Abstract

Activated sludge process has been widely adopted to remove pollutants in wastewater treatment plants (WWTPs). However, stable operation of activated sludge process is often compromised by the occurrence of filamentous bulking. The aim of this study is to build a proper model for timely diagnosis and prediction of filamentous sludge bulking in an activated sludge process. This study developed a state-based Gaussian Process Regression (GPR) model to monitor the filamentous sludge bulking related parameter, sludge volume index (SVI), in such a way that the evolution of SVI can be predicted over multi-step ahead. This methodology was validated with SVI data collected from one full-scale WWTP. Online diagnosis and prediction of filamentous bulking sludge with real-time SVI prediction was tested through a simulation study. The results showed that the proposed methodology was capable of predicting future SVIs with good accuracy, thus providing sufficient time for predicting and controlling filamentous sludge bulking.

Similar content being viewed by others

Introduction

Eutrophication caused by excess wastewater discharge is recognized as a serious water pollution problem worldwide. To prevent water pollution, biological wastewater treatment has been widely adopted to remove pollutants. In terms of its economical and technical feasibility, activated sludge process (ASP) is the most commonly used biological wastewater treatment process to remove organic matter and nutrients (mainly nitrogen and phosphorus). The successful operation of ASP mainly relies on efficient biological conversions in bioreactors and normal sludge separation in secondary clarifiers. Filamentous bacteria are normal components of activated sludge biomass, where the existence of a fraction of filamentous bacteria is important and helpful to form flocs by serving as the floc-backbone for other bacteria to attach1. However, filamentous bulking sludge, a term used to describe the excess proliferation of filamentous bacteria, often results in deteriorating sludge settleability, poorer operational performance and higher treatment cost2,3. Filamentous bulking sludge is considered the most serious problem usually happening in WWTPs adopting ASP. It is documented that more than 50% of WWTPs encounter the filamentous bulking sludge problem worldwide3.

In order to prevent from serious deterioration of sludge settleability, predictive models have been proposed to achieve early warning for filamentous sludge bulking. In terms of underlying model development fundamentals, predictive models can be divided into three categories, i.e., mechanistic, gray-box and black-box models4. The mechanistic models are often used to achieve optimization and control of process. For example, the activated sludge model family5 can provide a comprehensive description of the significant biological processes of the ASP system, while a secondary settling tank model6 can provide more realistic predictions of the sludge settleability performance. Compared to mechanistic models, gray-box modeling approaches are relatively simple for the design of predictive models, since a reduced number of parameters will be estimated by statistical or mathematical techniques. Predictive methodologies based on black-box models also gains popularity resulting from the fact that they do not require detailed understanding of the system7. In addition, black-box models are cost-effective to perform prediction, which attempt to automatically capture the dominant processes and to link input to output variables, consequently being seen as an alternative when mechanistic models are not available or not valid. To predict filamentous sludge bulking, few linear black-box models, such as Auto-Regressive and Moving Average (ARMA)8, Hidden Markov model9 and partial least squares (PLS)10 were performed. However, due to strong non-linearity, predictions using such linear models (e.g. ARMA and PLS) often deviate significantly from the real state of the WWTP. Thus, nonlinear models are proposed to deal with these problems, including the nonlinear PLS method11, artificial neural networks12 and the support vector machine (SVM) based regression method13,14. Although these nonlinear models exhibit advantages to predict filamentous sludge bulking, building a high performance prediction model is very laborious, since input variables and samples for model construction have to be selected carefully and parameters have to be tuned appropriately. Particularly for the artificial neural networks15,16, the number of layers and the number of neurons for each layer should be selected carefully by trial and errors. Furthermore, the computational intensity is prohibited for most of cases, e.g. the number of layers being more than six.

To predict filamentous sludge bulking timely, the model needs not only to capture strongly nonlinear effects of operational conditions on sludge settleability, but also to be robust for the presence of uncertainty and noise in WWTPs. Building models for activated sludge systems purely based on a theoretical understanding of underlying physical or biochemical principles can be unfeasibly complex and requires a large number of simplifying assumptions. Additionally, uncertainty in the WWTP would have negative influences on a certain decision making for a reliable operation of the system. If ignoring uncertainty or relying on the expectation of uncertainty, the prediction could be poor and result in deviation of fault diagnosis or prognosis. Gaussian Process for regression (GPR) model is a new proposed distribution-driven methodology, which is not only able to model dynamic processes of both linear and nonlinear systems, but also to generate predicted distribution (interval prediction), rather than point prediction, to facilitate our decision making for filamentous bulking17. Traditionally, predicted models output a bare prediction without any associated confidence values and hence have to rely on the previous experience or relatively loose theoretical upper bounds on the probability of error to gauge the quality of the given prediction. On the contrary, resulted intervals from the GPR model would become wide or narrow to indicate how confident it is for the predicted values. Also, through the choice of covariance function, a wide range of modeling assumptions would be expressed to be able to approach different operational states of WWTP.

Generally, black-box models are able to serve as the basis to assist in fault diagnosis. The task of fault diagnosis is mainly to identify the abnormal states and recognize them as early as possible, thus enabling prevention of emergent accidents and reducing the cost of downtime maintenance. However, one-step (OS) ahead prediction does not provide sufficient time for sludge settleability recovery. Therefore, it is imperative to recognize future emergent events in advance as early as possible. One of plausible ways is to apply multi-step (MS) ahead prediction, which is able to predict the progress of the filamentous bulking for a long-term operation MS ahead prediction would also add further complexity of uncertainty description for a GPR model, as the propagation of uncertainties is calculated recursively as prediction moves ahead. So far, few studies have devoted to fault diagnosis and fault prognosis (fault prediction) with MS ahead prediction in bio-chemical processes18. In particular, few attempts based on MS ahead prediction are used for filamentous sludge bulking fault diagnosis and prognosis.

The objective of this study is to develop a state-based GPR model aiming to detect and provide a warning for the prevention of sludge bulking in advance. The contributions of this paper are summarized as follows. Firstly, this study is the first attempt to develop a state-based GPR model to characterize for the evolution of filamentous sludge bulking. Given different degrees of severity during the evolution of filamentous sludge bulking, two types of GPR models, i.e., OS ahead prediction for normal state and MS ahead predictions after recognition of filamentous sludge bulking, are constructed in this model, respectively. Further, to coordinate the both of OS and MS GPR models as well as different states concerning the evolution of filamentous sludge bulking, hybrid automata is introduced, which is able to characterize the transitions of OS and MS GPR models smoothly. Secondly, since distribution-driven model, GPR, is used for prediction, uncertain factors contributing to filamentous sludge bulking can be accounted, thus providing distribution-based prediction, rather than point prediction for filamentous sludge bulking, which would alleviate the false alarms properly during the fault diagnosis and prognosis processes. Finally, considering it is difficult to define an accurate threshold to distinguish different sludge bulking state, we proposed to use an interval fault diagnosis limit to envelop the uncertainties resulting from the model parameters and external disturbances (variations of wastewater components and weather influence).

Results

Development of predictive model for fault diagnosis and prognosis of filamentous bulking

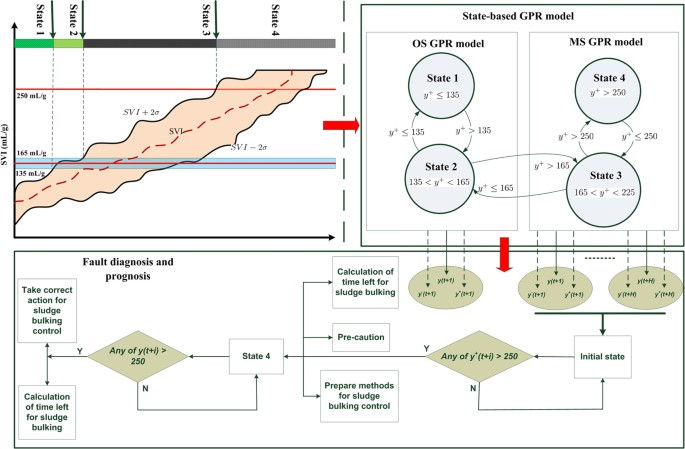

In practice, Sludge Volume Index (SVI) is an empirical measurement used to characterize the sludge bulking problem19. The SVI is able to represent different typical states of filamentous bulking sludge, when SVI reaches the pre-specified level (in most cases SVI of 150âmL/g as a threshold value). Some different values for SVI of 100, 180, even 280âmL/g are also used as a threshold value to distinguish filamentous bulking sludge with good sludge settleability20. Definition of an accurate threshold to indicate filamentous sludge bulking is still an open issue. In the previous study21, three different sludge states are defined in terms of SVI values: normal state with SVI of 0â150âmL/g, limited filamentous bulking sludge with SVI of 150â250âmL/g and serious filamentous bulking sludge with SVI of more than 250. However, by taking into account the negative influence of uncertainties (such as variations of wastewater components, model parameters and weather influence, render accurate measurement of SVI impossible), ±10% is added to the control limit of limited filamentous bulking sludge in this study. On the contrary, due to severity of serious filamentous bulking sludge, the hard control limit of 250âmL/g is used. Consequently in this study, four states (State 1: SVI of 0â135âmL/g, normal state; State 2: SVI of 135â165âmL/g, limited filamentous bulking sludge pre-caution; State 3: SVI of 165â250âmL/g, limited filamentous bulking sludge; State 4: SVI of more than 250âmL/g, serious filamentous bulking sludge) are defined in our models.

To characterize different states of SVI, the construction of GPR models becomes important, since it serves as the basis for the state-based GPR. Firstly, the OS GPR model is built for States 1 and 2 as shown in Fig. 1. The most important part of the OS GPR model is to identify the unknown parameters by maximize the corresponding likelihood function. Then, by supplying the new coming data points x*, the prediction values of SVI and their corresponding variances, SVIâââ2Ï and SVIâ+â2Ï can be obtained. Secondly, the MS GPR model is built for States 3 and 4 as well (Fig. 1). Different from the OS GPR model, only time series data of SVI is selected due to recursive MS prediction strategy applying to perform the MS GPR model. By performing the MS GPR model, prediction values of SVI and their corresponding variances, SVIâââ2Ï and SVIâ+â2Ï over the entire prediction horizon, H, can be derived. Thirdly, both of OS GPR model and MS GPR are further served as the basis for a hybrid automata (the details can be found in the section of Methods). The hybrid automaton is a mathematical model for precisely describing systems in which digital computational processes interact with analog physical processes22,23. Differently, this paper implements hybrid automata for the accurate characterization of interactions between OS ahead and MS ahead prediction. To date, this has not been applied to filamentous bulking sludge prediction, even though the use of hybrid automata for this purpose in chemical industries is widespread. The hybrid automata for SVI is shown as Fig. 1 to coordinate different states. The variable y, yâ and y+ represent the SVI, SVIâââ2Ï and SVIâ+â2Ï, respectively. Hereby, Ï is the variance of predicted SVI obtained from the GPR model, representing the effect resulting from the uncertainty (model parameters, uncertainty for collected data and significant disturbances of a WWTP). The reason why y+ is used to recognize the filamentous sludge bulking occurrence is the fact that y+ is prone to capture the worst case and enable the prevention of filamentous sludge bulking in advance. In control States 1 and 2, filamentous bulking sludge did not occur yet, SVI and its corresponding uncertain boundary can be obtained for OS ahead prediction using the developed GPR (the details can be found in Section Methods), respectively. In control mode State 1, the SVI is on the normal state. According to the jump condition y+â>â135 (limited filamentous bulking sludge lower limit), the SVI is still calculated by the same GPR model as State 1, but the state of limited filamentous bulking sludge pre-caution should be declared to indicate the potentials of limited filamentous bulking sludge. On the contrary, the SVI will jump back state 1 if y+â<â135. Once the y+ runs over 165, the MS GPR model will be triggered to make multi-step ahead prediction. This is mainly due to the significant potentials to transit from limited filamentous bulking sludge to severe filamentous bulking sludge. States 3 and 4 jump on the basis of their corresponding jump conditions. Even though y+ generated from GPR models is able to provide a pre-caution in advance and to alleviate the deviations of predicted values, y. The value of y can be used to further confirm the occurrence of sludge bulking.

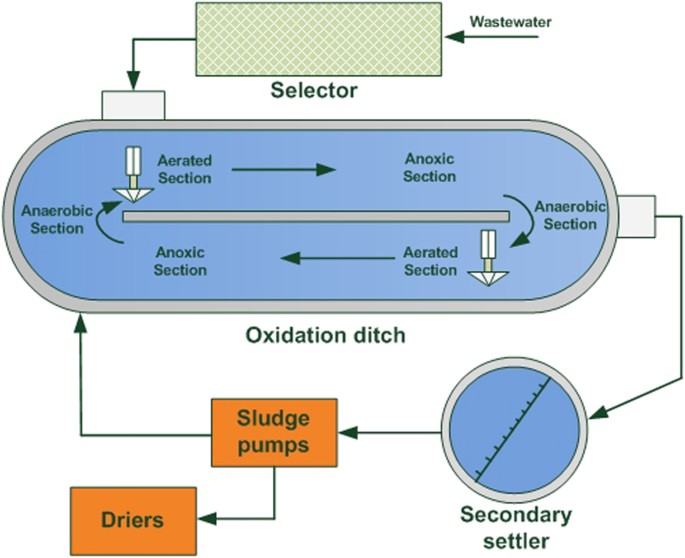

A Case study-filamentous sludge bulking diagnosis and prognosis in a full-scale WWTP

The presented case is a full-scale WWTP (Beijing, China), which mainly treated municipal wastewater with an Oxidation ditch (OD) process. OD process is a modified activated sludge biological treatment process that utilizes long solids retention time (SRT) to achieve good nitrogen removal performance. Figure 2 shows a schematic of the reactor for the full-scale WWTP. In this plant, the average influent flow was about 170,000âm3/d, with an average OD hydraulic retention time (HRT) of 16.5âh. SRT was kept 15â22âd by withdrawing sludge from the second settler. Due to low COD loading rate (<0.25âkgCOD/kgMLSS/d), the occurrence of filamentous bulking sludge was observed in this plant. The phenomenon of bulking sludge lasted for about half a year. The influent characteristics, operation conditions and the evolution of SVI were recorded during the period of filamentous sludge bulking. These data were used to develop and validate the GPR model in this study.

In order to select the most relevant variables as inputs for the OS-GPR model, the Variable Importance in Projection (VIP) method together with the mechanical knowledge is used24. Eight process variables are selected as model inputs for the OS-GPR model, as listed in Table 1. A total of 213 data points are collected from the full-scale operational observations. Of these samples, 50âwere utilized for OS-GPR model training, while the remaining 50 samples before limited filamentous bulking occurrence were used to test the performance of the OS-GPR-based prediction. However, once the SVI transits to limited filamentous bulking, MS-GPR model is trained using the data before the occurrence of limited filamentous bulking. Since the transition of SVI is from the 101st data, all of the previous data are used for MS-GPR model training. The remaining data are then left for MS-GPR model and fault prognosis testing. It should be noted that different from OS-GPR model usage of eight variables as inputs, MS-GPR model is constructed based on time series data, i.e., the most recent lagged SVI (More details see Table 1). The dimension selection for MS-GPR modeling inputs is achieved by performing Auto Correlation Function (ACF) and Partial Auto Correlation Function (PACF)25.

Prediction of limited filamentous bulking with one-step ahead prediction models

In this paper, the Root Mean Square Error (RMSE) and coefficient (r) were used to access the prediction performance of inferential model. The Root Mean Square Error (RMSE criterion is defined as follows for quality comparisons of different methods

where yi and  are the measured and prediction values, respectively, n represents the number of sample points.

are the measured and prediction values, respectively, n represents the number of sample points.

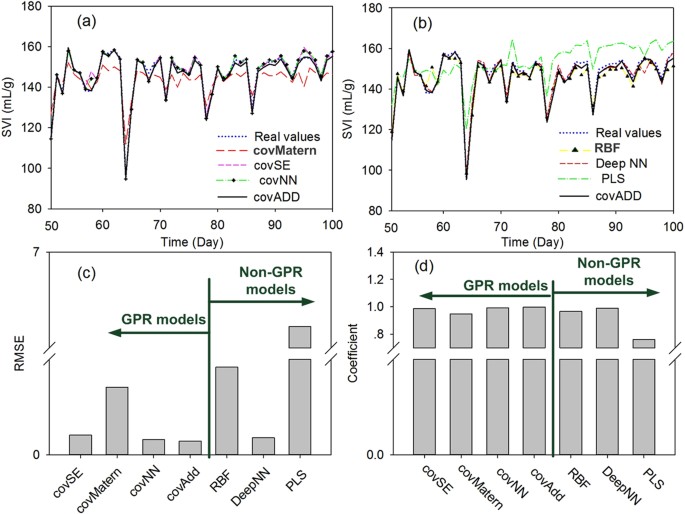

The performance of four GPR models with different Covariance is shown in Fig. 3(a), suggesting that the GPR model with additive Covariance achieved the best performance in terms of RMSE (Fig. 3(c)) and r (Fig. 3(d)). The reason mainly lies on the fact that the additive Covariance is more flexible, thus being able to approach strong non-linear relationship and describe the non-local integrations of the data. In contrast, other GPR models are only limited to one type Covariance, thus being unable to track some data with different Covariance shape. In order to illustrate the efficiency of GPR model with addictive Covariance, the profiles of SVI prediction are presented in Fig. 3(b) compared with other models, suggesting that GPR model with addictive Covariance still achieves the best performance in terms of RMSE (Fig. 3(c)) and r (Fig. 3(d)). It is obvious that, due to being unable to capture the nonlinearity of SVI, PLS gains the worst performance, whereas the nonlinear model RBF achieved a relative better performance. In addition, Deep Neural Network, which is a new algorithm to deal with strong nonlinearity using more layers structure26, performed better fairly. However, its computational intensity prohibits its widely use, which is five times than the GPR model with addictive Covariance. The presented algorithmsâ parameters are set up as Table S1 (Supporting Information).

Comparisons of Gaussian processes for micro sludge bulking diagnosis with different covariance functions (covSE: Squared-Exp kernel; covNN: Neural Network kernel; covMatérniso: Matérniso kernel; covAdd: Addictive kernel) and other models (RBF: Radical Basis Function; DeepNN: Deep Neural Network; PLS: Partial Squares Least; More details about the Kernel can see Supplementary Information).

Fault prognosis with MS ahead prediction models

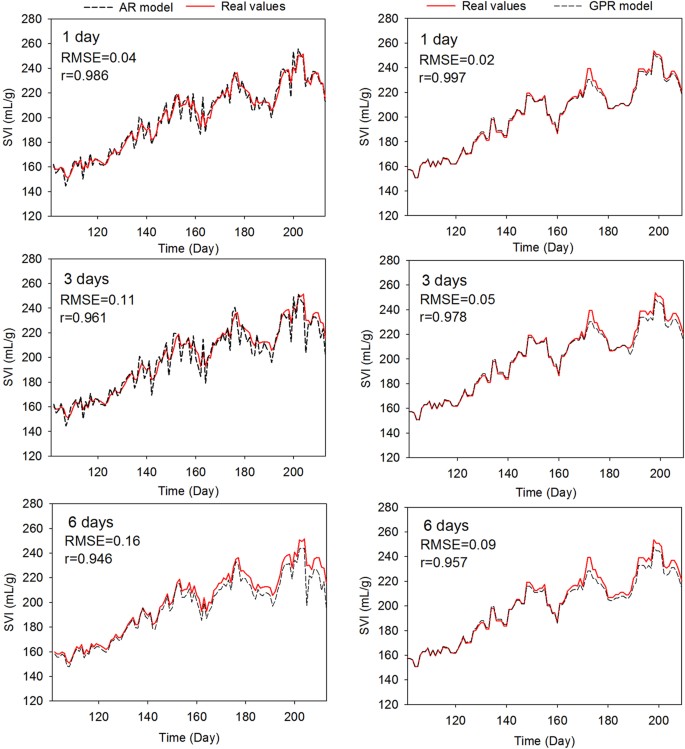

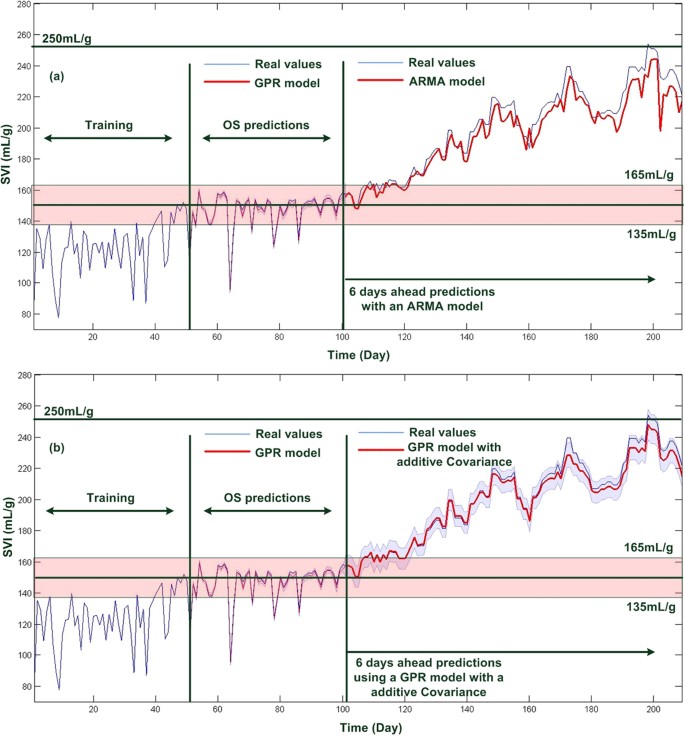

In order to account for evolution of SVI, OS prediction is not capable of providing sufficient time for filamentous sludge bulking control. Thus, once the y+ crosses control limit 165âmL/g, MS-GPR model is triggered immediately. To evaluate the performance of fault prognosis, the ARMA model, which is widely used for multi-steps-ahead prediction, is tested for 1, 3 and 6âdays ahead predictions firstly. Obviously, the ARMA model is able to capture the propagation of fault, even though a bit shifts is happening as more days ahead prediction. Also, due to the noise sensitivity, the ARMA model exhibits a significant fluctuation and thus further deteriorates the performance of corresponding models. As compared to the ARMA model, the GPR model is also presented. The time lag of GPR is set to be 7âdays by considering the correlation between few recent lagged samples. As shown in Fig. 4 (right), the GPR model with additive Covariance achieves a relative better performance for three kinds of scenarios (1, 3 and 6âdays ahead predictions) in terms of RMSE and r.

Fault prognosis with uncertainty analysis

Since uncertainty in a WWTP might be resulted from many factors such as equipment degradation, plant model mismatch and other disturbances, decision-making under uncertainty is not trivial if it is desired to fulfill reliability requirements and quality standards. To reduce the false alarms and ensure robust control limit for diagnosis in our diagnosis methodologies, we relaxed the limited filamentous bulking control limit to 150â±â15âmL/g, rather than 150âmL/g exactly. Such relaxation represents 90% confidence on the diagnosis results. It is obvious that the boundaries of GPR models during the OS and MS perdition periods are capable of enveloping the variations of SVI (Fig. 5). Since the OS ahead prediction has been in the envelop of 150â±â15âmL/g, the limited filamentous bulking pre-caution is forwarded. Sequentially, due to the use of 6âdays ahead predictions after recognizing the ending of limited filamentous bulking, the boundary of the MS-GPR model become wider, representing less confident on the prediction results. The wider boundary is, in turn, able to envelope the true values properly. In these methodologies, the worst case strategy is considered. Once the upper boundary of OS-GPR model crosses over 165âmL/g, MS-GPR model is triggered to perform multiple ahead predictions to indicate how far it is from the serious filamentous bulking pre-caution control limit, 250âmL/g (Fig. 5). Figure 5 also suggests that, even though the MS-GPR model cannot tract the evolution of SVI exactly after day 190, the uncertainty envelop is able to compensate such deviations and facilitate the fault prognosis properly.

Discussion

The present work investigated the use of GPR model for the fault diagnosis and prognosis of filamentous sludge bulking in activated sludge process. The OS-GPR and MS-GPR models are coordinated by hybrid automata to provide a simple, but powerful tool to predict the evolution of SVI. This, along with uncertainty information that was generated from a GPR model by nature, supported the design of fault diagnosis and prognosis of filamentous bulking, yielding excellent performance. To the best of authorâs knowledge, this is the first attempt for filamentous sludge bulking prediction with multiple-step ahead prediction.

Different from traditional fault diagnosis and prognosis having decisions making exactly, uncertainty was involved to form the worst case for decision making. This approach is adopted by considering the uncertainty information from factors such as model parameters, collected data and the significant disturbances of a WWTP. Furthermore, ±15âmL/g was added to the limited filamentous bulking to make the fault diagnosis and prognosis more reliable to account for the uncertainty influence. Due to sufficient time requirement to deal with the filamentous bulking, not only one day ahead but also six days was presented. Although in the case study we limited the number of predicted horizon to six days, the methodology is clearly applicable when much more days ahead predictions are made. This will provide sufficient time for filamentous sludge bulking control.

However, since the recursive multi-step ahead prediction is performed, avoiding predicted error accumulation is infeasible. In fact, it only needs to improve the recursive way by combining the direct prediction methodology27. A direct prediction methodology aims to estimate a set of H prediction models, each returning a forecast for the ith values (iâââ{1, â¦, H}, where H represents the number of predicted step). The idea behind this strategy is to combine aspects from both, the direct and the recursive strategy. In other words, a different model is used at each step but the approximations from previous steps are introduced into the input set. We presented the methodology using an OD process as an example. The methodology can be extended to other activated sludge processes. The use of GPR model is able to be expanded to other models with uncertainty description. The performance of more powerful prediction algorithm requires further study.

In this study, we demonstrated the novel design of fault diagnosis and prognosis of filamentous sludge bulking through simulation studies. Our proposed model can track and predict the variations of SVI, but it cannot distinguish the bulking type (filamentous bulking or non-filamentous bulking). In order to distinguish the bulking type, integration of image analysis with model prediction will be performed further in future. While we used an advanced model giving realistic representations of real system, the proposed fault diagnosis and prognosis methodology requires further verification through its application into a real activated sludge process.

Methods

GPR model

GPR model is a simple and general class of models of functions. To be precise, a GPR is any distribution over functions such that any finite set of function values {f(x1), f(x2), â¦f(xn)} have a joint Gaussian distribution. GPR is usually formulated as follows: given a training set  of n pairs of inputs xi and noisy outputs yi, compute the predictive distribution of f at a new testing input x*. We assume that the noise is additive, independent and Gaussian, such that the relationship between the (latent) function f (xi) and the observed noisy targets y are given by28

of n pairs of inputs xi and noisy outputs yi, compute the predictive distribution of f at a new testing input x*. We assume that the noise is additive, independent and Gaussian, such that the relationship between the (latent) function f (xi) and the observed noisy targets y are given by28

where  represents a Gaussian process with mean and covariance matrix equaling to 0 and k(·, ·), respectively. The noise ε follows the Gaussian distribution with mean 0 and covariance

represents a Gaussian process with mean and covariance matrix equaling to 0 and k(·, ·), respectively. The noise ε follows the Gaussian distribution with mean 0 and covariance  .

.

To be simplicity, we define covariance matrix Kâ=âkij. By inference, it is easy to obtain that the outputs follow multivariate joint Gaussian distribution:

where  , Ky is the covariance matrix with dimension being nâÃân, the corresponding (i, j)th element is

, Ky is the covariance matrix with dimension being nâÃân, the corresponding (i, j)th element is

where δij is the Kronecker function29. The major difference of K and Ky is that K is noise free but Ky is noise-depended. In summary, the parameters needed to be identified are formulated as  , where l is the width of kernel k(xi, xj).

, where l is the width of kernel k(xi, xj).

OS ahead prediction with GPR

Due to  following Gaussian distribution also, the prediction at the location x* can be obtained with the mean and variance:

following Gaussian distribution also, the prediction at the location x* can be obtained with the mean and variance:

where  represents the correlated relationship between x* and training set data xi. The corresponding likelihood function is shown as follows:

represents the correlated relationship between x* and training set data xi. The corresponding likelihood function is shown as follows:

which can be optimized to derive θ. By performing OS prediction, the evolution of SVI can be monitored properly real time, even one sample ahead.

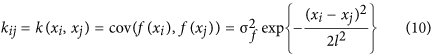

In the GPR model, the most commonly used covariance matrix is Squared-Exp (SE) shown as follows:

where  and l are hyper-parameters in need of identification, respectively. Different from the general Covariance function, we use a new proposed addictive Covariance function together with Squared-Exp (SE) as a base Covariance function shown as follows:

and l are hyper-parameters in need of identification, respectively. Different from the general Covariance function, we use a new proposed addictive Covariance function together with Squared-Exp (SE) as a base Covariance function shown as follows:

where  is the base kernel Squared-Exp (SE), d is the column number of training samples. This model, in fact, is a sum of functions of all possible combinations of input variables. This model can be specified by a weighted sum of all possible products of one-dimensional kernels. In our model, the only design choice necessary to specify an additive kernel is the selection of a one-dimensional base kernel for each input dimension. Parameters of the base kernels (such as length-scales (l1, l1, â¦, ld) can be learned as per usual by maximizing the marginal likelihood of the training data. It should be noted that commonly-used kernels such as the Squared-Exp (SE), Neural Network (NN) or Matérn kernels are local kernels28, depending only on the scaled Euclidean distance between two points. Therefore, models based on local kernels are particularly susceptible to the curse of dimensionality15 and are unable to extrapolate away from the training data. Methods based solely on local kernels sometimes require training examples at exponentially-many combinations of inputs. In contrast, additive kernels can allow extrapolation away from the training data, more details about kernel selection can be seen in Supplementary Information.

is the base kernel Squared-Exp (SE), d is the column number of training samples. This model, in fact, is a sum of functions of all possible combinations of input variables. This model can be specified by a weighted sum of all possible products of one-dimensional kernels. In our model, the only design choice necessary to specify an additive kernel is the selection of a one-dimensional base kernel for each input dimension. Parameters of the base kernels (such as length-scales (l1, l1, â¦, ld) can be learned as per usual by maximizing the marginal likelihood of the training data. It should be noted that commonly-used kernels such as the Squared-Exp (SE), Neural Network (NN) or Matérn kernels are local kernels28, depending only on the scaled Euclidean distance between two points. Therefore, models based on local kernels are particularly susceptible to the curse of dimensionality15 and are unable to extrapolate away from the training data. Methods based solely on local kernels sometimes require training examples at exponentially-many combinations of inputs. In contrast, additive kernels can allow extrapolation away from the training data, more details about kernel selection can be seen in Supplementary Information.

MS ahead prediction with GPR

However, for most of cases, OS ahead prediction does not provide sufficient time for filamentous sludge bulking control. In order to predict time series values of many time steps into the future, MS techniques30,31 have been developed to achieve this goal. In this paper, we extend aforementioned GPR model for MS ahead prediction using a recursive strategy. In this strategy, a single model f is trained to perform one-step-ahead prediction firstly.

where  . Sequentially, we use the value just forecasted as part of the input variables for estimating the next step with the same OS ahead model. This step is continued until the entire horizon, H, has been performed. Then the forecasts are given by:

. Sequentially, we use the value just forecasted as part of the input variables for estimating the next step with the same OS ahead model. This step is continued until the entire horizon, H, has been performed. Then the forecasts are given by:

where H is the MS prediction horizon,  is the model input dimension and

is the model input dimension and  is an estimate of the output at time-step tâ+âH. Such the recursive strategy has been successfully used to forecast many real world time series by using different machine learning models27.

is an estimate of the output at time-step tâ+âH. Such the recursive strategy has been successfully used to forecast many real world time series by using different machine learning models27.

Hybrid automata definition

Given the mixture of OS and MS prediction models in this paper, a tool to describe such hybrid behaviors is necessary. A hybrid automata provides an alternative to deal with this issue. The automaton is a formal model for a dynamic system with discrete and continuous components32. The semantics of a hybrid automaton is defined in terms of a labeled transition system between states, where a state consists of the current location of the automaton and the current valuation of the real variables. To formalize the semantics of the hybrid automaton, first we need to define the concept of a hybrid automatonâs state. Then, upon the constraint for each state, current valuation of the real variables can be obtained by a specified function or model. In fact, a hybrid automaton evolves depending on two kinds of transitions: continuous transitions, capturing the continuous evolution of states and discrete transitions, capturing the changes of location33,34.

A hybrid automaton can be divided into autonomous and controlled types, which depend on whether their transitions are uncontrollable or controllable. By using the hybrid automata, the transition behaviors can be accounted for properly. More details for hybrid automata definition can be seen in the Supplementary Information. Also, an example to suggest how to construct a hybrid automaton is shown in the Supplementary Information.

General methods for prediction model construction

In order to provide references for the proposed methodology of OS-GPR for fault diagnosis, Partial Least Squares (PLS) is used firstly. The purpose of PLS is to find a linear regression model by projecting the input variables X and the output variables Y to a new space. Because both X and Y data are projected to new spaces, the PLS family of methods are known as bilinear factor models. Secondly, a typical neural network Radial Basis Function (RBF)35,36 is considered as an alternative to approach nonlinear relationship between the input variables X and the output variables Y. The output of the network is a linear combination of radial basis functions of the inputs and neuron parameters. However, due to significant nonlinearity for modeling data, the predictions using shallow neural networks (the number of layers are less than three) deviate from the true values dramatically and failed to represent the data properly. Therefore, as a comparison, a deep neural network (DeepNN) is presented thirdly, which is five layers and trained by the deep learning algorithm15.

In order to compare with the MS-GPR model for fault prognosis, a ARMA model is presented. An ARMA model provide a parsimonious description of a (weakly) stationary stochastic process in terms of two polynomials, one for the auto-regression (AR) and the second for the moving average (MA). Given a time series data Xt, the ARMA model is a tool for understanding and being able to predict future values in this series37.

Additional Information

How to cite this article: Liu, Y. et al. Prediction of Filamentous Sludge Bulking using a State-based Gaussian Processes Regression Model. Sci. Rep. 6, 31303; doi: 10.1038/srep31303 (2016).

References

Guo, J. et al. Control filamentous bulking caused by chlorine-resistant Type 021N bacteria through adding a biocide CTAB. Water research 46, 6531â6542 (2012).

Olsson, G. ICA and me â A subjective review. Water Research 46, 1585â1624 (2012).

Martins, A. M. P., Pagilla, K., Heijnen, J. J. & van Loosdrecht, M. C. M. Filamentous bulking sludgeâa critical review. Water Research 38, 793â817 (2004).

Dürrenmatt, D. J. & Gujer, W. Data-driven modeling approaches to support wastewater treatment plant operation. Environmental Modelling & Software 30, 47â56 (2012).

Mogens, H., Willi;, G., Takashi, M. & Mark, V. L. Activated sludge models ASM1, ASM2, ASM2d and ASM3. (IWA publishing, 2000).

Li, B. & Stenstrom, M. K. A sensitivity and model reduction analysis of one-dimensional secondary settling tank models under wet-weather flow and sludge bulking conditions. Chemical Engineering Journal 288, 813â823 (2016).

Kadlec, P., Gabrys, B. & Strandt, S. Data-driven Soft Sensors in the process industry. Computers & Chemical Engineering 33, 795â814 (2009).

Smets, I. Y. et al. Dynamic modeling of filamentous bulking in lab-scale activated sludge processes. Journal of Process Control 16, 313â319 (2006).

Bansal, N. K., Feng, X., Zhang, W., Wei, W. & Zhao, Y. Modeling Temporal Pattern and Event Detection using Hidden Markov Model with Application to a Sludge Bulking Data. Procedia Computer Science 12, 218â223 (2012).

Amaral, A. L. & Ferreira, E. C. Activated sludge monitoring of a wastewater treatment plant using image analysis and partial least squares regression. Anal. Chim. Acta 544, 246â253 (2005).

Liu, Y., Pan, Y. & Huang, D. Development of a Novel Adaptive Soft-Sensor Using Variational Bayesian PLS with Accounting for Online Identification of Key Variables. Industrial & Engineering Chemistry Research 54, 338â350 (2015).

Harvey, R., McBean, E. & Gharabaghi, B. Predicting the Timing of Water Main Failure Using Artificial Neural Networks. Journal of Water Resources Planning and Management 140, 425â434 (2014).

Kaneko, H. & Funatsu, K. Applicability domain of soft sensor models based on one-class support vector machine. AIChE Journal 59, 2046â2050 (2013).

Liu, Y., Chen, J., Sun, Z., Li, Y. & Huang, D. A probabilistic self-validating soft-sensor with application to wastewater treatment. Computers & Chemical Engineering 71, 263â280 (2014).

Bengio, Y. Learning Deep Architectures for AI. Foundations and Trends® in Machine Learning 2, 1â127 (2009).

Han, H. & Qiao, J. Hierarchical Neural Network Modeling Approach to Predict Sludge Volume Index of Wastewater Treatment Process. Control Systems Technology, IEEE Transactions on 21, 2423â2431 (2013).

Ni, W., Wang, K., Chen, T., Ng, W. J. & Tan, S. K. GPR model with signal preprocessing and bias update for dynamic processes modeling. Control Engineering Practice 20, 1281â1292 (2012).

Zhao, C. & Gao, F. Online fault prognosis with relative deviation analysis and vector autoregressive modeling. Chemical Engineering Science 138, 531â543 (2015).

Soyupak, S. Effects of operational parameters on the settling properties of activated sludge. Environmental Technology Letters 10, 471â478 (1989).

Rensink, J. H. New Approach to Preventing Bulking Sludge. Journal (Water Pollution Control Federation) 46, 1888â1894 (1974).

Guo, J.-H. et al. Energy saving achieved by limited filamentous bulking sludge under low dissolved oxygen. Bioresource Technology 101, 1120â1126 (2010).

Chakraborty, P., Saxena, P. C. & Katti, C. P. Fifty Years of Automata Simulation: A Review. ACM Inroads 2, 59â70 (2011).

Fehnker, A. Automotive control revisited linear inequalities as approximation of reachable sets in Hybrid Systems: Computation and Control. LNCS 1386, 110â125 (1998).

Andersen, C. M. & Bro, R. Variable selection in regressionâa tutorial. Journal of Chemometrics 24, 728â737 (2010).

Chen, J., Ganigué, R., Liu, Y. & Yuan, Z. Real-Time Multistep Prediction of Sewer Flow for Online Chemical Dosing Control. Journal of Environmental Engineering 140, 0401â4037 (2014).

Bengio, Y. Learning Deep Architectures for AI. Found. Trends Mach. Learn. 2, 1â127 (2009).

Ben Taieb, S., Bontempi, G., Atiya, A. F. & Sorjamaa, A. A review and comparison of strategies for multi-step ahead time series forecasting based on the NN5 forecasting competition. Expert Syst Appl 39, 7067â7083 (2012).

Rasmussen, C. E. & Williams, C. K. I. Gaussian Processes for Machine Learning. (MIT Press, 2006).

Chalupka, K., Williams, C. K. I. & Murray, I. A framework for evaluating approximation methods for Gaussian process regression. J. Mach. Learn. Res. 14, 333â350 (2013).

Chen, K. & Yu, J. Short-term wind speed prediction using an unscented Kalman filter based state-space support vector regression approach. Applied Energy 113, 690â705 (2014).

Papageorgiou, E. I. & Froelich, W. Multi-step prediction of pulmonary infection with the use of evolutionary fuzzy cognitive maps. Neurocomputing 92, 28â35 (2012).

Henzinger, T. A. In Eleventh Annual IEEE Symposium on Logic in Computer Science. 278-292 (IEEE).

Uzam, M. & Gelen, G. The real-time supervisory control of an experimental manufacturing system based on a hybrid method. Control Engineering Practice 17, 1174â1189 (2009).

Paoletti, S., Juloski, A. L., Ferrari-Trecate, G. & Vidal, R. Identification of Hybrid Systems A Tutorial. European Journal of Control 13, 242â260 (2007).

Guang-Bin, H., Saratchandran, P. & Sundararajan, N. A generalized growing and pruning RBF (GGAP-RBF) neural network for function approximation. Neural Networks, IEEE Transactions on 16, 57â67 (2005).

Zhang, J. C. & Hou, J. X. Process Parameters Monitoring by Soft-Sensor Technology Based on RBF Neural Networks. Proceedings of 2009 International Conference of Management Engineering and Information Technology, Vols 1 and 2, 820â823 (2009).

Chen, J., Ganigué, R., Liu, Y. Q. & Yuan, Z. G. Real-time Multi-step Prediction of Sewer Flow for Online Chemical Dosing Control. Journal of Environmental Engineering in press (2014).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (61403142) and the National Natural Science Foundation of Guangdong, China (2015A030313225). Jianhua Guo acknowledges the support from the Australian Research Council Discovery Early Career Researcher Award (DE 130101401). Qilin Wang acknowledges the funding support from the University of Queensland Early Career Research Grant (ECR040).

Author information

Authors and Affiliations

Contributions

Y.L. and J.G. performed the modeling and analyzed the data, further wrote the paper; Q.W. and D.H. contributed materials/analysis tools; All authors reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the articleâs Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Liu, Y., Guo, J., Wang, Q. et al. Prediction of Filamentous Sludge Bulking using a State-based Gaussian Processes Regression Model. Sci Rep 6, 31303 (2016). https://doi.org/10.1038/srep31303

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep31303

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.