment. Journal of Intelligent Manufacturing, 30(1), 317–334. https://doi.org/10.1007/s10845-016-1250-x

Martinez Lastra, J., Delamer, I., & Ubis, F. (2010). Domain Ontologies for Reasoning Machines in Factory Automation (International Society of Automation (ISA), 2010). https://researchportal.tuni.fi/en/publications/domain-ontologies-for-reasoning-machines-in-factory-automation

Mascardi, V., Cordì, V., Rosso, P. (2008). A comparison of upper ontologies (technical report disi-tr-06-21). Dipartimento di Informatica e Scienze dell’Informazione (DISI), Universitr degli Studi di Genova, Via Dodecaneso 35, 16146.

May, G., Cho, S., Correia, A. T., Siafaka, R., Stokic, D., & Kiritsis, D. (2022). Toward a reference terminology for product-service systems in the manufacturing domain. Computers in Industry, 142, 103729. https://doi.org/10.1016/j.compind.2022.103729

May, G., Cho, S., Majidirad, A., & Kiritsis, D. (2022). A semantic model in the context of maintenance: A predictive maintenance case study. Applied Sciences, 12(12), 6065. https://doi.org/10.3390/app12126065

May, M. C., Kiefer, L., Kuhnle, A., & Lanza, G. (2022). Ontology-based production simulation with ontologysim. Applied Sciences (Switzerland), 12(3), Art.-Nr.: 1608.

Mazzola, L., Kapahnke, P., Vujic, M., & Klusch, M. (2016) in IC3K 2016, ed. by A. Fred, J. Dietz, D. Aveiro, K. Liu, J. Bernardino, J. Filipe (SCITEPRESS - Science and Technology Publications Lda, Setúbal, Portugal, 2016), pp. 136–143. https://doi.org/10.5220/0006056301360143

Melkote, S. N. Development of ifab (instant foundry adaptive through bits) manufacturing process and machine library.

Mizoguchi, R., & Toyoshima, F. (2017). YAMATO: Yet another more advanced top-level ontology with analysis of five examples of change. Applied Ontology, 17, 211–232.

Mohd Ali, M., Rai, R., Otte, J. N., & Smith, B. (2019). A product life cycle ontology for additive manufacturing. Computers in Industry, 105, 191–203. https://doi.org/10.1016/j.compind.2018.12.007

Molinas Comet, L. (2022) Guidelines for the Creation of Semantic Models in the Internet of Production (IOP). https://github.com/lcomet/UnifiedGuidelinesOntologyDevelopmentForIoP/blob/main/Guideline_OntologiesDevelopment_IOP-V3.pdf

Mönch, L., & Stehli, M. (2003). Multiagent system technologies, Lecture notes in computer science Lecture notes in artificial intelligence, vol. 2831, ed. by M. Schillo (SPRINGER, Berlin and Heidelberg, 2003), pp. 156–167. https://doi.org/10.1007/978-3-540-39869-1_14

Montero Jiménez, J. J., Vingerhoeds, R., Grabot, B., & Schwartz, S. (2023). An ontology model for maintenance strategy selection and assessment. Journal of Intelligent Manufacturing, 34(3), 1369–1387. https://doi.org/10.1007/s10845-021-01855-3

Morbach, J., Wiesner, A., Marquardt, W. (2008). 18th European Symposium on Computer Aided Process Engineering, Computer Aided Chemical Engineering (Vol. 25, pp. 991–996). Elsevier. https://doi.org/10.1016/S1570-7946(08)80171-X

Muñoz, E., Kopanos, G., Espuña, A., & Puigjaner, L. (2009). 19th European Symposium on Computer Aided Process Engineering, Computer Aided Chemical Engineering, vol. 26, ed. by J. Jezowski, J. Thullie (Elsevier, 2009), pp. 883–888. https://doi.org/10.1016/S1570-7946(09)70147-6. https://www.sciencedirect.com/science/article/pii/S1570794609701476

Nagy, L., Ruppert, T., & Abonyi, J. (2021). Ontology-based analysis of manufacturing processes: Lessons learned from the case study of wire harness production. Complexity. https://doi.org/10.1155/2021/8603515

Negri, E., Fumagalli, L., Garetti, M., & Tanca, L. (2016). Requirements and languages for the semantic representation of manufacturing systems. Computers in Industry, 81, 55–66. https://doi.org/10.1016/j.compind.2015.10.009

Noy, N., & Mcguinness, D. (2001). Ontology development 101: A guide to creating your first ontology. Knowledge Systems Laboratory, 32.

Nuñez, D. L., & Borsato, M. (2018). Ontoprog: An ontology-based model for implementing prognostics health management in mechanical machines. Advanced Engineering Informatics, 38, 746–759.

O. W3C. Qb4st: Rdf data cube extensions for spatio-temporal components (2017). Retrieved April 21, 2023, from https://www.w3.org/TR/qb4st/

OAGi. Industrial Ontologies Foundry. (2023). Retrieved January 10, 2024, from https://oagi.org/pages/industrial-ontologies

O. W3C. Time ontology in owl (2020). Retrieved April 21, 2023, from https://www.w3.org/TR/owl-time/

OAGi. OAGI Organization (2023). Retrieved January 10, 2024, from https://oagi.org/

Ocker, F., Paredis, C. J., & Vogel-Heuser, B. (2019). Applying knowledge bases to make factories smarter. Automatisierungstechnik, 67(6), 504–517. https://doi.org/10.1515/auto-2018-0138

Oemig, F., & Snelick, R. (2016). Healthcare interoperability standards compliance handbook: Conformance and testing of healthcare data exchange standards (Springer, Cham, Switzerland, 2016). https://search.ebscohost.com/login.aspx?direct=true &scope=site &db=nlebk &db=nlabk &AN=1302178

Ontocommons.eu. OntoCommons—Ontology-Driven Data Documentation For Industry Commons (2020). Retrieved January 10, 2024, from https://ontocommons.eu

Panetto, H., Dassisti, M., & Tursi, A. (2012). Onto-pdm: Product-driven ontology for product data management interoperability within manufacturing process environment. Advanced Engineering Informatics, 26(2), 334–348.

Paulheim, H. (2017). Knowledge graph refinement: A survey of approaches and evaluation methods. Semantic Web, 8(3), 489–508.

Peng, L., & Man, Y. (2013). Proceedings 2013 International Conference on Mechatronic Sciences, Electric Engineering and Computer (MEC). (pp. 1693–1696) Shenyang. https://doi.org/10.1109/MEC.2013.6885329

Pfrommer, J., Klein, J. F., Wurster, M., Rapp, S., Grauberger, P., Lanza, G., Albers, A., Matthiesen, S., & Beyerer, J. (2022). An ontology for remanufacturing systems. Automatisierungstechnik, 70(6), 534–541. https://doi.org/10.1515/auto-2021-0156

Polenghi, A., Roda, I., Macchi, M., & Pozzetti, A. (2021). Multi-attribute ontology-based criticality analysis of manufacturing assets for maintenance strategies planning. IFAC-PapersOnLine, 54(1), 55–60. https://doi.org/10.1016/j.ifacol.2021.08.192

Psarommatis, F., Dreyfus, P.A., & Kiritsis, D. (2022). Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology, ed. by D. Mourtzis (pp. 243–275). Elsevier. https://doi.org/10.1016/B978-0-12-823657-4.00012-9.

Psarommatis, F., Fraile, F., & Ameri, F. (2023). Zero defect manufacturing ontology: A preliminary version based on standardized terms. Computers in Industry, 145, 103832. https://doi.org/10.1016/j.compind.2022.103832

qudt.org. Qudt (2022). Retrieved April 21, 2023, from https://www.qudt.org

Raileanu, S., Borangiu, T., & Radulescu, S. (2014). Service Orientation in Holonic and Multi-Agent Manufacturing and Robotics, Studies in Computational Intelligence, vol. 544, ed. by T. Borangiu, D. Trentesaux, A. Thomas (Springer International Publishing, Cham, 2014), pp. 97–109. https://doi.org/10.1007/978-3-319-04735-5_7

Ramírez-Durán, V. J., Berges, I., & Illarramendi, A. (2020). ExtruOnt: An ontology for describing a type of manufacturing machine for industry 4.0 systems. Semantic Web, 11, 887–909.

Ramis Ferrer, B., Mohammed, W. M., Ahmad, M., Iarovyi, S., Zhang, J., Harrison, R., & Martinez Lastra, J. L. (2021). Comparing ontologies and databases: A critical review of lifecycle engineering models in manufacturing. Knowledge and Information Systems. https://doi.org/10.1007/s10115-021-01558-4

Ramos, L., Gil, R., Anastasiou, D., & Martin-Bautista, M. J. (2014). Towards a machine of a process (MOP) ontology to facilitate e-commerce of industrial machinery. Computers in Industry, 65(1), 108–115. https://doi.org/10.1016/j.compind.2013.07.012

Reference Architecture Model Industrie 4.0 (RAMI4.0). Standard, Beuth Verlag GmbH, Berlin (2016)

Riddick, F., & Lee, Y. (2010). Core Manufacturing Simulation Data (CMSD): A Standard Representation for Manufacturing Simulation-related Information. NIST Interagency/Internal Report (NISTIR) (National Institute of Standards and Technology, Gaithersburg, MD, 2010). https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=906307

Sabou, M., Kovalenko, O., & Novák, P. (2016). Semantic Web Technologies for Intelligent Engineering Applications, ed. by S. Biffl, M. Sabou (Springer International Publishing, Cham, 2016), pp. 105–136. https://doi.org/10.1007/978-3-319-41490-4_5

Saha, S., Usman, Z., Jones, S., Kshirsagar, R., & Li, W. (2017). 2017 IEEE 11th International Conference on Semantic Computing (ICSC) (IEEE, San Diego, USA, 2017), pp. 384–389. https://doi.org/10.1109/ICSC.2017.44

Saha, S., Usman, Z., Li, W., Jones, S., & Shah, N. (2019). Core domain ontology for joining processes to consolidate welding standards. Robotics and Computer-Integrated Manufacturing, 59, 417–430.

Sapel, P., & Hopmann, C. (2023). Towards an ontology-based dictionary for production planning and control in the domain of injection molding as a basis for standardized asset administration shells. Journal of Industrial Information Integration. https://doi.org/10.1016/j.jii.2023.100488

Schlenoff, C., Hong, T., Liu, C., Eastman, R., & Foufou, S. (2013). 2013 IEEE International Symposium on Robotic and Sensors Environments (ROSE). (pp. 96–101). https://doi.org/10.1109/ROSE.2013.6698425

Semantic Arts. gist (2022). Retrieved April 21, 2023, from https://www.semanticarts.com/gist/

Seyedamir, A., Ramis Ferrer, B., & Martinez Lastra, J. (2018). Proceedings - IEEE 16th International Conference on Industrial Informatics, INDIN 2018 (Institute of Electrical and Electronics Engineers Inc., Piscataway, USA, 2018), IEEE International Conference on Industrial Informatics (pp. 374–380).https://doi.org/10.1109/INDIN.2018.8471929

Sicilia, M. A. (2014). Handbook of metadata, semantics and ontologies. World Scientific. https://doi.org/10.1142/9789812836304. https://permalink.obvsg.at/

Simperl, E. (2009). Reusing ontologies on the semantic web: A feasibility study. Data & Knowledge Engineering, 68(10), 905–925. https://doi.org/10.1016/j.datak.2009.02.002

Smith, B., Ameri, F., Cheong, H., Kiritsis, D., Sormaz, D., Will, C., & Otte, N. (2019). Proceedings of the Joint Ontology Workshops 2019 (Graz, Austria)

Smith, B., Kumar, A., & Bittner, T. (2005). Basic formal ontology for bioinformatics.

Šormaz, D., & Sarkar, A. (2019). Simpm—Upper-level ontology for manufacturing process plan network generation. Robotics and Computer-Integrated Manufacturing, 55, 183–198.

Staab, S., & Studer, R. (2004). (eds.), Handbook on Ontologies. International Handbooks on Information Systems. Springer. https://doi.org/10.1007/978-3-540-24750-0

Streeton, R., Cooke, M., & Campbell, J. (2004). Researching the researchers: Using a snowballing technique. Nurse Researcher, 12(1), 35–46. https://doi.org/10.7748/nr2004.07.12.1.35.c5929

Strzelczak, S. (2015). in Advances in Production Management Systems: Innovative Production Management Towards Sustainable Growth, IFIP Advances in Information and Communication Technology, vol. 460, ed. by S. Umeda, M. Nakano, H. Mizuyama, H. Hibino, D. Kiritsis, G. von Cieminski (Springer International Publishing, Cham, 2015), 467–475. https://doi.org/10.1007/978-3-319-22759-7_54.

Usman, Z., Young, R.I.M., Chungoora, N., Palmer, C., Case, K., & Harding, J. (2011). Enterprise Interoperability, Lecture Notes in Business Information Processing, vol. 76, ed. by W. van der Aalst, J. Mylopoulos, N.M. Sadeh, M.J. Shaw, C. Szyperski, M. van Sinderen, P. Johnson (Springer Berlin Heidelberg, Berlin, Heidelberg, 2011), pp. 5–18. https://doi.org/10.1007/978-3-642-19680-5_3

Usman, Z., Young, R., Chungoora, N., Palmer, C., Case, K., & Harding, J. A. (2013). Towards a formal manufacturing reference ontology. International Journal of Production Research, 51(22), 6553–6572. https://doi.org/10.1080/00207543.2013.801570

Ustundag, A., & Cevikcan, E. (2018) Industry 4.0: Managing The Digital Transformation. Springer eBook Collection Engineering. Springer. https://doi.org/10.1007/978-3-319-57870-5

Vegetti, M., Leone, H., & Henning, G. (2011). Pronto: An ontology for comprehensive and consistent representation of product information. Engineering Applications of Artificial Intelligence, 24(8), 1305–1327. https://doi.org/10.1016/j.engappai.2011.02.014

Vigo, M., Bail, S., Jay, C., & Stevens, R. (2014). Overcoming the pitfalls of ontology authoring: Strategies and implications for tool design. International Journal of Human-Computer Studies, 72(12), 835–845. https://doi.org/10.1016/j.ijhcs.2014.07.005

W3C. Data catalog vocabulary (dcat)—version 2 (2020). Retrieved April 21, 2023, from https://www.w3.org/TR/vocab-dcat/

W3C. Data on the web best practices: Data quality vocabulary (2010). Retrieved April 21, 2023, from https://www.w3.org/TR/vocab-dqv/

W3C. Describing linked datasets with the void vocabulary. (2010). Retrieved April 21, 2023, from https://www.w3.org/TR/void/

W3C. Prov-o: The prov ontology (2013). Retrieved April 21, 2023, from https://www.w3.org/TR/prov-o/

W3C. Skos simple knowledge organization system extension for labels (skos-xl) namespace document - html variant (2009). Retrieved April 21, 2023, from https://www.w3.org/TR/skos-reference/skos-xl.html

W3C. Skos simple knowledge organization system primer (2009). Retrieved April 21, 2023, from https://www.w3.org/TR/skos-primer/

W3C. The Organization Ontology (2014). Retrieved April 21, 2023, from https://www.w3.org/TR/vocab-org/

W3C. The rdf data cube vocabulary (2014). Retrieved April 21, 2023, from https://www.w3.org/TR/vocab-data-cube/

W3C. vcard ontology - for describing people and organizations (2014). Retrieved April 21, 2023, from https://www.w3.org/TR/vcard-rdf/

Wache, H., Vögele, T., Visser, U., Stuckenschmidt, H., Schuster, G., Neumann, H., & Hübner, S. (2001). Proceedings of the IJCAI’01 Workshop on Ontologies and Information Sharing (pp. 108–117). https://ceur-ws.org/Vol-47/wache.pdf

W.U.B. Research. Om 2: Units of measure (2015). Retrieved April 21, 2023, from http://www.ontology-of-units-of-measure.org/

Wan, J., Yin, B., Li, Di., Celesti, A., Tao, F., & Hua, Q. (2018). An ontology-based resource reconfiguration method for manufacturing cyber-physical systems. IEEE/ASME Transactions on Mechatronics, 23(6), 2537–2546. https://doi.org/10.1109/TMECH.2018.2814784

Wlazlak, P., Andersen, A.L., & Raudberget, D. (2020). SPS2020, ed. by K. Säfsten, F. Elgh, Advances in Transdisciplinary Engineering. IOS Press. https://doi.org/10.3233/ATDE200192

Workgroup, M. (2022). Metadata4ing: An ontology for describing the generation of research data within a scientific activity. Retrieved April 21, 2023, from https://nfdi4ing.pages.rwth-aachen.de/metadata4ing/metadata4ing/index.html

Yahya, M., Breslin, J. G., & Ali, M. I. (2021). Semantic web and knowledge graphs for industry 4.0. Applied Sciences. https://doi.org/10.3390/app11115110

Yahya, M., Zhou, B., Breslin, J. G., Ali, M. I., & Kharlamov, E. (2023). Semantic modeling, development and evaluation for the resistance spot welding industry. IEEE Access. https://doi.org/10.1109/ACCESS.2023.3267000

Zahri, I., Sekkat, S., El-hassani, I., Zemmouri, E.m., & Douimi, M. (2023). in Proceedings of the 8th International Conference on Advanced Intelligent Systems and Informatics 2022, Lecture Notes on Data Engineering and Communications Technologies, vol. 152, ed. by A.E. Hassanien, V. Snášel, M. Tang, T.W. Sung, K.C. Chang (Springer International Publishing, Cham, 2023), pp. 692–706.https://doi.org/10.1007/978-3-031-20601-6_57

Zhdanova, A. V. (2006). P. Shvaiko. In Y. Sure & J. Domingue (Eds.), The semantic web: Research and applications (pp. 34–49). Springer.

Zheng, X., Petrali, P., Lu, J., Turrin, C., & Kiritsis, D. (2022). Rmpfq: A quality-oriented knowledge modelling method for manufacturing systems towards cognitive digital twins. Frontiers in Manufacturing Technology, 2, 901364. https://doi.org/10.3389/fmtec.2022.901364

Zhou, X., Gao, G., Ming, X., Wang, L., Yin, D., & Ma, X. (2021). 2021 International Conference on Service Science (ICSS) (pp. 30–37). Xi’an, China, 2021. https://doi.org/10.1109/ICSS53362.2021.00013. https://ieeexplore.ieee.org/document/9492206

Acknowledgements

Funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) under Germany’s Excellence Strategy - EXC-2023 Internet of Production—390621612.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sapel, P., Molinas Comet, L., Dimitriadis, I. et al. A review and classification of manufacturing ontologies. J Intell Manuf (2024). https://doi.org/10.1007/s10845-024-02425-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10845-024-02425-z