Full Lift Spring Loaded Open PDF

Full Lift Spring Loaded Open PDF

Uploaded by

Venkatespatange RaoCopyright:

Available Formats

Full Lift Spring Loaded Open PDF

Full Lift Spring Loaded Open PDF

Uploaded by

Venkatespatange RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Full Lift Spring Loaded Open PDF

Full Lift Spring Loaded Open PDF

Uploaded by

Venkatespatange RaoCopyright:

Available Formats

Full lift Spring Loaded Safety Valve Open Bonnet

VSE 1, VSR 1

The VSE 1/ VSR 1 type Full Lift Safety Valves are specifically designed for Steam Boiler Service and meet the requirements of the Indian Boiler Regulations and the German Technical Rules for Power boilers (TRD 401 / 421). These valves are available in 16 sizes with orifice letters (A to R) and DIN flanges and 13 sizes with API-526 orifice sizes (EA-TA) and ANSI flanges covering set pressure ranges from 0.5 Bar to 500 Bar. A variety of materials are available to cover temperature ranges upto 5500C. The salient design and constructional features are : Inlet Full Nozzle made of forged materials to ensure safe operation at the highest pressure conditions. Body as well as inlet/outlet connections are deliberately oversized compared to the recommendations of API 526 to provide favourable flow characteristics and keep flow velocities and dynamic pressure losses low in the feed pipe. Stem is precisely guided by a piston, which slides in the guide bush. The piston and guide bush provide a large guiding area, which ensures concentric spindle loading and repeatability of opening and closing cycles. All internal parts made from corrosion resistant austenitic materials with balanced thermal expansion co-efficients. Provision of a Balanced Piston design to eliminate the effects of back pressure and achieve low reseat pressure differences (blowdown). Precisely wound spring made from chrome vanadium steel specially designed to eliminate eccentric loading and provide full relieving capacity at an accumulation of only 3%. Atmospheric cooling of spring and selfcompensating thermal design ensures that spring compression and rate remain consistent resulting in repeatability of operation at varying temperature conditions. All Valve bodies provided with sturdy mounting brackets to absorb reaction forces. All valves precisely set on pneumatic test bench and tested for seat leakage as per API-527. Type Tested TV . SV..- 519

Nozzle A105

Body ASTMA 216WCB 150 300 600 900 1500 2500 Psig

Range of Application Pressure / Temperature Rating for Flanges Working Temperature in 0C -29 to +38 50 100 150 200 250 300 350 19.6 18.65 51.1 48.75 102.1 100 153.2 150.3 253.3 250.4 452.6 412.3 2 Pressure in kg/cm (g) 17.7 46.4 92.8 139.1 231.9 386.5 15.85 45.1 92.5 135.7 226.1 376.9 14.0 43.8 87.6 131.5 219.1 365.2 12.1 41.7 83.4 125.2 208.6 347.2 10.2 38.7 77.5 116.2 193.7 322.8 8.85 36.9 73.9 110.9 184.8 308.9

375 7.5 35.7 72.9 109.4 182.3 303.9

400 6.5 34.5 69.0 103.5 172.5 287.5

425 5.5 2.9 57.5 86.3 143.8 239.6

ASTM Material

Nozzle A182 F22

Body ASTMA 217WC9 150 300 600 900 1500 2500 Psig

-29 to +38

50

Range of Application Pressure / Temperature Rating for Flanges Working Temperature in 0C 100 150 200 250 300 350 375 400 17.9 49.0 98.1 147.1 245.2 408.7 16.17 46.5 93.3 139.9 233.2 388.6 14.06 44.8 89.7 134.5 224.2 373.7 11.95 44.2 88.4 132.7 221.1 368.5 10.20 42.4 84.9 127.3 212.1 353.5 18.77 40.3 80.5 120.7 201.2 335.3 7.73 38.6 77.6 116.4 194.0 323.4 6.5 36.5 73.2 109.8 182.9 304.9

425 5.6 35.1 70.2 105.3 175.5 292.5

450 4.5 35.0 67.6 101.4 169.0 281.7

475 3.72 31.6 63.3 95.0 158.3 263.8

500 2.67 27.7 55.6 83.4 139.0 231.6

525 1.93 21.8 43.8 65.8 109.6 182.7

ASTM Material

20.5 19.33 52.5 51.1 103.4 102.4 155.1 153.6 258.6 256 431.0 426.7 2 Pressure in kg/cm (g)

Smallest Flow Diameter (do) and Smallest Flow Area (Ao) API-526 Orifice Code Letters

Orifice do Ao 2 letters (mm) (mm ) EA I II III 18 254 FA 18 254 EA I II III 24.5 471 FA 24.5 471 GA 24.5 471 HA 26.4 547 EA IV 13.2 139 JA 33.3 897 KA 40.4 1282 LA 51 2043 MA 59 2734 NA 62 3019 PA 80 5027 QA 99 7699 RA 126 12467 TA 156 19116 do - smallest flow diameter (mm) 2 A0 - Smallest flow area (mm )

For inspection dismantling a free space X=600mm must remain above

Accessory 110 A cooling spacer is recommended between body and bonnet to protect the spring at temperatures greater than 400 C. Height H increases by H1.

Example For Valve Specification:

VSE1 - 150 - 1 EA 2 -I -12 - 110 API Orifice and ANSI conn.

Data to be specified with enquiry or order:

Operating medium State of fluid (gaseous or liquid) Set. Pressure and service pressure. Service temperature. ( C) Discharge Capacity (Kg/hr) Ends Connections - Inlet/Outlet Density Sp. Gravity/ Mol. Wt. Of Medium. Pipe /Equipment Material

Standard accessories Material specification Spring Pressure group Outlet size DN Orifice code letter Inlet size DN Inlet nominal pressure Type of valve abbr.

API 526 Orifice Code Letters and ANSI Connections

Inlet DN 1 1 1 1 1 API Orifice Code EA (A) FA (B) GA (D) Outlet DN 2 2 2 2 2 2 2 2 2 2 2 2 3 3 3 3 4 4 4 4 4 4 4 4 6 6 6 6 6 6 6 6 6 6 6 6 8 8 8 8 8 Press. Group I II II III I I II III I I II III I I II III I I II II III I II III I II III I II III I II III I II III I II III I II EAHA 2 12 Set Pressure min max psig psig 7 640 640 1780 640 1780 1780 2850 7 640 7 640 640 1780 1780 2850 8 285 8 448 446 1280 1280 1990 8 285 8 448 448 1280 1280 1990 8 8 320 320 895 7 285 795 23 228 570 18 180 505 18 180 505 14 128 356 12 114 284 9 90 JA-KA 2 16 PN psig 150 150 300 300 150 150 300 300 150 150 150 300 150 150 150 300 Outlet S1 in. 4 4 5 5 4 6 6 6 1/2 4 6 6 6 7 4 /8 7 4 /8 4 7/8 3 6 /8 4 /8 5 5 /8 5 5 /8 6 6 3 6 /8 3 6 /8 1 8 /2 7 8 8 7 7 8 8 8 8 9 9 10 9 9 9 1/2 9 9 PA - RA 5 4 /16 26

7

1 1 2 2 2 2 2 2 2 2 / 3 3/4 3/4 4 4 4 4 6

HA (E)

PN psig 150-300 600-900 1500 1500-2500 150-300 600-900 1500 1500-2500 150-300 300-600 900 1500 150-300 300-600 600-900 1500 150-300 150-300 300-600 600 900-1500 150-300 300-600 900 -1500 150-300 300 600-900 150-300 300-600 600-900 150-300 300-600 600-900 150-300 300-600 600> 150-300 150-300 600 150 300

Inlet S2 in. 1 4 /8 1 4 /8 1 4 /8 1 4 /8 7 4 /8 7 4 /8 7 4 /8 7 4 /8 7 4 /8 7 4 /8 7 4 /8 7 4 /8 1 5 /8 1 5 /8 1 5 /8 1 6 /16 5 /8 3 5 /8 3 5 /8 1 6 /8 1 6 /8 1 6 /8 1 6 /8 7 1 7 /16 1 7 /16 1 7 /16 7 7 7 7 7 7 1 7 /8 1 7 /8 1 8 /8 7 9 /16 7 9 /16 9 7/16 7 9 /16 7 9 /16

3

H max. in. 12 12 12 14 12 12 12 14 13 13 14 18 12 12 14 14 16 16 16 16 18 16 16 21 22 28 22 23 29 29 23 29 29 39 42 42 39 42 42 40 44

Weight In lbs 22 22 22 38 22 22 22 38 31 31 49 66 66 66 107 145 70 70 110 110 160 86 120 75 132 178 220 200 245 310 200 245 310 350 375 440 465 485 485 575 600

JA (G) KA (H) LA (K) MA (L) NA (L) PA (N)

QA (P) RA 6 (R) Seat Code Letter Access 110 height mm H1 mm

285 150 320 150 895 150 895 150 1420 300 285 150 795 150 1280 300 228 150 570 150 1280 150 180 150 505 150 1000 150 180 150 505 150 1000 150 128 150 356 150 1010 150 114 150 284 150 600 150 90 150 230 150 LA-NA 2 26

Accessories For Safety Relief VALVES VSE 1. VSR 1 Balanced Piston SN 144

The VSE1/VSR1 valves can be fitted with balanced piston. SN 144. Which makes valves independent of back pressure. Valves with balanced pistons work in the same way as valves with bellows. The outer diameter of the balanced piston corresponds to the average seat diameter of the valve. The gap between the outer diameter of the piston and the inner diameter of the related bore in the cover is sealed by a gasket. This further increases tightness to the outside. The rear of the piston is relieved towards the atmosphere. The permissible back pressure ranges are the same as for the VSE/VSR5 valves, but there is here no limit set regards the loadability of the bellows. The loadability of the body must be taken into account with back pressures higher that 15%. Closing pressure differences of 5% can be obtained with accessory 144.

Recommended spare parts available as spare part kits. Material specification Service temperatures 13 14 17 12 0 0 0 0 -10 up to+425 (460) C. +425 up to+550 C +550 up to+650 C -50 up to+425 C Material A105 A216 WCB X20CrMo17 SS 431 SS 410 Cast Steel SS 304 SS 410 Carbon Steel A197B7 A194 2H 50CrV4 IS:320HT2 C20 GGG.40 SS304 A216 WCB SC20 SS SS 9S20 SS410 C20 SS410 A216WCB C20 SS SS X20Cr13 GGG40 C20 GGG40 GTW35 C20 Soft Iron C20 ST 37 Soft Iron X20Cr13 Soft Iron St37 Spring Steel Steel Material A182 F22 A217 WC9 X20CrMo17 SS 431 SS410 Cast Steel SS 304 SS 410 Carbon Steel A197B7 A194 2H 50CrV4 IS:320HT2 C20 GGG.40 SS304 A216 WCB SC20 SS SS 9S20 SS410 C20 SS410 A216WCB C20 SS SS X20Cr13 GGG40 C20 GGG40 GTW35 C20 Soft Iron C20 ST 37 Soft Iron X20Cr13 Soft Iron St37 Spring Steel Steel Material SS 304/316 A 351CF8 X20CrMo17 SS 431 SS410 Cast Steel SS 304 SS 410 GGG 40 A197B7 A194 2H 50CrV4 IS:320HT2 C20 GGG.40 SS304 A216 WCB SC20 SS SS 9S20 SS410 C20 SS410 A216WCB C20 SS SS X20Cr13 GGG40 C20 GGG40 GTW35 C20 Soft Iron C20 ST 37 Soft Iron X20Cr13 Soft Iron St37 Spring Steel Steel Material SS 316 A 216 WCB X20CrMo17 SS 431 SS410 Cast Steel SS 304 SS 410 GGG 40 A197B7 A194 2H 50CrV4 IS:320HT2 C20 GGG.40 SS304 A216 WCB SC20 SS SS 9S20 SS410 C20 SS410 A216WCB C20 SS SS X20Cr13 GGG40 C20 GGG40 GTW35 C20 Soft Iron C20 ST 37 Soft Iron X20Cr13 Soft Iron St37 Spring Steel Steel

Part Part Name No. 1 2 3 4 5 6 6a 7 8 9 9a 10 11 12 13 14 15 17 18 19 20 21 22 23 24 25 28 29 30 31 32 36 37 38 40 41 42 43 44 45 46 47 48 Inlet nozzle Body Seat Zone Disc Guide piston Guide bush Cover Stem Bonnet Bonnet stud Bonnet nut Spring Adjusting screw Lock nut Cap Adjusting ring Cooling spacer Gag plug Ball Dowel pin Spilt ring Stop bush Distance bush Pressure bush Spring stop Spring plate Lock nut Cotter pin Bush Fork Square shaft Lever Washer Hexagonal nut Gasket Cap Screw Drain plug Gasket Lock screw Gasket Washer Retaining ring Needle bearing

CLICK FOR ADDRESS

You might also like

- ASV 10 20 BrochureDocument8 pagesASV 10 20 BrochureThomas Duane DavidsonNo ratings yet

- Danflo Liquid Surge Relief Valve MJDocument8 pagesDanflo Liquid Surge Relief Valve MJSelvan McsNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCONo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Block & Bleed Valve: High Technology Valve & Fitting SeriesDocument20 pagesBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelNo ratings yet

- Vctds-02233 Model 171c (Asme) - enDocument12 pagesVctds-02233 Model 171c (Asme) - enDGWNo ratings yet

- 100G - 2100G ClavalDocument2 pages100G - 2100G Clavale1901bNo ratings yet

- MasterSeries 860 Specification SheetDocument2 pagesMasterSeries 860 Specification SheetFEBCONo ratings yet

- Series TDV Specification SheetDocument2 pagesSeries TDV Specification SheetWattsNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- AUTOMAX Supernova BrochureDocument12 pagesAUTOMAX Supernova BrochureEnrique Domingo Rubio100% (1)

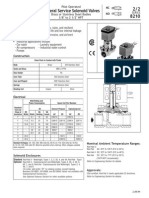

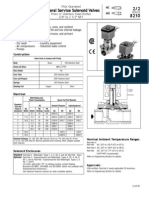

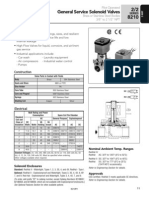

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- General Service Solenoid Valves: NC NODocument6 pagesGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzNo ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Series 805YD Specification SheetDocument2 pagesSeries 805YD Specification SheetFEBCONo ratings yet

- Spirax Sarco 25 PDocument2 pagesSpirax Sarco 25 Pmairimsp2003No ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- MasterSeries 880V Specification SheetDocument4 pagesMasterSeries 880V Specification SheetFEBCONo ratings yet

- Ball Valves: For SteamDocument8 pagesBall Valves: For SteamcontorrresjulianNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- Faslt 0020 enDocument6 pagesFaslt 0020 enshashikanth79No ratings yet

- DeZURIK KCG Knife Gate ValvesDocument12 pagesDeZURIK KCG Knife Gate ValvesKithkarnonNo ratings yet

- DSM PDFDocument8 pagesDSM PDFSlobodan AnticNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- AAP S18 Butterfly Valves E2 SDocument9 pagesAAP S18 Butterfly Valves E2 SPete KardumNo ratings yet

- Catálogo Válvula DirecionalDocument20 pagesCatálogo Válvula DirecionalcristianoclemNo ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- Econ Gate ValvesDocument22 pagesEcon Gate ValvesRiyas Udheen100% (1)

- Series U009 Specification SheetDocument4 pagesSeries U009 Specification SheetWattsNo ratings yet

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- 06 SCT Extended PDFDocument40 pages06 SCT Extended PDFSlobodan Antic100% (2)

- Gestra Check ValveDocument4 pagesGestra Check Valvetilakthakar1No ratings yet

- rc33026 D12-UscDocument7 pagesrc33026 D12-Usceww08No ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Valvula Check 6000 Lbsv3xDocument6 pagesValvula Check 6000 Lbsv3xMaik AmayaNo ratings yet

- Swagwlok Lap Flange PDFDocument6 pagesSwagwlok Lap Flange PDFPraveen KumarNo ratings yet

- Eko4000-4100 WebDocument4 pagesEko4000-4100 WebSubramanian SaravananNo ratings yet

- ASCO 8210r3Document6 pagesASCO 8210r3Ricardo RodrigoNo ratings yet

- Perar Compact Ball ValvesDocument16 pagesPerar Compact Ball ValvesUday GokhaleNo ratings yet

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- EJ Series Butterfly ValvesDocument12 pagesEJ Series Butterfly ValvesGia Minh Tieu TuNo ratings yet

- Reduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesDocument2 pagesReduced Port Ductile Iron Dual Chamber Basic Valve: Mustang Series Basic ValvesWattsNo ratings yet

- 8210 General Solenoid Valve ASCODocument6 pages8210 General Solenoid Valve ASCOyuri0527No ratings yet

- ABZ ValveDocument8 pagesABZ ValveJavierfox98No ratings yet

- RMG by Honeywell BD 277 Hi-Flo GB 2010-10Document8 pagesRMG by Honeywell BD 277 Hi-Flo GB 2010-10Jorge Henostroza IntiNo ratings yet

- Keystone Betterfly Valves AR1 y AR2 KEYMC-0025-USDocument4 pagesKeystone Betterfly Valves AR1 y AR2 KEYMC-0025-USpca97No ratings yet

- Series G4000-FDA Specification SheetDocument2 pagesSeries G4000-FDA Specification SheetWattsNo ratings yet

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)