Abstract

Recycled steel fiber comes from the waste produced by machining. Adding recycled steel fiber into concrete can significantly enhance the toughness of concrete. In order to study the impact toughness of recycled steel fiber-reinforced concrete, the drop weight repeated impact experiment method was used to study the performance of recycled steel fiber-reinforced concrete under repeated impact load. Four kinds of recycled steel fiber-reinforced concrete samples with different volume contents were designed and made, and the loading impact experiments under five working conditions were carried out. Taking the drop weight and drop height as changing parameters, the corresponding blow counts of the first crack and sample failure under the impact of the drop hammer are recorded, and the ductility coefficients of different samples are calculated. The results show that the impact resistance of the sample decreases significantly with the increase of the drop weight and drop height. With the increase of recycled steel fiber content, the impact toughness of the sample increases obviously. The impact toughness of recycled steel fiber-reinforced concrete under standard loading conditions is the best.

1 Introduction

Brittle materials such as concrete will crack and destroy rapidly after being subjected to impact force, resulting in the loss of the bearing capacity of the structure [1,2,3]. In order to enhance the absorptive capacity of concrete structures for impact, adding fiber to concrete can improve the brittleness of concrete, enhance its toughness and its ability to absorb impact energy [4,5,6]. In addition, the research of Sheta et al. [7,8,9,10] showed that the composite structure formed by the combination of fiber concrete and light steel structure can significantly improve the torsional performance of light steel structure, especially the combination of ECC material and cold-formed steel, making the mechanical properties of the composite structure significantly improved. Steel fiber-reinforced concrete is the most widely used civil engineering composite material in all kinds of fiber-reinforced concrete. It has good crack resistance and excellent impact resistance. It is widely used in roads and bridges, airport runways, marine engineering, and military facilities [11,12,13].

Adding recycled steel fiber into concrete can obtain an effect similar to that of industrial steel fiber and can also achieve the purpose of solid waste utilization [14]. Scholars at home and abroad have conducted extensive research on the basic mechanical properties of recycled fiber. Silica fume is added into steel fiber-reinforced concrete, and its basic mechanical properties are tested, the research shows that recycled steel fiber concrete and copper-plated steel fiber concrete have very close physical and mechanical properties [15]. The basic mechanics of recycled steel fiber-reinforced rubber concrete short columns is experimentally studied [16]. The results show that the section stress and deformation of recycled steel fiber rubber recycled concrete short columns are similar to that of ordinary concrete.

Kang et al. [17] studied the seismic performance of recycled steel fiber rubber recycled concrete frame joints under low-cycle repeated loading. The results show that the recycled steel fiber rubber recycled concrete frame joints have good ductility and good ability to absorb and dissipate seismic energy in case of joint failure.

Sengul and Eisa [18,19] used the steel fiber recovered from the waste tire to prepare the grouting permeable fiber concrete. Through the experiment, the full load-deformation curve of the axial compression of the specimen is obtained. The results show that the waste steel fiber recovered from the tire has similar mechanical properties to ordinary steel fiber concrete. The study also shows that the flexural strength and toughness of the specimen are improved with the increase in fiber content. Liew and Akbar [20] believe that the use of recycled steel fiber can effectively reduce various wastes generated in the production process of ordinary commercial steel fiber, so as to protect the environment and achieve the goal of sustainable development.

Caggiano et al. [21] studied the mechanical response of recycled steel fiber and industrial steel fiber hybrid fiber concrete. The results show that as long as the recycled fiber has sufficient geometric properties, the industrial fiber can be completely replaced by the same amount of recycled fiber without significantly reducing the corresponding mechanical properties of recycled fiber concrete. Najim et al. [22] studied the flexural capacity of recycled steel fiber-reinforced concrete beams, Chaboki et al. [23] studied the shear capacity of recycled steel fiber-reinforced concrete beams, and Nitesh et al. [24] studied the torsional capacity of recycled steel fiber-reinforced concrete beams. The results show that recycled steel fiber can effectively enhance the bearing capacity of structural members.

The results show that there is little difference between the flexural, shear, and torsional bearing capacity of recycled steel fiber-reinforced concrete beams and that of ordinary steel fiber-reinforced concrete beams. It is feasible to use recycled steel fiber-reinforced concrete in engineering practice. In addition, the impact test of the original steel fiber-reinforced concrete found that its failure under impact showed an obvious ductile state, and the sample did not show obvious separation after failure, and the crack trend was generally in a broken line state and a large number.

Based on the earlier research, it is found that the current research on waste steel fiber-reinforced concrete mainly focuses on the basic mechanical properties of materials and the bearing capacity of basic components under static action, while there is less research on the performance of waste steel fiber-reinforced concrete under impact action. In order to study the toughness of waste steel fiber-reinforced concrete under impact, the spiral waste steel fiber produced by machining is used as raw material to form recycled steel fiber after sorting. The repeated drop weight impact experiments of three weight specifications and three different drop heights were used to study the repeated impact experiments of four kinds of recycled steel fiber specimens [25–27]. The number of blows during the initial crack development and failure of the specimen is analyzed, the relationship between the crack development and the drop weight, drop height, and recycled steel fiber content is determined, and the toughness of recycled steel fiber concrete under impact is explored.

2 Materials and methods

2.1 Materials

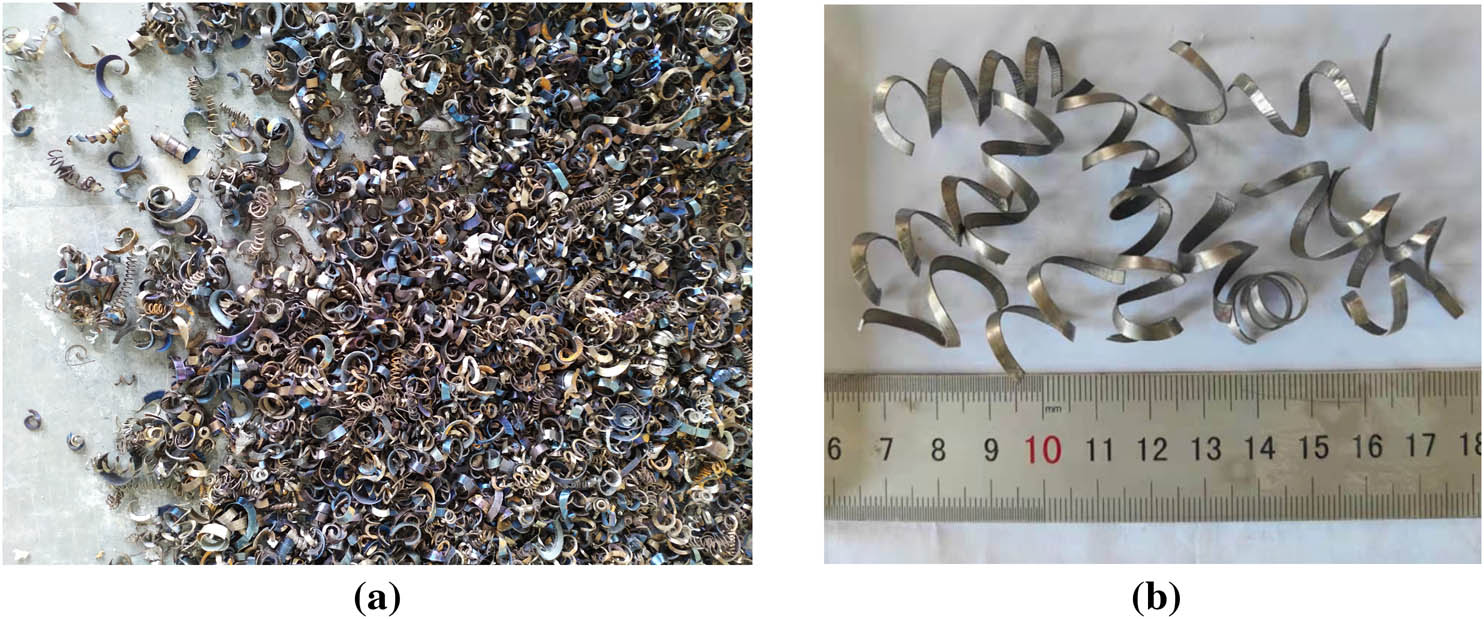

Figure 1 shows the recycled steel fiber used in the experiment, which comes from the waste after machining and has a curly spiral shape. The length range is about 20–40 mm, and the average thickness is 0.5 mm. The average tensile strength is 381.1 MPa, and the elastic modulus is 2.05 × 105 MPa.

Waste steel fiber: (a) raw materials and (b) sorted materials.

The cement adopts P.O 42.5 ordinary Portland cement, the stone adopts crushed stone with a particle size of 10–20 mm, the sand is machine-made sand with fineness modulus of 40–50, and the water reducing agent is polycarboxylic acid high-performance water reducing agent. In order to achieve the required specimen strength, fine silica fume is added to the mixture. The mix proportion of recycled steel fiber concrete is determined by the combination of empirical method and trial mix. Table 1 shows the mix proportion of recycled steel fiber concrete for repeated drop weight impact experiment specimens.

Mix proportion of recycled steel fiber reinforced concrete

| No | Material consumption per unit volume (kg·m−3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | Sand | Aggregate | Fly ash | Silica fume | Water | Superplasticizer | RSF | |

| RSFC0 | 391.8 | 1063.2 | 573.9 | 68 | 33 | 181.4 | 9.4 | 0 |

| RSFC0.5 | 412.1 | 1063.2 | 502.8 | 68 | 33 | 189.7 | 13.1 | 38.9 |

| RSFC0.75 | 412.1 | 1063.2 | 502.8 | 68 | 33 | 187.7 | 13.1 | 58.4 |

| RSFC1.0 | 417.3 | 1051.7 | 468.1 | 68 | 33 | 204.1 | 14.2 | 78.1 |

Note: RSFC0 refers to the concrete with zero volume content of recycled steel fiber, RSFC0.5 refers to concrete with recycled steel fiber volume content of 0.5%, RSFC0.75 refers to concrete with recycled steel fiber volume content of 0.75%, and RSFC1.0 refers to the concrete with the volume content of recycled steel fiber of 1.0%.

The size of the cylinder specimen for repeated drop hammer impact experiment is φ 150 × 65 mm. The cube compressive strength experiment piece size is 150 × 150 × 150 mm, and ultrasonic pulse velocity (UPV) tester is used for ultrasonic pulse nondestructive testing. The splitting tensile strength test cube size is 150 × 150 × 150 mm.

2.2 Method

The weight, falling height, and falling speed of the test hammer are determined according to the provisions of the document “Measurement of Properties of Fiber Reinforced Content” (ACI544-2R). The corresponding relationship between hammer weight and falling height of repeated drop hammer impact experiment of waste steel fiber-reinforced concrete is as follows: the drop height of the hammer weighing 4.5 kg is 450, 575, and 700 mm, respectively; the drop height of the hammer weighing 6.0 and 7.5 kg is 450 mm. The volume content of recycled steel fiber in concrete is 0, 0.5, 0.75, and 1.0%, respectively. Each group of drop weight experiments adopts six samples, and the total number of samples with four fiber contents is 120. Figure 2 shows the loading device of repeated drop hammer impact experiment.

Repeated drop hammer impact experimental device.

Before placing and positioning the sample, the waste engine oil at the bottom of the sample is brushed to reduce the impact of the bottom plate on the sample. Then, the positioning frame is installed, the sample is placed and the limit plate is installed to prevent the sample from moving during the experiment. In order to ensure that the falling hammer deviates in the middle of the falling process, a plastic pipe is installed above the positioning frame, the drop hammer repeatedly falls freely from the plastic pipe, until the first visible crack occurs, and the corresponding number of blows is recorded.

Then, the experiment is continued until the experiment fails, and the number of blows is recorded. The judgment standard of experiment failure is that the sample has visible cracks whose length is not less than the diameter of the sample. With reference to documents [28,29], combined with the actual situation of the experiment, the weight and height of the drop hammer for the experiment are determined, the steel ball with a falling weight of 4.5 kg corresponds to three falling heights of 450, 575, and 700 mm, and the drop weight is 6.0 and 7.5 kg, respectively, corresponding to the drop height of 700 mm.

3 Experimental result

3.1 Strength experiment

After 28 days of standard curing, the specimen shall be experimented with for cube compressive strength and splitting tensile strength. The experiment results are shown in Table 2. The results show that with the increase in volume content of recycled steel fiber, the strength of four kinds of recycled steel fiber concrete shows an increasing trend, but the overall growth rate is small. The cube compressive strength of RSFC1.0 is the highest, which is only 7.4% higher than that of RSFC0. This reflects that the use of recycled steel fiber has no obvious effect on the compressive strength of the concrete cube in this experiment.

Tensile and compressive strength of recycled steel fiber-reinforced concrete

| No | RSFC0 | RSFC0.5 | RSFC0.75 | RSFC1.0 |

|---|---|---|---|---|

| Cube strength (MPa) | 43.1 | 43.4 | 44.2 | 46.3 |

| Splitting tensile strength (MPa) | 4.1 | 4.4 | 5.1 | 5.7 |

The tensile strength of the concrete also shows an increasing trend with the increase in the content of recycled steel fiber. The tensile strength of RSFC1.0 is the largest, which is 39% higher than that of RSFC0 without adding. The contribution of recycled steel fiber to the tensile strength of concrete is significantly greater than that of compressive strength, and this shows that the crack resistance of recycled steel fiber in concrete under compression is lower than that under tension. In essence, the influence of ordinary steel fiber on the strength of concrete basically shows this law, which is basically consistent with the research results of ordinary steel fiber concrete by scholars at home and abroad [30,31,32,33,34,35].

3.2 Ultrasonic pulse experiment

Figure 3 shows the ultrasonic pulse nondestructive testing device, and Table 3 shows the ultrasonic pulse nondestructive testing speed value. With the increase in recycled steel fiber content, the UPV decreased continuously. The reason is that the distribution of steel fibers in concrete is random, and the direction of steel fibers is also random. When the sound wave propagates in it, it forms multi-directional scattering. The more the steel fiber content is, the more obvious the scattering will be, resulting in the decreasing trend of the wave velocity. In addition, if ultrasonic pulse nondestructive testing is applied in practical engineering, the appropriate coupling agent should be selected, and the residual gravel on the sample surface should be cleaned while keeping the test surface smooth and tidy.

Ultrasonic pulse nondestructive testing device.

Ultrasonic wave velocity of recycled steel fiber-reinforced concrete

| No | RSFC0 | RSFC0.5 | RSFC0.75 | RSFC1.0 |

|---|---|---|---|---|

| UPV (km·s−1) | 4.221 | 4.089 | 4.036 | 3.292 |

3.3 Repeated drop weight impact experiment

Figure 4 shows the 4.5 kg drop hammer at 450, 575, and 700 mm drop height, respectively, and the number of blows corresponding to the first crack of recycled steel fiber-reinforced concrete specimens with different contents. Figure 5 shows the number of blows corresponding to the failure of the specimen under the same conditions. The results show that the impact-strengthening effect of recycled steel fiber on the sample is obvious in both stages.

Relationship between blow count and steel fiber content when the first crack appears.

Relationship between blow count and steel fiber content in case of sample failure.

Figures 4 and 5 show that the impact resistance of recycled steel fiber-reinforced concrete increases obviously with the increase of fiber content, which is due to the active connection of steel fiber when transferring load along a crack, just like “bridge.” When the concrete is loaded, these fibers prevent or slow down the growth of cracks, so as to absorb more impact energy. Steel fiber can improve the tensile strength of concrete by controlling the development of cracks, so as to produce greater ductility of concrete under tensile, bending and impact loads.

Figures 4 and 5 also show that regardless of the fiber content, the greater the drop hammer height, the number of blows of the first crack, and the number of blows corresponding to failure are significantly reduced. The reason is that the impact force increases with the increase of drop hammer height. Therefore, the specimens with repeated impact at a small drop height have a longer duration before cracking and failure than those at a large drop height.

For specimens with recycled steel fiber content of 0, 0.5, 0.75, and 1.0%, respectively, a drop hammer weighing 4.5 kg at a drop height of 450 mm, the number of blows when the first crack of each specimen appears is 78, 349, 497, and 671, respectively, the corresponding hammering times in the failure stage are 81, 380, 611 and 788, respectively. For the falling height of 575 mm, the blow counts of the first crack of each sample are 73, 199, 297, and 395, respectively, and the corresponding blow counts of failure are 71, 251, 329, and 451, respectively. When the falling height is 700 mm, the corresponding blow counts of the first crack of each sample are 41, 105, 176, and 244, while the corresponding values in the failure stage are 42, 119, 211, and 292, respectively. The experiment results reflect the adverse effect of the increase in the falling height of the drop hammer on the number of blows.

If the effect of air resistance on the falling hammer is ignored, and the influence factors such as the swing of the sample under impact are ignored; it can be assumed that the impact energy when the falling hammer falls freely is the impact energy absorbed by the sample. In order to evaluate the effect of falling height on impact, the impact energy absorption of the sample is compared. Referring to the existing literature [36,37], the formula for calculating the impact energy absorbed by the sample is as follows (1):

where E i is the impact energy absorbed by the sample (kJ), N is the number of blows corresponding to the first crack or sample failure, W is the falling weight (kg), v is the impact velocity of the falling hammer (m·s−1), g is the acceleration of gravity (m·s−1), and H is the falling height of the drop hammer (mm).

As shown in Figures 6 and 7, the ability of the sample to absorb impact energy, whether for the first crack or the impact failure of the sample, decreases with the increase in the drop weight height, but the sample with zero content of recycled steel fiber is an exception. The reason is that the impact force produced by the larger falling height is greater, which has a more significant impact on the microstructure of the sample after each impact. Therefore, when the specimen is at a higher falling height, the internal microstructure of the concrete will crack and fracture at a higher rate. Obviously, with the increase in the falling height of the drop hammer, the first crack and failure absorption energy of each sample recorded a decrease.

Relationship between impact energy and steel fiber content when the first crack occurs.

Relationship between impact energy and steel fiber content during specimen failure.

Figures 6 and 7 show that the impact energy absorbed by the sample jumps significantly with the increase of steel fiber content from 0 to 1.0%, which again shows that the addition of steel fiber has a significant impact on the development of impact resistance of concrete. The existence of steel fiber along the crack effectively improves the transmission of stress along the crack, so as to improve the ability of crack propagation. Therefore, more impact times are needed to apply effective stress, so as to destroy the bond between the fiber and the surrounding concrete, until the steel fiber breaks or the steel fiber is pulled out of the concrete, and the sample fails. For the samples with 0, 0.5, 0.75, and 1.0% recycled steel fiber, when the drop weight is 4.5 kg and the drop height is 450 mm, the impact energy absorbed by the first crack is 1.5, 6.9, 9.8 and 13.3 kJ, respectively; for the drop height of 700 mm, the above values are 1.2, 3.2, 5.4, and 7.5 kJ, respectively. Compared with the absorbed energy, it can be seen that when the falling height of the falling hammer increases by more than 50%, the absorbed energy decreases by about half.

Figures 8 and 9 compare the number of blows experienced by the sample when the first crack appears and fails when the falling height of the falling hammer is 450 mm and different falling weights. The results show that with the increase in the drop weight, the number of blows required for the first crack to appear and fail is significantly reduced. The reason is that after the crack is formed, the impact resistance of the sample mixed with recycled steel fiber depends on the tensile strength of steel fiber and the bond strength between steel fiber and concrete. The increase in drop weight will produce greater impact energy, resulting in greater stress repeatedly applied at the crack, so the number of impacts required to destroy the bond between steel fiber and concrete becomes lower.

Relationship between blow count and steel fiber content when the first crack appears.

Relationship between hammering times and steel fiber content during specimen failure.

The number of blows with a drop weight of 4.5 kg is shown in Figures 4 and 5. For specimens containing 0, 0.5, 0.75 and 1.0% recycled steel fiber, when the drop weight is 6.0 kg, the corresponding blow counts of the first crack are 66, 171, 211, and 349, respectively. When the drop weight is 7.5 kg, the corresponding blow counts of the first crack are 33, 98, 111, and 131, respectively.

Figures 10 and 11 show the absorbed impact energy corresponding to the occurrence of the first crack and the failure of the sample when 4.5, 6.0, and 7.5 kg drop hammer impact the sample from the falling height of 450 mm, respectively. It is obvious that the increase in the weight of the drop hammer directly leads to the increase in the impact force. The results show that for the same sample, the energy absorption capacity decreases significantly with the increase of drop weight. With the increase of the weight or height of the falling hammer, the impact effect caused by the falling hammer also increases significantly. Placing the sample under the action of a large repeated impact force will accelerate the degradation of the internal microstructure of concrete, increase the development of cracks, and reduce the ability to absorb energy until the sample cracks or fails.

Relationship between impact energy and steel fiber content when the first crack occurs.

Relationship between impact energy and steel fiber content during specimen failure.

3.4 Effect of steel fiber content on impact properties

Figures 12–15 show the comparison of the increase of corresponding hammering times between the concrete sample with recycled steel fiber and the sample without recycled steel fiber. Figures 12 and 14, respectively, show the comparative relationship between variable drop height and variable drop weight when the first crack of the sample appears. Figures 13 and 15 show that the minimum impact resistance of the specimen in the failure stage increased by more than 150%, while the maximum increment exceeded 800%.

The number of hammering increases when the first crack occurs compared with ordinary concrete.

The number of hammering increases compared with that of ordinary concrete when the specimen fails.

Increase in number of hammers compared with ordinary concrete (the first crack appears).

The number of hammering increases compared with that of ordinary concrete when the specimen fails.

Figures 12–15 show that regardless of the weight or height of the drop hammer, the percentage of impact resistance increases with the increase of steel fiber content, and the change law is the same in both the first crack stage and the sample failure stage. This shows that after adding recycled steel fiber to concrete, the crack appears obviously lag, the crack development is obviously delayed, and the steel fiber significantly improves the toughness and impact resistance of concrete.

3.5 Failure mode and impact toughness

Figure 16 shows the crack development and failure of ordinary concrete with zero recycled steel fiber content and concrete samples with recycled steel fiber. Compared with the concrete sample mixed with recycled steel fiber, the impact resistance of the ordinary concrete sample is much lower regardless of changing the drop weight or drop height. Ordinary concrete samples will fail soon even after the first crack appears, which reflects the brittle behavior of ordinary concrete samples under impact. When the cracking limit is reached, a linear crack as shown in Figure 16(a) will be formed. After 1 to 3 times of hammering, the crack widens and extends to the edge of the cylinder, and extends downward to the bottom to divide the sample into two parts. In this process, other small cracks will appear in the sample, as shown in Figure 16(a). This failure mode is a common failure mode of ordinary concrete cylinders under hammering, which is also confirmed by the research literature [38,39].

Failure mode of specimen: (a) failure of NC sample, (b) failure of RSFC0.5 sample, and (c) failure of RSFC1.0 sample.

It is observed from the experiment that ordinary concrete has a brittle failure, but the number of samples broken into four parts is very small. The reason for the brittle behavior of ordinary concrete under repeated drop hammer impact is that there is no connecting element to prevent the development of concrete cracks. When the impact load is transferred from the steel ball to the center of the sample, due to the non-uniform characteristics of concrete, the stress will be transferred along the development direction of potential cracks. When the stress is greater than the action required for the development of potential cracks, the cracks will widen and deepen, and even form more cracks.

The specimens mixed with recycled steel fiber show completely different shapes, and the ability of the specimens to withstand repeated drop hammer impact is significantly enhanced [40]. Due to more impact times, a central circular fracture zone is formed under the steel ball. With the increase in impact times, the area of this area becomes larger and larger, resulting in small fracture cracks on the surface. Figure 16(b) and (c) show the crack development of the sample mixed with recycled steel fiber. With the increase in impact times, the width of these cracks will increase significantly. With the further increase in impact times, the bond between the steel fiber in the crack and the surrounding concrete body is gradually lost, resulting in the steel fiber being straightened or even pulled out. At this time, the sample fails. Due to the addition of recycled steel fiber, the sample can not only absorb more impact energy, but also significantly increase the number of cracks, which indicates that the sample failure has an obvious process; that is, the sample failure is ductile, not brittle.

3.6 Ductility of specimen

Ductility refers to the ability of a material to withstand plastic deformation under load, which is usually used in tensile and bending tests [41,42]. This concept is introduced into the repeated drop weight impact experiment; that is, the ratio of the impact times when the specimen is damaged to the impact times when the first crack appears is defined as the ductility ratio [43,44,45,46]. After the first crack appears, the ordinary concrete sample will fail after 1–3 times of impact. Therefore, the ductility ratio of ordinary concrete samples is about 1.0. When the steel fiber content is 0.5, 0.75, and 1.0%, the fiber sample shows good ductility, and the average ductility ratio is about 1.17, 1.24, and 1.19, respectively. The increase in specimen ductility is attributed to the connection of steel fiber in the concrete. It increases the overall impact resistance of the specimen, makes the specimen absorb more impact energy after cracking, delays the failure time of the specimen, and increases the impact times after cracking.

3.7 Relationship between impact resistance and UPV

UPV can reflect the internal defects of concrete, such as internal holes, crack depth, compactness, and other indicators. Figures 17 and 18 show the linear relationship between the impact times and UPV when the first crack of the sample occurs and the sample fails. Obviously, the UPV at the first crack and failure decreases with the increase of impact times. Table 4 lists these linear relationship expressions. The values in Table 3 show that the UPV value decreases with the increase in recycled steel fiber content. In essence, the relationship between UPV and steel fiber content and impact times is related. The greater the content of steel fiber, the more impact times of the sample. Therefore, there is an inverse relationship between UPV and steel fiber content and impact times.

Linear relationship between hammering number and UPV when the first crack appears.

Linear relationship between hammering number and UPV during specimen failure.

Linear relationship between hammering times and UPV

| Impact condition | Number of impacts when the first crack appears (N 1) | Number of shocks at failure (N f) | ||

|---|---|---|---|---|

| Linear model | R 2 | Linear model | R 2 | |

| W = 4.5 kg, H = 450 mm | N 1 = −2074.4UPV + 8850.3 | 0.953 | N 1 = −2475.9UPV + 10555 | 0.939 |

| W = 4.5 kg, H = 575 mm | N 1 = −1101.6UPV + 4727.3 | 0.945 | N 1 = −1294.6UPV + 5555.1 | 0.966 |

| W = 4.5 kg, H = 700 mm | N 1 = −964.82UPV + 4130.9 | 0.999 | N 1 = −1068.1UPV + 4576.5 | 0.989 |

| W = 6.0 kg, H = 450 mm | N 1 = −711.14UPV + 3038.3 | 0.962 | N 1 = −902.52UPV + 3844.4 | 0.959 |

| W = 7.5 kg, H = 450 mm | N 1 = −334.63UPV + 1458.2 | 0.939 | N 1 = −439.2UPV + 1917.9 | 0.831 |

In addition, in order to further study the impact resistance of recycled steel fiber-reinforced concrete and compare it with that of original steel fiber-reinforced concrete, such experimental research is underway.

4 Conclusion

Repeated drop hammer impact experiments were carried out on recycled steel fiber-reinforced concrete samples from the three aspects of recycled steel fiber content, drop weight and drop height, and the following conclusions were obtained:

Under the impact of the falling hammer, the brittle failure of the ordinary concrete sample occurs, while the ductile failure of the recycled steel fiber concrete occurs. Compared with ordinary concrete samples, the addition of recycled steel fiber increases the impact resistance times of the sample when the first crack occurs and the sample fails (N 1 and N f). N 1 and N f increase with the increase of steel fiber content.

When the falling height is fixed, the greater the weight of the falling hammer, the smaller the N 1 and N f values of the sample. When the falling weight is fixed, the greater the falling height, the smaller the N 1 and N f values of the sample.

With the increase in the content of recycled steel fiber, the N 1 and N f values of the sample show an increasing trend when the falling weight is fixed or the falling height is fixed. At the same time, with the increase in the content of recycled steel fiber, the energy consumption performance of the sample increases continuously. In combination with the N 1 and N f values of the sample and the energy consumption performance, it is suggested that the optimal volume of recycled steel fiber should be 1.0%.

UPV decreases with the increase in steel fiber content or impact times, indicating that recycled steel fiber has a good effect on reducing concrete defects and enhancing the compactness of concrete.

The ductility ratio of ordinary concrete in repeated drop weight impact tests is about 1.0, while the ductility ratio of recycled steel fiber-reinforced concrete is between 1.1 and 1.4, which is significantly higher than that of ordinary concrete.

Acknowledgments

The authors thank professor Xu Qiang and State Key Laboratory of Geohazard Prevention and Geoenvironment Protection for their guidance.

-

Funding information: This study was Supported by the Open Fund Declaration of State Key Laboratory of Geohazard Prevention and Geoenvironment Protection, Chengdu University of Technology (Grant no. SKLGP2019K019), Guangzhou Basic and Applied Basic Research Project (202201010750), and Sichuan Provincial research and development program (Grant no. 2020YFS0061).

-

Author contributions: Yongtao Gao, Bin Wang, and Qiang Xu wrote the article. Changjiang Liu, David Hui, Weiguang Yuan, Haifeng Tang, and Jianjun Zhao checked the manuscript. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Reviews on Advanced Materials Science. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

-

Data availability statement: The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Pan, H. M. and Y. C. Ma. Impact resistance of steel fiber reinforced concrete and its mechanism of crack resistance and toughening. Journal of Building Materials, Vol. 20, No. 6, 2017, pp. 956–961 (in Chinese).Search in Google Scholar

[2] Murali, G. and K. Ramprasad. A feasibility of enhancing the impact strength of novel layered two stage fibers concrete slabs. Engineering Structure, Vol. 175, 2018, pp. 41–49.10.1016/j.engstruct.2018.08.034Search in Google Scholar

[3] Abid, S. R., A. Hilo, and Y. H. Daek. Experimental tests on the underwater abrasion of engineered cementitious composites. Construction Building Material, Vol. 71, 2018, pp. 779–792.10.1016/j.conbuildmat.2018.03.213Search in Google Scholar

[4] Abid, S. R., M. S. Shamkhi, N. S. Mahdi, and H. DaekYasir. Hydro-abrasive resistance of engineered cementitious composites with PP and PVA fibers. Construction Building Material, Vol. 187, 2018, pp. 168–177.10.1016/j.conbuildmat.2018.07.194Search in Google Scholar

[5] Alabduljabbar, H., R. Alyousef, F. Alrshoudi, A. Alaskar, A. Fathi, and A. M. Mohamed. Mechanical effect of steel fiber on the cement replacement materials of self-compacting concrete. Fibers, Vol. 7, 2019, pp. 1–11.10.3390/fib7040036Search in Google Scholar

[6] Khabaz, A. Analysis of sliding mechanism of straight steel fibers in concrete and determine the effect of friction. Archives of Civil and Mechanical Engineering, Vol. 17, 2017, pp. 599–608.10.1016/j.acme.2017.01.005Search in Google Scholar

[7] Sheta, A., X. Ma, Y. Zhuge, M. ElGawady, J. Mills, and E. Abd-Elaal. Flexural strength of innovative thin-walled composite cold-formed steel/PE-ECC beams. Engineering Structures, Vol. 267, 2022, id. 114675.Search in Google Scholar

[8] Sheta, A., X. Ma, Y. Zhuge, M. A. ElGawady, J. E. Mills, and E. S. Abd-Elaal. Shear behaviour of thin-walled composite cold-formed steel/PE-ECC beams. Steel and Composite Structures-An International Journal, Vol. 46, No. 1, 2023, pp. 75–92.10.1016/j.engstruct.2022.114675Search in Google Scholar

[9] Sheta, A., X. Ma, Y. Zhuge, M. ElGawady, J. E. Mills, and E. Abd-Elaal. Axial compressive behaviour of thin-walled composite columns comprise high-strength cold-formed steel and PE-ECC. Thin-Walled Structures, Vol. 184, 2023, id. 110471.10.1016/j.tws.2022.110471Search in Google Scholar

[10] Sheta, A., X. Ma, Y. Zhuge, M. A. ElGawady, J. E. Mills, A. Singh, et al. Structural performance of novel thin-walled composite cold-formed steel/PE-ECC beams. Thin-Walled Structures, Vol. 162, 2021, id. 107586.10.1016/j.tws.2021.107586Search in Google Scholar

[11] Chen, M., H. Wang, M. Qi, Y. Li, S. H. Wang, and E. L. Wang. Experimental study on dynamic compressive properties of composite layers of rock and steel fiber reinforced concrete. Chinese Journal of Rock Mechanics and Engineering, Vol. 39, No. 6, 2020, pp. 1222–1230 (in Chinese).Search in Google Scholar

[12] Murali, G., R. Gayathri, V. R. Ramkumar, and K. Karthikeyan. Two statistical scrutinize of impact strength and strength reliability of steel fiber-reinforced concrete. KSCE Journal of Civil Engineering, Vol. 22, 2018, pp. 257–269.10.1007/s12205-017-1554-1Search in Google Scholar

[13] Fakoor, M. and M. Nematzadeh. A new post-peak behavior assessment approach for effect of steel fibers on bond stress-slip relationship of concrete and steel bar after exposure to high temperatures. Construction and Building Materials, Vol. 278, 2021, id. 122340.10.1016/j.conbuildmat.2021.122340Search in Google Scholar

[14] Chen, M., Y. B. Liu, and Y. X. Tao. Experimental study on properties of recycled tyre polymer fiber reinforced concrete. Journal of Northeastern University (Natural Science), Vol. 41, No. 6, 2020, pp. 870–874.Search in Google Scholar

[15] Karimi, A. and M. Nematzadeh. Axial compressive performance of steel tube columns filled with steel fiber-reinforced high strength concrete containing tire aggregate after exposure to high temperatures. Engineering Structures, Vol. 219, 2020, id. 110608.10.1016/j.engstruct.2020.110608Search in Google Scholar

[16] Nematzadeh, M., M. Mousavimehr, J. Shayanfar, and M. Omidalizadeh. Eccentric compressive behavior of steel fiber-reinforced RC columns strengthened with CFRP wraps: experimental investigation and analytical modeling. Engineering Structures, Vol. 226, 2021, id. 111389.10.1016/j.engstruct.2020.111389Search in Google Scholar

[17] Kang, T.H.-K., S. Kim, J. H. Shin, and J. M. LaFave. Seismic behavior of exterior beam-column connections with high-strength materials and steel fibers. ACI Structural Journal, Vol. 273, No. 4, 2019, pp. 31–43.10.14359/51715568Search in Google Scholar

[18] Sengul, O. Mechanical properties of slurry infiltrated fiber concrete produced with waste steel fibers. Construction and Building Materials, Vol. 186, 2018, pp. 1082–1091.10.1016/j.conbuildmat.2018.08.042Search in Google Scholar

[19] Eisa, A. S., M. T. Elshazli, and M. T. Nawar. Experimental investigation on the effect of using crumb rubber and steel fibers on the structural behavior of reinforced concrete beams. Construction and Building Materials, Vol. 252, 2020, id. 119078.10.1016/j.conbuildmat.2020.119078Search in Google Scholar

[20] Liew, K. M. and A. Akbar. The recent progress of recycled steel fiber reinforced concrete. Construction and Building Materials, Vol. 232, 2020, pp. 2–16.10.1016/j.conbuildmat.2019.117232Search in Google Scholar

[21] Caggiano, A., P. Folino, C. Lima, E. Martinelli, and M. Pepe. On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Construction and Building Materials, Vol. 147, 2017, pp. 286–295.10.1016/j.conbuildmat.2017.04.160Search in Google Scholar

[22] Najim, K. B., A. Saeb, and Z. Al-Azzawi. Structural behaviour and fracture energy of recycled steel fibre self-compacting reinforced concrete beams. Journal of Building Engineering, Vol. 17, 2018, pp. 174–182.10.1016/j.jobe.2018.02.014Search in Google Scholar

[23] Chaboki, H. R., M. Ghalehnovi, A. Karimipour, J. de Brito, and M. Khatibinia. Shear behaviour of concrete beams with recycled aggregate and steel fibers. Construction and Building Materials, Vol. 204, 2019, pp. 809–827.10.1016/j.conbuildmat.2019.01.130Search in Google Scholar

[24] Nitesh, K. S., S. V. Rao, and P. R. Kumar. An experimental investigation on torsional behaviour of recycled aggregate based steel fiber reinforced self compacting concrete. Journal of Building Engineering, Vol. 22, 2019, pp. 242–251.10.1016/j.jobe.2018.12.011Search in Google Scholar

[25] Abirami, T., M. Loganaganandan, G. Murali, R. Fediuk, R. V. Sreekrishna, T. Vignesh, et al. Experimental research on impact response of novel steel fibrous concretes under falling mass impact. Construction and Building Materials, Vol. 222, 2019, pp. 447–457.10.1016/j.conbuildmat.2019.06.175Search in Google Scholar

[26] Asrani, N. P., G. Murali, K. Parthiban, K. Surya, A. Prakash, K. Rathika, et al. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: experiments and modelling. Construction and Building Materials, Vol. 203, 2019, pp. 56–68.10.1016/j.conbuildmat.2019.01.072Search in Google Scholar

[27] Murali, G., N. P. Asrani, V. R. Ramkumar, A. Siva, and M. K. Haridharan. Impact resistance and strength reliability of novel two-stage fibre-reinforced concrete. Arabian Journal for Science and Engineering, Vol. 44, 2019, pp. 4477–4490.10.1007/s13369-018-3466-xSearch in Google Scholar

[28] Islam, A., U. J. Alengaram, M. Z. Jumaat, N. B. Ghazali, S. Yusoff, and I. I. Bashar. Influence of steel fibers on the mechanical properties and impact resistance of lightweight geopolymer concrete. Construction and Building Materials, Vol. 152, 2017, pp. 964–977.10.1016/j.conbuildmat.2017.06.092Search in Google Scholar

[29] Siddika, A., M. A. Al Mamun, R. Alyousef, Y. M. Amran, F. Aslani, and H. Alabduljabbar. Properties and utilizations of waste tire rubber in concrete: A review. Construction and Building Materials, Vol. 224, 2019, pp. 711–731.10.1016/j.conbuildmat.2019.07.108Search in Google Scholar

[30] Zhang, W., S. Chen, and Y. Liu. Effect of weight and drop height of hammer on the flexural impact performance of fiber-reinforced concrete. Construction and Building Materials, Vol. 140, 2017, pp. 31–35.10.1016/j.conbuildmat.2017.02.098Search in Google Scholar

[31] Zhong, H., E. W. Poon, K. Chen, and M. Zhang. Engineering properties of crumb rubber alkali-activated mortar reinforced with recycled steel fibres. Journal of Cleaner Production, Vol. 238, 2019, id. 117950.10.1016/j.jclepro.2019.117950Search in Google Scholar

[32] Jin, R., B. Li, A. Elamin, S. H. Wang, O. Tsioulou, and D. Wanatowski. Experimental investigation of properties of concrete containing recycled construction wastes. International Journal of Civil Engineering, Vol. 16, 2018, pp. 1621–1633.10.1007/s40999-018-0301-4Search in Google Scholar

[33] Sahraei, M. A., F. Omidinasab, and G. S. Moazami. Characterization of concrete containing RCA and GGBFS: mechanical, microstructural and environmental properties. Construction and Building Materials, Vol. 289, 2021, id. 123134.10.1016/j.conbuildmat.2021.123134Search in Google Scholar

[34] Omary, S., E. Ghorbel, G. Wardeh, and M. D. Nguyen. Mix design and recycled aggregates effects on the concrete’s properties. International Journal of Civil Engineering, Vol. 16, 2018, pp. 973–992.10.1007/s40999-017-0247-ySearch in Google Scholar

[35] Bui, T. T., W. S. A. Nana, B. Doucet-Ferru, A. Bennani, H. Lequay, and A. Limam. Shear performance of steel fiber reinforced concrete beams without stirrups: experimental investigation. International Journal of Civil Engineering, Vol. 18, 2020, pp. 865–881.10.1007/s40999-020-00505-8Search in Google Scholar

[36] Saif, K. M., A. A. Zaid, and B. N. Khalid. Effect of discarded steel fibers on impact resistance, flexural toughness and fracture energy of high-strength self-compacting concrete exposed to elevated temperatures. Fire Safety Journal, Vol. 121, 2021, id. 103271.10.1016/j.firesaf.2020.103271Search in Google Scholar

[37] AbdelAleem, B. H., M. K. Ismail, and A. A. Hassan. The combined effect of crumb rubber and synthetic fibers on impact resistance of self-consolidating concrete. Construction and Building Materials, Vol. 162, 2018, pp. 816–829.10.1016/j.conbuildmat.2017.12.077Search in Google Scholar

[38] Li, D., J. Xiao, Y. Zhuge, J. E. Mills, H. Senko, and X. Ma. Experimental study on crumb rubberised concrete (CRC) and reinforced CRC slabs under static and impact loads. Australian Journal of Structural Engineering, Vol. 21, No. 4, 2020, pp. 294–306.10.1080/13287982.2020.1809811Search in Google Scholar

[39] Ismail, M. K. and A. A. Hassan. Impact resistance and mechanical properties of self-consolidating rubberized concrete reinforced with steel fibers. Journal of Materials In Civil Engineering, Vol. 29, 2017, pp. 1–14.10.1061/(ASCE)MT.1943-5533.0001731Search in Google Scholar

[40] Nazarimofrada, E., F. Shaikhb, and M. Nilia. Effects of steel fibre and silica fume on impact behaviour of recycled aggregate concrete. Journal of Sustainable Cement-Based Materials, Vol. 6, No. 1, 2017, pp. 54–68.10.1080/21650373.2016.1230900Search in Google Scholar

[41] Yang, J. H., X. Y. Li, Y. Q. Ye, and X. Y. Wang. Strength and energy dissipation effect of fiber reinforced all-lightweight concrete based on SHPB impact tests. Journal of Vibration and Shock, Vol. 39, No. 2, 2020, pp. 148–154 (in Chinese).Search in Google Scholar

[42] Abbass, A. A., S. R. Abid, F. H. Arna’ot, R. A. Al-Ameri, and M. Ozakca. Flexural response of hollow high strength concrete beams considering different size reductions. Structure, Vol. 23, 2020, pp. 69–86.10.1016/j.istruc.2019.10.001Search in Google Scholar

[43] Chen, X., G. Xing, J. Niu, and B. Liu. Behavior of plastic-steel fifiber reinforced lightweight aggregate concrete columns subjected to concentric axial loading. International Journal of Civil Engineering, Vol. 19, 2021, pp. 283–300.10.1007/s40999-020-00564-xSearch in Google Scholar

[44] Omidinasab, F. and A. S. Moghadam. A. Effect of purposive distribution of fibers to prevent the penetration of bullet in concrete walls. KSCE Journal of Civil Engineering, Vol. 25, No. 3, 2021, pp. 843–853.10.1007/s12205-021-2016-3Search in Google Scholar

[45] Sahraei Moghadam, A., F. Omidinasab, and A. Dalvand. Experimental investigation of (FRSC) cementitious composite functionally graded slabs under projectile and drop weight impacts. Construction and Building Materials, Vol. 237, 2020, id. 117522.10.1016/j.conbuildmat.2019.117522Search in Google Scholar

[46] Sahraei Moghadam, A., F. Omidinasab, and A. Dalvand. Flexural and impact performance of functionally graded reinforced cementitious composite (FGRCC) panels. Structures, Vol. 29, 2021, pp. 1723–1733.10.1016/j.istruc.2020.12.042Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.