Organisation Study On Sitharam

Organisation Study On Sitharam

Uploaded by

Preema ReghuCopyright:

Available Formats

Organisation Study On Sitharam

Organisation Study On Sitharam

Uploaded by

Preema ReghuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Organisation Study On Sitharam

Organisation Study On Sitharam

Uploaded by

Preema ReghuCopyright:

Available Formats

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

INTRODUCTION TO THE STUDY

Organisational study is the systematic study and careful application of knowledge about how people as individuals and as groups act within organisation. Purpose of an organisational study is to define the legal and corporate structure of the business. An organisation study may also include professional background information about the business and the principles of the business and what skills they can contributes to the business. As part of Master of Business Administration programme, the researcher conducted organisational study Sitaram Textiles Ltd, Thrissur. This work will give a complete picture about the organisation structure and departments of the organisation and also study each department process and function. The researcher selected this topic to understand the well organised managerial structure of the organisation. So the study, regarding this topic is very crucial to analyse the factors which contribute to the quality of textile products as well as the factors regarding the defects of organisational climate development of an organisation. While conducting the study the researcher got a real idea about the structure of the management and harmonious working conditions of employees in Sitaram Textiles Ltd, Thrissure. A fair organizational study will help an organization to develop a lot. The suggestions given by the researcher will help to improve the efficiency and effectiveness of the organization in a systematic manner.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

OBJECTIVES OF THE STUDY

The main objectives of the study are : To understand more about the organization. To get more awareness about the departments of the company. To understand the overall performance of the company. To study the problems of the company. To give suggestions based on the findings for the improvement of efficiency and profitability of the company. To analyse the strength and weakness as well as opportunity and threats of the company to enhance the organizational performance.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

LIMITATIONS

Busy schedule of officers and employees is adversely affected the researcher. The information provided by the company assumed to be authentic. Certain areas are restricted, so a detailed study is not possible. The success of the study depends upon the response made by the employee.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

INDUSTRY PROFILE

INTRODUCTION Textiles industry in India is the second largest employment generator after agriculture. The modern textile industry in India has to origin in the 19th century. The textile industry plays an important role in the Indian economy. And Indian is next only to China among the worlds largest producers of textiles and garments. It holds significant status in India as it provides one of the most fundamental necessities of the people. Textile industry was one of the earliest industries to come into existence in India and it accounts for more than 30% of the total exports. In fact Indian textile industry is the second largest industry in the world.

The country is rich in natural resources such as cotton, just, and silk. Textile industry is unique in the terms that it is an independent industry from the basic requirement of raw materials on the final products, with huge value addition at every stage of processing. Textile industry in India has vast potential for creation of employment opportunities in the agricultural, industrial, organised and decentralised sectors and rural and urban areas particularly for women. Textile and garment manufacturers and exporters in India were expecting a bright future in the days to come as more International buyers were turning their attention to Indian markets following hike in prices of textile and garments in China, which had the largest share in the export market. Buyers from various countries, including US and European countries, were now started placing fresh orders with the textile garment exporters here.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

HISTORY OF THE INDUSTRY The terms TEXTILE is a Latin word originating from the TEXERE which means to weave Textiles refers to a flexible material comprising of a network of artificial fibers, known as yarn.

The development of the world textile industry was started in Britain as the sinning and weaving machines were invested in that country. High production of wool, cotton and silk over the world has boosted the next year. Through the industry was started in UK, in 19th century the textile production passed to Europe and northern America after mechanisation process in those areas. From time to time Japan, China, and India took part in industry their economic and concentrated more in that sector.

India has been well known for her textile goods since very ancient times. The traditional textile industry of India was virtually decayed during the colonial regime. However, the modern textile industry took birth in the early 19 th century, when the first textile mill in the country was established at foster glisters near Calcutta in 1818. The cotton textile industry however made its real beginning in Bombay in 1850s. The First cotton textile mill of Bombay was established in 1854 by a Parsi cotton merchant then engaged in overseas and internal trade. Indeed the vast majority of the early mills were the handy work of Parsi merchants engaged in yarn and cloth trade at home and Chinese and African markets. The first cotton mill in Ahmadabad, which was eventually to emerge as a rival centre to Bombay, was established in 1861. The spread of the textile industry to Ahmadabad was largely due to the Gujarati trading class.

The cotton textile industry made rapid progress in the second half of the 19th century and by the end of the century there were 178 cotton textiles mills; but during the year 1900 the cotton textile industry was in bad state due to the great famine and a number of mills of closed down for long periods.

5

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PRESENT STATUS OF THE INDUSTRY Modern textile industry in India has its origin in the 19th century. The textile industry plays a pivotal role in the Indian economy. This industry is very significant today because, this sector contributes substantially in providing employment and earning foreign exchange.

The Indian textile industry has a significant presents in the economy as well as in the international textile economy. Its contribution to this Indian economy is manifested in terms of its contribution to the industrial production, employment generation and foreign exchange earnings. It contributes 20% of industrial production, 9% of excise collections, and 18% of employment in the industrial sector, nearly 20% to the countrys total export earning and 4% of the GDP.

The country is in rich natural resources such as cotton, jute and silk. The textile industry is the second largest employer after agriculture, with a total work force of around 35 million. India is next only to China among the world worlds largest producers of textiles and garments. The activities in textiles range of from the production of natural raw material such as cotton, jute, silk and wool to the manufacture of quality products such as cellulose fibre, synthesis filament and span yarn. But during the last four years the industry has been suffering from a lot adverse factors. The major problem is technology lag. Recently the union government has come out with ambitions, technology up gradation fund of a possible magnitude of Rs.25,000 crores to help the industry catch up with the trends in the global market.

Here are a few important facts about Indians textile industry. 1. There are approximately 1200 medium ti large scale textile mills in India. 12 % of these mills are located in coimbatore (Tamilnadu)

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. 2. India has 34 million cotton textile spindles for manufacturing cotton yarn. Cotton yarns account for 70% of Indias textiles exports. (China has 40 million cotton spindles) 3. For the past tow years there has been a significant, mainly due to the increasing price of cotton 4. Of the Indian textile yarn exports, almost 80% come from coarser yarns consequently, there is a need to upgrade the technology.

FUTURE SCOPE OF THE INDUSTRY

Garment manufacturing and exporters in India were expecting a bright future in the days to come as more international buyers were turning their attention to Indian markets following hike in price of textile and garments in China, which had the largest share in the export market.

Buyers from various countries, including US and European countries, were now started placing fresh orders with the textile garments exporters here. Erode textile garment exporters association secretory S Sivandhan told it was reported that production and export of garments from China have started declining, due to various reasons including price hike of raw materials and increase in production cost.

Considering the continual capital investments in the textile industry, the government of India may extend the technology up gradation fund scheme (TUFS) by the end of the 11th five year plan (till 2011 -2012) in order to support the industry. The Indian textile industry is massively investing to meet the targeted output of $85 billion by the end of 2010, aiming export of $ 50 billion. There is substantial potential in Indian export of technical textiles and home texts as most European company want to setup facilities near by the emerging markets, such as India and China.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Union Ministry of Textiles certified Apparel Export Promotion Council (AEPC) has taken the responsibility to motivate the foreign investors to invest in Indian Textile Industry by exhibiting it massive unexplored domestic market. The objective is to trigger the foreign investment towards instituting textile units in India by offering numerous allowances to global investor like low priced work force and intellectual right fortification.

The government India has also taken few initiatives to promote the textile industry by permitting 100% Foreign Direct Investment (FDI) in the market. the Indian Textile Industry symbolized a strong existence in the complete value chain from raw commodities to finished products. The Synthetic and Rayon Textile Export Promotion Council (SRTEPC) has taken all the required steps to meet the target of doubling the synthetic textile export in India to US $ 6.2 billion by seizing 4% of market share by financial year 2011 -2012.

COTTON TEXTILE INDUSTRY

The cotton textile industry occupies a permanent place in the Indian economy, contributing to about 23.5% of the countrys industrial production. The textile sector is closely linked with agriculture, handlooms, power looms, garment manufacturing and a number of industries and trade, thus touching everyday life of the common man. Cotton textile industry is one of the oldest and largest industries in India which has made rapid change in the economy. The countrys first textile mill Express mill in Nagpur which was started by Tata was the first to down shutters. The premier group has sold of its textiles mills another has been taken over by National Textile Corporation (STC) Which has also taken over mills like Kohinoor.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

COTTON TEXTILE INDUSTRY IN INDIA

The cotton textiles industry occupies an important place in the Indian economy as its contribution to industrial production, employment generation and export earning are significant. Currently the industry possess 26 million spindles 2 lakh looms in the mill sector above one million power loom sector about 4 million looms in the handloom sector and a large number of process houses with total capacity of dyeing, printing and finishing of 10 million metres of per Annam. The industry place an important role in the Indian economy and as its accounts for nearly 60% of industrial production and large scale employment. It is also a foreign exchange earns as it contribute over 30% of the countrys total exports. The first Indian cotton textile mills was established at Fort Glisters near Calcutta as early as in 1838. The first cotton textile mill was in Bombay was the Bombay spinning and weaving company started in the year 1851. The cotton textile industry is admittedly the single largest organized industry in India and occupies second place among the countries of the world in cotton textile mills are located in those status like Maharashtra, Gujarat, Tamilnadu,West Bengal and Kerala.

COTTON TEXTILE INDUSTRY IN KERALA The state has number of Textile mills. Kerala cotton textile mills generate direct and indirect employment opportunities. There are more than 30 textile mills working in the state. The major raw materials used by the industry are cotton polyesters, synthetic fibres etc. These raw materials are not widely manufactured in Kerala. It is either obtained from other states especially from Maharashtra and Tamilnadu or they are imported from abroad. Since the climate conditions of Kerala frequently changes, Suitable arrangements should be made to maintain the desired conditions for the production of Yarn.

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

The present condition of textile industries of Kerala is not good. Most of the private owned mills have closed down and as a result large number of workers lost their job. Similarly some of the private operated mills are fairly the problem of taking over by the Government. Some of the mills are taken by the textile corporation of Kerala, National Textile Corporation and Kerala government. Some of them located in Thrissur are: Sitaram Textile Ltd, Thrissur. Alagappa Textiles, Alagappa Nagar Kerala Lakshmi Mills, Pullazhy

10

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PROFILE OF THE ORGANIZATION

Sitaram textile is a public limited company incorporated under the Indian companies Act 1956. It is a composite textile mill, fully owned by government of Kerala situated in Punkunnam, Thrissur. The registered office and production unit of the company is also situated in Punkunnam-[XXXXI /306 Punkunnam, Thrissur 680002, Kerala state.]. The cotton yarn and fabrics were the products of the company till 2000. Now the company produce only the cotton yarn and polyester yarn. The main objective of the company is to provide employment opportunities.

HISTORY OF THE COMPANY Sitaram textile Ltd a composite textile mill, fully owned by government of Kerala situated at Thrissur in central Kerala was incorporated on 11th February 1975 under the Indian companies Act 1956. The Sitaram spinning and weaving mills originally managed as a family concern was started as a power loom unit in the year 1903. It was started by Late Shri T.R.Ramachandra lyer. Slowly and steadily, with the passage of time the unit was expanded, diversified and become a public Ltd company. The Sitaram textile Ltd is a government of Kerala undertaking. Its registered office is situated in Punkunnam, Thrissur. As Sitaram textile Ltd is a public sector undertaking a brief expansion of the nature and outline of the public Ltd, companies relevant here. A public limited company is a company formed and registered under any of the previous companies act. It is an association of persons called members. But has existence apart from the members. Sitaram textile Ltd, Thrissur is a composite mill engaged in fabrics. The activities involved are spinning, weaving preparation, weaving and processing. The

11

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. finished products (yarn) are directly marketed to the depots in Bombay. Different varieties of cotton purchased from outside state such as Tamilnadu, Andrapradesh, Karnataka and Maharashtra. The products of the company were cotton yarn and fabrics till 2000. Now the company produces only cotton yarn and polyester yarn.

OBJECTIVES OF THE COMPANY

The main objectives of Sitaram textile are as follows;

To carry on manufacture of yarn at low cost. To produce high quality products To provide more employment opportunities To believe in healthy industrial relations and human treatment to its

employees To maintain higher ethical standards with its suppliers and customers. To continuously upgrade the quality of human resource of the company and to promote development. To enter in to foreign collaboration. To establish technical institution to provide the training to the employees.

VISION Sitaram believes in continuous up gradation of its product quality by investment in the latest technology and its successful implementation. It also focuses on providing employment opportune MISSION To be the most significant supplier of cotton yarns and polyester yarns to the world market.

12

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

BOARD OF DIRECTORS

Board of Directors has ultimate authority of the company. The share holders of the company are Government of Kerala. Board Of Directors of Sitaram Textiles Limited are :-

Chairman Managing Director

: N.R.Balan : C.K.Gopalakrishnan Nair

Directors B.Prakash (Govt. of Kerala{joint secretary}) K.Ramachandran Pillai (CMD, NTC) K.S.Lakshmirani (Finance joint secretary) K.A.Chandrasekheran (Director: Handloom and Textiles)

13

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

CAPITAL OF THE COMPANY

Capital refers to the money or moneys worth introduced or invested by the owner into business. The authorised capital of the company is 600000 equity shares of Rs.100 each. The starting capital investment of Sitaram Textiles was 2.5 crores. The present capital investment is 594 crores. This is raised by issuing 594000 shares of Rs.100 each. All these shares are owned by the Government of Kerala..

YEAR

SALES

PROFIT/LOSS

2006 2007 2008 2009 2010

63670571 67253459 79532217 74528657 98402628

(-)17100000 (-)9267268 (-)23519720 (-)15523681 3547606

The chart show the organisation has in net loss from the year 2006 to 2009. And in year 2010 the company has in profit at rs 3547606.

14

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PRODUCTION UNIT

The Sitaram Textiles has only one production unit which is situated in Punkunnam (Thrissur) in an area of 10 acres of land, engaged in the production of cotton yarn and polyester yarn. The raw material used in this conversion is cotton and polyester. They have eight different steps involved in this conversion process that are mixing, blow room, carding, drawing, simplex, spinning, cone winding, and packing. And this process are helps to maintain the quality and smooth production of yarn.

15

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

ORGANIZATION STRUCTURE

Board of Directors

Chairman

Managing Director

General Manager

Accounts Officer

Production Manager

Purchase Manager

Marketing Manager

Personnel Manager

Store Keeper

Accounts Staffs

Supervisors

Supervisor

Assistant. Marketing Manager

Head Time Keeper

Staffs

Production Staff

Workers

Clerk

Workers

GENERAL MANAGER

16

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

FUNCTIONAL ORGANIZATION STRUCTURE

The organization structure of the Sitaram Textiles is functional organization structure. Functional organization structure is one in which the employees are grouped on the basis of their functions. These functions are put under the charge of specialists. A functional head can give directions throughout the organization related with his functions.

Advantages 1. It is the most logical and easier form of an organization structure. 2. It provides specialisation thus making possible efficiency in operations. 3. It facilitates delegation of authority. 4. If facilitates better co-ordination of activities within each department. 5. Better supervision is facilitated since an individual manager is familiar with related tasks and activities. 6. It helps in training of specialist managers rather than generalist managers.

17

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PRODUCT LINE The products of the company were cotton yarn and cotton fabrics till 2000. Now the company produces only cotton yarn and polyester yarn. For producing cotton yarn, the period of time is one week. Cotton yarn Polyester yarn - 60 counts -70 counts

The term count implies the qualities of yarn. Higher the count higher the quality. The waste of cotton are categorised into three that is saleable waste, reusable waste and invisible waste.

The saleable wastes are gutter fly waste, lick ring fly cleaner, cowing ends, comber no in opener, hard waste and sweeping waste flat strap waste.

18

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

BUSINESS OPERATION

The company is situated in 10 acres of land engaged in the manufacturing of yarn. Two types of yarns are manufacturing there. Cotton yarn and polyester yarn. Around 200 employees are working in the organization. Now the company is in its growth stage. The company is incurring profits after a decline. The main objectives of the company is providing employment opportunities and carrying on manufacture of quality yarn with minimum cost.

Nature of business

The products of the company were cotton yarn and cotton fabrics till 2000. Now the company produces only cotton yarn and the polyester yarn. . The finished product (yarn) is directly marketed to the depots in Bombay. The company gets advance order for producing yarns. So they undertake Just-In Time manufacturing system.

Size of business The company is undertaking its production on a large scale. The company consist of more than 200 employees. The company has well qualified and skilled labours.

19

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Business Operation cycle

Bills receivables

Cash

Debtors

Raw material

Finised Goods

The business operation of Sitaram Textiles is start from cash converted into raw materials then the raw materials are processed and converted to finished goods. That is cotton yarn and polyester yarn. The finished product is directly marketed to the depots in Bombay and then the finished goods to debtors and debtors to bills receivables. The business operation goes on this flow and bills receivable to cash is next.

20

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

TRADE UNION PRESENCE

Trade union as a continuous association of wages earners for the purpose of maintaining or improving the condition of their working lives. It is the association of employees designed primarily to maintain or improve the condition of employment of its members. Unions are primarily concerned with the terms and conditions of employment. The main objective of trade unions is to present their needs before the management. The trade unions in this company are:INTUC [Indian national Trade Union Congress] AITUC [All India Trade Union Congress] CITU [Central Indian Trade Union] [BMS + CMP] co-ordination.

Functions

The main function of trade union in this organisation is to protect the interest of employees. Trade Union help to improve the working conditions in the company by negotiating for better pay packages, working conditions, and other allowances and present all the needs of employees before the management.

21

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

MARKET SHARE

COMPANIES

MARKET SHARES

Sitaram Textiles NTC GTN Thrikkot Mill OTHERS

2% 60% 2% 3% 33%

Sitaram Textiles, 2%

Others, 33%

NTC, 60% GTN, 2% Thrikkot Mill, 3%

22

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

COMPANY LIFE CYCLE

Sitaram Textiles Limited

profit

1975

1985

1995 year

2005

2010

2011

2015

Present status of the company

The company is in its growth stage. In this stage the demand and sales of the product increased rapidly. In this the profit is increasing. Till 2008 the company incurred continuous loss, but during the year 2010 and 2011 the company earns profits because of higher demand of the products. And the company expect the future growth.

23

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

COMPETITORS OF SITARAM

At the time when Sitaram Textiles Limited started it was the one and only concern in the field. Later new companies emerged in the field which increases the competition. Now Sitaram is facing cut throught competition.

NTC under taking mills are:1. 2. 3. 4. 5. Alagappa Textiles, Amballur Vijaya Mohini mills,Trivandrum Kerala Lakshmi Mills, Pullazhy. Parvathy Mills, Kollam. Spinning and weaving mill, Kannur.

Private firms are:1. 2. Palakkad Thrikkott Mills. GTN Industries Limited, Aluva

It faces competition from the private firms in Bombay working under this industry. They have to spend only less cost of transportation. All the above mentioned competitors are producing the same counts of yarn.

24

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

FUTURE PROSPECTS AND GROWTH PLAN

Textile and garment manufacturers and exporters in India were expecting a bright future in the days to come as more International buyers were turning their attention to Indian markets following hike in price of textile and garments in China, which had the largest share in the export market. Buyers from various countries, including US and European countries, were now started placing fresh orders with the textile garment exporters here. Considering this opportunity, the company is looking to increase the production with minimum investment. For these the company is planning to modernise the entire existing machinery with automatic machines with an outlay of INR 396 lakhs. Now the company is working with 30 year old machinery. After the implementation, the unit becomes a viable one. The future plans are. Promote the high Sales Quality Should Precede Production Maintenance Should properly done, and that will be increase quality Effective communication, co-ordination and co-operation

25

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

DEPARTMENTS

In every organisation there will be departments. The main advantage of the department is the work can be done very easily and in a smooth way. Otherwise it will be very difficult to carry out work in an organisation.

Human Recourse Department Purchase Department Marketing Department Production Department Finance Department Quality control department

26

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

HUMAN RESOURCE DEPARTMENT

Personnel Manager

Head Time Keeper

ESI and PF clerk

Security Officer

Senior Time Keeper

Wage clerk

Security Guards

Shift Time Keeper

27

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

The Human Resource Management (HRM) function covers a wide range of activities. Human resources are the lively elements of an organization. An organization utilises human resources along with technological, financial, physical and other resources. In HRM, is related with the management of man power. The important task of HRM is to help every employee to grow himself to the maximum. It is mainly concerned with methods of recruitment, selection, training and placement of personnel and performance appraisal. Personnel manager is a staff officer in the organization. He gives advice to top-level management in relation with personnel policies and programmes. Human Resource Management checks whether the workers are given fair working conditions, allowances etc. There are more than 200 people working in Sitaram Textiles. Functions The functions and responsibilities of human resource management are as follows 1. To establish good relation with employees. 2. To develop human capital. 3. To forecast and balance the demand for and supply suitable personnel. 4. To have efficient performance of the managerial functions. 5. To effectively utilise the technology and other resources. 6. To maximise productivity. 7. To develop higher employee morale. 8. To motivate human resources for better performance. 9. To ensure optimum utilisation of human resources.

28

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Strength of the company

Workers

161

Officers supervisors Office assistant Drivers Security Peons TOTAL

8 5 15

5 5 3 202

Wages & other benefits

Basic wages Increase in basic wages in certain categories on account of special increase given by the management. Increase in basic wages as per the terms of IRC (Industrial Relation Committee of Textile) settlement dated 29 June 1999.

29

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Revised occupational wages Occupational wages means the basic wages fixed for the category or occupation under the IRC settlement and doesnt include the annual increments. Dearness Allowance. Dearness allowance will be on the basis of Trivandrum cost of living index with 1970=100 Employees State Insurance (ESI) The employment State Insurance Act provides benefits to employees in case of

sickness, maternity or any injury. An employee drawing salary less than Rs 10000 per month will come under this act. It is applicable to both accidents and Sickness. The employee will get free treatment and compensation. The employee can take 90 days leave for sickness and accidents. For accidents leave, he or she will get 75% of their basic wages and dearness allowance. In case of sickness leave, the employee can draw 50%of their wages and dearness allowance. Employee Provident Fund Scheme. The employee contribution towards provident fund is 10%of monthly contribution by the company. It is the amount received by the employee at the time of retirement in lump sum. From the companies contribution Rs541 will be paid to every employees pension fund each month. Maternity Benefit The maternity benefit is also provided as per the provisions of ESI act 1948. 84 days leave will be granted as Maternity benefit. If delivery is done at hospitals referred from ESI hospital then the full amount of treatment will be reimbursed. Gratuity If the employees complete a five years of continuous service, they are eligible to get gratuity. In case of death or disablement the qualifying period of 5 years is not necessary. Sitaram textile Ltd, provide gratuity to the act, 1972.

30

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Canteen Sitaram textile Ltd, Punkunnam provide a well established canteen. Both the

management and workers can use the canteen facility. Canteen extends its service for round the clock.

Shelters and rest room There is sufficient number of shelters and rest rooms are arranged separately for the men and women workers. They can utilize the rest room at the leisure time or for taking meals. Leave with pay For every employee, one day granted as leave for every 20 working days. The employee has to work minimum days in the previous years. Travelling allowances The employees of Sitaram textiles get a travelling allowance of Rs 26 per month for 26 working days. Pension Workers 1000 to 1500 Staff - 7000 to 8000

Supervisors- 7000 Junior manager 8000 Assistant manager- 9000 above Deputy manager- 10000 Manager- 12000 General Manager 14000 Managing director- 20000

31

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Selection of employees

The staffs of the organisation are appointed through the PSC (Public Service Commission) and the lower workers are recruited through agreement between trade unions & workers.

Shift of workers There are three shifts in the company. They are

FROM 7.00 AM

TO 3.30 PM

3.30 PM

12.00 AM

12.00AM

7.00 AM

Man power requirements

Mixing attendant Schutcher attendant Cording Tender Combers Drawing Tender Simplex Tender Simplex Doffing Boys

32

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. Spinning Slider Doffing Boy Cone winners Packing Filter Assistant Filter Filter Helper Cleaning gang Shift Electrician Jobbers and others

Employees turnover of Sitaram Labour turnover is the rate of change in the labour force of an organisation during a given period. Therefore it signifies the shifting of work force from one organisation to another and also the loss of manpower due to discharge, retirement, death etc. Employees turnover of Sitaram is 3 to 5 employees per annum. It is mainly because of retirement.

33

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PRODUCTION DEPARTMENT

Production Manager

Supervisors

Production Staffs

Workers

Sitaram textile Ltd manufactures different count of yarns. In order to have a clear understanding, the manufacturing process can be sequenced as follows.

34

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

The products of the company were cotton yarn and cotton fabrics till 2000. Now the company produces only cotton yarn and polyester yarn. For producing cotton yarn, the period of time is one week. The total consumption per day is 2000kg. Cotton yarn Polyester yarn - 60 counts -70 counts

The term count implies the qualities of yarn. Higher the count higher the quality. At the time of production wastes are created. The waste of cotton are categorised into three that is saleable waste, reusable waste and invisible waste. Reusable waste can be used for production of yarn. The saleable wastes are gutter fly waste, lick ring fly cleaner, cowing ends, comber no in opener, hard waste and sweeping waste flat strap waste. Invisible waste cannot be count but it is estimated as 2% out of total input.

35

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PRODUCTION CHART

MIXING BALE BLOW ROOM

AUTO MIXER

SCUTCHER

CARDING A. SILVER LAP B. RIBBON LAP

COMBER

DRAWING

SIMPLEX

RING FRAME (SPINNING)

CONE WINDING

PACKING

36

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Production process

The raw material used in this conversion is cotton and polyester. The different steps involved in this conversion are as follows.

a. Mixing There are mainly two type of mixing. That is polyester mixing and cotton mixing. Mixing is done at both manually and mechanically.

b. Blow room In this section, mainly opening and cleaning of bale take place. Firstly the bale passes through the bale breaker for the opening of the compressed bales. Secondly it passes through a machine called step cleaner which is used for cleaning the bale by step by step process. Thirdly, it passes through a machine called Hopper feeder, which is also known as temporary storage area of raw materials. Lastly the raw material passes through another machine and the lap from of raw material is obtained with impurities removed to a certain extent.

c. Carding The lap form of raw materials are processed and cleaned to remove all the impurities and they are converted to slivers. These slivers are collected in drums. This is of non uniform thickness. The machine used for carding is called card machine and product is known as card sliver.

37

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. d. Drawing Here, the card sliver is processed to get sliver of uniform thickness. This process is done twice. So the thickness is reduced and made uniform. The product obtained by it is drawing sliver. e. Simplex The thin uniform sliver is passed in to the spindle machine for the purpose of raring it. A number of spindles are used for it. The raw is further thinned and the sliver is converted in to actual yarn and it is wound in the bobbins. If there is break in one spindle, the machine automatically switched off. The bobbins can carry 2 kg of yarn. The rowing bobbins are then passed to the next department known as spinning department.

f. Spinning The cop winding is started in this department. There are number of machines used for it. Five machines are controlled by one worker. In this section, works of workers are more. But it is not very risky work.

g. Cone winding The cop form of yarn is wound on the paper cone by using power 100m. The cone can carry 1.25 kg of yarn. This is used for selling distribution. In cone winding, yarn from a single cop is wound one by one to make 1.25 kg of cone. Like cone winding there is also double winding. In these type of winding instead of winding yarn from a single cone at a time, two cops is wound at the same time, by this the yarn become stronger. h. Packing The cone of 1.25 kg is packed first in plastic. So that it does not get wet and damaged while in transit. The product is sold in bulk quantities is a bag of 50 kg. 40 cones are packed together and slip specifying the type of yarn is also kept with the pack.

38

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

STORES DEPARTMENT

Store Keeper

Staffs

This department works under the store keeper. The entire department needs certain items for the smooth working. These items were always kept optimum in the store. The items will be issued by producing a material issue voucher to the concerned departments. There are two types of purchases. One is centralized purchasing and the other is local purchases. The local purchases are made for the stores purchases. Bill of material is received for the purchase. And these are recorded in Inwards Receipt book. The inward receipts books include the following details.

1. 2. 3. 4. 5. 6.

Name of the supplier Time and date of purchase Quantity of material purchased Place Name of person who purchased Name and designation of person who received and inspected the material.

39

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. 7. 8. Registered number of vehicle in which the goods had been brought in. Transportation cost.

Each item in the store has been given a unique code number and they are stored according to the code number and according to the cost centres. Bin card is used to recording the receipts and issues of various materials. Proper and scientific way of analyzing is not maintained in the company.

Even though the traditional technique, are being used in stores management and the system is not suitable for the modern era of industry, the personnel in stores manages to ensure each items in time when it is needed.

Methods of valuation of inventories

1. Stores , spares and coals at average cost

2. Raw materials at moving weighted average cost or net realizable value whichever is lower

3. Finished goods -packed yarn at cost or net realizable value whichever is lower

4. Stock with retail shop at landed cost/ latest landed cost or realizable value after making previous for obsolescence whichever is lower

5. Waste at realizable value

6. Material in processing. Spinning and weaving in progress. Loose yarn at lower cost or net realizable value

40

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. 7. The unfinished job conversion contracts for yarn are recognized as work in progress valued at contracted price less expense still to be incurred for making it ready for delivery.

Store department is responsible for storing the raw materials, finished goods and spare parts required for the smooth functioning of the organization. In this highly competitive companies cannot survive without a well managed stores department. Inventories are the stock of the product. The store keeper in the Sitaram keeps an inventory of finished product to be sold to customers whenever they demand.

Raw material inventory These are materials inputs of production process. These are

used to manufacture the final products. Sitaram uses the raw materials like cotton,

polyester etc Work in progress inventory These are semi finished products. These are the products that need more work before they become finished products. Finished goods inventory These are finished or final products which are ready for sale. The finished product of Sitaram is yarn.

41

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

FINANCE DEPARTMENT

Accounts Officer

Accounts Staffs

The main function of finance department is to record day to day transactions of business. The chief of finance department is finance manager. Finance department plays a role of providing relevant financial information to all departments

Functions of finance department

Two main functions of finance department are as follows 1. 2. Accounting function Finance function

1. Accounting function Accounting function involves of keeping or recording day to day accounts. The transactions namely receipts, disbursement of money transactions

42

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. relating to purchase, production, sales, other income , fixed amount salaries& wages and other expenses like manufacturing , administration, selling and distribution.

Objectives of accounting function

All assets and liabilities are recorded and classified properly in accordance with the statutory requirements to reflect the financial position of the company as at any particular date. To maintain the truth and fairness of financial statements, via profit & Loss account and balance sheet. Receipts and payments of money are accurately recorded so that all payables receivables are correctly reflected... All expense and income of a particular period are accurately reflected in accordance with the relevant statistics to understand the working result of that period. The company maintains adequate books of accounts. There by complying with the procedure of companys Act1956. Sitaram textiles fully computerized its accounting functions. The following are the books of accounts maintained by the company.

A. B. C. D.

General ledger Cash book Day book Sales register

43

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. E. F. G. H. I. Purchase register Store inventory register Store issue register Semi finished goods register Finished goods register

2. Finance function It includes procurement of funds and effective utilization of the same of the business. The finance function will help us to control all expenses with comparing budgeted expenses and actual expenses. Objectives of finance function Selection of an optimum mix of different source of capital Profit maximization and more importantly wealth maximization To ensure control over expenses by constantly watching expenditure and income. To provide dividends to share holders of the company To utilize funds in such a manner that is rupee is made to work at its optimum level without endangering the financial solvency of the company through decision such as capital budgeting, profit planning, tax management and working capital management.

Capital structure of the company The share capital of the company is divided in to equity shares with an authorized capital of 6 crores (6, 00,000 equity shares of Rs.100 /each) and issued and paid up capital of Rs.5.94 crores (5, 94,000 equity shares of Rs 100/ each). All these shares are owned by the Government of Kerala.

44

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

PURCHASE DEPARTMENT

Purchase Manager

Supervisor

Workers

Purchasing is the procuring of goods as per the needs either for further sale, use or storage- against payment of an optimum price. The main item produced in the mill at present is yarn. The cotton yarn and polyester yarn is manufactured by the company. The main raw material of the product is raw cotton. The raw material in the mill is compressed from cotton bales which weight 185 kg. Different varieties of cotton purchased from outside state that is mainly from Tamilnadu, Andra Pradesh, Karnataka and Maharashtra.

45

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

Objectives of purchase function

The main objectives of purchase management are to ensure availability of required goods of services, as and when they are needed by the organization. This is to maintain a proper flow of supplies of goods as per the specifications and on a cost effective basis.

The purchase should be done when the stores are required. Purchase are always made on the principle of optimum price and cost effectiveness. The acquiring of goods as per defined specifications.

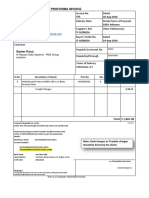

PURCHASE ORDER

FROM

TO

RELATED DEPARTMENT

STORE KEEPER

PURCHASE DEPARTMENT

46

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

MATERIAL MANAGEMENT AT A GLANCE

The main raw material is raw cotton.

REORDER POINT

52 Days - 90000kg

MINIMUM QUANTITY LEVEL

RAW COTTON Credit availability Consumption per day - 60 Days - 2000kg.

OUT PUT Saleable output Saleable waste Reusable waste Invisible waste Total

- 100% - 70% - 13% - 15% - 2% 100%

REORDER OUTPUT

- 30 days

Total cost of consumption - 2.5 lakh

47

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

QUALITY CONTROL DEPARTMENT

The main product of the company is cotton yarn and polyester yarn. The yarn quality is termed as count. Higher the count higher the quality. The count is calculated by using this formula:-

Count = length in hanks / weight of pounds.

1 hank = 840 yarn length 1 khandi = 355kg.

The quality control department works under production manager. Actually there are two sides for the production process. One is production and the other is the quality control. The quality is checked from each stage of production and from raw material to finished goods.

48

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

MARKETING DEPARTMENT

Marketing manager

Ass. Marketing Manager

Marketing is one of the most important operative functions of management. It is the process by which goods produced are made available to the consumers. Thus goods produced are to be stored and transferred from the place of production to the place consumption thereby creating time and place utilities. The products of Sitaram Textiles are cotton yarn and polyester yarn. Certain present of the waste of products can also be sold. The products of the company are highly qualified. So the demand of the product is high. The company follows direct distribution channel (zero level marketing). Direct marketing Direct marketing becomes common in this world. The company do not create dealer network. The products are directly marketed to the depots in Maharashtra. Direct marketing is very beneficial for customers as well as seller and producers. It eliminates the gap between producer and consumer. The products can be effectively displayed and demonstrated right in front of the customers. These goods and services are available at fair price.

49

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur. The company did not give importance to promotional activities because the company has high demand in its products. They produce finished goods after receiving orders. The price of the product is fixed by the government of Kerala. Management and workers have a strong confidence to success in the market. If the government of Kerala provides the working capital (at least 2 crores) but the company has to deliver the goods in time with consistency in quality. Therefore the company can able to increase the order. So that the company can definitely capture the entire market. Now the company is facing cut throught competition from the firms which carries same business operations. Severe price competition from the unorganized power loom sector has restricted its operation to producing yarn.

50

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

SWOT ANALYSIS

Swot analysis is under taken to understand the firms external and internal environments. A conscious identification of the relevant environment enables an organization to focus its attention on these factors which are intimately related to its mission, objectives and strategies.

STRENGTH The company has a well defined internal control system. The company provides high quality products. The company is blessed with highly qualified and skilled personnel. The company has cordial relationship with employees .The employees are more cooperative. The company ensure workers participation in management for improvement. The company is situated in10 acres of land. So expansion is possible. The company has taken various steps to improve productivity. Industrial relations are maintained harmonious. The company has productive work force.

51

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

WEAKNESSES.

The trade union of the company are powerful. The company has not repaid interest towards principal amount of loan. High transportation cost offset the profits of the company. Technological obsolesce is the major problem, now the company is used 30 year old machinery. Shortage of capital prevents the companys effective performance. High labour turnover of employees. Employees turnover is mainly because of retirement. The loss of control is an important weakness of the company. The company follows direct marketing so the company cant capture the whole market. The company has not followed any promotional activities so the company cannot attract the customers. Frequent change of BOD adversely affects the performance of management. The BOD is selected by government of Kerala. No facility for research and development.

52

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

OPPORTUNITY The company need to focus on product development. Proper up gradation of the technology helps the company to make quality good with minimum cost of production. The company can capture the foreign markets. Proper recruitments and selection of personnel for vacant posts Control of the department functions will helps the company for improvement. By changing the distribution channel the company can widen the market opportunity. A research and development wing helps the company to improve the products quality and aiso helps to invent new products to the customers. By introducing new production plants the company can improve their capacity.

THREATS The cut throat competition from the similar field. Frequent changes in political policies and system are a threat of the company. Increasing trend in the price of raw material. The pollution created by the invisible waste of the cotton may cause health problems. Frequent changes in government policies obstruct the effective performance of the company.

53

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

The Swot analysis give the clear picture about the organization both in terms of internal and external environment. The organization have high quality strength and opportunity to minimises weaknesses and threats. And the strength can be use to utilises the maximum opportunity and the maximum utilisation of the creative and productive opportunity that helps to avoid the weaknesses and minimises the threats and producing quality product with new technology. The good relation with the employees that helps to increase the production and minimises the chance of making problems of the trade unions in the organization. And these better strategies are formulated that can helps to increase the market share of the organization.

54

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

CONCLUSION

The research entitled An Organizational Study of Sitaram Textiles Limited Was under taken with a view to study, understand, learn, analyses about the operation of the organization. It also helps the researcher to gain more knowledge and to get practical experience about the functions of each department. In this era, companies should ensure that they offer job satisfaction and labour remuneration to the perspective knowledge in the organization. There is a greater co-operation between and the management and employees. The firm must also communicate regarding their product and services.

55

Nirmala College of Information Technology, Chalakudy

An Organizational Study Report on Sitaram Textiles Limited, Thrissur.

56

Nirmala College of Information Technology, Chalakudy

You might also like

- 1 2 3 Do Your Own Mortgage Securitization AuditDocument4 pages1 2 3 Do Your Own Mortgage Securitization Auditkimberly_cromwell88% (8)

- Gokaldas PVT LTD: Visvesvaraya Technological UniversityDocument51 pagesGokaldas PVT LTD: Visvesvaraya Technological UniversityChandana DevrajNo ratings yet

- Organisation Study On Atlus Garment CompanyDocument68 pagesOrganisation Study On Atlus Garment CompanyAravinth Seetharaman100% (1)

- Introduction 34Document61 pagesIntroduction 34sundar11298100% (2)

- Summar Training ReportDocument35 pagesSummar Training ReportSuruli Ganesh100% (1)

- A Study On Sowmiya Spinning Mills at CoimbatoreDocument91 pagesA Study On Sowmiya Spinning Mills at CoimbatoreMeena Sivasubramanian100% (2)

- Internship Report On Cotton IndustryDocument28 pagesInternship Report On Cotton IndustryTariq Saleem83% (6)

- Gokaldas Company ReportDocument36 pagesGokaldas Company ReportShravani Raja100% (1)

- Report SipDocument37 pagesReport SipAmit Rewatkar50% (2)

- Apparel - Internship Aquarelle FinalDocument189 pagesApparel - Internship Aquarelle FinalDipika KumariNo ratings yet

- OS ReportDocument72 pagesOS ReportPrasanth C NairNo ratings yet

- Hacienda Luisita vs. PARC Case DigestDocument21 pagesHacienda Luisita vs. PARC Case DigestCyrus91% (11)

- Valuing ProjectsDocument5 pagesValuing ProjectsAjay SinghNo ratings yet

- Practice Problem Set #1 Capital Budgeting - Solution - : FIN 448, Sections 2 & 3, Fall 2020 Advanced Financial ManagementDocument5 pagesPractice Problem Set #1 Capital Budgeting - Solution - : FIN 448, Sections 2 & 3, Fall 2020 Advanced Financial ManagementAndrewNo ratings yet

- Research MethodologyDocument52 pagesResearch MethodologyBalakrishnan BalakrishnanNo ratings yet

- Organization Study About The Ikon Exports Manufacture and Export of Garments at TirupurDocument65 pagesOrganization Study About The Ikon Exports Manufacture and Export of Garments at TirupurMeena SivasubramanianNo ratings yet

- My SoreDocument38 pagesMy SoreRa Hu L MalladiNo ratings yet

- Gokaldas PVT LTD: Visvesvaraya Technological UniversityDocument51 pagesGokaldas PVT LTD: Visvesvaraya Technological UniversityChandana DevrajNo ratings yet

- Rajashekar Internship ReportDocument50 pagesRajashekar Internship ReportRAJASHEKAR A N100% (1)

- Insutrial Training: A Report On KG Denim Ltd. CoimbatoreDocument11 pagesInsutrial Training: A Report On KG Denim Ltd. CoimbatorePrabhakar Manoharan100% (2)

- Internship Report - Production Department (Garments) of AKH Knitting & Dyeing LTDDocument48 pagesInternship Report - Production Department (Garments) of AKH Knitting & Dyeing LTDJoshua Smith0% (1)

- Objectives of The InternshipDocument44 pagesObjectives of The InternshipRinkesh YadavNo ratings yet

- Textile Instution Training ReportDocument5 pagesTextile Instution Training Reportsathis_kumr91% (11)

- Summer Training Project in Textile by Vikas HedaDocument206 pagesSummer Training Project in Textile by Vikas Hedavikasheda68% (25)

- Industrial Vist Report PDFDocument13 pagesIndustrial Vist Report PDFDheesna A.SNo ratings yet

- A Summer Internship Report: Recruitment and Other HR Operations at Aditya Birla Fashion and Retail LimitedDocument30 pagesA Summer Internship Report: Recruitment and Other HR Operations at Aditya Birla Fashion and Retail Limitedarpit agrawal100% (3)

- 08 Review of LiteratureDocument24 pages08 Review of LiteratureShashi Bhushan100% (1)

- Ratio Analysis of Gokaldas Exports LTDDocument21 pagesRatio Analysis of Gokaldas Exports LTDGreeshmaNo ratings yet

- Textile ProjectDocument38 pagesTextile Projectsathyamoorthisasu80% (5)

- Industry ProfileDocument6 pagesIndustry Profilerams191989No ratings yet

- Report On Textile Industry of Surat.Document31 pagesReport On Textile Industry of Surat.PATELSHANI0% (1)

- Coc Project FinalDocument46 pagesCoc Project FinalMYTHRIYA DEVANANDHANNo ratings yet

- Siya RamDocument74 pagesSiya RamSubramanya Dg100% (1)

- Malabar Spinning and Weaving MillsDocument51 pagesMalabar Spinning and Weaving MillsMelvinNo ratings yet

- PandisitpDocument40 pagesPandisitpkrishna0% (1)

- Siyaram's Project Final New Hosp-Cod - SCRDocument46 pagesSiyaram's Project Final New Hosp-Cod - SCRdeeksha singh100% (3)

- Full Project ReportDocument110 pagesFull Project Reporteswari100% (3)

- Analysis of Textile IndustryDocument31 pagesAnalysis of Textile IndustryDinesh Gupta25% (4)

- Weaving MILL Summer Training ReportDocument41 pagesWeaving MILL Summer Training ReportArjun100% (2)

- Madura CoatsDocument53 pagesMadura CoatsGanga Dharan100% (7)

- South India Spinning Mills PVT LTD Swot Analysis: StrengthsDocument5 pagesSouth India Spinning Mills PVT LTD Swot Analysis: StrengthsananthakumarNo ratings yet

- Spinning Mill Organizational StudyDocument37 pagesSpinning Mill Organizational Studykarthick1679100% (5)

- On Arvind by VishalDocument34 pagesOn Arvind by VishalVishal ShahNo ratings yet

- Executive SummaryDocument2 pagesExecutive SummarySohel SiddiquiNo ratings yet

- Wa0004.Document51 pagesWa0004.Leelesh G100% (2)

- A Project Report On Working Capital at Banhatti Co-Operative Spinning Mill LTD, BanhattiDocument102 pagesA Project Report On Working Capital at Banhatti Co-Operative Spinning Mill LTD, BanhattiBabasab Patil (Karrisatte)No ratings yet

- Inplant Project Report On Malabar Spinning & Weaving MillsDocument75 pagesInplant Project Report On Malabar Spinning & Weaving MillsPrasanth Prabhakar81% (31)

- An Organizational Study On, Atlas Export Enterprises, ThirupurDocument64 pagesAn Organizational Study On, Atlas Export Enterprises, ThirupurShowmiya Maha0% (1)

- Chapter - V Summary of Findings, Suggestions and ConclusionDocument21 pagesChapter - V Summary of Findings, Suggestions and Conclusionsundar100% (2)

- Finance Project - TextileDocument72 pagesFinance Project - TextilePooja Bindal100% (1)

- A Report On Organizational Study Done at CHATHANNOR CO-OPERATIVE SPINNING MILLDocument73 pagesA Report On Organizational Study Done at CHATHANNOR CO-OPERATIVE SPINNING MILLanoopvince123No ratings yet

- 8 INTERNSHIP REPORT MTM Textile Mill Limited MBADocument85 pages8 INTERNSHIP REPORT MTM Textile Mill Limited MBAtajala33% (3)

- Brand Perception of Raymond Brand Project ReportDocument61 pagesBrand Perception of Raymond Brand Project ReportAbhi RoyNo ratings yet

- Spinning Mill Summer Internship ReportDocument63 pagesSpinning Mill Summer Internship ReportAnu Priya67% (3)

- Nagammal MillsDocument15 pagesNagammal Millsbala krisNo ratings yet

- Performance Appraisal System SPINNING MILLDocument85 pagesPerformance Appraisal System SPINNING MILLAkhil Anil Kumar75% (4)

- Siyaram Cloth ReportDocument76 pagesSiyaram Cloth ReportBipin Kumar100% (4)

- Company ProfileDocument8 pagesCompany Profileananthakumar100% (1)

- Alok Industries Final Report 2010-11.Document117 pagesAlok Industries Final Report 2010-11.Ashish Navagamiya0% (1)

- DSM Textile Industry at KarurDocument79 pagesDSM Textile Industry at KarurMeena Sivasubramanian50% (2)

- Performance AppraisalDocument35 pagesPerformance AppraisalR.SenthilNo ratings yet

- Industry ProfileDocument13 pagesIndustry ProfileMukesh kannan MahiNo ratings yet

- INDUSTRY PROFILE Senkunthar New EditedDocument10 pagesINDUSTRY PROFILE Senkunthar New EditedMukesh kannan MahiNo ratings yet

- Cotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingFrom EverandCotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingHua WangNo ratings yet

- Chapter 3Document7 pagesChapter 3Preema ReghuNo ratings yet

- Chapter 2Document1 pageChapter 2Preema ReghuNo ratings yet

- Chapter 1Document6 pagesChapter 1Preema ReghuNo ratings yet

- Chapter 1Document6 pagesChapter 1Preema ReghuNo ratings yet

- Basics of ISO 14001Document21 pagesBasics of ISO 14001Preema ReghuNo ratings yet

- Basics of ISO 14001Document21 pagesBasics of ISO 14001Preema ReghuNo ratings yet

- Contract of SaleDocument3 pagesContract of SaleMehwish JamilNo ratings yet

- Development & Financing Modular Refinery Project: NigeriaDocument10 pagesDevelopment & Financing Modular Refinery Project: NigeriaEmmanuel Tunde Renner100% (2)

- Internship Report On Trust Bank LimitedDocument126 pagesInternship Report On Trust Bank Limiteddigital_romeoNo ratings yet

- ViewDocument1 pageViewAhmad SaifanNo ratings yet

- Payal Sip DimrDocument39 pagesPayal Sip DimrPriyanka DashNo ratings yet

- Daftar Kantor Akuntan PublikDocument16 pagesDaftar Kantor Akuntan PublikLeni JanarkoNo ratings yet

- NCFM Model Test PaperDocument8 pagesNCFM Model Test PapersplfriendsNo ratings yet

- Department of Labor: Cepr062706Document2 pagesDepartment of Labor: Cepr062706USA_DepartmentOfLaborNo ratings yet

- Compak Suggested AnswersDocument8 pagesCompak Suggested Answersknprop134No ratings yet

- Horse Sport Ireland 2009 AccountsDocument57 pagesHorse Sport Ireland 2009 AccountsthestorydotieNo ratings yet

- Prepare CrossDocument139 pagesPrepare CrossRajashekar Reddy100% (1)

- Lehman Brothe-Ethical ReasoningDocument5 pagesLehman Brothe-Ethical ReasoningXu KeNo ratings yet

- OpTransactionHistoryUX506 05 2024Document6 pagesOpTransactionHistoryUX506 05 2024lokeshchandrakarNo ratings yet

- Class 1 Mathematical Basis For Managerial Decision - Chapter1 - GauravDocument42 pagesClass 1 Mathematical Basis For Managerial Decision - Chapter1 - Gauravlakshay187No ratings yet

- Solved Samuel Reese Sold 1 000 Shares of His Stock in MaroonDocument1 pageSolved Samuel Reese Sold 1 000 Shares of His Stock in MaroonAnbu jaromiaNo ratings yet

- AsahiDocument2 pagesAsahiABHAY KUMAR SINGHNo ratings yet

- Ratio Analysis of Textile IndustryDocument16 pagesRatio Analysis of Textile IndustryTanmayVanmali100% (1)

- Financial AccountingDocument9 pagesFinancial AccountingLegends FunanzaNo ratings yet

- Draft Scott Slides You Might Want To Use More To FollowDocument134 pagesDraft Scott Slides You Might Want To Use More To FollowSue Bozgoz100% (1)

- Chapter 1Document17 pagesChapter 1meet123097No ratings yet

- Gujarat Apollo Industries LimitedDocument30 pagesGujarat Apollo Industries LimitedChitsimran NarangNo ratings yet

- Rules AccessionDocument6 pagesRules AccessionEllen Glae DaquipilNo ratings yet

- A Study On Merger and Acquisition in Insurance Industry in IndiaDocument10 pagesA Study On Merger and Acquisition in Insurance Industry in IndiaYogendraNo ratings yet

- A Presentation On Inventory ManagementDocument24 pagesA Presentation On Inventory ManagementHari RittiNo ratings yet

- Chapter 6 Problems (Corporation)Document10 pagesChapter 6 Problems (Corporation)Xam Lawrenz Ramos67% (3)

- FINANCIAL REHABILITATION and INSOLVENCY ACT of 2010Document9 pagesFINANCIAL REHABILITATION and INSOLVENCY ACT of 2010Lara Delle0% (1)