Abstract

The pore-structure characteristics of hybrid basalt–polypropylene fibre-reinforced concrete were investigated by using mercury intrusion porosimetry. The applicability of various fractal models in characterising the HBPRC pore structure was compared. The results show that the types and content of fibres show different influences on the cumulative pore volume and fractal characteristics of hybrid basalt-polypropylene fibre-reinforced concrete. Compared with pore-volume and solid mass, the fractal characteristics of pore surface area of hybrid basalt-polypropylene fibre-reinforced concrete is more significant. Furthermore, the pore-surface fractal model that established based on the energy conservation relationship during mercury intrusion is more accurate and effective for the characterization of fractal dimension of hybrid basalt-polypropylene fibre-reinforced concrete. The research results can provide important theoretical guidance for the study of pore structure and fractal characteristics of fibre-reinforced concrete.

1 Introduction

Because of their high brittleness and low tensile properties, ordinary concrete materials are prone to cracking under an actual service state, which reduces the service performance of concrete structures. However, the brittleness of concrete can be significantly reduced by adding fibre, particularly hybrid rigid and flexible fibres [1,2,3,4,5,6]. Basalt fibre (BF) is a new type of environment-friendly inorganic rigid fibre with an elastic modulus as high as 93–115 GPa and a tensile strength of up to 200–5,000 MPa. In addition, BF also possesses good temperature and chemical stability [7]. Polypropylene fibre (PF) has low tensile strength and elastic modulus; thus, it belongs to flexible-fibre materials. However, it possesses good ductility and chemical stability [8,9]. Therefore, when rigid BF and flexible PF are mixed in the concrete, their synergistic effect can effectively improve the concrete toughness [10,11,12]. However, the addition of BF and PF certainly increases the amount of interface in concrete (the interface between the fibres and concrete matrix) and introduces air bubbles during the mixing process, thus affecting the pore structure of concrete [13,14].

Pore structure is the main determinant of the macroscopic performance of concrete [15,16,17,18,19,20]. The existence of pores affects not only the mechanical properties and durability but also the thermal insulation performance of concrete. At present, many methods are available for testing the pore structure of concrete materials. However, because of its simple principle, easy operation, and wide range of measurable pore diameter, the mercury intrusion porosimetry (MIP) method remains the most widely used and most recognised method for testing the pore structure of concrete materials [21,22,23,24,25]. According to the MIP method, the important pore-structure parameters such as porosity, pore-size distribution, and critical pore size of concrete can be obtained. The pore-structure characteristics of concrete materials are extremely complex, and reasonably characterising the pore structure of concrete materials using its simple characterisation parameters, such as porosity and pore-size distribution [26,27,28,29,30], is difficult. Many studies have indicated that the pore structure of cement-based materials demonstrates obvious fractal characteristics, and the complex characteristics of the pore structure of cement-based materials can be effectively characterised using the fractal theory [31,32,33,34]. Fractal dimension is a rational parameter for comprehensively characterising the advantages and disadvantages of the pore structure of cement-based materials.

Currently, the pore-structure fractal-dimension models of cement-based materials mainly include the pore-surface, pore-volume, and solid-volume fractal models [35,36]. Among them, the representative pore-surface fractal models mainly include the pore-surface fractal model of pulverised coal particles established by Frieden and Mikula [37] based on the Menger sponge model, pore-surface fractal model of porous materials established by Neimark [38] based on the thermodynamic method, and pore-surface fractal model of cementitious materials established by Zhang and Li [34,39] based on the energy-conservation principle of the MIP method. The pore-volume fractal models mainly include the pore-volume fractal model of cement-based materials established by Ji et al. [40] and that of porous materials developed by Pfeifer and Avnir [41] based on the relationship between the pore volume and pore diameter. The solid-volume fractal model is mainly one of the solid drug-dosage forms established by Usteri et al. [42] by studying the relationship between the solid volume and total volume of fractals. Different types of fractal models describe different fractal objects. In addition, the same type of fractal model adopts different construction methods and has different fractal principles. These differences will affect the effectiveness of fractal models to characterise the fractal characteristics of cement-based materials.

Zeng et al. [43,44] studied the pore structure and fractal characteristics of uranium bearing sandstone. The results show that the leaching efficiency of uranium is related to the fractal dimensions of pore surface area, pore volume and solid mass. Bernal and Bello [45] compared the effectiveness of the above fractal models to characterise the pore-structure characteristics of building stones. All the fractal models were suitable for building stones except the Ji et al. model. Chen et al. [30] studied the applicability of fractal model to characterise the pore structure of paster, mortar, and concrete. The results showed that the pore-surface fractal dimension of paster and concrete calculated by the Neimark model was beyond the range of definitions and had no physical significance, but the pore-surface fractal dimension of mortar met this range. That is to say, the Neimark model is not applicable to characterise the pore-structure fractal characteristic of paster and concrete, but it is applicable to that of mortar [30].

Theoretically, the pore-structure characteristics of concrete matrix will be affected by the accumulation mode of solid particles, and the fractal characteristics of pore structure as well as the applicability of fractal models will change accordingly. As for fibre-reinforced concrete, the addition of fibres will inevitably change the accumulation mode of solid phase in concrete, which may make the pore fractal characteristics and the applicability of fractal model of fibre-reinforced concrete different from that of the ordinary concrete.

The validity of fractal model characterisation is an important premise of fractal analysis. Wood [46] studied the applicability of three fractal models to characterise the surface roughness of shales, compared the characterisation efficiency of different fractal dimensions, and emphasised the importance of realistic selectins of appropriate fractal dimensions. Therefore, to effectively determine the fractal characteristics of the pore structure of hybrid basalt–polypropylene fibre-reinforced concrete (HBPRC), we need to compare the applicability of each fractal model to determine a reasonable and effective fractal calculation model for the pore structure of HBPRC.

At present, few research results on the pore-structure characteristics of HBPRC are available, and the research conclusions are not consistent [47,48]. Therefore, the pore-structure characteristics of HBPRC with different matrix strengths were first tested using the MIP method in the present study, and the applicability of the representative fractal models in determining the fractal characteristics of the pore structure of HBPRC was compared.

2 Materials and experiments

2.1 Raw materials and mixture proportions

Binder used included P·O 42.5R Portland cement (C), silica fume (SF), fine-grade fly ash (FA), and ground-granulated blast furnace slag (GGBS); their properties are listed in Tables 1 and 2. Coarse aggregates (CAs) with a particle size of 5–20 mm and finer aggregates (S) with a fineness modulus of 2.8 were used. The physical and mechanical properties of BF and PF are listed in Table 3. A polycarboxylic-based superplasticiser (PBS) with a 30% water-reducing rate was used, and potable tap water (W) was used for mixing.

Physical–mechanical properties of cement

| Water content for standard consistency (%) | Specific surface area/(m2·kg−1) | Soundness | Ignition loss (%) | Setting time (h) | Compressive strength (MPa) | Flexural strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 days | 28 days | 3 days | 28 days | ||||

| 25.8 | 334 | Satisfied | 2.79 | 2.3 | 3.4 | 28.8 | 48.6 | 6.4 | 8.6 |

Physical properties of admixtures

| Type | Water content (%) | Ignition loss (%) | Density/(g·cm−3) | Specific surface area (m2·kg−1) | 28-days active index (%) |

|---|---|---|---|---|---|

| SF | 0.06 | 5.48 | 2.1 | 23,000 | 131 |

| FA | 0.2 | 2.85 | 2.35 | 340 | 97 |

| GGBS | 0.7 | 0.3 | 2.86 | 410 | 1.4 |

Physical and mechanical properties of BF and PF

| Type | Length (mm) | Diameter (μm) | Density (g·cm−3) | Tensile strength (MPa) | Elastic modulus (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| BF | 18 | 15 | 2.56 | 4,500 | 75,000 | 3.15 |

| PF | 19 | 30 | 0.91 | 270 | 3,000 | 40 |

2.2 Preparation of specimens

The concrete matrix strengths were designed as C30 and C40, and the proportions of each concrete mixture are listed in Table 4. Letters L and H represent the low- and high-strength matrices, respectively; NC denotes the reference concrete; BC, PC, and BPC denote the concrete that was reinforced by BF, PF, and hybrid BF–PF, respectively; the fibre amounts by volume of concrete were 0.1 and 0.2, and the amounts of BF and PF were equal for the hybrid fibre.

Mix proportions of HBPRC (kg·m−3)

| Mixture | C | SF | FA | GGBS | PBS | W | SA | CAs | BF | PF |

|---|---|---|---|---|---|---|---|---|---|---|

| LNC | 234.2 | 22.0 | 73.2 | 36.6 | 3.66 | 161.0 | 683.0 | 1162.9 | 0.0 | 0.0 |

| LBC-0.1 | 2.6 | 0.0 | ||||||||

| LPC-0.1 | 0.0 | 0.9 | ||||||||

| LBPC-0.1 | 1.3 | 0.5 | ||||||||

| LBPC-0.2 | 2.6 | 0.9 | ||||||||

| HNC | 241.6 | 15.8 | 79.2 | 59.4 | 3.96 | 150.5 | 683.4 | 1163.6 | 0.0 | 0.0 |

| HBC-0.1 | 2.6 | 0.0 | ||||||||

| HPC-0.1 | 0.0 | 0.9 | ||||||||

| HBPC-0.1 | 1.3 | 0.5 | ||||||||

| HBPC-0.2 | 2.6 | 0.9 |

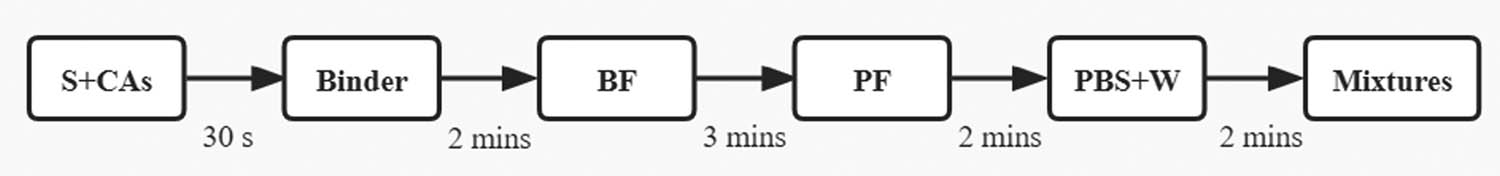

The specific mixing process of HBPRC is illustrated in Figure 1. After mixing evenly, the concrete pastes were poured into 100 mm cubic moulds and compacted on a vibration table. The specimens were then placed in an indoor environment and sealed with a plastic film to prevent water evaporation. After 24 h, the specimens were demoulded and cured in a standard curing room at a temperature of 20 ± 2°C and a relative humidity greater than 95% for 28 days.

Mixing process of concrete mixtures.

2.3 MIP

Before the MIP test, the specimens were crushed. In order to maximise the characterisation of the pore-structure characteristics of HBPRC, core mortar particles (including fibre) with a size of 3–5 mm, which include not only the pore characteristics of the concrete matrix, but also the pore characteristics of the fibre-concrete matrix interface transition zone, as well as the pore characteristics of the fibre- and aggregate-concrete matrix interface transition zone, were selected and immersed in anhydrous ethanol to prevent further hydration. Subsequently, the samples were dried in an oven with 55°C to a constant weight after the ethanol was completely volatilised.

According to the measurement principle of MIP, the external pressure and the pore radius of the measured object satisfied the Washburn equation [49,50] as:

where P i is the external pressure at step i, r i is the pore radius measured at step i, θ is the solid–liquid contact angle (θ = 130°), and γ is the surface tension of the mercury (0.458 N·m−1).

3 Fractal models of pore structure

3.1 Pore-surface fractal models

3.1.1 Friesen and Mikula model

According to the construction principle of the Menger sponge model, Friesen and Mikula [37] established a calculation model of the pore-surface fractal dimension in combination with the relationship between the exerted pressure and measured pore diameter in the MIP method

where P is the exerted pressure; V P is the intrusive mercury volume corresponding to exerted pressure P, which is the measured pore volume; and D F is the pore-surface fractal dimension of the Friesen and Mikula model.

3.1.2 Neimark model

Neimark [38] established the relationship between the pore-surface area and pore diameter using the thermodynamic method, namely,

where S(ε) is the surface area that is measured using a gauge (or a yardstick) with size ε.

When the pore-structure characteristics of porous materials are measured using the MIP method, the exerted pressure and pore radius of the measured object satisfy the Washburn equation.

By combining equations (1) and (3), the following formula can be obtained:

where S is the cumulative pore-surface area and D N is the pore-surface fractal dimension of the Neimark model.

3.1.3 Zhang and Li model

Zhang and Li [34,39] suggested that the work done by the exerted pressure on liquid mercury during the MIP test is equal to the surface-energy increment of the intruding mercury, namely,

where ΔV i is the pore volume measured at the ith step of mercury injection.

The fractal geometric relationship between the pore volume and pore-surface area of the fractals is expressed as follows:

where V is the cumulative pore volume.

By substituting equations (1) and (6) into equation (5), a calculation formula for the pore-surface fractal dimension is obtained as follows:

where r n and V n are the pore radius and cumulative pore volume measured at the nth step of mercury injection, respectively; C is a constant; and D Z is the pore-surface fractal dimension of the model established by Zhang and Li.

3.2 Pore-volume fractal models

3.2.1 Pfeifer and Avnir model

According to the relationship between the pore volume and pore diameter of the fractals, a calculation model for the pore-volume fractal dimension was established by Pfeifer and Avnir [41] as follows:

where D P is the pore-volume fractal dimension of the Pfeifer and Avnir model and r is the pore radius.

3.2.2 Ji et al. model

Ji et al. [40] suggested that the pore-filling process due to the hydration of materials in cement-based materials can be regarded as a pore-formation process of the Menger sponge model. A reverse cumulative pore volume was introduced to characterise the cumulative pore volume from small to large pores. In this manner, a logarithmic relationship between the reverse cumulative pore volume and pore diameter was established as follows:

where D J is the pore-volume fractal dimension of the model established by Ji et al. and V * is the reverse cumulative pore volume.

3.3 Solid-volume fractal model

Usteri et al. [41] proposed the concept of a solid particle fractal for the first time and defined solid-volume fraction χ as the ratio of the solid volume to the total volume, that is,

where L is the side length of the researched object.

Therefore, χ and pore radius r satisfy the following:

where D U is the solid-volume fractal dimension of the model established by Usteri et al.

4 Results and discussion

4.1 Pore-structure characteristics of HBPRC

The pore-size and cumulative pore-volume distribution curves of HBPRC are shown in Figures 2 and 3. When the matrix strength is the same, the addition of fibres increases the cumulative pore volume of concrete. In comparison with the single BF and PF, the effect of the hybrid BF and PF on the cumulative pore volume of concrete is more significant, and the higher the hybrid content, the larger the cumulative pore volume of HBPRC.

Cumulative pore volume and pore-size distribution of HBPRC with matrix strength of C30. (a) LNC, (b) LBC-0.1, (c) LPC-0.1, (d) LBPC-0.1, and (e) LBPC-0.2.

Cumulative pore volume and pore-size distribution of HBPRC with matrix strength of C40. (a) HNC, (b) HBC-0.1, (c) HPC-0.1, (d) HBPC-0.1, and (e) HBPC-0.2.

On the basis of the pore-size distribution characteristics of HBPRC, the pore size is accordingly divided with 50 nm as the critical pore diameter. According to refs [50–52], pores with diameters of less than 50 nm, including gel pores (<10 nm) and small capillary pores (10–50 nm), are collectively referred to as harmless and less harmful pores; pores with diameters that are larger than 50 nm, including large capillary pores (50–104 nm) and large pores (>104 nm), are collectively referred to as harmful pores. The volume fraction of each pore is shown in Figure 4. In general, the proportion of medium and small capillary pore of concrete with matrix strength of C30 is higher than that of concrete with matrix strength of C40, while the proportion of gel pore is relatively low. This result can be attributed to the fact that a greater number of hydration products are produced from the hydration of cementitious materials in concrete with matrix strength of C40, resulting in a greater number of gel pores. In addition, the filling effect of hydration products on the capillaries further reduces the content of medium and small capillary pores and increases the content of gel pores. As for concrete with the same matrix strength, the addition of BF and PF reduces the proportion of harmless pores in HBPRC but increases the proportion of harmful pores, particularly the large pores. For the same fibre content, the effect of single BF on the proportion of large pores is greater than that of single PF. Compared with a single fibre, the effect of hybrid BF and PF on the proportion of harmful pores is more significant, and the higher the content of hybrid BF and PF, the larger the proportion of the harmful pores.

Pore volume fraction of HBPRC. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

4.2 Applicability of fractal model

The test results of the HBPRC pore structure are introduced into each fractal model, and the double logarithm diagrams are drawn, as shown in Figures 5–10. The pore-surface area, pore volume, and solid volume of HBPRC show obvious fractal characteristics. The pore fractal dimension of HBPRC, which is calculated based on all fractal models, is shown in Figure 11. Fractal dimension represents the complexity of a fractal. The pore-surface fractal dimension represents the roughness of pore-surface area, and the pore-volume fractal dimension represents the uniformity of pore volume fraction, while the solid-volume fractal dimension represents the complexity of the accumulation mode of solid particles.

Calculated results of pore-surface fractal dimension of Friesen and Mikula model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Calculated results of pore-surface fractal dimension of the Neimark model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Calculated results of pore-surface fractal dimension of Zhang and Li model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Calculated results of pore-volume fractal dimension of the Pfeifer and Avnir model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Calculated results of pore-volume fractal dimension of the Ji et al. model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Calculated results of solid-volume fractal dimension of the Usteri et al. model. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

Pore-structure fractal dimension of HBPRC. (a) HBPRC with matrix strength of C30 and (b) HBPRC with matrix strength of C40.

4.2.1 Pore-surface fractal models

Figures 5–7 show the calculation results of pore-surface fractal dimension. Generally, the pore-surface area of HBPRC has fractal characteristics in the entire pore measurement range. With regard to the Friesen and Mikula model, the linear correlation of log(−dV/dP i ) against log(P i ) is relatively poor, particularly in the harmless or less-harmful pore range, and the dispersion of the logarithmic curve is more evident and reduces the accuracy of the calculation results of D F to a certain extent. In addition, as shown in Figure 11, the calculation results of D F are greater than 3. According to the fractal geometry, the pore fractal dimension of concrete is a non-integer between 2 and 3; beyond this range, the pore fractal dimension has no physical significance [32,45,53]. Therefore, the Friesen and Mikula model is considered unsuitable for characterising the pore-surface fractal characteristics of HBPC.

As shown in Figures 6 and 7, the linear correlations of the logarithmic curve of the Neimark model, and the Zhang and Li model are both higher. Compared with the Friesen and Mikula model, the calculation results of both the Neimark model and the Zhang and Li model are more accurate. Figure 11 illustrates the calculation results of D N and D Z. Although both the Neimark model and the Zhang and Li model are based on the thermodynamic relationship of MIP, the calculation results of D N and D Z are quite different. D N is greater than 3, whereas D Z is in the range of 2.892–2.929. The main reason is that the Neimark model is based on a cylindrical pore hypothesis, and the pore-surface area is calculated by establishing the geometrical relationship between the volume and surface area of a cylinder, which is quite different from that of actual concrete. In contrast, the Zhang and Li model has no assumption on the pore geometry, and the pore-surface area is calculated by establishing the energy conservation relationship during mercury intrusion [52]. Therefore, the Zhang and Li model is more suitable for characterising the pore-surface fractal characteristics of HBPRC.

4.2.2 Pore-volume fractal models

Figures 8 and 9 show the calculation results of pore-volume fractal dimension. By comparison, it was found that the applicable pore ranges of the Pfeifer and Avnir model and the Ji et al. model are quite different. The Pfeifer and Avnir model is suitable for the entire pore range of HBPRC, and log(−dV/dr) against log(r) has a linear relationship. However, as shown in Figure 11, the calculation results of D P are greater than 3 and have no physical significance. Thus, the Pfeifer and Avnir model is not considered to be applicable for characterising the pore-volume fractal characteristics of HBPRC. For the Ji et al. model, the entire pore range of HBPRC can be divided into two parts: a small pore range without pore-volume fractal characteristics and a large pore range (usually with a pore radius larger than 50 nm and named as fractal region) with obvious pore-volume fractal characteristics. The Ji et al. model is only applicable to the fractal region of HBPRC. The calculation results of D J are shown in Figure 11. It can be seen that the D J satisfies the definition range of pore fractal dimension; however, the D J only includes the pore-structure characteristics in the fractal region. According to the analysis in the previous section, pores with a radius less than 50 nm occupy a large proportion of HBPRC. Accordingly, it is difficult to characterise the pore-structure characteristics of the entire pore range of HBPRC by using only the D J in the fractal region. In addition, the variation of D J is insignificant with the corporation of fibre. For an HBPRC with a high matrix strength, the variation of D J is less than 0.003. Therefore, the Ji et al. model is not applicable for characterising the pore-volume fractal characteristics of HBPRC.

4.2.3 Solid-volume fractal model

The calculation results of D U for the Usteri et al. model are shown in Figures 10 and 11. Figure 10 shows that the solid volume of HBPRC has obvious fractal characteristics, and the solid-volume fractal characteristics are scale-dependent on pore radius. According to the differences of solid-volume fractal characteristics, the entire pore measurement range can be divided into fractal region 1 and fractal region 2. The values of D U in each fractal region are shown in Figure 11. It can be seen that D U in each fractal region satisfies the definition of fractal dimension; however, the variation of D U is also insensitive. Taking HBPRC with a high matrix strength as an example, with the addition of fibres, the variation of D U in fractal region 1 is less than 0.001 and in fractal region 2 less than 0.003. Therefore, the Usteri et al. model cannot clearly reflect the effect of fibres on the pore-structure fractal characteristics of HBPRC.

4.3 Effects of BF and PF on the pore-structure fractal characteristics of HBPRC

From the comparison of the applicability of each fractal model in characterising the fractal characteristics of the HBPRC pore structure, we can observe that the pore-surface fractal model established by Zhang and Li demonstrates better applicability. The pore-surface fractal dimension of HBPRC calculated according to the model established by Zhang and Li is shown in Figure 11. The addition of BF and PF reduces the pore-surface fractal dimension of concrete, and the effect of BF on the pore-surface fractal dimension of concrete is greater than that of PF. For the same content, the effect of hybrid BF and PF on the pore-surface fractal dimension of concrete is greater than that of a single fibre. When the fibre content increases to 0.2, the effect of the hybrid BF and PF on the pore-surface fractal dimension of concrete is more significant. Additionally, as shown in Figure 11, the pore-surface fractal dimension of HBPRC with matrix strength of C30 is smaller than that of HBPRC with matrix strength of C40, and the effect of fibre addition on the pore-surface fractal dimension is more significant.

The pore-surface fractal dimension is a parameter that characterises the complexity of a pore surface. The more complex and irregular the pore surface, the larger the pore-surface fractal dimension. For the same or approximate total pore volume, a larger number of small pores and a smaller number of large pores result in a more complex pore surface and larger pore-surface fractal dimension. According to the cumulative pore-volume curve of HBPRC, for the same matrix strength, the addition of BF and PF has a negligible effect on the total pore volume. However, it significantly affects the proportion of all types of pores, as shown in Figure 4. The addition of BF and PF reduces the proportion of harmless pores and increases the proportion of harmful pores, thus reducing the pore-surface fractal dimension of HBPRC. In general, the reduced amplitude in the pore-surface fractal dimension caused by BF is larger than that by PF, and the reduced amplitude of the pore-surface fractal dimension caused by the hybrid BF and PF is larger than that by a single fibre. The reduced amplitude of the pore-surface fractal dimension of HBPRC with hybrid fibre content of 0.2 is more significant than that of the HBPRC with hybrid fibre content of 0.1.

As shown in Figures 4 and 11, both the proportion of harmful pores and the pore-surface fractal dimension of HBPRC with matrix strength of C40 are smaller than that of the HBPRC with matrix strength of C30, which is consistent with the research results on the fractal characteristics of pore-surface area of high-volume fly-ash cement paste by Zeng et al. that the higher the matrix strength, the smaller the pore-surface fractal dimension [54]. Compared to HBPRC with matrix strength of C30, the cumulative pore volume of HBPRC with matrix strength of C40 is smaller, the effect of BF and PF on the proportion of harmful pores is more significant, and the change in the pore-surface fractal dimension is more obvious. In conclusion, the pore-surface fractal dimension in the model established by Zhang and Li effectively reflects the influence of the type and content of fibres on the pore structure of concrete.

5 Conclusions

Fractal theory is an important tool for studying the pore structure of cement-based materials. In the characterization of pore structure, Fractal dimension can quantitatively describe the distribution of pore structure, which is irreplaceable by other pore structure parameters. In this study, the addition of fibres changes the accumulation mode of solid phase in HBPRC, which may make the pore fractal characteristics of HBPRC different from that of the ordinary concrete, and the applicability of fractal model may change accordingly. In this study, the pore-structure characteristics of HBPRC were investigated using the MIP method, and the applicability of different pore-structure fractal models in defining the fractal characteristics of the HBPRC pore structure was compared. The main conclusions are enumerated as follows.

For the same fibre content, the effect of single BF on the pore volume of concrete is greater than that of single PF. The effect of hybrid BF and PF on the pore volume of concrete is greater than that of a single fibre.

The calculation results of D F, D N, and D P are greater than 3 and have no physical significance. The calculation result of D J only contains the pore-structure characteristics of the large capillary pores and large pores, and does not fully characterise the pore-volume fractal characteristics of HBPRC in the entire pore range. The calculation result of D U is extremely insensitive to the concrete matrix strength, amount of fibre, and fibre addition method.

In comparison with the other fractal models, the pore-surface fractal model established by Zhang and Li is more suitable for defining the pore-structure fractal characteristics of HBPRC. The addition of BF and PF reduces D Z of HBPRC. The effect of BF on D Z is greater than that of PF, whereas the effect of hybrid BF and PF on D Z is greater than that of a single fibre. The higher the content of hybrid BF and PF, the smaller the value of D Z.

-

Funding information: This study was supported by the National Natural Science Foundation of China (Grant No. 51590914, 51608432), the Natural Science Foundation of Shaanxi Province (Grant No. 2019JQ-481), Key Research and Development Program of Shaanxi Province (Grant No. 2022SF-375), Research Project of China Railway 20th Bureau Group Co. Ltd. (Grant No. YF2200LJ12B), China Postdoctoral Science Foundation (No. 2022M723683), and Shaanxi Key Laboratory of Safety and Durability of Concrete Structures Open Fund project (No. SZ02307).

-

Author contributions: Dan Li: conceptualization, methodology, software; Bo Liu: data curation, writing – original draft preparation; Lu He and Tianrui Mai: visualization, investigation; Qiang Fu: supervision, writing – reviewing and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Teng, S., V. Afroughsabet, and C. P. Ostertag. Flexural behavior and durability properties of high performance hybrid-fiber-reinforced concrete. Construction and Building Materials, Vol. 182, 2018, pp. 504–515.10.1016/j.conbuildmat.2018.06.158Search in Google Scholar

[2] Pakravan, H. R., M. Latifi, and M. Jamshidi. Hybrid short fiber reinforcement system in concrete: A review. Construction and Building Materials, Vol. 142, 2017, pp. 280–294.10.1016/j.conbuildmat.2017.03.059Search in Google Scholar

[3] Guo, L., J. Deng, R. Li, T. Li, and Z. Dong. Shear strengthening of RC short columns with CFRP grid-reinforced FRC matrix: Cyclic loading tests. Journal of Building Engineering, Vol. 47, 2022, p. 103915.10.1016/j.jobe.2021.103915Search in Google Scholar

[4] Guo, X. L. and X. J. Pan. Mechanical properties and mechanisms of fiber reinforced fly ash-steel slag based geopolymer mortar. Construction and Building Materials, Vol. 179, 2018, pp. 633–641.10.1016/j.conbuildmat.2018.05.198Search in Google Scholar

[5] Jin, L., R. B. Zhang, Y. D. Tian, G. Q. Dou, and X. L. Du. Experimental investigation on static and dynamic mechanical properties of steel fiber reinforced ultra-high-strength concretes. Construction and Building Materials, Vol. 178, 2018, pp. 102–111.10.1016/j.conbuildmat.2018.05.152Search in Google Scholar

[6] Yang, Y. and Y. Deng. Mechanical properties of hybrid short fibers reinforced oil well cement by polyester fiber and calcium carbonate whisker. Construction and Building Materials, Vol. 182, 2018, pp. 258–272.10.1016/j.conbuildmat.2018.06.110Search in Google Scholar

[7] Fiore, V., T. Scalici, G. Di Bella, and A. Valenza. A review on basalt fibre and its composites. Composition Part B, Vol. 74, 2015, pp. 74–94.10.1016/j.compositesb.2014.12.034Search in Google Scholar

[8] Chakravarthy, R., S. Venkatesan, and I. Patnaikuni. Mechanical properties of high volume fly ash concrete reinforced with hybrid fibers. Advances in Materials Science and Engineering, Vol. 2016, 2016, pp. 1638419–7.10.1155/2016/1638419Search in Google Scholar

[9] Hsie, M., C. Tu, and P. S. Song. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Materials Science and Engineering: A, Vol. 494, 2008, pp. 153–157.10.1016/j.msea.2008.05.037Search in Google Scholar

[10] Fu, Q., D. T. Niu, J. Zhang, D. G. Huang, Y. Wang, M. S. Hong, et al. Dynamic compressive mechanical behavior and modelling of basalt-polypropylene fibre-reinforced concrete. Archives of Civil and Mechanical Engineering, Vol. 18, 2018, pp. 914–927.10.1016/j.acme.2018.01.016Search in Google Scholar

[11] Fu, Q., D. T. Niu, D. Li, Y. Wang, J. Zhang, and D. G. Huang. Impact characterization and modelling of basalt-polypropylene fibre-reinforced concrete containing mineral admixtures. Cement and Concrete Composites, Vol. 93, 2018, pp. 246–259.10.1016/j.cemconcomp.2018.07.019Search in Google Scholar

[12] Fu, Q., D. T. Niu, J. Zhang, D. G. Huang, and M. S. Hong. Impact response of concrete reinforced with hybrid basalt-polypropylene fibers. Powder Technology, Vol. 326, 2018, pp. 411–424.10.1016/j.powtec.2017.12.022Search in Google Scholar

[13] Jiang, C. H., K. Fan, F. Wu, and D. Chen. Experimental study on the mechanical properties and microstructure of chopped basalt fiber reinforced concrete. Materials & Design, Vol. 58, 2014, pp. 187–193.10.1016/j.matdes.2014.01.056Search in Google Scholar

[14] Wu, H. J., J. Zhao, and Z. C. Wang. Study on micro-structure and durability of fiber concrete. Research Journal of Applied Sciences, Vol. 5, No. 2, 2013, pp. 659–664.10.19026/rjaset.5.5005Search in Google Scholar

[15] Chen, X. D., S. X. Wu, and J. K. Zhou. Influence of porosity on compressive and tensile strength of cement mortar. Construction and Building Materials, Vol. 40, 2013, pp. 869–874.10.1016/j.conbuildmat.2012.11.072Search in Google Scholar

[16] Zou, C., G. Long, Y. Xie, J. He, C. Ma, and X. Zeng. Evolution of multi-scale pore structure of concrete during steam-curing process. Microporous and Mesoporous Materials, Vol. 288, 2019, id. 109566.10.1016/j.micromeso.2019.109566Search in Google Scholar

[17] Gong, F. Y., D. W. Zhang, E. Sicat, and T. Ueda. Empirical estimation of pore size distribution in cement, mortar and concrete. Journal of Materials in Civil Engineering, Vol. 26, 2014, id. 04014023.10.1061/(ASCE)MT.1943-5533.0000945Search in Google Scholar

[18] Diamond, S. Aspects of concrete porosity revisited. Cement and Concrete Research, Vol. 29, 1999, pp. 1181–1188.10.1016/S0008-8846(99)00122-2Search in Google Scholar

[19] Pia, G., L. Casnedi, M. Ionta, and U. Sanna. On the elastic deformation properties of porous ceramic materials obtained by pore-forming agent method. Ceramics International, Vol. 41, 2015, pp. 11097–11105.10.1016/j.ceramint.2015.05.057Search in Google Scholar

[20] Jin, S. S., J. X. Zhang, and B. S. Huang. Fractal analysis of effect of air void on freeze-thaw resistance of concrete. Construction and Building Materials, Vol. 47, 2013, pp. 126–130.10.1016/j.conbuildmat.2013.04.040Search in Google Scholar

[21] Zhang, J. Z., F. Bian, Y. R. Zhang, Z. F. Fang, C. Q. Fu, and J. Guo. Effect of pore structures on gas permeability and chloride diffusivity of concrete. Construction and Building Materials, Vol. 163, 2018, pp. 402–413.10.1016/j.conbuildmat.2017.12.111Search in Google Scholar

[22] Kalliopi, K. A. Pore structure of cement-based materials: Testing, interpretation and requirements, Taylor & Francis, New York, 2006.Search in Google Scholar

[23] Ma, H. Y. Mercury intrusion porosimetry in concrete technology: Tips in measurement, pore structure parameter acquisition and application. Journal of Porous Materials, Vol. 21, 2014, pp. 207–215.Search in Google Scholar

[24] Mahamud, M., O. Lopez, J. J. Pis, and J. A. Pajares. Textural characterization of coals using fractal analysis. Fuel Processing Technology, Vol. 81, 2003, pp. 127–142.10.1016/S0378-3820(03)00004-3Search in Google Scholar

[25] Tuan, N. V., G. Ye, K. van Breugel, and O. Copuroglu. Hydration and microstructure of ultra high performance concrete incorporating rice husk ash. Cement and Concrete Research, Vol. 41, 2011, pp. 1104–1111.10.1016/j.cemconres.2011.06.009Search in Google Scholar

[26] Ozturk, A. U. and B. Baradan. A comparison study of porosity and compressive strength mathematical models with image analysis. Computational Materials Science, Vol. 43, 2008, pp. 974–979.10.1016/j.commatsci.2008.02.011Search in Google Scholar

[27] Olson, R. A., C. M. Neubauer, and H. M. Jennings. Damage to the pore structure of hardened portland cement paste by mercury intrusion. Journal of the American Ceramic Society, Vol. 80, No. 9, 1997, pp. 2454–2458.10.1111/j.1151-2916.1997.tb03144.xSearch in Google Scholar

[28] Chen, X. D. and S. X. Wu. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Construction and Building Materials, Vol. 38, 2013, pp. 804–812.10.1016/j.conbuildmat.2012.09.058Search in Google Scholar

[29] Gao, Y., J. Y. Jiang, G. D. Schutter, G. Ye, and W. Sun. Fractal and multifractal analysis on pore structure in cement paste. Construction and Building Materials, Vol. 69, 2014, pp. 253–261.10.1016/j.conbuildmat.2014.07.065Search in Google Scholar

[30] Chen, X. D., J. K. Zhou, and N. Ding. Fractal characterization of pore system evolution in cementitious materials. KSCE Journal of Civil Engineering, Vol. 19, 2015, pp. 719–724.10.1007/s12205-013-0320-2Search in Google Scholar

[31] Winslow, D. N. The fractal nature of the surface of cement paste. Cement and Concrete Research, Vol. 15, 1985, pp. 817–824.10.1016/0008-8846(85)90148-6Search in Google Scholar

[32] Kim, J. Y., C. C. Yong, and S. C. Choi. Fractal characteristic of pore structures in GGBFS-based cement pastes. Applied Surface Science, Vol. 428, 2018, pp. 304–314.10.1016/j.apsusc.2017.09.165Search in Google Scholar

[33] Lange, D. A., H. M. Jennings, and S. P. Shah. Image analysis techniques for characterization of pore structure of cement-based materials. Cement and Concrete Research, Vol. 24, 1994, pp. 841–853.10.1016/0008-8846(94)90004-3Search in Google Scholar

[34] Zhang, B. Q. and S. F. Li. Determination of the surface fractal dimension for porous media by mercury porosimetry. Industrial & Engineering Chemistry Research, Vol. 34, 1995, pp. 1383–1386.10.1021/ie00043a044Search in Google Scholar

[35] Mahamud, M., O. Lopez, J. J. Pis, and J. A. Pajares. Textural characterization of chars using fractal analysis. Fuel Processing Technology, Vol. 86, 2004, pp. 135–149.10.1016/j.fuproc.2004.01.001Search in Google Scholar

[36] Gao, Y., J. Y. Jiang, and K. Wu. Fractal modeling of pore structure and ionic diffusivity for cement paste. Advances in Materials Science and Engineering, Vol. 42, No. 8, 2016, pp. 9583–9590.10.1155/2016/7645954Search in Google Scholar

[37] Friesen, W. I. and R. J. Mikula. Fractal dimensions of coal particles. Journal of Colloid and Interface Science, Vol. 120, No. 1, 1987, pp. 263–271.10.1016/0021-9797(87)90348-1Search in Google Scholar

[38] Neimark, A. A new approach to the determination of the surface fractal dimension of porous solids. Physica A, Vol. 191, 1992, pp. 258–262.10.1016/0378-4371(92)90536-YSearch in Google Scholar

[39] Zhang, B. Q., W. Liu, and X. F. Liu. Scale-dependent nature of the surface fractal dimension for bi- and multi-disperse porous solids by mercury porosimetry. Applied Surface Science, Vol. 253, 2006, pp. 1349–1355.10.1016/j.apsusc.2006.02.009Search in Google Scholar

[40] Ji, X., S. Y. N. Chan, and N. Feng. Fractal model for simulating the space-filling process of cement hydrates and fractal dimensions of pore structure of cement-based materials. Cement and Concrete Research, Vol. 2711, 1997, pp. 1691–1699.10.1016/S0008-8846(97)00157-9Search in Google Scholar

[41] Pfeifer, P. and D. Avnir. Chemistry in noninteger dimensions between two and three. I: Fractal theory of heterogeneous surfaces. Journal of Chemical Physics, Vol. 79, 1983, pp. 3558–3565.10.1063/1.446210Search in Google Scholar

[42] Usteri, M., J. D. Bonny, and H. Leuenberger. Fractal dimension of porous solid dosage forms. Pharmaceutica Acta Helvetiae, Vol. 65, No. 1, 1990, pp. 55–61.Search in Google Scholar

[43] Zeng, S., N. Zhang, and S. W. Zhang. Fractal characteristics of uranium‐bearing sandstone structure and their effects on acid leaching. Energy Science & Engineering, Vol. 7, 2019, pp. 1862–1866.10.1002/ese3.396Search in Google Scholar

[44] Zeng, S., Y. Shen, and B. Sun. Fractal kinetic characteristics of uranium leaching from low permeability uranium-bearing sandstone. Nuclear Engineering and Technology, Vol. 54, 2022, pp. 1175–1184.10.1016/j.net.2021.10.013Search in Google Scholar

[45] Bernal, J. L. P. and M. A. Bello. Fractal geometry and mercury porosimetry comparison and application of proposed models on building stones. Applied Surface Science, Vol. 185, 2001, pp. 99–107.10.1016/S0169-4332(01)00649-3Search in Google Scholar

[46] Wood, D. A. Techniques used to calculate shale fractal dimensions involve uncertainties and imprecisions that require more careful consideration. Advances in Geo-Energy Research, Vol. 5, No. 2, 2021, pp. 153–165.10.46690/ager.2021.02.05Search in Google Scholar

[47] Huang, D. G., D. T. Niu, Q. Fu, and D. M. Luo. Pore structure analysis of concrete with hybrid basalt-polypropylene fiber. Concrete, Vol. 7, 2018, pp. 51–53 (in Chinese).Search in Google Scholar

[48] Luo, B. B., and Q. W. Bi. Experimental study on the influence of pore structure of hybrid fibers self-compacting concrete on compressive strength. Bulletin of the Chinese Ceramic Society, Vol. 31, 2012, pp. 626–630 (in Chinese).Search in Google Scholar

[49] Ma, H. Y. Mercury intrusion porosimetry in concrete technology: Tips in measurement, pore structure parameter acquisition and application. Journal of Porous Materials, Vol. 21, 2014, pp. 207–215.10.1007/s10934-013-9765-4Search in Google Scholar

[50] Canut, M. M. C. Pore structure in blended cement pastes, PhD thesis, Technical University of Denmark, Department of Civil Engineering, Denmark, 2012, p. 346.Search in Google Scholar

[51] Mehta, P. K. and P. J. M. Monteiro. Concrete: Microstructure, properties, and materials, McGraw-Hill Publishing, New York, 2006.Search in Google Scholar

[52] Mindness, S., J. F. Young, and D. Darwin. Concrete, Prentice Hall, Pearson Education, Inc., Upper Saddle River, NJ, USA, 2003.Search in Google Scholar

[53] Avnir, D., D. Farin, and P. Pfeifer. Chemistry in noninteger dimensions between two and three Ⅱ: Fractal surfaces of absorbents. Journal of Chemical Physics, Vol. 79, No. 7, 1983, pp. 3566–3571.10.1063/1.446211Search in Google Scholar

[54] Zeng, Q., K. Li, T. Fen-Chong, and P. Dangla. Surface fractal analysis of pore structure of high-volume fly-ash cement pastes. Applied Surface Science, 25, 2010, pp. 762–768.10.1016/j.apsusc.2010.07.061Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.