Intelligent-packaging/kemasan cerdas.pdf

- 1. INTELLIGENT PACKAGING COST Action FP1405 Active and intelligent fibre-‐based packaging – innovation and market introduction DIANA GREGOR-‐SVETEC UNIVERSITY OF LJUBLJANA, FACULTY OF NATURAL SCIENCES AND ENGINEERING

- 2. UNIVERSITY OF LJUBLJANA • Established in 1919. • Number of staff: 5,481. • Number of students: 42,922. • 26 Members. Among the top 500 of the world's best universities on the Shanghai, Times and Webometrics ranking lists. HE institution Shanghai QS Webometrics URAP University of Ljubljana 401-‐500 551-‐600 192 284

- 3. FACULTY OF NATURAL SCIENCES AND ENGINEERING DEPARTMENT OF TEXTILES, GRAPHIC ARTS AND DESIGN Chair of Information and Graphic Arts Technology 4 study programmes: • Graphic and Interactive Communications (undergraduate level) • Graphic and Media Technology (undergraduate level) • Graphic and Interactive Communications (postgraduate level) • Textile Engineering, Graphic Communications and Textile Design (doctoral study programme)

- 4. Chair of Information and Graphic Arts Technology R&D activities are performed in a variety of fields of modern graphic and information technology: • prepress, printing, finishing, • graphic and packaging materials, printed electronics, packaging, • image processing, 3D modelling 3D printing, • photography, typography, graphic design.

- 5. INTELLIGENT PACKAGING Intelligent packaging is a packaging system that is capable of carrying out intelligent functions (such as detecting, sensing, recording, tracing, communicating, and applying scientific logic) to facilitate decision making to extend shelf life, enhance safety, improve quality, provide information, and warn about possible problems. Intelligent packaging is an extension of the communication function of traditional packaging and communicates to the consumer based on its ability to detect, sense and record the changes in the products environment.

- 6. INTELLIGENT PACKAGING • data carriers intended for storage, distribution, and traceability purposes – to make the information flow within the supply chain more efficient; • sensors allow a rapid and definite quantification of the analytes in packed product; • indicators provide more convenience and inform about product quality.

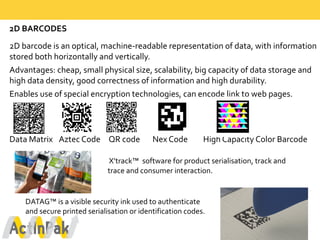

- 7. 2D BARCODES 2D barcode is an optical, machine-‐readable representation of data, with information stored both horizontally and vertically. Advantages: cheap, small physical size, scalability, big capacity of data storage and high data density, good correctness of information and high durability. Enables use of special encryption technologies, can encode link to web pages. Data Matrix Aztec Code QR code Nex Code High Capacity Color Barcode X’track™ software for product serialisation, track and trace and consumer interaction. DATAG™ is a visible security ink used to authenticate and secure printed serialisation or identification codes.

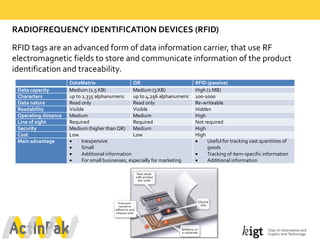

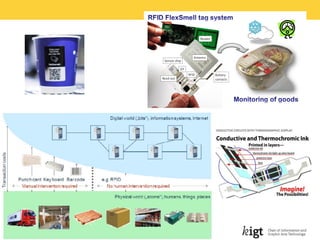

- 8. RADIOFREQUENCY IDENTIFICATION DEVICES (RFID) RFID tags are an advanced form of data information carrier, that use RF electromagnetic fields to store and communicate information of the product identification and traceability. DataMatrix QR RFID (passive) Data capacity Medium (1.5 KB) Medium (3 KB) High (1 MB) Characters up to 2,335 alphanumeric up to 4,296 alphanumeric 100-‐1000 Data nature Read only Read only Re-‐writeable Readability Visible Visible Hidden Operating distance Medium Medium High Line of sight Required Required Not required Security Medium (higher than QR) Medium High Cost Low Low High Main advantage • Inexpensive • Small • Additional information • For small businesses, especially for marketing • Useful for tracking vast quantities of goods • Tracking of item-‐specific information • Additional information

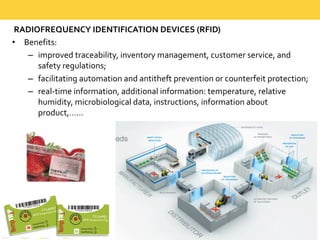

- 9. RADIOFREQUENCY IDENTIFICATION DEVICES (RFID) • Benefits: – improved traceability, inventory management, customer service, and safety regulations; – facilitating automation and antitheft prevention or counterfeit protection; – real-‐time information, additional information: temperature, relative humidity, microbiological data, instructions, information about product,……

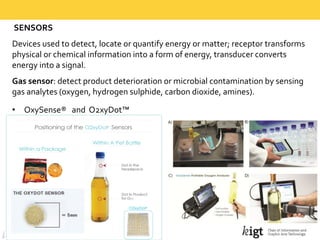

- 10. SENSORS Devices used to detect, locate or quantify energy or matter; receptor transforms physical or chemical information into a form of energy, transducer converts energy into a signal. Gas sensor: detect product deterioration or microbial contamination by sensing gas analytes (oxygen, hydrogen sulphide, carbon dioxide, amines). • OxySense® and O2xyDot™

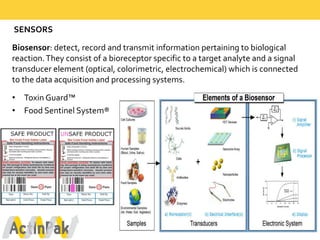

- 11. SENSORS Biosensor: detect, record and transmit information pertaining to biological reaction. They consist of a bioreceptor specific to a target analyte and a signal transducer element (optical, colorimetric, electrochemical) which is connected to the data acquisition and processing systems. • Toxin Guard™ • Food Sentinel System®

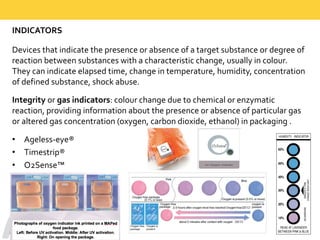

- 12. INDICATORS Devices that indicate the presence or absence of a target substance or degree of reaction between substances with a characteristic change, usually in colour. They can indicate elapsed time, change in temperature, humidity, concentration of defined substance, shock abuse. Integrity or gas indicators: colour change due to chemical or enzymatic reaction, providing information about the presence or absence of particular gas or altered gas concentration (oxygen, carbon dioxide, ethanol) in packaging . • Ageless-‐eye® • Timestrip® • O2Sense™

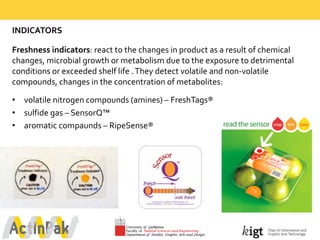

- 13. INDICATORS Freshness indicators: react to the changes in product as a result of chemical changes, microbial growth or metabolism due to the exposure to detrimental conditions or exceeded shelf life . They detect volatile and non-‐volatile compounds, changes in the concentration of metabolites: • volatile nitrogen compounds (amines) – FreshTags® • sulfide gas – SensorQ™ • aromatic compaunds – RipeSense®

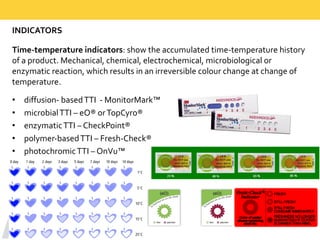

- 14. INDICATORS Time-‐temperature indicators: show the accumulated time-‐temperature history of a product. Mechanical, chemical, electrochemical, microbiological or enzymatic reaction, which results in an irreversible colour change at change of temperature. • diffusion-‐ based TTI -‐ MonitorMark™ • microbial TTI – eO® or TopCyro® • enzymatic TTI – CheckPoint® • polymer-‐based TTI – Fresh-‐Check® • photochromic TTI – OnVu™

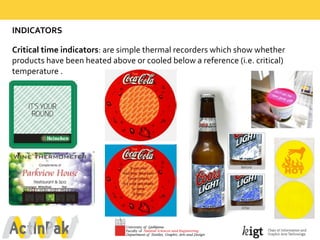

- 15. INDICATORS Critical time indicators: are simple thermal recorders which show whether products have been heated above or cooled below a reference (i.e. critical) temperature .

- 16. FUNCTIONAL INKS FOR INTELLIGENT PACKAGING Diana Gregor-‐Svetec, Marta Klanjšek Gunde, Maristiina Nurmi, Viera Jančovičová, Miguel A. Cerqueira, Fanny Hoeng, Aurore Denneulin, Julien Bras, Wim Deferme

- 17. PRINTED ELECTRONICS A process in which printing technology is used to produce various kinds of electronic goods, such as electronic circuits, displays, sensors, RFID,…..

- 18. PRINTED ELECTRONICS Integrated smart systems are built from different components, such as printed batteries, printed memory, active (transistors, diodes, logic circuits, display elements) or passive (resistors, capacitors, conductors) devices integrated by one process or by a combination of separately produced components. • Turbo Tag™ RFID Time and Temperature Monitoring System • ThinFilm RF Temperature-‐Tracking Sensor System

- 19. FUNCTIONAL INKS Printing inks in packaging are made to provide images and deliver certain message, they can be spot colors, formulated especially for particular product, or include some functionality, such as security features to protect from fraud, or add some intelligent features to packaging. Functional inks need to perform certain tasks, such as conduct or block electric current, change color. They may possess electromagnetic, thermal, chemical, optical properties. Inks may be conductive, semiconductive, dielectric, thermochromic, photochromic, magnetic or may have another targeted functionality.

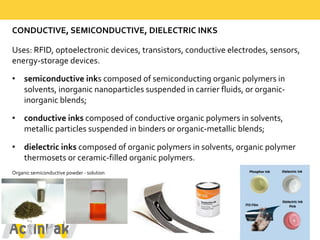

- 20. CONDUCTIVE, SEMICONDUCTIVE, DIELECTRIC INKS Uses: RFID, optoelectronic devices, transistors, conductive electrodes, sensors, energy-‐storage devices. • semiconductive inks composed of semiconducting organic polymers in solvents, inorganic nanoparticles suspended in carrier fluids, or organic-‐ inorganic blends; • conductive inks composed of conductive organic polymers in solvents, metallic particles suspended in binders or organic-‐metallic blends; • dielectric inks composed of organic polymers in solvents, organic polymer thermosets or ceramic-‐filled organic polymers. Organic semiconductive powder -‐ solution

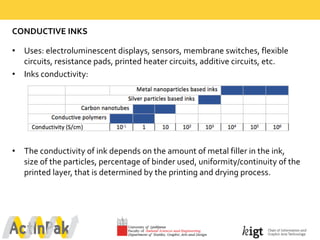

- 21. CONDUCTIVE INKS • Uses: electroluminescent displays, sensors, membrane switches, flexible circuits, resistance pads, printed heater circuits, additive circuits, etc. • Inks conductivity: • The conductivity of ink depends on the amount of metal filler in the ink, size of the particles, percentage of binder used, uniformity/continuity of the printed layer, that is determined by the printing and drying process.

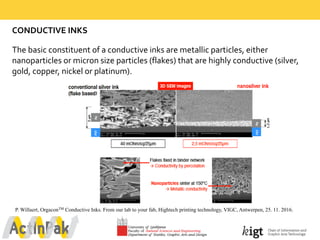

- 22. CONDUCTIVE INKS The basic constituent of a conductive inks are metallic particles, either nanoparticles or micron size particles (flakes) that are highly conductive (silver, gold, copper, nickel or platinum). P. Willaert, OrgaconTM Conductive Inks. From our lab to your fab, Hightech printing technology, VIGC, Antwerpen, 25. 11. 2016.

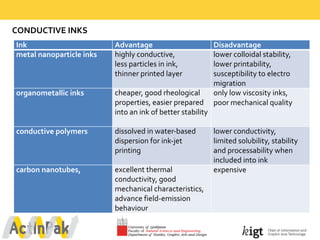

- 23. CONDUCTIVE INKS Ink Advantage Disadvantage metal nanoparticle inks highly conductive, less particles in ink, thinner printed layer lower colloidal stability, lower printability, susceptibility to electro migration organometallic inks cheaper, good rheological properties, easier prepared into an ink of better stability only low viscosity inks, poor mechanical quality conductive polymers dissolved in water-‐based dispersion for ink-‐jet printing lower conductivity, limited solubility, stability and processability when included into ink carbon nanotubes, excellent thermal conductivity, good mechanical characteristics, advance field-‐emission behaviour expensive

- 24. CHROMOGENIC INKS Chromogenic materials are those that change their optical properties in response to an external stimulus: • change in temperature (thermochromic), • irradiation from light (photochromic), • change of pH (chemochromic), • electric potential (electrochromic).

- 25. PHOTOCHROMIC INKS Use: smart labels and packaging materials, indicators and displays. Colour change with the incoming light intensity or spectral distribution of light. They are reversible and nearly invisible when they are not exposed to UV light, exposure to UV light causes fast transition and the darkening of the ink.

- 26. THERMOCHROMIC INKS Use: smart labels and packaging materials, indicators and displays. Temperature-‐sensitive materials that change color if exposed to different temperatures, whether from colorless to colored, from colored to colorless or from one color to another color.

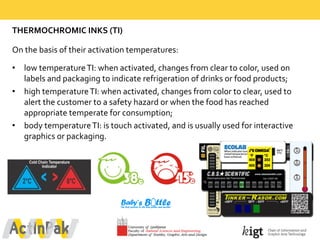

- 27. THERMOCHROMIC INKS (TI) On the basis of their activation temperatures: • low temperature TI: when activated, changes from clear to color, used on labels and packaging to indicate refrigeration of drinks or food products; • high temperature TI: when activated, changes from color to clear, used to alert the customer to a safety hazard or when the food has reached appropriate temperate for consumption; • body temperature TI: is touch activated, and is usually used for interactive graphics or packaging.

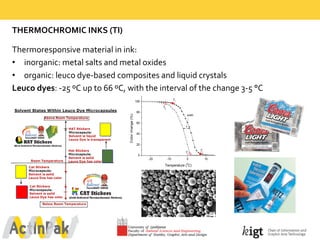

- 28. THERMOCHROMIC INKS (TI) Thermoresponsive material in ink: • inorganic: metal salts and metal oxides • organic: leuco dye-‐based composites and liquid crystals Leuco dyes: -‐25 ºC up to 66 ºC, with the interval of the change 3-‐5 °C -20 -10 0 10 0 20 40 60 80 100 T4 T3 T2 Color change (%) Temperature ( 0 C) T1 width

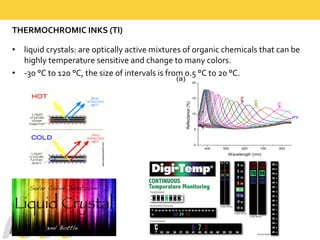

- 29. THERMOCHROMIC INKS (TI) • liquid crystals: are optically active mixtures of organic chemicals that can be highly temperature sensitive and change to many colors. • -‐30 °C to 120 °C, the size of intervals is from 0.5 °C to 20 °C. 400 500 600 700 800 0 5 10 15 20 30 o C 29 o C 28 o C Reflectance (%) Wavelength (nm) (a) 27 o C

- 30. MAGNETIC INKS Used: magnetic ink character recognition for security documents; • to print self-‐healing batteries, electrochemical sensors and wearable, textile-‐ based electrical circuits; • antenna miniaturization (Co nanoparticles for patch antennas).

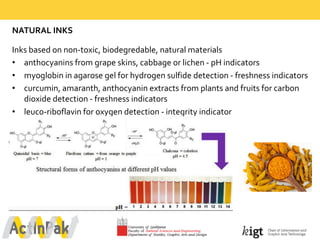

- 31. NATURAL INKS Inks based on non-‐toxic, biodegredable, natural materials • anthocyanins from grape skins, cabbage or lichen -‐ pH indicators • myoglobin in agarose gel for hydrogen sulfide detection -‐ freshness indicators • curcumin, amaranth, anthocyanin extracts from plants and fruits for carbon dioxide detection -‐ freshness indicators • leuco-‐riboflavin for oxygen detection -‐ integrity indicator

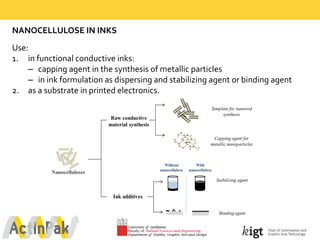

- 32. NANOCELLULOSE IN INKS Use: 1. in functional conductive inks: – capping agent in the synthesis of metallic particles – in ink formulation as dispersing and stabilizing agent or binding agent 2. as a substrate in printed electronics.

- 33. I

- 34. INTELLIGENT PACKAGING Benefits Considerations higher quality, safety of products, anti-‐ counterfeit price better management, distribution, tracebility consumers perceeption and legislative aspects consumer convenience technical limitations reducing the food waste more unsold products (food) excellent marketing tool and brand differentiation recyclability and environmental impact

- 35. INTELLIGENT PACKAGING IN ACTINPAK SHOWROOM

- 36. INTELLIGENT PACKAGING IN ACTINPAK SHOWROOM

- 37. References K.L. Yam, P.T. Takhistov, J. Miltz, Intelligent packaging: Concepts and applications, J. Food Sci. 70 (2005) 1-‐10. D. Restuccia, U.G. Spizzirri, O. Parisi, G. Cirillo, M. Curcio, F. Iemma, F. Puoci, G. Vinci, N. Picci, New EU regulation aspects and global market of active and intelligent packaging for food industry applications, Food Control 21 (2010) 1425-‐1435. C.E. Realini, B. Marcos, Active and intelligent packaging systems for a modern society, Meat Sci. 98 (2014) 404-‐419. M. Ghaani, M. Cozzolino, C.A. Castelli, G.S. Farris, An overview of the intelligent packaging technologies in the food sector, Trends Food Sci. Tech. 51 (2016) 1-‐11. S.J. Lee, A.T.M. Mijanur Rahman, Intelligent Packaging for Food Products, in: J.H. Han (Eds.), Innovations in Food Packaging, Elsevier, Amsterdam, 2014, 171-‐203. S.A. Hogan, J.P. Kerry, Smart packaging of meat and poultry products, in: J. Kerry, P. Butler (Eds.), Smart Packaging Technologies for Fast Moving Consumer Goods, 2008, 33-‐59. A. Pekarovicova, Graphic and Functional Inks, Recent Advances in Electrical Engineering and Computer Science, in: Proceedings of the 13th International Conference on Electronics, Hardware, Wireless and Optical Communications (EHAC '15), Seoul, South Korea, 2015, 13-‐21 M. Ferrara, M. Bengisu, Materials that Change Color: Smart Materials, Intelligent Design, Springer, 2014. http://www.bakeryandsnacks.com/Processing-‐Packaging/Smart-‐packaging-‐event-‐draws-‐industry-‐and-‐government-‐experts http://iot-‐spain.com/?p=3504&lang=en http://www.fdbusiness.com/intelligent-‐packaging-‐sends-‐alerts-‐when-‐food-‐is-‐spoiled/ http://freshpoint-‐tti.com.keam.co.il/article/time-‐temperature-‐integrators-‐the-‐current-‐technology-‐and-‐future-‐developments-‐.aspx http://www.oxysense.com/portable-‐oxygen-‐analyzer.html http://www.packaging-‐gateway.com/contractors/brand-‐protection/arjo-‐solutions/arjo-‐solutions2.html http://www.rfid-‐ready.com/rfid-‐reader/writer.html https://en.wikipedia.org/wiki/Barcode http://skyrfid.com/RFID_Label_Tag.php http://www.sciencedirect.com/science/article/pii/S0924224415301163 https://www.slideshare.net/Sudama04/biosensor-‐33928243 http://pakbec.blogspot.si/2008/08/crise-‐de-‐la-‐listeria-‐lemballage.html http://www.telatemp.com/p/470/reversible-‐humidity-‐indicator-‐card-‐AEC826004NE http://www.mgc.co.jp/eng/products/abc/ageless/eye.html http://www.ripesense.co.nz/ https://www.packworld.com/article/food/proteins/smart-‐label-‐sensor-‐gives-‐superior-‐results http://slideplayer.com/slide/4685866/ http://www.tiptemp.com/Products/Time-‐Temperature-‐Labels/THGSEN006-‐Temperature-‐Label-‐Monitor-‐Mark-‐Model-‐9860C-‐50F-‐10C-‐48Hrs.html http://cerig.pagora.grenoble-‐inp.fr/memoire/2017/bacteria-‐detector-‐label.htm http://cmuscm.blogspot.si/2014/09/inventory-‐management-‐of-‐perishable-‐items.html http://vitsab.com/index.php/en/tti-‐label/ https://nejilock.sg/product-‐list/electroluminescent-‐materials/ https://vorbeck.com/

- 38. References http://soken-‐asia.com/en/product/OCM/verazol_ht/index.html https://www.plasticsportal.net/wa/plasticsEU~tr_TR/portal/show/common/content/literature/plastics/0110/plastics_0110_focus_packaging_label_shows_freshness http://www.idtechex.com/printed-‐electronics-‐europe-‐15/photos.asp http://www.techprintinc.com/index.html https://www.plusplasticelectronics.com/retail/exclusive-‐printed-‐electronics-‐pack-‐enables-‐intelli http://www.print-‐electronic.com/news-‐media-‐gallery.html http://www.prelonic.com/technology/printed.html http://blog.drupa.com/de/printed-‐electronics-‐for-‐interactive-‐packaging/ https://www.rfidjournal.com/purchase-‐access?type=Article&id=4248&r=%2Farticles%2Fview%3F4248 http://www.foodqualitynews.com/R-‐D/Food-‐safety-‐goes-‐digital-‐with-‐time-‐temperature-‐sensor Andreas Schaller: workshopandreasschaller2010-‐2011-‐130427124550-‐phpapp02.pdf http://www.nanalyze.com/2014/04/a-‐flexible-‐battery-‐from-‐blue-‐spark-‐technologies/ http://www.ccieurolam.com/en/printed-‐electronics-‐inks http://thermochromic.ink/ https://mods-‐n-‐hacks.gadgethacks.com/news/friday-‐fresh-‐make-‐your-‐own-‐electroluminescent-‐ink-‐more-‐0122468/ P. Willaert, OrgaconTM Conductive Inks. From our lab to your fab, Hightech printing technology, VIGC, Antwerpen, 25. 11. 2016. http://www.packaging-‐gateway.com/news/news-‐cti-‐launches-‐photochromic-‐inks-‐4337535 http://www.thedieline.com/blog/2015/1/15/concepts-‐we-‐wish-‐were-‐real http://graphicproducts.weebly.com/smart-‐materials-‐amp-‐inks.html http://www.aist.go.jp/aist_e/list/latest_research/2011/20110202/20110202.html http://www.mdpi.com/1996-‐1944/3/12/5029 http://www.packagingnews.com.au/news/photochromic-‐first-‐for-‐flexible-‐packaging https://solarcolordust.com/products/liquid-‐crystal-‐thermochromic-‐ink-‐3ml-‐bottle https://www.hallcrest.com/products/industrial-‐temperature-‐monitoring-‐labels/reversible/digitemp-‐standard-‐portfolio https://measuretech.com.au/food-‐safety-‐temperature-‐measurement/346-‐cold-‐chain-‐temperature-‐indicator.html http://www.foodengineeringmag.com/articles/96675-‐automated-‐temperature-‐monitoring-‐and-‐control-‐ensure-‐food-‐safety http://www.yankodesign.com/2009/02/05/not-‐too-‐hot-‐not-‐too-‐cold-‐just-‐right/ http://www.colourchange.com/case-‐studies.php?case=metz https://www.asiapapermarkets.com/huhtamaki-‐unveils-‐adtone-‐cup-‐with-‐digital-‐content/ Maja Jakovljević, Branka Lozo and Marta Klanjšek Gunde, Spectroscopic evaluation of the colour play effect of thermochromic liquid crystal printing inks, Color. Technol. 133 (2017) 81–87 http://www.printedelectronicsworld.com/articles/10181/magnetic-‐ink-‐to-‐print-‐self-‐healing-‐devices-‐that-‐heal-‐in-‐record-‐time http://onlinewww.jpier.org/PIER/pier127/23.12031408.pdf Smithers Pira: Thermochromic inks and reducing household food waste, <www.wrap.org.uk/food/>

- 39. THANK YOU FOR YOUR ATTENTION!