Planning Pick-and-Place tasks with two-hand regrasping

Jean-Philippe Saut1,2 , Mokhtar Gharbi1,2 , Juan Cortés1,2 , Daniel Sidobre1,2 , Thierry Siméon1,2

{jpsaut, mgharbi, jcortes, daniel, nic}@laas.fr

1

CNRS ; LAAS ; 7 avenue du colonel Roche, F-31077 Toulouse, France

2

Université de Toulouse; UPS, INSA, INP, ISAE ; LAAS ; F-31077 Toulouse, France

Abstract— This paper proposes a planning framework to

deal with the problem of computing the motion of a robot

with dual arm/hand, during an object pick-and-place task. We

consider the situation where the start and goal configurations

of the object constrain the robot to grasp the object with

one hand, to give it to the other hand, before placing it in

its final configuration. To realize such a task, the proposed

framework treats the grasp computation, for one or two multifingered hands, of an arbitrarily-shaped object, the exchange

configuration and finally the motion of the robot arms and

body. In order to improve the planner performance, a contextindependent grasp list is computed offline for each hand and for

the given object as well as computed offline roadmap that will be

adapted according to the environment composition. Simulation

results show the planner performance on a complex scenario.

I. I NTRODUCTION

While humanoid torso robots offer better manipulation

capacities compared to single arm/hand robots, they also

introduce new issues. For instance, in the case of a twoarm robot, if the object start and goal configurations are not

within the workspace of the same arm, it is necessary to

change the grasping hand to achieve the task. An efficient

and elegant way to change the grasp is to plan a dual-hand

grasp of the object.

Among the earlier work on this topic, [1] proposed a

practical planner for arms manipulating an object using a

predefined set of grasps. More recent work addressed a

similar problem for the case of dual-arm manipulation with

regrasping for a humanoid robot [2].

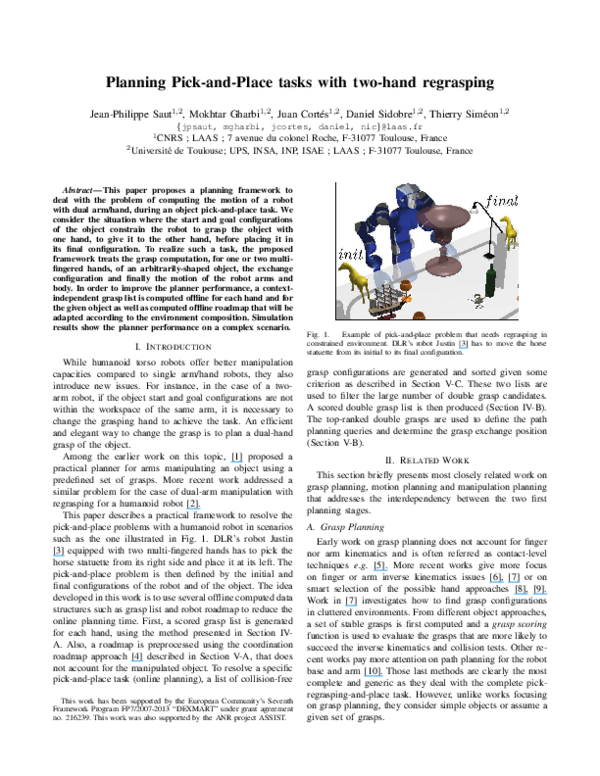

This paper describes a practical framework to resolve the

pick-and-place problems with a humanoid robot in scenarios

such as the one illustrated in Fig. 1. DLR’s robot Justin

[3] equipped with two multi-fingered hands has to pick the

horse statuette from its right side and place it at its left. The

pick-and-place problem is then defined by the initial and

final configurations of the robot and of the object. The idea

developed in this work is to use several offline computed data

structures such as grasp list and robot roadmap to reduce the

online planning time. First, a scored grasp list is generated

for each hand, using the method presented in Section IVA. Also, a roadmap is preprocessed using the coordination

roadmap approach [4] described in Section V-A, that does

not account for the manipulated object. To resolve a specific

pick-and-place task (online planning), a list of collision-free

This work has been supported by the European Community’s Seventh

Framework Program FP7/2007-2013 “DEXMART” under grant agreement

no. 216239. This work was also supported by the ANR project ASSIST.

Fig. 1.

Example of pick-and-place problem that needs regrasping in

constrained environment. DLR’s robot Justin [3] has to move the horse

statuette from its initial to its final configuration.

grasp configurations are generated and sorted given some

criterion as described in Section V-C. These two lists are

used to filter the large number of double grasp candidates.

A scored double grasp list is then produced (Section IV-B).

The top-ranked double grasps are used to define the path

planning queries and determine the grasp exchange position

(Section V-B).

II. R ELATED W ORK

This section briefly presents most closely related work on

grasp planning, motion planning and manipulation planning

that addresses the interdependency between the two first

planning stages.

A. Grasp Planning

Early work on grasp planning does not account for finger

nor arm kinematics and is often referred as contact-level

techniques e.g. [5]. More recent works give more focus

on finger or arm inverse kinematics issues [6], [7] or on

smart selection of the possible hand approaches [8], [9].

Work in [7] investigates how to find grasp configurations

in cluttered environments. From different object approaches,

a set of stable grasps is first computed and a grasp scoring

function is used to evaluate the grasps that are more likely to

succeed the inverse kinematics and collision tests. Other recent works pay more attention on path planning for the robot

base and arm [10]. Those last methods are clearly the most

complete and generic as they deal with the complete pickregrasping-and-place task. However, unlike works focusing

on grasp planning, they consider simple objects or assume a

given set of grasps.

�Our planner includes a generic grasp planner for multifingered hands and determines a set of single grasps that can

be used to find an exchange double grasp, even in a cluttered

environments and for an object with a complex shape.

B. Motion Planning

Sampling-based planners are able today to solve complex problems in high-dimensional spaces. In particular,

the probalistic methods like PRM, introduced in [11], and

RRT [12] have been shown to perform well for a broad

class of problems, even if their performance degrades in the

presence of narrow passages. Many variants and extensions

have been proposed to alleviate this problem (see [13] for

a survey). Our planner is based on recent work [4], that

proposes a roadmap coordination approach for multi-arm

systems.

C. Manipulation Planning

One of the challenging issues of manipulation planning is

to integrate the additional difficulty of planning the grasping

and re-grasping operations to the path planning problem.

This interdependency between path and grasp planning was

first touched in early work on automatic robot programming

systems (e.g. [14]). The manipulation planning approach

in [15] provided a unified framework allowing to better tackle

the interdependency issues between both planning levels.

More recently, the BiSpace, algorithm [10] was proposed

to plan how to go and grasp an object. The idea is to

first compute a set of grasp configurations for the hand

alone. Once one or more collision-free configurations for

the hand are found, they become the start nodes of several

RRT trees [12], that explore the hand workspace, while

another RRT is grown from the robot start configuration,

that explores the robot configuration space (CS).

Our work also considers a particular instance of manipulation planning problem and focuses on the combination of

efficient grasp and motion synthesis techniques to solve a

pick-and-place task requiring two-hand regrasping.

III. P ROBLEM F ORMULATION AND A PPROACH

The studied system is composed of a dual-arm robot, with

a hand mounted on each arm, an object and a set of static

obstacles. The problem inputs are the initial and final (goal)

configurations of the robot (qri and qrf ) and of the object

(qoi and qof ). qoi and qof correspond to stable placements of

the object on a support. qoi is such that the object is only

reachable with one of the arm, referred as Arm1 . qof is such

that the object is only reachable with the other arm, referred

as Arm2 . The robot will thus have to exchange the object

between its two hands. The exchange configuration is qoe for

the object, qre for the whole robot (torso plus arms). The

robot will grasp the object in qoi with configuration qrg and

will place it in qof with configuration qrp .

The method proposed in this paper for planning pickand-place tasks relies on two sub-task planners: The Grasp

planner presented in next section and the path planner

presented in Section V.

Fig. 2. The object mesh is uniformly sampled with a point set and then

partitioned using a kd-tree.

IV. G RASP P LANNING

Grasp planning basically consists in finding a configuration for the hand(s) or end effector(s) that will allow to pick

up the object. In the present context, we are interested in

two kinds of grasps: One-handed grasps (or single grasps)

and two-handed grasps (or double grasps). We consider only

precision grasps i.e. contacts are made with fingertips only.

This allows to reason with point contact only, that is the

most common case in literature. It also gives more grasping

possibilities as smaller parts can be grasped, at the cost

of a weaker stability compared to power grasps. We have

implemented our algorithm for the Schunk Anthropomorphic

hand (SAH hand, depicted on Fig. 3). Our method is not

specific to this hand but we will use it for illustration purpose.

The first stage of our grasp planner consists in building a

grasp list to capture the variety of the possible grasps.

A. Single Grasp Planning

A single grasp is defined for a specific hand type and for

a specific object. It is defined by:

• A grasp frame, i.e. a relative pose of the hand reference

frame (e.g. palm or wrist frame) wrt. the object frame.

• A set of contact points (a point on the object surface

and the ID of the finger realizing the contact).

• A hand configuration (finger joint parameters).

As our main concern is motion planning, it is not possible

to rely on the computation of an only grasp or on a heuristic

that could introduce a bias on the choice of the grasp. It is

preferable to compute a grasp list that aims to reflect the best

the variety of all possible grasps of the object. Our algorithm

applies the following steps that will be detailed further:

• Build a set of grasp frame samples.

• Compute a list of grasps from the set of grasp frames.

• Perform a stability filter step and compute a quality

score for each grasp.

1) Grasp frame sampling: To avoid biasing the possible

approach of the hand when we compute the grasp, we choose

to uniformly sample the possible grasp frames, by the mean

of a grid. We have chosen a grasp frame that is centered on

the intersection of the finger workspaces so that it is roughly

centered where the contacts may occur. We set as an input

the numbers of positions and orientations, each pair positionorientation defining a frame. The positions are uniformly

sampled in the object axis-aligned bounding box with a step

computed to fit the desired number of position samples. The

orientations are computed with an incremental grid as in [16].

For each grasp frame, a set of grasps will be computed.

�2) Grasp list computation: As the proposed grasp planning method does not restrict the possible hand poses or

contact surface on the object, it requires a lot of computation.

Therefore, we have to introduce some data structures to

reduce the computation times. Except for collision test, the

most expensive computation is the finger inverse kinematics.

One has to be able to know the fastest possible if, for a

given hand pose (relative to the object), a finger can establish

a contact on the object surface and, if it can, where. The

contacts can only occur in the intersection of the finger

workspace and the object surface. For each finger, it is

consequently crucial to find this intersection or at least an

approximation. We propose to approximate the object surface

with a point set. The set is obtained by a uniform sampling

of the object surface. The sampling step magnitude is chosen

from the fingertip radii. A kd-tree is built upon the point set

in order to have a hierarchical space partition of the points

(Fig. 2).

We then need to find the intersection of each finger

workspace with the object kd-tree. As spheres are invariant

in rotation, they are interesting to build an approximation

of the finger workspace. Starting from grid approximations

of the finger workspace’s interior volume W and envelope

E (Fig. 3), we build incrementally a set of spheres fitting

inside the workspace using Algorithm 1. The interior volume

grid is obtained by sampling the three joint angles over

their respective ranges. The envelope grid is obtained by

blocking one of the joint angle to its limit values (lower

then upper) and sampling the two others. By construction, the

sphere hierarchy starts from the biggest ones, corresponding

to workspace parts that are the farthest to the finger joint

bounds.

Algorithm 1: Finger workspace approximation

: W = a set of points strictly inside the finger

workspace ; E= a set of points on the envelope of the finger workspace ; kmax = the

desired maximal number of spheres ; rmin =

the desired minimal sphere radius ;

output : S= a set of spheres Sk

S=∅;k=1;

while k < kmax do

foreach p ∈ W do

d(p) = min (kp − pi k) ;

input

pi ∈(E∪S)

pbest = {p ∈ W : d(p) = max (d(pi ))};

Once we have both the kd-tree and the sphere hierarchy,

it is very fast to determine the intersection of the two sets

and so the contact points. The intersection is tested from the

biggest to the smallest sphere, guarantying that the “best”

parts of the workspace will be tested first, i.e. the one farthest

to workspace singularities, due to the joint bounds. For a

given grasp frame, the grasp is computed finger by finger, i.e.,

if we have the contact and configurations of the fingers 1 to

i − 1, we search a contact point for finger i and test collision

only with fingers 1 to i as the other finger configurations are

not yet known. We start from the thumb as no stable grasp

can be obtained without it. If a finger can not establish a

contact, it is left in a “rest” (stretched) configuration. if we

have three contacts or more, we can proceed to the stability

test. Note that, at this stage, we have a collision-free grasp

i.e. no collision between the hand and the object and do not

yet consider collision with the environment or the robot arms

or body.

3) Stability filter and quality score: The stability test

is based on a point contact with friction model. From the

contact positions and normals, we compute a force-closure

stability score [17]. All the grasps that do not verify forceclosure are discarded. The stability score is not sufficient to

discriminate good grasps so we build a more general quality

score. Several aspects can be taken into account to compute a

grasp quality measure [18]. A tradeoff is often chosen with a

score that is a weighted sum of several measures. We used the

following scores: the above force-closure score, the distance

from the contact centroid to the mass center of the object,

the sum of the angles between each contact normal and the

force ellipsoid major axis of the associate finger, the sum of

the object’s surface inverse curvature at the contact points.

The curvatures are normalized over all the values on the

sampled object’s surface. The weights were set manually.We

found that (1.0, 1.0, 1.0, 6.0 (curvature score)) offers a

good trade-off even though it might not always be the case.

Combining different quality scores remains however a hard

problem, beyond the scope of this paper.

B. Double Grasp Planning

A double grasp is a grasp involving both hands. It is

computed from two single grasp lists L1 and L2 , obtained

for each hand. Each single grasp pair sg1 and sg2 , belonging

to L1 and L2 respectively, is tested. All colliding pairs are

rejected. To avoid an excessive number of pairs to test, we

first filter L1 and L2 to remove all the grasps that lead to a

collision with the environment for the given initial and final

pi ∈W

Sk = sphere(center = pbest , radius = d(pbest )) ;

S = S ∪ Sk ;

W = W − {p ∈ W : p ⊂ Sk } ;

k =k+1 ;

if d(pbest ) < rmin then

break ;

return S ;

Fig. 3. The finger workspace discretized with a grid (forefinger workspace,

left image). The grid is converted to a volumetric approximation as a set of

spheres (right image).

�Fig. 4. The decomposition of the humanoid system into elementary parts.

The two arms and the head are the “independent” parts and the torso is the

“common” one.

object poses. For instance, all the grasps that take the object

from “below” will be removed as they lead to a collision

between the object support and the hand. For each double

grasp, a score is then computed based on two scores: the

quality of each single grasp and a robot configuration score.

• The minimum of sg1 and sg2 quality is used as a the

first score for the double grasp.

• A robot configuration score is computed for sg1 and

sg2 , based on how “natural” is the way to grasp the

object in its start and goal configuration using sg1 and

sg2 . For the double grasp, we take the minimum of the

robot configuration scores of sg1 and sg2 .

After normalizing these two scores separately for all the

computed double grasps, we sum them for each double grasp

to obtain its score.

V. PATH PLANNING

A. Offline roadmap

Computing an offline roadmap is suitable to speed up the

task resolution. This roadmap is computed using specially

designed one for multi-arm systems [4]. During this generation, only self-collisions and collisions against static objects

are considered while ignoring the object to move. The multiarm systems roadmap composition algorithm [4] is a suitable

method to efficiently plan multi-arm systems motions in

constrained workspaces. It is based on the decomposition

of the system into kinematically independent parts, which

are treated as individual robots in a multi-robot roadmap

composition approach. Fig. 4 illustrates the different parts

of Justin. Each arm is independent from the other. If the

value of an arm joint is modified, the change does not affect

the position of any other part in the system. However, a

change in one of the torso joints modifies the pose of the

arms and the head. In general case, a part is said to be

independent, if the change of its configuration does not affect

the pose of other system parts. Thus, this system involves

three independent parts P I : the right and the left arms (PrI

and PlI respectively), and the head (PhI ); and a common

one: the torso (PtC ). Given the relatively low mobility of the

head, it can be considered together with the torso in order

to simplify the system decomposition.

This decomposition permits to split the roadmap construction into two stages. The first stage is to compute two

collision-free roadmaps Rr and Rl for the two sub-systems

composed by the torso and the right and left arms respectively. Such roadmaps construction considers self-collisions

of the sub-system and collisions with the obstacles in the

Fig. 5. On the left, a representation of elementary roadmaps computed

for the presented system (circle and square). The generated Super Graph

on the right.

workspace. Any PRM-like method can be used to generate

these roadmaps. However, the use of methods generating

compact roadmaps such as [19] or [20] is preferable in order

to limit the size of the composite roadmap, which is defined

as the Cartesian product of all the sub-system roadmaps, and

whose size may become huge if standard PRM methods are

used.

The constructed roadmaps are then merged into a composite one, called Super Graph (SG), extending the idea initially

proposed in [21] for the case of multiple car-like robots.

Merging two nodes from Rr and Rl creates SG node. The

SG nodes are connected via SG edges. Fig. 5 illustrates the

principle of the SG construction. Creation of nodes and edges

are explained below.

1) Super Graph Nodes: The SG nodes are created by

the composition of elementary nodes xr and xl , in Rr and

Rl respectively. Due to change of common configuration

parameters in xr and xl , merging consists of creating two

SG nodes, obtained by fusing configurations of the independent parts. Each SG node is only partially checked for

self-collision, since nodes of the elementary roadmaps are

collision-free with the environment. Each independent part

configuration added up to an elementary node has been

checked against the other independent parts, the common

parts, and the workspace obstacles. Only the collision-free

nodes are kept in SG.

2) Super Graph Edges: Once a node X is created and

inserted into SG, its connection to the other SG nodes Y is

computed. In order to preserve the efficiency of the roadmap

construction, a filter, based on the information given by the

elementary nodes, only considers connections between two

SG nodes X and Y if their composing nodes, xr and yr , and

xl and yl are connected in Rr and Rl respectively. Another

possible strategy for saving computing time is to construct a

roadmap tree instead of a graph. In this case, connection tests

(using a local planner) are only performed between SG nodes

belonging to different connected component of SG. Like

for the SG nodes, validating SG edges only requires to

test collisions between pairs of parts and with workspace

obstacles that have not been checked when computing the

edges of the elementary roadmaps. A SG edge is added to

the SG if it is collision-free.

B. Online planning

We explain below how robot motions are computed online

in order to realize the pick, regrasp and place task, given the

precomputed single / double grasps and roadmap. The task

can be decomposed into four consecutive steps:

�Grasp the object (from qri to qrg )

g

e

• Carry it to the exchange position (from qr to qr )

p

e

• Place it (from qr to qr )

f

p

• Goto rest configuration (from qr to qr )

with qri and qrf given as input and the three other configurations (qrg , qre and qrp ) are generated by the planner.

Once the grasp configurations have been generated (Section V-C), the path planner executes the four previously

presented queries sequentially. To obtain collision-free paths,

the previously computed roadmap has to take into account

the manipulated object. In fact, by adding an object in the

robot working space, the collision-free CS of the robot

changes. The CS also changes when the robot carries the

object. Revalidating online the entire roadmap would be too

costly. We use instead a lazy node and edge revalidation as

in [22].

First the query is executed in the precomputed roadmap

disregarding the collisions of the existing nodes and edges

in the graph. Once a path is found, each local path composing it is checked for collision against the manipulated

object that is not considered in the preprocessed roadmap.

If a collision is detected for some local paths, replanning

strategy is performed as follows. First, the collision-free

configurations bounding the collision portion are determined.

An alternative path between the disconnected configurations

is then searched in the precomputed graph. If no solution

is found, local reconnections are computed using RRT-like

planners [12]. The path is iteratively modified until all its

local paths are collision-free. Our implementation uses the

same data structure for storing PRM roadmaps and RRT

diffusion trees. Then, it is easy to enrich a graph computed

using PRMs with RRTs to efficiently reconnect the disconnected components in the graph.

•

C. Grasp Configuration

The grasp and place configurations of the robot are simply

derived from the object initial and final placement qoi and qof

provided as input. However, the exchange configuration qoe

of the object is unknown. The object position is determined

by minimizing wrist motions to perform the task. The minimization is done on a 3D grid. The object exchange position

is the collision-free grid node that minimizes the length sum

of the edges depicted on Fig. 6, in 3D space. Once a position

i

Arm 1

VI. R ESULTS

To evaluate the performance of the planner, we propose to

plan a pick-and-place task with Justin [3], equipped with two

SAH hands (Fig. 1). Justin is composed of a 3-DoFs torso,

two 7-DoFs DLR-Lightweight-Robot-III arms, and a 2-DoFs

head. The SAH hands are composed of four 3-DoFs fingers

plus a movable thumb base. Disregarding the neck joints,

which are considered to be fixed in our experiments, Justin

involves 43-DoFs. The object to work with is a highly nonconvex body with several parts (a horse statuette, whose 3D

model (widely used in CG community) has been simplified

to 672 vertices and 1334 triangles).

In this task, Justin has to pick the object at his right

and place it behind the desk lamp at his left. The legged

lamp and the vase constrain the robot motions and the

exchange configuration. As the single grasp generation is

i

Arm 2

e

Arm 1-2

f

g

Arm 1

is selected, the object is tested against the static obstacles in

predetermined orientations to ensure a collision-free object

exchange. Unlike object exchange position, the orientation is

determined by the selected double grasp directions and the

object position wrt. the robot torso.

The grasp, place and exchange configurations are generated in nearly the same way. All robot joints are sampled

except the arm(s) grasping the object (one arm for grasp and

place configurations and both for exchange configuration),

that are computed using the inverse kinematics characterized

by the grasps and the object position. Then, a collision test

is performed on the generated configuration. For exchange

configuration, the object configuration is sampled following

a Gaussian distribution centered on the theoretical best qoe

previously computed.

The robot grasp configuration score used in the double

grasp scoring formula, takes into account grasping and freearm configurations. The grasping arm score is determined

with cosine of the angle between the selected grasp and the

object robot-base directions. This will give a bad score for

grasps whose direction is far from the object-(robot base)

axis. The free-arm score is added to favor “natural” robot

configurations. This score is composed of the joint distance

between the sampled arm configuration and a user defined

rest configuration of the arm. It is also composed by the

height difference between the sampled and rest configurations, and the distance between the arm wrist and the plane

composed by the robot’s torso and shoulders.

Arm 1

f

Arm 2

p

Arm 2

Fig. 6. Top view of a pick-and-place task showing the elementary distances

to be minimized over a 3D grid in order to compute the double grasp

position (the center red circle). Superscripts corresponds to the different

key-configurations of the arms ([i=initial, f=final, g=grasping, e=exchange,

p=placement]-configuration).

Fig. 7. Example of computed exchange positions for different initial (red)

and final (green) object poses, taking into account the cost to minimize and

obstacle collision avoidance.

�TABLE I

N UMERICAL R ESULTS

Problem

Online Planning

Path Validation

Total

Grasp

n

T (s)

65

2.7

3

0.3

68

3

n

53

18

71

Carry

T (s)

2.6

1.5

4.1

n

32

12

44

Place

T (s)

1.2

1.1

2.3

n

49

3

51

Rest

T (s)

1.9

0.3

2.1

a deterministic and workspace independent operation, the

same single grasps lists (one for each hand) are used for all

tests. Right grasp list contains 17 valid grasps and 22 for left

list, each one computed in about 1 minute1 . In the presented

scenario, given the single grasp lists, the planner generates 4

(right) and 7 (left) collision-free single grasps configurations

in 4.2 seconds, and 4 double-grasp configurations in 2.6

seconds. Fig. 7 shows two examples of computed double

grasps, used for regrasping. They are computed for the same

object but for different initial and final object poses. The

computed exchange configuration brings the object near the

robot torso, leading to a motion that looks more “natural”

than a simple straight line linking initial and final poses.

Table I reports the numerical results (n= node number,

T = computation time) obtained for the presented pick-andplace planner, following the task decomposition presented

in Section V-B. The offline roadmap is computed in about

5 minutes and contains near 1700 nodes. The nodes are

produced by merging two elementary roadmaps generated

using Vis-PRM algorithm [19], each one containing 50

nodes. Using this offline roadmap, our planner solves the

entire task in 11.6 seconds. Comparatively, by putting a

single query planner [12], one needs 35 seconds to solve the

same problem. These two last results do not include the time

needed to compute single and double grasps configurations.

Table I also shows that the time consumed in path validation for Carry and Place phases is more important than

for the two other planning phases. This is due to the bigger

change of the robot CS, induced by considering the object as

a robot’s body instead of just a static obstacle. However, the

time needed to plan (without revalidation) Grasp and Rest

phases are higher because of the highly constrained grasp

and place configurations.

VII. C ONCLUSION AND F UTURE W ORK

We have presented a planner that can automatically compute the motion of a dual-arm/hand robot during a pick-andplace task requiring an object exchange between the hands.

The planner computes as well all the necessary intermediate

configurations. The integration of several offline computed

and reusable data structures such as grasp lists and arm

roadmaps, allows the planner to significantly reduce its

computation times compared to the use of simple singlequery techniques. Simulation results show the efficiency of

the planner for solving a difficult manipulation task involving

a humanoid robot equipped with two redundant arms and two

1 All numerical results in the paper have been averaged over 20 runs of

the planner. Computing time corresponds to a Dual-Core AMD Opteron

processor 2222 at 3.0 GHz

multi-fingered hand, a complex-shaped object and a cluttered

environment.

In some situations, no solution may be found by the

planner because the initial pose of the object constrains too

much the choice of the single grasp used to pick the object

up, that in turn constrains the choice of the exchange double

grasp, constraining in turn the choice of the single grasp used

to place the object in its final configuration. To treat such a

case, one or more intermediate placements are mandatory. A

more complex version of our planner could try to integrate

such notions.

R EFERENCES

[1] Y. Koga and J.-C. Latombe, “On multi-arm manipulation planning,”

IEEE Conf. on Rob & Autom., vol. 2, pp. 945–952, 1994.

[2] N. Vahrenkamp and et al., “Humanoid motion planning for dualarm manipulation and re-grasping tasks,” in IEEE/RSJ Int. Conf. on

Intelligent Robots & Systems, October 2009.

[3] C. Ott and et al., “A humanoid two-arm system for dexterous manipulation,” in IEEE-RAS Int. Conf. on Humanoid Robots, 2006.

[4] M. Gharbi, J. Cortés, and T. Siméon, “Roadmap composition for multiarm systems path planning,” in IEEE/RSJ Int. Conf. on Intelligent

Robots & Systems, Oct. 2009, pp. 2471–2476.

[5] V.-D. Nguyen, “Constructing force-closure grasps,” IEEE Conf. on

Rob. & Autom., vol. 3, pp. 1368–1373, Apr 1986.

[6] Z. Xue, J. Marius Zoellner, and R. Dillmann, “Grasp planning: Find

the contact points,” IEEE Int. Conf. on Robotics and Biomimetics, pp.

835–840, Dec. 2007.

[7] D. Berenson, R. Diankov, K. Nishiwaki, S. Kagami, and J. Kuffner,

“Grasp planning in complex scenes,” in IEEE-RAS International

Conference on Humanoid Robots (Humanoids07), December 2007.

[8] A. Miller, S. Knoop, H. Christensen, and P. Allen, “Automatic grasp

planning using shape primitives,” IEEE Conf. on Rob. & Autom., vol. 2,

pp. 1824–1829 vol.2, Sept. 2003.

[9] K. Huebner, S. Ruthotto, and D. Kragic, “Minimum volume bounding

box decomposition for shape approximation in robot grasping,” IEEE

Conf. on Rob. & Autom., pp. 1628–1633, May 2008.

[10] R. Diankov, N. Ratliff, D. Ferguson, S. Srinivasa, and J. Kuffner,

“Bispace planning: Concurrent multi-space exploration,” in Robotics:

Science and Systems, vol. IV, Zurich, Switzerland, June 2008.

[11] L. E. Kavraki, P. Svestka, J.-C. Latombe, and M. H. Overmars, “Probabilistic roadmaps for path planning in high-dimensional configuration

spaces,” IEEE Trans. on Rob. & Autom., vol. 12(4), pp. 566–580, 1996.

[12] S. M. LaValle and J. J. Kuffner, “Rapidly-exploring random trees:

Progress and prospects,” in Proceedings of Workshop on the Algorithmic Foundations of Robotics, 2000.

[13] S. M. LaValle, Planning Algorithms. New York: Cambridge University Press, 2006.

[14] T. Lozano-Pérez, J. L. Jones, P. A. O’Donnell, and E. Mazer, Handey:

a robot task planner. Cambridge, MA, USA: MIT Press, 1992.

[15] T. Siméon, J. Laumond, J. Cortés, and A. Sahbani, “Manipulation planning with probabilistic roadmaps,” The Int. J. of Robotics Research,

vol. 23, iss. 7-8, pp. 729–746, August 2004.

[16] A. Yershova and S. LaValle, “Deterministic sampling methods for

spheres and so(3),” in IEEE Int. Conf. Robot. & Autom., 2004.

[17] B. Bounab, D. Sidobre, and A. Zaatri, “Central axis approach for

computing n-finger force-closure grasps,” IEEE Conf. on Rob. &

Autom., pp. 1169–1174, May 2008.

[18] R. Suarez, M. Roa, and J. Cornella, “Grasp quality measures,” in

Universitat Politecnica de Catalunya (UPC), Technical Report, 2006.

[19] T. Siméon, J.-P. Laumond, and C. Nissoux, “Visibility-based probabilistic roadmaps for motion planning,” Advanced Robotics Journal,

vol. 14(6), pp. 477–494, 2000.

[20] L. Jaillet and T. Siméon, “Path deformation roadmaps: Compact graphs

with useful cycles for motion planning,” Int. J. of Robotics Research,

vol. 27, no. 11-12, pp. 1175–1188, 2008.

[21] P. Svestka, “Robot motion planning using probabilistic roadmaps,”

Ph.D. dissertation, Universiteit Utrecht, 1997.

[22] L. Jaillet and T. Siméon, “A prm-based motion planner for dynamically

changing environments,” in IEEE/RSJ Int. Conf. on Intelligent Robots

& Systems, vol. 2, Sept. 2004, pp. 1606 – 1611 vol.2.

�

Daniel Sidobre

Daniel Sidobre Juan Cortés

Juan Cortés