Kérjük, válasszon kiszállítási helyet

Az ország/régió kiválasztása befolyásolhatja az árat, a szállítási lehetőségeket és a termékválasztékot.Ön elhagyja az alábbi oldalt: igus.hu

Az ország/régió kiválasztása befolyásolhatja az árat, a szállítási lehetőségeket és a termékválasztékot.Az oldalak váltása esetén igyekszünk megfeleltetni a jelenleg a kosárban található termékeket az adott ország termékkínálatával.Kérjük, a váltás után ellenőrizze kosarának tartalmát.

Kapcsolattartóm

igus® Hungária Kft.- iroda

The igus® Robot Control software

Programming - simulating - controlling robots free of charge and license-free

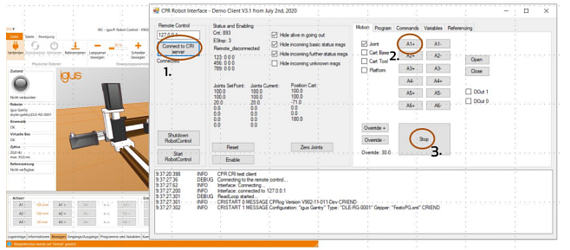

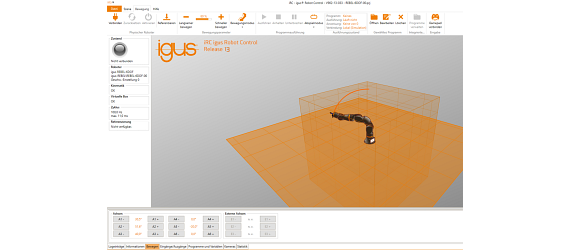

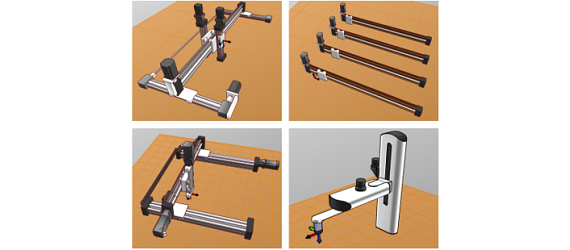

igus® Robot Control enables simple and intuitive robot programming and control and an easy entry into automation. Due to the modular design, different robot kinematics can be controlled, e.g. delta robots, linear robots and multi-axis joint robots. The software can be used to simulate the individual movements of the robot on the 3D interface - the robot does not need to be connected for this step.Introduction to automation with the intuitive robot software as freeware

- Simple connection between robot and control system

- Intuitive operation with a 3D surface and digital twin enables direct execution and checking of the movement sequences

- Camera interface configuration directly via control system and software possible

- Programming of delta, linear robot, SCARA and articulated arm robots

- Free software enables risk-free testing

System requirements:

- PC with Windows 10 operating system

- Communication via Ethernet or WLAN

- 500MB free disk space

Try free software now

Interfaces

PLC interfaces

The PLC interface enables the execution of basic functions and the signalling of states by means of digital inputs and outputs. In addition to the control by a PLC, this interface also allows operation by hardware buttons.To the SPS Wiki

Digital inputs & outputs

Robot programs can be loaded and started and gripper commands can be sent via digital inputs or global signals. This is useful, for example, if a program is to be selected from a given selection using buttons or the CRI-GSig instruction.To the I/O Wiki

Modbus TCP/IP

For example, PLCs can send data and instructions to the robot control system and receive status information via the Modbus TCP interface.To the TCP/IP Wiki

CRI interface

The CRI interface enables complex instructions to be sent and information and settings to be retrieved via the Ethernet interface via TCP/IP. iRC uses this interface to connect to robots with integrated control systems or other instances of iRC.To the CRI Wiki

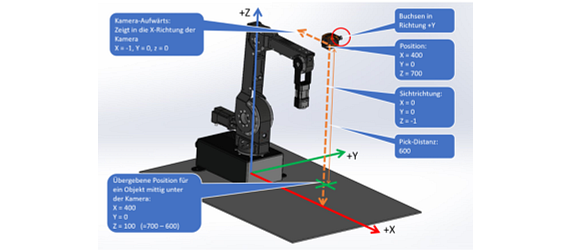

Camera interface

The camera interface allows the use of object detection and video cameras. Object detection cameras recognise the position and class of objects and transmit them, optionally with a video image, to the control system. The control system calculates positions in the robot coordinate system from the object positions of the camera. Pure video cameras only deliver images and can therefore only be used to observe the work area, but not for object detection.To the Wiki

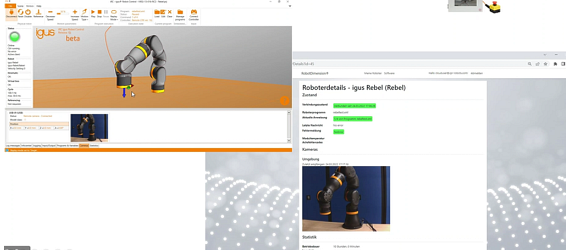

Cloud

The Cloud interface enables the robot to be monitored via RobotDimension. After activation and login, the robot sends basic status information and camera images to the online service. On the website, the user can list his robots and call up the information.

ROS, Matlab, LabView, and many more.

Integrate the robots into your ROS environment. Documentation and packages for hardware communication, Teleop and moveITo the sample programs

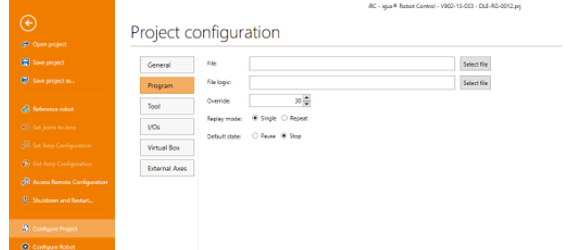

Project configurations

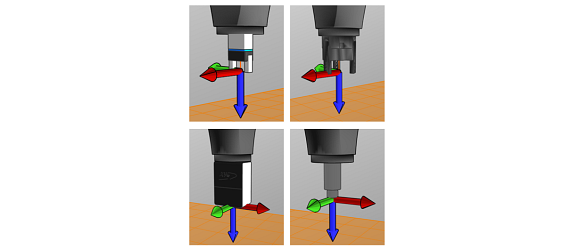

Gripper

The installed tool can be specified here. Changing the tool requires reloading the project or restarting the integrated control system. New tools can be defined as a configuration file in the "Data/Tools" directoryTo the I/O Wiki

Virtual box

The virtual box settings limit the range of movement of the robot arm. This functionality helps to avoid mechanical damage and simplifies programming according to the application. If a program is executed that violates the virtual box, it is stopped with an error message.To the Virtual Box Wiki

External axes

The robot control system supports up to three additional axes (also called "external axes" in iRC). These can be installed according to the robot axes and configured via the configuration area of iRC.Go to the External Axes Wiki

Programs

Here you can set the robot and logic program, the movement speed (as a percentage of the maximum speed), the playback mode and the reaction to program errors.

Special kinematics

The robot control system can be individually configured for your robot with a digital twin. We configure the inverse kinematics to suit your project business.

Programming

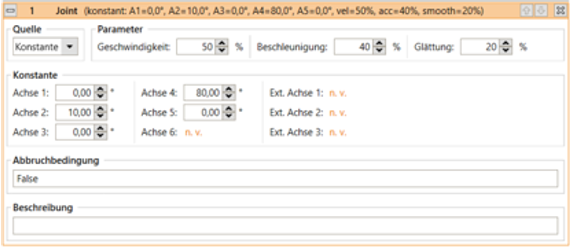

Axis movements

The Joint command moves the robot to an absolute target position specified in axis coordinates (e.g. axis angle or position of a linear axis). The resulting movement of the TCP is usually a curve and not a straight line.

Linear movement

The Linear command moves the robot to an (absolute) target position specified in Cartesian coordinates. The resulting movement of the TCP follows a straight line.

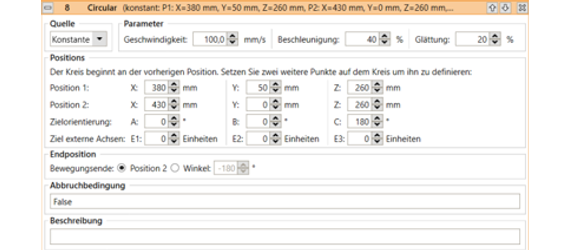

Circular movements

The Circular Movement instruction enables movements along a full or partial circle. It is compatible with linear movements, so that the transition from and to linear movements can be smoothed over.

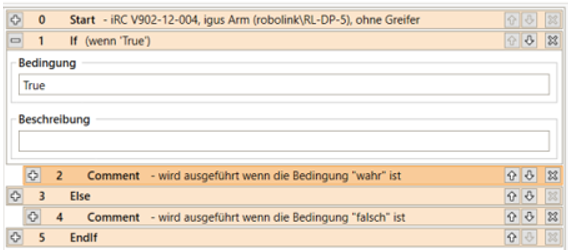

Conditions

Conditions can be used in if-then-else commands, loops and as termination conditions in movement commands. The conditions can be combinations of digital inputs, global signals, Boolean operations and comparisons.

Matrix calculation

The grid instructions calculate positions that are aligned with a grid, e.g. as gripping or depositing positions for palletising tasks.

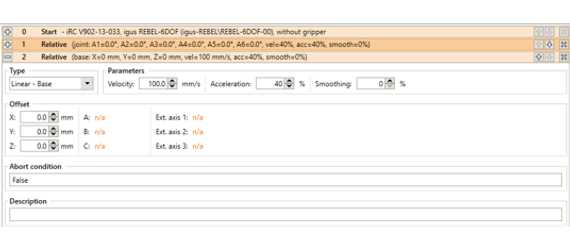

Relative

The Relative command allows moving the robot relative to its current position. It can be called up via the menu items under "Action" → "Relative movement".

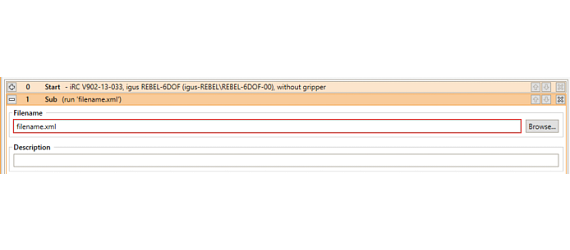

Subprograms

Subprograms can be called up with the Sub command. The path to the subprogram file is specified under "File name". It is relative to the "Programs" subfolder of the iRC "Data" folder.

Variables and variable access

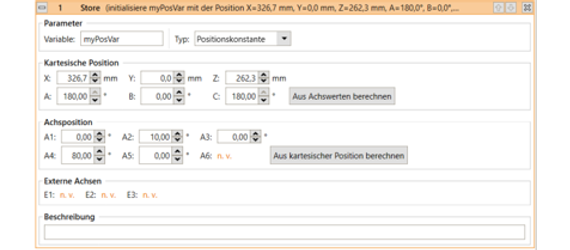

Two types of variables are supported in programs for iRC and TinyCtrl:- Numerical variables: these can be used to store integer or floating point numbers.

- Position variables: these can be used to store Cartesian positions and joint positions. Whether such a variable is interpreted as a Cartesian position or a joint position depends on the context.

Sample programs

Save time and money with our sample programmes:

Faster integration of igus® Robot Control for your machines by combining simple components and igus® sample programmes.

Faster integration of igus® Robot Control for your machines by combining simple components and igus® sample programmes.

- On-demand training videos

- Media library with many training videos

- Videos on each robot kinematics application

- All content available on demand

To the sample programs

The igus® Robot Control software

Robot programming couldn't be easier.Our software allows for simple and intuitive robot programming and control, making it easy to get started with automation. Due to the modular design, it is possible to control different robot kinematics, for example, delta robots, linear robots and multi-axis joint robots. With the software, users can simulate the individual movements of the robot on the 3D interface.

Test the software now for free

Bevásárlókosár

The selected article has been added to your shopping cart.

From here you can initiate enquiries or orders.

#XML B2bOnlyHintHU#

From here you can initiate enquiries or orders.

#XML B2bOnlyHintHU#