PPL100 General Information

PPL100 General Information

Uploaded by

Anonymous PkeI8e84RsCopyright:

Available Formats

PPL100 General Information

PPL100 General Information

Uploaded by

Anonymous PkeI8e84RsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

PPL100 General Information

PPL100 General Information

Uploaded by

Anonymous PkeI8e84RsCopyright:

Available Formats

100 General Information

Abstract

The Pipeline Manual is a guide for the basic design and construction of pipeline systems. It focuses on design fundamentals, guidelines for practical installations, and specification and purchase of materials and services. It is applicable to small gathering pipelines, large transmission pipeline systems and offshore pipelines. Its guidelines encompass the experience of the Corporations Operating Companies. The manuals broad applicability makes it useful to both engineers and operating personnel. The Pipeline Manual is concerned only with pipelines. It does not provide design information for pump stations, compressor stations or tank terminals, even though these facilities may be covered by the pipeline design codes. The manual includes certain topics related to operations and maintenance, but not a comprehensive description of these functions. The Pipeline Manual organizes in one place much of the Companys information on pipelines, presented in guideline form. It includes Company specifications which are easily used by any Operating Company. Industry standards are also included. For some subjects it advises reference to the more complete discussions in other ETD manuals. Contents 110 120 130 140 150 Contents Code Compliance Legal Requirements Engineering Judgment Mandatory and Recommended Practice Page 100-2 100-2 100-3 100-4 100-4

Chevron Corporation

100-1

November 1988

100 General Information

Pipeline Manual

110 Contents

The Pipeline Manual is organized into two parts:

Part I - Engineering Guidelines

Section 100 provides a road map for the entire manual, and background information on engineering style. Section 200 describes how to select a pipeline route. Section 300 describes the selection of the physical parts of a pipeline: the pipe, components and coating. Section 400 explains pipeline design and the Companys preferred methods. Section 500 tells how to monitor your pipeline system by using SCADA systems. Section 600 discusses pipeline construction activities and contracting. Section 700 tells you how to ensure a good product through careful inspection and testing. Section 800 explains some operations and maintenance considerations that help produce practical designs. Section 900 covers the subject of offshore pipeline design and construction, discussing the differences and recapitulating the similarities between onshore and offshore pipelines.

Part II - Specifications

Section 2000 introduces the Specifications part of the manual and tells you how to use the documents contained there. The Company Specifications section contains model format specifications with comments and their corresponding data sheets. The Standard Forms and Drawings section contains forms and drawings that pertain to the pipeline guidelines in this manual. The Industry Codes and Practices section provides the industry specifications and practices that the Guidelines and Company Specifications reference. The Appendices provide references, conversion tables, sample specifications, sample guidelines, and background design calculations.

120 Code Compliance

The various pipeline codes (such as ANSI/ASME Codes B31.4 and B31.8 in the United States) contain practices necessary for safe pipeline systems, but are not intended to be complete specifications for all phases of design. The Company recognizes this fact, and the guidelines and specifications in this manual provide the

November 1988

100-2

Chevron Corporation

Pipeline Manual

100 General Information

supplemental requirements normally needed to obtain economical systems for basic fluid services. A few requirementswhere experience has shown them to be better choicesare more stringent than code minimums. Engineers responsible for design and construction of pipelines are expected to be familiar with and to comply with the appropriate codes even though some of their provisions may not be specifically included in this manual.

130 Legal Requirements

In general, pipelines which conform with ANSI/ASME Codes B31.4 and B31.8 will meet the legal requirements in the USA for gas and liquid pipelines and facilities such as pump stations and compressor stations. See Section 400 for elaboration. In the United States, the Occupational Safety and Health Act (OSHA) is mandatory. Other countries have similar legislation. For general petroleum industry piping, the major effect of OSHA is on construction safety and to forbid the use of regular cast iron for flammable or combustible liquids having a flash temperature below 200F or a temperature within 30F of their flash temperature. Steel, ductile cast iron or malleable cast iron are required. The details of OSHA regulations are still changing, and the most recent revision should be reviewed where the economic effect of this requirement is considerable. Pipeline activities in Canada are governed by the CAN3-Z183 and CAN/CSA-Z184 pipeline codes, and the CAN3-Z245 line pipe code. Some states and localities in the United States have adopted some sections of ANSI/ASME Code B31; however, it is not a legal requirement in most states. OSHA regulations strongly encourage use of Code B31 by stating that compliance with Code B31 and specific OSHA rules is prime facie evidence of compliance with OSHA basic requirements. The United States Code of Federal Regulations, Title 49, Part 192 and Part 195 (49 CFR 192 and 195) cover interstate and continental shelf oil piping and essentially all gas transportation piping. They define the minimum design requirements for oil and gas pipelines. Pipelines regulated by 49 CFR 192 and 195 are the responsibility of the Department of Transportation (DOT). 49 CFR 192 does not incorporate Code B31.8 by reference, while 49 CFR 195 does incorporate Code B31.4 by reference. However, Codes B31.4 and B31.8 contain supplemental design information and their use is recommended. In case of conflict, the applicable part of 49 CFR will govern. The United States Code of Federal Regulations, Title 30 Part 250 (30 CFR 250) covers oil, gas, and sulfur operators in the continental shelf. Pipelines regulated by 30 CFR 250 are the responsibility of the Department of the Interior (DOI). 30 CFR 250 covers flowlines, platforms, separation facilities, pumps, and compressors upstream of the first flange on the sales pipeline, which is usually a DOT responsibility pipeline. See Section 900 for explanation. Engineers responsible for design and construction of pipelines in the United States are expected to determine which codes are legally required and if there are any other federal, state, or local regulations governing such construction. The Company

Chevron Corporation

100-3

November 1988

100 General Information

Pipeline Manual

requires compliance with the most stringent practice. For installations outside the United States and Canada, the engineer responsible for piping design and construction should determine if there are national and local regulations pertaining to piping design. The ANSI/ASME codes remain good guidelines where no other regulations exist.

140 Engineering Judgment

The use of these Guidelines does not eliminate the need for sound engineering judgment. A few examples of special cases that are not covered by these guidelines and that should be given special consideration are: Extraordinary service conditions such as earthquake, high wind, other unusual dynamic loadings, or unusual superimposed dead loads Cold climates that may require special materials to avoid brittle fractures High H2S concentrations that may place restrictions on valve trim and weld hardness Consider upgrading of Class 150 flanges to Class 300 flanges where frequent blinding is required

It is necessary that the user of this manual realize that its use does not release him from his responsibility to use sound judgment in the selection of materials, fittings, valves, and other piping items to meet safety and economic considerations. No attempt has been made to provide for all the in-between or gray areas. Some examples of areas where variations could apply: Use of lighter wall pipe for low pressure systems Use of higher yield strength materials when economics dictate Variation in corrosion allowance or selection of material for handling of corrosive/erosive material

150 Mandatory and Recommended Practice

For the most part, this manual covers RECOMMENDED practice. However, certain codes govern some activities and require that the design and materials conform to a specific standard. These codes are therefore mandatory. MANDATORY in this context means that the engineer and/or operating personnel selecting equipment must conform to the selections as required by the governing code in order to meet minimum safety standards and government requirements. The following definitions also apply throughout this manual: SHALL and IS REQUIRED mean mandatory per code and/or Company requirements.

November 1988

100-4

Chevron Corporation

Pipeline Manual

100 General Information

SHOULD means advisory guidelines that are to be adhered to where no overriding objections are apparent. An advisory guideline represents a design which is applicable in most cases and represents the experience and expertise of the Company. PREFERRED and RECOMMENDED mean guide-lines which are generally and successfully used within the Company, but there are other choices and methods which are acceptable. MAY means acceptable or permitted options. The above definitions are the same as those used in the Companys Safety-inDesigns Manual.

Chevron Corporation

100-5

November 1988

You might also like

- B149 1handbookDocument241 pagesB149 1handbookDom Bergeron57% (7)

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Energy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamFrom EverandEnergy Calculations & Problem Solving Sourcebook: A Practical Guide for the Certified Energy Manager ExamNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

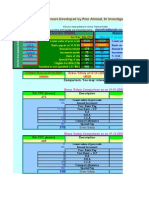

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Piping Chevron OffDocument44 pagesPiping Chevron OffdfdflkNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansRating: 5 out of 5 stars5/5 (2)

- Is My Machine OK?: A Field Guide to Assessing Process MachineryFrom EverandIs My Machine OK?: A Field Guide to Assessing Process MachineryNo ratings yet

- Boat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsFrom EverandBoat Mechanical Systems Handbook (PB): How to Design, Install, and Recognize Proper Systems in BoatsNo ratings yet

- SmokingFetish 1000 p1-100Document100 pagesSmokingFetish 1000 p1-100Anonymous PkeI8e84Rs63% (8)

- Codes and Standards: What Is A CodeDocument7 pagesCodes and Standards: What Is A CodeRushikesh TawareNo ratings yet

- 100 General Information: 110 Codes and Industry Practices 100-2Document15 pages100 General Information: 110 Codes and Industry Practices 100-2mika cabello100% (1)

- 1 - Introductoin To Non-Newtonian Fluid Time IndependentDocument13 pages1 - Introductoin To Non-Newtonian Fluid Time Independentsuruchi shrivastavaNo ratings yet

- Piping Design Codes and StandardDocument30 pagesPiping Design Codes and StandardHashim Ali100% (2)

- Engineering StandardsDocument14 pagesEngineering StandardsAbu SaemNo ratings yet

- CODES and STANDARDS PDFDocument10 pagesCODES and STANDARDS PDFemnptn2667No ratings yet

- American and British and Indian Codes and Standards: Benadict Subhash 7/8/2019Document10 pagesAmerican and British and Indian Codes and Standards: Benadict Subhash 7/8/2019Karthikeyan Parthasarathy100% (1)

- Module1 Stress ObjectiveDocument48 pagesModule1 Stress ObjectivepalluraviNo ratings yet

- Welding Code IndexDocument6 pagesWelding Code IndexAkhilesh KumarNo ratings yet

- American Society of Mechanical EngineersDocument4 pagesAmerican Society of Mechanical Engineersb3 qualNo ratings yet

- ASME B31.4a PDFDocument69 pagesASME B31.4a PDFhussein100% (1)

- Edc - Piping StandardsDocument11 pagesEdc - Piping StandardsSrikrishnan KrishNo ratings yet

- Practical Piping Course PDFDocument46 pagesPractical Piping Course PDFBhupendra S KhadtaleNo ratings yet

- Standards & Its Description OverviewDocument8 pagesStandards & Its Description OverviewBalakumarNo ratings yet

- AnsiDocument4 pagesAnsiHendrie NMcNo ratings yet

- Piping CourseDocument46 pagesPiping Coursemr_heeraNo ratings yet

- Piping CodesDocument3 pagesPiping Codesmexx4u2nvNo ratings yet

- Piping Codes & StandardsDocument12 pagesPiping Codes & StandardsAhmed Mansour100% (1)

- ASME B31 - Standards of Pressure PipingDocument3 pagesASME B31 - Standards of Pressure PipingRachit OzaNo ratings yet

- ETI - Standards and SpecificationsDocument31 pagesETI - Standards and SpecificationsLaurence MalanumNo ratings yet

- MSS SP 96 2001Document30 pagesMSS SP 96 2001Edi SupriyantoNo ratings yet

- Piping PDFDocument46 pagesPiping PDFGORO43100% (1)

- Asme B31 - Pressure PipingDocument3 pagesAsme B31 - Pressure PipingAndhyka Cakrabuana AdhitamaNo ratings yet

- Asme B31.1 Power PipingDocument21 pagesAsme B31.1 Power PipingIj Ooo100% (1)

- International Welding Codes and StandardsDocument17 pagesInternational Welding Codes and StandardsDominic Apollo Robles100% (1)

- Ni 2543Document11 pagesNi 2543marguepaNo ratings yet

- Welding Codes and How They're UsedDocument5 pagesWelding Codes and How They're UsedPasquale CutriNo ratings yet

- ASME Piping Code 2007 & ANSI CodeDocument162 pagesASME Piping Code 2007 & ANSI CodeTotoNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- FAR-AMT 2025: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2025: Federal Aviation Regulations for Aviation Maintenance TechniciansNo ratings yet

- FAR/AIM 2025: Federal Aviation Regulations/Aeronautical Information ManualFrom EverandFAR/AIM 2025: Federal Aviation Regulations/Aeronautical Information ManualNo ratings yet

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BFrom EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Audel HVAC Fundamentals, Volume 3: Air Conditioning, Heat Pumps and Distribution SystemsFrom EverandAudel HVAC Fundamentals, Volume 3: Air Conditioning, Heat Pumps and Distribution SystemsRating: 5 out of 5 stars5/5 (1)

- FAR-AMT 2019: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2019: Federal Aviation Regulations for Aviation Maintenance TechniciansRating: 5 out of 5 stars5/5 (2)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- Fluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryFrom EverandFluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- FAR-FC 2025: Federal Aviation Regulations for Flight CrewFrom EverandFAR-FC 2025: Federal Aviation Regulations for Flight CrewNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Codification of Statements on Standards for Attestation Engagements, January 2018From EverandCodification of Statements on Standards for Attestation Engagements, January 2018No ratings yet

- Textbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringFrom EverandTextbook of Urgent Care Management: Chapter 5, Business Formation and Entity StructuringNo ratings yet

- Instrument Procedures Handbook (2024): FAA-H-8083-16BFrom EverandInstrument Procedures Handbook (2024): FAA-H-8083-16BRating: 4 out of 5 stars4/5 (5)

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Quality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsFrom EverandQuality and Reliability Aspects in Nuclear Power Reactor Fuel Engineering: Guidance and Best Practices to Improve Nuclear Fuel Reliability and Performance in Water Cooled ReactorsNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Busty Mature Lady Smokes A CigaretteDocument1 pageBusty Mature Lady Smokes A CigaretteAnonymous PkeI8e84Rs0% (2)

- SmokingFetish 1000 p101 198Document98 pagesSmokingFetish 1000 p101 198Anonymous PkeI8e84Rs50% (4)

- Álvarez ATE 2016Document16 pagesÁlvarez ATE 2016Anonymous PkeI8e84RsNo ratings yet

- Item 2U Staff ReportDocument22 pagesItem 2U Staff ReportAnonymous PkeI8e84RsNo ratings yet

- Sample of WorkDocument21 pagesSample of WorkAnonymous PkeI8e84RsNo ratings yet

- Test Doc 001Document1 pageTest Doc 001Anonymous PkeI8e84RsNo ratings yet

- Smoking BabeDocument3 pagesSmoking BabeAnonymous PkeI8e84RsNo ratings yet

- CHP 11Document62 pagesCHP 11Anonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ kkfkdf90595lllkkkkkkkkDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ kkfkdf90595lllkkkkkkkkAnonymous PkeI8e84RsNo ratings yet

- Hillary Has Fun2Document1 pageHillary Has Fun2Anonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJ LLL LLDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJ LLL LLAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJ JJ JJJAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDF HHJJJAnonymous PkeI8e84RsNo ratings yet

- SDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDFDocument1 pageSDSD 88 88 999 Ji Iuy F Iyta 8889 987 JJJ SDSD 9999jjj KK JJ KKFKDFAnonymous PkeI8e84RsNo ratings yet

- Conversion From Volume To Energy MeasurementDocument3 pagesConversion From Volume To Energy Measurementaliscribd46No ratings yet

- Psychometric Success Numerical Ability - Estimation Practice Test 1Document0 pagesPsychometric Success Numerical Ability - Estimation Practice Test 1Anonymous PkeI8e84Rs100% (1)

- Pe Civil Cost Analysis Fall 2012Document67 pagesPe Civil Cost Analysis Fall 2012Anonymous PkeI8e84Rs100% (1)