Thrust Journal Bearing Failure Hepling presentation.pdf

- 1. Sin 0 Cos 0 0 0-1 0-2 0-3 0-4 0-5 0-6 0-7 0-8 0-9 1 10 09 08 07 06 05 04 03 02 01 00 10 20 30 40 50 60 70 80 Oil level 0-deg. J I A P2 P2 H P1 O F B Thrust Bearing LEVELING PLATE SET SCREW BASE RING LOWER LEVELING PLATE UPPER LEVELING PLATE THRUST SHOE ASSEMBLY BASE RING KEY COLLAR BASE RING KEY SCREW BASE RING DOWEL JOURNAL SHOE JRL SHOE STOP PIN RETAINING PLATE SCREW RETAINING PLATE ALIGNING RING RETAINING PLATE RETAINING PLATE SCREW RETAINING PLATE JOINT SCREW RETAINING PLATE JOINT DOWEL ALIGNING RING ANTI-ROTATION PIN Journal Bearing A GENERAL GUIDE TO THE PRINCIPLES, OPERATION AND TROUBLESHOOTING OF HYDRODYNAMIC BEARINGS

- 2. 2 K Table Of Contents Preface Introduction History Typical Applications Section I Hydrodynamic Bearings Hydrodynamic Principle Basic Pivoted Shoe Thrust (& Journal) Parts Related Parameters Operation And Monitoring Section II Introduction Discussion Base Ring Leveling Plates Shoe Support Shoe Body Shoe Surface Collar/Runner/Journal Surface Oil Operational Data Recommended Reading and References 3 4 6 7 7 9 10 15 15 13 15 15 15 16 16 24 24 25 26

- 3. K Preface 3 During every second of every day, machines all over the world are working to provide the products we demand. These machines rely on the successful support of bearings. If a machine goes off line, extreme pressure is placed on those involved to correct the problem(s). It is the intention of this presentation to assist the reader in problem solving by providing background information on hydro-dynamic bearings and distress modes. INTRODUCTION Bearings which support rotating shafts can be classified into four basic categories: Rolling contact – load supported by balls or rollers. Hydrostatic – load supported by high pressure fluid. Hydrodynamic – load supported by a lubricant film. Magnetic – load supported by magnetic fields. This guide contains information on hydrodynamic, pivoted shoe bearings using oil as a lubricant. However, much of the information can be applied to hydrodynamic bearings in general. Section I describes the principles, parts, related parameters and operation of the bearing in order to provide a base for a better understanding of Section II. Section II provides an overview of a structured troubleshooting approach, with information on distress modes and recommended repair. Holtwood Generating Station (See page 4)

- 4. 4 K Preface HISTORY In the late 1880s, experiments were being conducted on the lubrication of bearing surfaces. The idea of “floating” a load on a film of oil grew from the experiments of Beauchamp Tower and the theoretical work of Osborne Reynolds. PIVOTED SHOE THRUST BEARINGS (Fig. 1) Prior to the development of the pivoted shoe thrust bearing, marine propulsion relied on a “horseshoe” bearing which consisted of several equally spaced collars to share the load, each on a sector of a thrust plate. The parallel sur- faces rubbed, wore, and produced considerable friction. Design unit loads were on the order of 40 psi. Comparison tests against a pivoted shoe thrust bearing of equal capacity showed that the pivoted shoe thrust bearing, at only 1/4 the size, had 1/7 the area but operated successfully with only 1/10 the frictional drag of the horseshoe bearing. In 1896, inspired by the work of Osborne Reynolds, Albert Kingsbury conceived and tested a pivoted shoe thrust bearing. According to Dr. Kingsbury, the test bearings ran well. Small loads were applied first, on the order of 50 psi (which was typical of ship propeller shaft unit loads at the time). The loads were gradually increased, finally reaching 4000 psi, the speed being about 285 rpm. FIRST APPLICATION In 1912, Albert Kingsbury was contracted by the Pennsylvania Water and Power Company to apply his design in their hydroelectric plant at Holtwood, PA. The existing roller bearings were causing extensive down times (several outages a year) for inspections, repair and replacement. The first hydrodynamic pivoted shoe thrust bearing was installed in Unit 5 on June 22, 1912. At start-up of the 12,000 kW unit, the bearing wiped. In resolving the reason for failure, much was learned about Figure 1 Hydrodynamic, Equalizing Pivoted Shoe Thrust Bearing

- 5. K Preface tolerances and finishes required for the hydro- dynamic bearings to operate. After properly finishing the runner and fitting the bearing, the unit ran with continued good operation. This bearing, owing to its merit of running 75 years with negligible wear under a load of 220 tons, was designated by ASME as the 23rd International Historic Mechanical Engineering Landmark on June 27, 1987. JOURNAL BEARINGS The cylindrical hydrodynamic journal bearing is the most basic hydrodynamic bearing. It has a cylindrical bore, typically with two axial grooves for lubrication. This bearing has a high load capacity, and the simple design is compact, bi-rotational, and easy to manufacture. However, as the design speeds of machines increased, it was found that this bearing had limitations due to oil whirl. Oil whirl is very undesirable because of high vibration amplitudes, forces, and cyclic stresses that are imposed on the shaft, bearings and machine. Efforts to suppress and eliminate oil whirl have resulted in a variety of fixed geometry bearings which are modifications to the profile of the bearing bore. Variations are the lemon bore, pressure dam, lobed, and other fixed profile bearings. The pivoted shoe concept (Fig. 2) was first applied to journal bearings approximately seventy-five years ago. Extensive tests and applications have proved the pivoted shoe jour- nal bearing to be most effective in eliminating oil whirl. 5 Figure 2 Hydrodynamic Pivoted Shoe Journal Bearing

- 6. 6 K Preface TYPICAL APPLICATIONS Early history had proven that hydrodynamic pivoted shoe bearings provided considerable benefits. They were smaller, less expensive, required less maintenance, lasted longer, and were more efficient. The oil film also provided additional benefits in regard to shock absorbing capability, and allowed damping as a design parameter to control vibration. These considerable benefits allowed the design to be used in a wide variety of applications. Indeed, the invention made it possible to build the high-tech machines and ships of today. Figure 3 Hydrodynamic Pivoted Shoe Thrust and Journal Bearing INDUSTRIAL APPLICATIONS Hydroelectric Generators Hydraulic Turbines Steam Turbines Gas Turbines Dredge Pumps Boiler Feed Pumps High Speed Blowers Centrifugal Compressors Electric Motors Deep Well Pumps Oil Pumps Cooling Pumps Pulp Refiners Turbochargers Air Preheaters Rock Crushers Extruders SHIPBOARD APPLICATIONS Main Propeller Journals Propeller Line Shaft Turbine-Generator Sets Main Gear Box Clutch Pumps Blowers Auxiliary Machinery

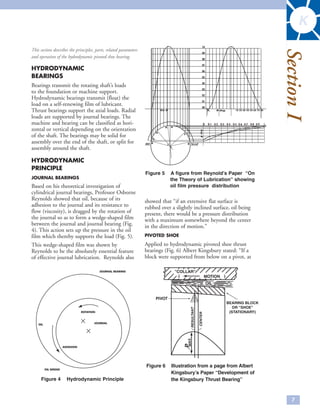

- 7. This section describes the principles, parts, related parameters and operation of the hydrodynamic pivoted shoe bearing. HYDRODYNAMIC BEARINGS Bearings transmit the rotating shaft’s loads to the foundation or machine support. Hydrodynamic bearings transmit (float) the load on a self-renewing film of lubricant. Thrust bearings support the axial loads. Radial loads are supported by journal bearings. The machine and bearing can be classified as hori- zontal or vertical depending on the orientation of the shaft. The bearings may be solid for assembly over the end of the shaft, or split for assembly around the shaft. HYDRODYNAMIC PRINCIPLE JOURNAL BEARINGS Based on his theoretical investigation of cylindrical journal bearings, Professor Osborne Reynolds showed that oil, because of its adhesion to the journal and its resistance to flow (viscosity), is dragged by the rotation of the journal so as to form a wedge-shaped film between the journal and journal bearing (Fig. 4). This action sets up the pressure in the oil film which thereby supports the load (Fig. 5). This wedge-shaped film was shown by Reynolds to be the absolutely essential feature of effective journal lubrication. Reynolds also showed that “if an extensive flat surface is rubbed over a slightly inclined surface, oil being present, there would be a pressure distribution with a maximum somewhere beyond the center in the direction of motion.” PIVOTED SHOE Applied to hydrodynamic pivoted shoe thrust bearings (Fig. 6) Albert Kingsbury stated: “If a block were supported from below on a pivot, at 7 K Section I JOURNAL BEARING OIL WEDGE ADHESION OIL ROTATION JOURNAL Figure 4 Hydrodynamic Principle 10 09 08 07 06 05 04 03 02 01 00 10 20 30 40 50 60 70 80 Oil level 0-deg. Sin 0 Cos 0 J I A P2 P2 H P1 O F B Figure 5 A figure from Reynold’s Paper “On the Theory of Lubrication” showing oil film pressure distribution Figure 6 Illustration from a page from Albert Kingsbury’s Paper “Development of the Kingsbury Thrust Bearing”

- 8. 8 K Section I about the theoretical center of pressure, the oil pressures would automatically take the theoretical form, with a resulting small bearing friction and absence of wear of the metal parts. In this way a thrust bearing could be made with several such blocks set around in a circle and with proper arrangements for lubrication.” The same concept applies to the pivoted shoe journal bearing. As with the plain cylindrical bearing, the pivoted shoe thrust and journal bearings rely on adhesion of the lubricant to provide the film with a self-renewing supply of oil. BASIC PIVOTED SHOE THRUST (& JOURNAL) PARTS (See Fig. 7) This section discusses the associated thrust bearing parts, with corresponding journal bearing information in parenthesis. ROTATING COLLAR (JOURNAL) The collar transmits the thrust load from the rotating shaft to the thrust shoes through the lubricant film. It can be a separate part and attached to the shaft by a key and nut or shrink fit, or it may be an integral part of the shaft. The collar is called a runner in vertical machines. (In the radial direction, the shaft journal transmits the radial loads to the journal shoes through the lubricant film.) In hydrodynamic bearings, the fluid film is on the order of .025 mm (.001”) thick. With this and the information from HYDRODYNAMIC PRINCIPLE, two points can be realized: 1. The stack-up of tolerances and misalign- ment in hydrodynamic bearings has to be less than .025 mm (.001”), or some means of adjustment has to be incorporated. 2. The collar surfaces must be flat and smooth (and journal surface cylindrical and smooth) in comparison to the film thickness, but not so smooth as to inhibit the adhesion of the lubricant to the surface. THRUST SHOE (JOURNAL SHOE) ASSEMBLY The shoe (also called a pad, segment, or block) is loosely constrained so it is free to pivot. The shoe has three basic features - the babbitt, body, and pivot, and so is usually referred to as an assembly. BABBITT The babbitt is a high-tin material, metallurgically bonded to the body. As with the collar, the babbitt surface must be smooth and flat in comparison to the film thickness. The babbitt is a soft material (compared to the shaft) which serves two functions: It traps and imbeds contaminants so that these particles do not heavily score or damage the shaft. It also protects the shaft from extensive damage should external conditions result in interruption of the film and the parts come in contact. BODY The shoe body is the supporting structure which holds the babbitt and allows freedom to pivot. The material is typically steel. Bronze is sometimes used (with or without babbitt) depending on the application. Chrome copper is used to reduce babbitt tem- perature. PIVOT The pivot allows the shoe to rotate and form a wedge. It may be integral with the shoe body, or be a separate insert. The pivot surface is spherical to allow 360˚ rolling freedom. BASE RING (ALIGNING RING) The base ring loosely holds and constrains the shoes against rotating so as to allow freedom to pivot. It may have passages for the supply of lubricant, and contain features to adapt for misalignment and tolerance in the parts. The base ring (aligning ring) is keyed or doweled to the housing to prevent rotation of the bearing assembly. LEVELING PLATES The leveling plates (not applicable to journal bearings) are a series of levers designed to

- 9. K Section I 9 Figure 7 Thrust and Journal Bearing Part Schematic

- 10. 10 K Section I compensate for manufacturing tolerances by distributing the load more evenly between thrust shoes. The leveling plates compensate for minor housing deflections or misalignment between the collar and the housing’s support- ing wall. A description is given later under the section on misalignment. LUBRICANT The lubricant is another important “element” of the bearing (See Fig 8-1). The loads are transmitted from the shaft to the bearing through the lubricant which separates the parts and prevents metal-to-metal contact. The lubricant also serves to carry heat caused by friction out of the bearing. RELATED PARAMETERS TOLERANCE, ALIGNMENT AND EQUALIZATION In a machine, alignment and load distribution are not perfect because of manufacturing tolerances in the housing, shaft and bearing elements. There are three areas of concern: 1. The squareness of the collar (and parallelism of the journal) to the axis of the shaft which is assembled to, or machined on the shaft. 2. The alignment of shaft with the bearing and housing, which is a manufacturing tolerance stack-up of the bearing parts and the housing bores and faces. 3. The alignment of shafts between machines which are aligned and coupled together on site. Misalignment of the shaft to the bearing and housing, and between machines is considered static misalignment and can be adjusted at assembly if proper design features are incorpo- rated. Other sources of misalignment termed dynamic misalignment are due to operating or changing conditions such as: thermal housing distortion, shaft deflection from imposed loads, movement caused by thermal expansion, move- ment caused by settling of foundations, pipe strain, etc. In pivoted shoe thrust bearings, static mis- alignment and manufacturing tolerances in the shoe height are accommodated by the leveling plates. Referring to Figure 8-2, the load transmitted by the rotating collar to any thrust shoe forces the shoe against the upper leveling plate behind it. If one shoe were slightly thicker than the others, the resulting higher film force bears the shoe down against the upper leveling plate. Each upper leveling plate is supported on one radial edge of each of two adjacent lower leveling plates. The lower leveling plates rock very slightly and raise the shoes on either side and so on around the ring. This feature also compensates for minor housing deflec- tions or misalignment between the housing’s supporting wall and the collar face. END PLAY AND RADIAL CLEARANCE End play is the axial thrust bearing clearance which is the distance the shaft can move between opposing thrust bearings. For journal bearings, the radial clearance is half the differ- ence of the journal bearing bore and journal diameter. End play and radial clearance are required to allow for misalignment, shoe movement, and thermal expansion of the parts. If set too tight, power is wasted. If too Figure 8-1 Pivoting Shoe Hydrodynamic Film Formation Figure 8-2 Thrust Bearing Load Equalization and Alignment Features

- 11. loose, the unloaded side shoes are too far from the shaft to develop a film pressure and can flutter causing damage to the unloaded shoes. Filler plates and shim packs provide a means for setting end play and axial positioning of the rotating elements. Adjusting screws are also used to accomplish this function. PRELOAD Preload pertains mostly to journal bearings and is a measure of the curvature of the shoe to the clearance in the bearing. The shoe cur- vature is another parameter which effects the hydrodynamic film, allowing design variations in bearing stiffness and damping to control the dynamics of the machine. The geometry and definition are given in Figure 9. LUBRICATION For hydrodynamic bearings to operate safely and efficiently, a suitable lubricant must always be present at the collar and journal surfaces. The lubricant needs to be cooled to remove the heat generated from oil shear, before re-entering the bearing. It must also be warm enough to flow freely, and filtered so that the average particle size is less than the minimum film thickness. Various methods are applied to provide lubri- cant to the bearing surfaces. The bearing cavities can be flooded with oil such as vertical bearings which sit in an oil bath. The bearings can also be provided with pressurized oil from an external lubricating system. The flow path of a horizontal, flooded pivoted shoe thrust bearing is shown in Figure10. For high speed bearings, the frictional losses from oil shear and other parasitic losses begin to increase exponentially as the surface speed enters a turbulent regime. The amount of lubricant required increases proportionately. Industry trends for faster, larger machines necessitated the design of lower loss bearings. This has been incorporated by the introduc- tion of other methods of lubrication. 11 K Section I Figure 9 Pivoted Shoe Journal Bearing Preload

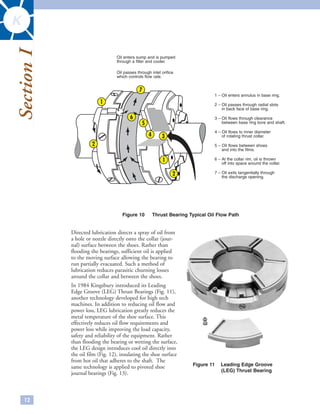

- 12. 1 – Oil enters annulus in base ring. 2 – Oil passes through radial slots in back face of base ring. 3 – Oil flows through clearance between base ring bore and shaft. 4 – Oil flows to inner diameter of rotating thrust collar. 5 – Oil flows between shoes and into the films. 6 – At the collar rim, oil is thrown off into space around the collar. 7 – Oil exits tangentially through the discharge opening. 12 K Section I Directed lubrication directs a spray of oil from a hole or nozzle directly onto the collar (jour- nal) surface between the shoes. Rather than flooding the bearings, sufficient oil is applied to the moving surface allowing the bearing to run partially evacuated. Such a method of lubrication reduces parasitic churning losses around the collar and between the shoes. In 1984 Kingsbury introduced its Leading Edge Groove (LEG) Thrust Bearings (Fig. 11), another technology developed for high tech machines. In addition to reducing oil flow and power loss, LEG lubrication greatly reduces the metal temperature of the shoe surface. This effectively reduces oil flow requirements and power loss while improving the load capacity, safety and reliability of the equipment. Rather than flooding the bearing or wetting the surface, the LEG design introduces cool oil directly into the oil film (Fig. 12), insulating the shoe surface from hot oil that adheres to the shaft. The same technology is applied to pivoted shoe journal bearings (Fig. 13). Figure 10 Thrust Bearing Typical Oil Flow Path Figure 11 Leading Edge Groove (LEG) Thrust Bearing Oil enters sump and is pumped through a filter and cooler. Oil passes through inlet orifice which controls flow rate.

- 13. COOLING SYSTEM A cooling system is required to remove the heat generated by friction in the oil. The housing may simply be air cooled if heat is low. Vertical bear- ings typically sit in an oil bath with cooling coils (Fig. 14), but the oil can also be cooled by an external cooling system as typical in horizontal applications. The heat is removed by a suitable heat exchanger. OPERATION AND MONITORING Under operation, the capacity of hydrodynamic bearings is restricted by minimum oil film thick- ness and babbitt temperature. The critical limit for low-speed operation is minimum oil film thickness. In high-speed operation, babbitt temperature is usually the limiting criteria. Temperature, load, axial position, and vibration monitoring equipment are used to evaluate the operation of the machine so that problems may be identified and corrected before catastrophic failure. 13 K Section I Figure 12 Leading Edge Groove Lubricant Flow Path. Figure 13 Leading Edge Groove (LEG) Journal Bearing

- 14. Of these, bearing health are commonly monitored through the use of temperature detectors. The temperature of the bearing varies significantly with operating conditions and also varies across and through the shoe. Therefore, for the measurement to be meaningful, the location of the detector must be known. The recommended location for a detector is termed the “75/75 location” on a thrust shoe face, i.e. 75% of the arc length of the shoe in the direction of rotation and 75% of the radial width of the shoe measured from the ID to the OD. In a journal bearing, sensor location should be 75% of the arc length on the center line of the shoes. This position represents the most critical area because it is the point where peak film pressures, minimum film thickness, and hot temperatures co-exist. 14 K Section I Figure 14 Vertical Thrust Bearing Oil Sump and Cooling Coils

- 15. K Section II INTRODUCTION This section of the paper presents an overview of a structured bearing troubleshooting approach. The approach is developed based on an understanding of bearing operation and the potential effects of related parameters. Of par- ticular interest are the rotating journal, collar, or runner, the babbitted shoe surface, all con- tact points within the bearing assembly, and the lubricating oil. Machine specific opera- tional and performance data must also be considered. The following approach can be used with all types of fluid-film bearings, but the discussion is centered on equalizing thrust bearings. These bearings contain the most moving parts and are widely used. The remarks made herein are readily adaptable to other fluid-film bear- ing types (i.e., non-equalizing thrust bearings, pivoted shoe journal bearings, journal shells). When evaluating bearing distress, the babbitted shoe surface is commonly the only area that is examined. Although a great deal of informa- tion can be extracted from the babbitt appear- ance, additional information exists elsewhere. These "secondary sources" of diagnostic infor- mation often prove to be very valuable, since the babbitted surfaces are usually destroyed in a catastrophic bearing failure. Even a bearing wipe, which is the most common appearance of distress, hides valuable information. The "textbook" cases of failure modes are especially useful prior to the damage that occurs when a bearing can no longer support an oil film. Through the prudent use of tem- perature and vibration monitoring equipment, routine oil analyses, lubrication system evalua- tions and machine operational performance reviews, bearing distress may be identified and evaluated before catastrophic failure occurs. Bearing health is commonly monitored through the use of temperature measurements. Be aware that temperature sensors are mounted in a wide variety of locations, with a correspond- ing variation in significance. The specific location and type of sensor must be known in order for the measured temperature data to have any real value. DISCUSSION To begin an evaluation, the bearing assembly should be completely disassembled. In this manner, all of the bearing components may be evaluated. Do not clean the bearing, since valuable information may be lost. BASE RING Examine the base ring. During routine opera- tion, the lower leveling plates (LLP) will form indentations in the base ring, on either side of the dowels that locate them. The indentations should be identical and barely noticeable. Deep, wide indentations are an indication of a high load. The rocking strip on the bottom of the LLP contacts the base ring, and its condition presents another indication of bearing load. The cleanliness of the bearing and oil can also be determined, since deposits are often trapped in the base ring. Evidence of water contamina- tion, particularly in vertical machines, may go unnoticed unless the base ring is examined. LEVELING PLATES The spherical pivot in the rear of each thrust shoe rests in the center of a flat area on the hardened upper leveling plate (ULP). This flat- tened area is susceptible to indentation due to the point contact of the pivot. The indentation is easily identified by a bright contact area. This area indicates where the shoe operates on the ULP, and its depth gives an indication of load. Close examination of the upper leveling plate near the contact area may also produce evidence of electrical pitting. As noted previously in SECTION I, the upper leveling plates interact with the lower leveling plates on radiused "wings." The upper leveling plates are typically hardened; the lower leveling plates are sometimes not. When new, the leveling plates have line contact. There is little friction between the wings, and the bearing can react quickly to load changes. Depending on the nature and magnitude of the thrust load, the wing contact area will increase in time. The contact region of the wings, again noted by bright areas, will normally appear larger on the lower leveling plates. If the rotat- ing collar is not perpendicular to the shaft axis, the leveling plates will continuously equalize, causing rapid wear. 15

- 16. 16 K Section II SHOE SUPPORT The shoe pivot is the hardened spherical plug in the rear face of each thrust shoe. Based on the magnitude and nature of the thrust loads, the spherical surface will flatten where it con- tacts the upper leveling plate. The contact area will appear as bright spot on the plug. If evi- dence of hard contact exists (a large contact spot), rest the shoes (pivot down) on a flat surface. If the shoes do not rock freely in all directions they should be replaced. The pivot can also appear to have random contact areas, indicating excessive end play, or it may be discolored, indicating lack of lubrication. SHOE BODY The shoe body should be periodically examined for displaced metal or pitting. Indentations routinely occur where the shoe contacts the base ring shoe pocket in the direction of rotation. Displaced metal exhibit- ing a coarse grain may indicate erosion damage; bright or peened spots may indicate unwanted contact. Depending upon the shape of the individual pits, pitting may indicate corrosion or undesirable stray shaft currents. SHOE SURFACE When evaluating the shoe surface, the first step is to determine the direction of rotation. This may be accomplished by evaluating: • Abrasion scratches • Discoloration (75-75 location) • Babbitt flow • Babbitt overlay • Thrust shoe/base ring contact Use caution when evaluating babbitt overlay (babbitt "rolled over" the edges of the shoes), since it may appear on both the leading and trailing shoe edges. NORMAL A healthy shoe will exhibit a smooth finish, with no babbitt voids or overlays. The dull grey finish of a brand new shoe may remain unchanged after many hours of operation, or it may appear glossy in spots or in its entirety. Routine thermal cycling of the bearing may cause the emergence of a mild "starburst" or mottled pattern in the babbitt. This is harmless, providing the shoe is flat and cracks do not exist. SCRATCHES Abrasion A bearing surface exhibiting circumferential scratches is the result of abrasion damage (Fig. 15). Abrasion is caused by hard debris, which is larger than the film thickness, passing through Figure 15 Thrust Shoe Surface Abrasion

- 17. K Section II the oil film. The debris may embed itself in the soft babbitt, exhibiting a short arc on the shoe surface, ending at the point where the debris becomes embedded. Depending on the debris size, the scratch may continue across the entire shoe surface. Abrasion damage becomes worse with time. Surface scratches allow an escape for lubricating oil in the oil wedge, decreasing the film thick- ness. This will eventually lead to bearing wipe. Another source of abrasion damage is a rough journal, collar or runner surface. Roughness may be due to previous abrasion damage. It may also be from rust formed after extended periods of down time. New bearings should not be installed when the rotating component is visibly damaged. Random scratches, which may run a staggered path both circumferentially and radially, are more likely to appear in the unloaded bearing or unloaded portion of the bearing. In a thrust bearing, it may indicate excessive end play (axial clearance). Random scratches may also indicate careless handling at installation or disassembly. In order to eliminate abrasion damage, the lubricating oil must be filtered. If the oil cannot be filtered or has degraded, it should be replaced. It is important to evaluate the filtering system, since the problem may be an incorrectly sized filter. The filter should only pass debris smaller in size than the predicted bearing minimum film thickness. In addition to filtering/replacing the oil, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The original bearing finish should also be restored. Journal shoes typically must be replaced, but if the correction leaves the bearing within design tolerance, the bearing may be reused. Although the babbitted surface is usually damaged more severely, the rotating collar or journal surface must also be evaluated. Debris partially lodged in the babbitt may score the steel surfaces.These surfaces must be restored by lapping or hand stoning. DISCOLORED Tin Oxide Damage This is one of several electrochemical reactions which eliminate the embedability properties of a fluid-film bearing. Tin oxide damage (Fig. 16) is recognizable by the hard, dark brown or black film that forms on the babbitt. Tin oxide forms in the presence of tin-based babbitt, oil and salt water, beginning in areas of high temperature and pressure. Once it has formed, it cannot be dissolved, and its 17 Figure 16 Tin Oxide Damage

- 18. 18 K Section II hardness will prevent foreign particles from embedding in the bearing lining. This allows abrasion damage to occur. Pieces of tin oxide may break off during operation and score the journal, collar, or runner. The formation of tin oxide will also eliminate bearing clearance. This damage may be stopped by eliminating some or all of the contributing elements. The lubricating oil must be replaced. A reduction in oil temperature may also discourage the formation of tin oxide. In addition to replacing the oil, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned with mineral spirits. The bearing shoes should be replaced. The condition of the rotating journal, collar or runner surfaces must also be evaluated. They must be restored to original condition, either by lapping, hand stoning or replacement. Overheating Overheating damage may represent itself in many ways, such as babbitt discoloration (Fig. 18), cracking, wiping or deformation. Repeated cycles of heating may produce thermal ratcheting (Fig. 17), a type of surface deformation that occurs in anisotropic materials. These materials possess different thermal expansion coefficients in each crystal axis. Overheating may be caused by numerous sources, many of which concern the quantity and quality of the lubricant supply. Among the possible causes are: • Improper lubricant selection • Inadequate lubricant supply • Interrupted fluid film • Boundary lubrication The following conditions may also cause overheating: • Improper bearing selection • HP lift system failure • Poor collar, runner or journal surface finish • Insufficient bearing clearance • Excessive load • Overspeed • Harsh operating environment Figure 17 Thermal Ratcheting Figure 18 Overheating, Oil Additives Plated Out

- 19. K Section II Verify that the quantity and quality of oil flowing to the bearing is sufficient. These values should be available from the bearing manufacturer. If thermal ratcheting has occurred, examine the shoes for the existence and depth of cracks. Remove the cracks and restore the original shoe surface. If this cannot be done, replace the shoes. Journal shoes typically must be replaced, but if the correction leaves the bearing within design tolerance, the bearing may be reused. The condition of the rotating journal, collar or runner surfaces must also be evaluated. It must be restored to original condition, either by lapping, hand stoning or replacement. Oil Starvation It is often possible to distinguish oil starvation (i.e. the total absence of lubricant) from a less than adequate oil flow by closely examining the babbitted surface of the bearing. In Fig. 19, the babbitt has been completely removed from the shoe surface. If there had been any oil flow to the bearing, it would have sufficiently cooled the region to allow the molten babbitt to at least solidify and accumulate between the shoes. With no oil coming in at the leading edge of the shoe, this area typically shuts down, resulting in the babbitt being eliminated in the corner near the outer diameter in Fig. 20. In combination assemblies, such as Kingsbury’s CH unit, the cut-off of oil supply will also lead to destruction of the journal shell, where the molten babbitt can pool in the lower half. The extreme temperatures in such cases can lead to the fusion of the oil circulator to the collar (see Fig. 21), which has no quench marks in this instance, prime evidence that no lubricant ever reached the parts. 19 Figure 19 Pivoted Shoe Showing Complete Babbitt Removal Figure 20 Outer Edge Babbitt Erosion

- 20. 20 K Section II VOIDS Hydrogen Blisters In certain occasions, hydrogen gas becomes trapped during the casting or forging of parts made of steel. If the steel base is babbitted and the gas eventually migrates to the surface, blisters can form in the area, significantly weakening the babbitt bond (see Fig. 22). Thermal annealing has been proven to prevent blisters from forming by diffusing out hydro- gen before the part is babbitted. In Figure 23, the annealing process was accidentally missed and large hydrogen blisters emerged during the machining process. Electrical Pitting Electrical pitting (Fig. 24) appears as rounded pits in the bearing lining. The pits may appear frosted, or they may be blackened due to oil deposits. It is not unusual for them to be very small and difficult to observe with the unaided eye. A clearly defined boundary exists between the pitted and unpitted regions, with the pit- ting usually occurring where the oil film is thinnest. As pitting progresses, the individual pits lose their characteristic appearance as they begin to overlap. Pits located near the bound- ary should still be intact. The debris that enters the oil begins abrasion damage. Once the bear- ing surface becomes incapable of supporting an oil film, the bearing will wipe. The bearing may recover an oil film and continue to oper- ate, and pitting will begin again. This process may occur several times before the inevitable catastrophic bearing failure. Electrical pitting damage is caused by intermit- tent arcing between the stationary and rotating machine components. Because of the small film thicknesses relative to other machine clearances, the arcing commonly occurs through the bearings. Although the rotating and other stationary members can also be affected, the most severe pitting occurs in the soft babbitt. Electrical pitting can be electrostatic or electromagnetic in origin. Although both Figure 22 Hydrogen Blisters In The Babbitt Figure 23 Large Hydrogen Blisters Figure 21 Oil Circulator Fused To Collar

- 21. K Section II sources result in pitting damage, they differ in origin and destructive capabilities. Electrostatic shaft current (direct current) is the milder of the two. Damage progresses slowly, and it always occurs at the location with the lowest resistance to ground. It can be attributed to charged lubricant, charged drive belts, or impinging particles. This type of shaft current can be eliminated with a grounding brushes or straps. Bearing isolation is also recommended. Electromagnetic shaft current (alternating current) is stronger and more severe than electrostatic current. It is produced by the magnetization of rotating and/or stationary components. This type of current will not always occur at the location of lowest resistance. Because the current is stronger, bearing damage is often accompanied by journal, collar or runner damage. Electromagnetic currents are best eliminated by demagnetizing the affected component. Grounding brushes or straps may or may not be helpful. The bearings should be isolated. The lubricating oil must be filtered or replaced. Pitting damage often blackens the oil and fills it with debris. In addition to filtering/replacing the oil, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. The original bearing finish should also be restored. Journal shoes typically must be replaced, but if the correction leaves the bearing within design tolerance, the bearing may be reused. The condition of the rotating journal, collar or runner surfaces must also be evaluated. It must be restored to original condition, either by lapping, hand stoning or replacement. Fatigue Fatigue damage (Fig. 25, 26, 27) may represent itself as intergranular or hairline cracks in the babbitt. The cracks may appear to open in the direction of rotation. Pieces of babbitt may spall out or appear to be pulled away in the direction of rotation. The cracks extend toward the babbitt bond line, and may reveal the shoe backing. A combination of causes contribute to fatigue damage, but concentrated cyclic loading is usually involved. The fatigue mechanism involves repeated bending or flexing of the bearing, and damage occurs more rapidly with poor bonding. It is important to note that fatigue damage will occur without poor bonding. Fatigue can occur when conditions produce concentrated cyclic loads, such as: • Misalignment • Journal eccentricity • Imbalance 21 Figure 24 Stray Shaft Currents/ Electrical Pitting (Frosting) Figure 25 Edge Load Pivoted Shoe Showing Babbitt Mechanical Fatigue

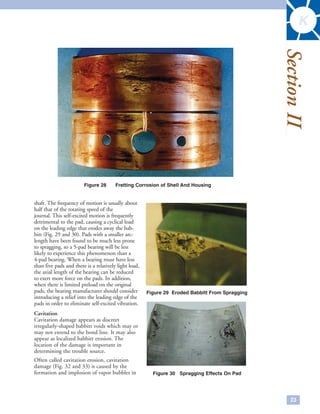

- 22. 22 K Section II • Bent shaft • Thermal cycling • Vibration Performance data should be reviewed to determine if a vibration increase occurred. The leveling plate wings should be examined for signs of excessive wear, indicating the rotating collar or runner is not perpendicular to the shaft axis. High bearing temperature may also be considered as a contributing factor to fatigue damage. As temperatures increase, the fatigue strength of bearing materials decrease. The lubricating oil must be filtered or replaced. In addition to filtering/replacing the oil, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Depending on the extent of damage, voids in the babbitt can be puddle-repaired. The original bearing finish must be restored. Journal shoes may also be puddle-repaired and refinished. If this cannot be done, the shoes must be replaced. Although the babbitted surface is usually damaged more severely, the rotating collar or journal surface must also be evaluated. This surface must also be restored to original condition, either by lapping or hand stoning. Fretting Corrosion Fretting, like fatigue, is due to a cyclical vibration, but it is normally due to minute oscillations between two non-rotating surfaces. Prime examples are the contact areas between shoe supports and leveling plates, journal bearing shells and the housing (see Fig. 28), and parts with an interference fit, such as the collar and shaft. As can be noted in the photograph, fretting corrosion is characterized by a red-orange iron oxide, which forms on the freshly “machined” steel surfaces. To reduce the risk of recurrence, the replacement parts should be adjusted to obtain a better fit that eliminates the oscillations. This journal shell had too much clearance between its outer diameter and the housing, which resulted in the typical orange-brown oxidation of the exterior surface of the bearing. Spragging In a tilting-pad journal bearing, the upper pads typically receive no load. These pads tend to float back and forth between the pivot point and the Figure 26 Edge Load Journal Shell With Babbitt Mechanical Fatigue Figure 27 Fatigue

- 23. K Section II shaft. The frequency of motion is usually about half that of the rotating speed of the journal. This self-excited motion is frequently detrimental to the pad, causing a cyclical load on the leading edge that erodes away the bab- bitt (Fig. 29 and 30). Pads with a smaller arc- length have been found to be much less prone to spragging, so a 5-pad bearing will be less likely to experience this phenomenon than a 4-pad bearing. When a bearing must have less than five pads and there is a relatively light load, the axial length of the bearing can be reduced to exert more force on the pads. In addition, when there is limited preload on the original pads, the bearing manufacturer should consider introducing a relief into the leading edge of the pads in order to eliminate self-excited vibration. Cavitation Cavitation damage appears as discreet irregularly-shaped babbitt voids which may or may not extend to the bond line. It may also appear as localized babbitt erosion. The location of the damage is important in determining the trouble source. Often called cavitation erosion, cavitation damage (Fig. 32 and 33) is caused by the formation and implosion of vapor bubbles in 23 Figure 28 Fretting Corrosion of Shell And Housing Figure 30 Spragging Effects On Pad Figure 29 Eroded Babbitt From Spragging

- 24. 24 K Section II areas of rapid pressure change. Damage often occurs at the outside diameter of thrust bear- ings due to the existence of higher velocities. This type of damage can also affect stationary machine components in close proximity to the rotor. Based on its source, cavitation can be eliminated in a number of ways: • Radius/chamfer sharp steps • Modify bearing grooves • Reduce bearing clearance • Reduce bearing arc • Eliminate flow restrictions (downstream) • Increase lubricant flow • Increase oil viscosity • Lower the bearing temperature • Change oil feed pressure • Use harder bearing materials The lubricating oil must be filtered or replaced. In addition to filtering/replacing the oil, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. Depending on the extent of damage, voids in the babbitt can be puddle-repaired. The original bearing finish must be restored. Journal shoes may also be puddle-repaired and refinished. If this cannot be done, the shoes must be replaced. Although the babbitted surface is usually dam- aged more severely, the rotating collar, runner or journal surface must also be evaluated. This surface must also be restored to original condition, either by lapping or hand stoning. Erosion Erosion damage may appear as localized bab- bitt voids with smooth edges, particularly in the direction of rotation. Damage is more likely to occur in stationary members. As a rule of thumb, if the babbitt has been affected, the cause was cavitation damage, not erosion. Since erosion is caused by sudden obstructions in oil flow, it is more likely to occur in other areas, since the babbitt is under high pressure. Once damaged, however, babbitt erosion may occur. Corrective action is similar to that employed in eliminating cavitation damage, with the emphasis on streamlining oil flow through the bearing. Figure 33 Cavitation Damage on Outside Diameter of Collar Figure 32 Thrust Shoe Cavitation Towards Outside Diameter

- 25. Corrosion Corrosion damage (Fig. 34) is characterized by the widespread removal of the bearing lining by chemical attack. This attack produces a latticework appearance. The damage may be uniform with the affected elements being "washed away," leaving the corrosion resistant elements behind. Corrosion may also affect the rotating collar, run- ner or journal, appearing as random, widespread rust or pitting. The pits are easily distinguished from electrical pitting, since they are not as uniform or smooth-bottomed. Corrosive materials may appear in the lubricating oil through: • Decomposition of oil additives • Acidic oxidation products formed in service • Water or coolant in lube oil • Direct corrosive contamination Bearing housing seals, oil additive packages, and oil reservoir operating temperatures should be evaluated as an initial step in eliminating corrosion. The integrity of cooling coils should also be examined. The cause of corrosion is best detected by knowledge of the babbitt composition and an oil analysis. Corrosion can be eliminated by replacing the lubricating oil. In addition, the entire bearing assembly, oil reservoir and piping should be flushed and cleaned. If the original bearing finish cannot be restored, the bearing must be replaced. The rotating collar, runner or journal surface must also be evaluated and restored to original condition, either by lapping or hand stoning. COLLAR/RUNNER/JOURNAL SURFACE The most commonly overlooked bearing component is the collar. It is the single most important part of the bearing. Collar rotation draws oil into the region between the collar and shoe surfaces. Oil adheres to the collar and is pulled into pressurized oil wedges. This occurs due to the collar surface finish. If the collar finish is too smooth (better than 12 RMS), it will not move an adequate supply of oil; too rough, and the bearing shoes will be damaged. Ideally the finish should be between 12 - 16 RMS. Each time a bearing is inspected, the collar should be inspected and worked as necessary. Glossy areas on the collar can easily be removed by hand scrubbing with a soft 600 grit oilstone. Collars with significant operating time may have lost their original surface flatness. This flatness, as well as the surface finish, should be restored. If a split runner is used, it should be separated into halves and evaluated. Relative motion between the halves will result in fretting damage to the runner, as well as potential cavitation-like damage to the bearing surfaces. It is very important that the collar faces be parallel, and perpendicular to the centerline of the shaft. Figure 34 Example of Bearing Corrosion K Section II 25

- 26. 26 K Section II If the collar is not within tolerance, the resul- tant "wobble" (Fig. 36) will force the shoes and leveling plates to constantly equalize, caus- ing rapid leveling plate wear. OIL A quick visual examination of the oil or oil filter may be all that is required to determine that a problem exists and that further investi- gation is necessary. Cloudy or discolored oil indicates that a problem exists. A thorough oil analysis can provide very useful data to assist in diagnosing bearing or machine distress. Be aware that the usefulness of the analysis is directly related to the information you request. As a minimum, the following should be supplied: • Particulate density • Particulate breakdown • Viscosity • Water contamination • Chemical breakdown The amount of particulate, as well as its content, can identify potential trouble spots. Oil viscosity will decrease in time, and whether or not distress is suspected, it should be periodically evaluated. Water contamination is extremely unwanted, since it can cause rust and oil foaming, and if it is drawn into the oil film, bearing failure. A chemical breakdown of the oil will help to determine the integrity of additive packages and the presence of unwanted contaminants. OPERATIONAL DATA Perhaps the most important source of diagnostic information is unit operational data. Identifying periods of load or speed changes, recent maintenance, pad temperature and vibration level trends, or the performance of related machinery may also help determine the root cause of distress. Vibration data or an analysis may help discover existing problems, as well as examining the remaining bearings in a troubled unit. AFTERMARKET SUPPORT Kingsbury operates aftermarket support facili- ties capable of inspecting and evaluating all makes, models, and types of fluid-film thrust and journal bearing designs. In most cases, Kingsbury is able to provide an evaluation and recommended repair, replacement, or performance upgrade at no charge and no Figure 36 Leveling Plate Wear Due To Collar Wobble

- 27. K References commitment to the customer. In addition, Kingsbury Field Service Technicians and Engineers are available to assist either in person or by phone and other means of communication. Please visit our website www.kingsbury.com for further details. References 1. Sohre, J.S., and Nippes, P.I., "Electromagnetic Shaft Currents and Demagnetization on Rotors of Turbines and Compressors", Proceedings of the Seventh Turbomachinery Symposium (1978) Recommended Reading and References "Practical Machinery Management for Process Plants", Bloch & Geitner, Volume 2, Gulf Publishing Company "Thermal Aspects of Fluid Film Tribology", Oscar Pinkus, ASME Press "Theory and Practice of Lubrication for Engineers", by Dudley D. Fuller, Wiley & Sons, Inc. EPRI GS-7352 Project 1648-10 Final Report "Manual of Bearing Failures and Repair in Power Plant Rotating Equipment", MTI 27

- 28. 10385 Drummond Road Philadelphia, PA 19154 Telephone: +1 215-824-4000 Fax: +1 215-824-4999 www.kingsbury.com Repair & Service Division East Coast 3615 Davisville Road Hatboro, PA 19040 Toll Free: (866) 581-5464 West Coast 219 Burns Drive Yuba City, CA 95993 Telephone: (801) 546-6373 Publication HB Printed in USA 3/15