Finishing Operations

Finishing Operations

Uploaded by

Nitin B maskeCopyright:

Available Formats

Finishing Operations

Finishing Operations

Uploaded by

Nitin B maskeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Finishing Operations

Finishing Operations

Uploaded by

Nitin B maskeCopyright:

Available Formats

138

Finishing processes

Valery Marinov, Manufacturing Technology

7.2 FINISHING OPERATIONS Introduction

As the name of this group of abrasive operations suggests, their objective is to achieve superior surface finish up to mirror-like finishing and very close dimensional precision. The finishing operations are assigned as the last operations in the single part production cycle usually after the conventional or abrasive machining operations, but also after net shape processes such as powder metallurgy, cold flashless forging, etc. The finishing processes discussed in this section include honing, lapping, superfinishing, polishing, and buffing. The typical surface finishes for these operations are presented in the figure. Also presented for comparison are surface roughness values for fine grit size grinding.

Honing

Honing is a finishing process performed by a honing tool, which contains a set of three to a dozen and more bonded abrasive sticks. The sticks are equally spaced about the periphery of the honing tool. They are held against the work surface with controlled light pressure, usually exercised by small springs. The honing tool is given a complex rotational and oscillatory axial motion, which combine to produce a crosshatched lay pattern of very low surface roughness:

Schematics of honing process showing the honing tool, how the abrasive sticks are pressed against the work surface by springs, and the resulting surface pattern.

Valery Marinov, Manufacturing Technology

Finishing processes

139

In addition to the surface finish of about 0.1 m, honing produces a characteristic crosshatched surface that tends to retain lubrication during operation of the component, thus contributing to its function and service life. A cutting fluid must be used in honing to cool and lubricate the tool and to help remove the chips. A common application of honing is to finish the holes. Typical examples include bores of internal combustion engines, bearings, hydraulic cylinders, and gun barrels.

Lapping

In lapping, instead of a bonded abrasive tool, oil-based fluid suspension of very small free abrasive grains (aluminum oxide and silicon carbide, with typical grit sizes between 300 and 600) called a lapping compound is applied between the workpiece and the lapping tool. The lapping tool is called a lap, which is made of soft materials like copper, lead or wood. The lap has the reverse of the desired shape of the workpart. To accomplish the process, the lap is pressed against the work and moved back and forth over the surface in a figure-eight or other motion pattern, subjecting all portions of the surface to the same action. Lapping is sometimes performed by hand, but lapping machines accomplish the process with greater consistency and efficiency.

Schematics of lapping process showing the lap and the cutting action of suspended abrasive particles.

The cutting mechanism in lapping is that the abrasives become embedded in the lap surface, and the cutting action is very similar to grinding, but a concurrent cutting action of the free abrasive particles in the fluid cannot be excluded. Lapping is used lo produce optical lenses, metallic bearing surfaces, gages, and other parts requiring very good finishes and extreme accuracy.

Superfinishing

Superfinishing is a finishing operation similar to honing, but it involves the use of a single abrasive stick. The reciprocating motion of the stick is performed at higher frequency and smaller amplitudes. Also, the grit size and pressures applied on the abrasive stick are smaller. A cutting fluid is used to cool the work surface and wash away chips.

Schematics of the superfinishig process.

140

Finishing processes

Valery Marinov, Manufacturing Technology

In superfinishing, the cutting action terminates by itself when a lubricant film is built up between the tool and work surface. Thus, superfinishing is capable only of improving the surface finish but not dimensional accuracy.The result of these operating conditions is mirror like finishes with surface roughness values around 0.01 m. Superfinishing can be used to finish flat and external cylindrical surfaces.

Polishing and buffing

Polishing is a finishing operation to improve the surface finish by means of a polishing wheel made of fabrics or leather and rotating at high speed. The abrasive grains are glued to the outside periphery of the polishing wheel. Polishing operations are often accomplished manually. Buffing is a finishing operation similar to polishing, in which abrasive grains are not glued to the wheel but are contained in a buffing compound that is pressed into the outside surface of the buffing wheel while it rotates. As in polishing, the abrasive particles must be periodically replenished. As in polishing, buffing is usually done manually, although machines have been designed to perform the process automatically.

Schematics of the buffing operation.

Polishing is used to remove scratches and burrs and to smooth rough surfaces while butting is used to provide attractive surfaces with high luster.

You might also like

- Inductance, Inductive Reactance, and Inductive Circuits Inductance, Inductive Reactance, and Inductive CircuitsDocument51 pagesInductance, Inductive Reactance, and Inductive Circuits Inductance, Inductive Reactance, and Inductive CircuitsKareen Chua0% (1)

- Lab Report M&EDocument11 pagesLab Report M&EKhairul NadzmiNo ratings yet

- Lab3 Study+on+Hydraulic+JumpDocument7 pagesLab3 Study+on+Hydraulic+JumpAhmadAliAKbarPhambraNo ratings yet

- Surface Finishing ProcessDocument28 pagesSurface Finishing ProcessRavichandran GNo ratings yet

- DM-Intro 16.0 L05 Geometry Simplification and RepairDocument24 pagesDM-Intro 16.0 L05 Geometry Simplification and RepairNitin B maskeNo ratings yet

- Blanking and PiercingDocument5 pagesBlanking and PiercingSatheesh Sekar100% (1)

- Assignment Hydrailics 2Document12 pagesAssignment Hydrailics 2shehan madusankaNo ratings yet

- Full Hacksaw ReportDocument7 pagesFull Hacksaw ReportIqbalRifat0% (1)

- Brinell Hardness ReportDocument3 pagesBrinell Hardness Reportjaibalayya100% (1)

- Standards of MeasurementDocument12 pagesStandards of MeasurementShubham KheraNo ratings yet

- Sigma ComparatorDocument4 pagesSigma ComparatorJonathan SequeiraNo ratings yet

- Workshop Practice Lab Report PDFDocument58 pagesWorkshop Practice Lab Report PDFAli ahmadNo ratings yet

- AUTOCOLLIMATORDocument6 pagesAUTOCOLLIMATORAhmed Almujabber100% (1)

- Radius Measurement NewDocument26 pagesRadius Measurement NewNayemNo ratings yet

- Assignment No 1 HTDocument4 pagesAssignment No 1 HTDhiraj DhimanNo ratings yet

- ME 4241-02-Screen Analysis Screen EffectivenessDocument51 pagesME 4241-02-Screen Analysis Screen EffectivenessEric PaderNo ratings yet

- Introduction To Casting Processes: BackgroundDocument5 pagesIntroduction To Casting Processes: BackgroundSubhasis BiswalNo ratings yet

- Experiment Title: Phenomenon of Choing in A Convergent-Divergent DuctDocument26 pagesExperiment Title: Phenomenon of Choing in A Convergent-Divergent Ductjohn100% (2)

- Shaper MachineDocument4 pagesShaper MachineJaydeep Sakariya60% (5)

- Lab 1 - MillingDocument12 pagesLab 1 - MillingLuqman HakimNo ratings yet

- Utm PDFDocument5 pagesUtm PDFaybi pearlNo ratings yet

- Functions and Characteristics of InstrumentsDocument29 pagesFunctions and Characteristics of InstrumentsMarion AlyssaNo ratings yet

- Measuring MachineDocument19 pagesMeasuring Machinegopir28No ratings yet

- Basic Principle of Bourdon Tube Pressure GaugeDocument3 pagesBasic Principle of Bourdon Tube Pressure GaugeLarry SmithNo ratings yet

- FMM - Unit Iv QBDocument52 pagesFMM - Unit Iv QBThiruvasagamoorthy KaNo ratings yet

- Unit 10 - Week 7: Assignment 7Document5 pagesUnit 10 - Week 7: Assignment 7Umamaheswararao TumatiNo ratings yet

- Mech Lathe Machine ReportDocument15 pagesMech Lathe Machine ReportLary Dela Cruz Guevarra100% (2)

- Lab Practical 1 (Moisture Content)Document7 pagesLab Practical 1 (Moisture Content)Saiful IsmawiNo ratings yet

- Apparatus:: Use The Vernier Caliper To Measure The Dimension of PinsDocument4 pagesApparatus:: Use The Vernier Caliper To Measure The Dimension of Pinsitezaz ahmedNo ratings yet

- Ipe Lab Report 4Document11 pagesIpe Lab Report 4Sourav Sutradhar0% (1)

- Linear Measurement ReportDocument11 pagesLinear Measurement ReportMuhd Qayyum Mohd FuadNo ratings yet

- Zonal CavityDocument32 pagesZonal CavityarkidechNo ratings yet

- Activity Activity Activity Activity Activity: Aboratory AnualDocument3 pagesActivity Activity Activity Activity Activity: Aboratory AnualHarsh ShahNo ratings yet

- Unit 4 Flow Through Mouthpieces and Minor Losses: StructureDocument25 pagesUnit 4 Flow Through Mouthpieces and Minor Losses: StructureMir Mustafa AliNo ratings yet

- Hole DiggerDocument67 pagesHole DiggerJeevan Landge Patil0% (1)

- Investigation of Mechanical and Electrical Properties of Kevlar/e-Glass and Basalt/e-Glass Reinforced Hybrid CompositesDocument8 pagesInvestigation of Mechanical and Electrical Properties of Kevlar/e-Glass and Basalt/e-Glass Reinforced Hybrid CompositesTJPRC PublicationsNo ratings yet

- Test On Open - Coiled Helical Spring: Ex. No.:8 Sahil ChoudhuryDocument5 pagesTest On Open - Coiled Helical Spring: Ex. No.:8 Sahil ChoudhurysahilNo ratings yet

- 3 Phase Lab ReportDocument2 pages3 Phase Lab ReportSheikh BajunaidNo ratings yet

- Notes - Workshop Practice (Fitting Shop)Document16 pagesNotes - Workshop Practice (Fitting Shop)Abubakar Ch100% (1)

- Three Point Bend TestDocument3 pagesThree Point Bend TestShreyansh Shukla100% (1)

- Mechanical Workshop ReportDocument4 pagesMechanical Workshop ReportHumaid Al-'Amrie83% (6)

- Geoinformatics Laboratory Exercise-1: Map Reading (Lab Report)Document2 pagesGeoinformatics Laboratory Exercise-1: Map Reading (Lab Report)vyushNo ratings yet

- FinalPaperTO VERIFY THE MOMENTUM EQUATION BY IMPACT OF JET APPRATUS ON FLAT PLATE 191283Document4 pagesFinalPaperTO VERIFY THE MOMENTUM EQUATION BY IMPACT OF JET APPRATUS ON FLAT PLATE 191283Katy PerryNo ratings yet

- S e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eDocument4 pagesS e N I H C A M G N I T S e T L A S R e V I N U C I N o R T C L eahana expotech lab abeerNo ratings yet

- KOM Expt. No. 2Document5 pagesKOM Expt. No. 2Vatsal PatelNo ratings yet

- Primary Shaping ProcessDocument51 pagesPrimary Shaping ProcessHar Quin50% (2)

- Lab 6 - Compression Testing of WoodDocument5 pagesLab 6 - Compression Testing of WoodManikandan Selvam0% (1)

- To Determine Central Deflection of Simply Supported Beam by A Concentrated Load at The MidDocument4 pagesTo Determine Central Deflection of Simply Supported Beam by A Concentrated Load at The MidzainNo ratings yet

- Generation of Electricity Using ShoesDocument17 pagesGeneration of Electricity Using ShoesMozammel HossainNo ratings yet

- Summing AmplifierDocument6 pagesSumming AmplifierAhmed ShaabanNo ratings yet

- Module 2: Friction: Junction GrowthDocument12 pagesModule 2: Friction: Junction GrowthMohammad Ishfaq BhatNo ratings yet

- Automatic Water Level Control of A TankDocument44 pagesAutomatic Water Level Control of A TankTadele AmogneNo ratings yet

- Lab 5Document16 pagesLab 5Poit X NincompoopsNo ratings yet

- Photocopying ProcessesDocument96 pagesPhotocopying Processesbishoppyrc100% (5)

- Unit 1 Introduction To EstimationDocument6 pagesUnit 1 Introduction To EstimationNidhi Mehta100% (2)

- My It ReportDocument27 pagesMy It Reportantonymous001No ratings yet

- Mce516 Lecture Note 5Document31 pagesMce516 Lecture Note 5Edward JNo ratings yet

- Unit IV Surface Finishing Opertrations 4 SEM GCOE S N GANDHAREDocument8 pagesUnit IV Surface Finishing Opertrations 4 SEM GCOE S N GANDHARE40 siddhesh petkarNo ratings yet

- Surface Finishing Processes - Manufacturing Processes-IIDocument68 pagesSurface Finishing Processes - Manufacturing Processes-IIrohan100% (2)

- Finishing OperationDocument10 pagesFinishing Operationমুকসেতিন আল রাজী রিফাতNo ratings yet

- 4b. Self Study - MEC 501 - Surface Finishing ProcessesDocument6 pages4b. Self Study - MEC 501 - Surface Finishing ProcessesShovan KarmakarNo ratings yet

- NSQF Level - 6Document43 pagesNSQF Level - 6Nitin B maskeNo ratings yet

- Welding JointsDocument87 pagesWelding JointsNitin B maskeNo ratings yet

- DEMONSTRATION - Const. of A HelixDocument2 pagesDEMONSTRATION - Const. of A HelixNitin B maske100% (1)

- Demo Plan BOLTDocument2 pagesDemo Plan BOLTNitin B maskeNo ratings yet

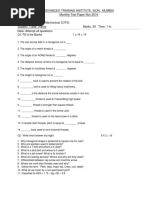

- Advanced Training Institute, Sion, Mumbai Monthly Test Paper Nov 2016 Trade: Draughtsman Mechanical (CITS) Subject: Trade Theory Marks: 30 Time: 1 HRDocument1 pageAdvanced Training Institute, Sion, Mumbai Monthly Test Paper Nov 2016 Trade: Draughtsman Mechanical (CITS) Subject: Trade Theory Marks: 30 Time: 1 HRNitin B maskeNo ratings yet

- Locking DeviceDocument38 pagesLocking DeviceNitin B maskeNo ratings yet

- Tamil-Marathi Dictionary. तमिऴ-मराठी शब्दकोश (PDFDrive) PDFDocument815 pagesTamil-Marathi Dictionary. तमिऴ-मराठी शब्दकोश (PDFDrive) PDFNitin B maske75% (4)

- Urdu-marathi dictionary. उर्दू-मराठी शब्दकोश. اُردو مراٹھی شبدکوشDocument500 pagesUrdu-marathi dictionary. उर्दू-मराठी शब्दकोश. اُردو مراٹھی شبدکوشNitin B maske100% (1)

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocument34 pagesNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maskeNo ratings yet

- Boiler MountingsDocument42 pagesBoiler MountingsNitin B maskeNo ratings yet

- Boiler AccessoriesDocument46 pagesBoiler AccessoriesNitin B maskeNo ratings yet

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocument27 pagesNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maske100% (1)

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsDocument24 pagesNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maskeNo ratings yet

- Nsti, Mumbai: Draughtsman Mechanical - CitsDocument41 pagesNsti, Mumbai: Draughtsman Mechanical - CitsNitin B maskeNo ratings yet

- Annexure III - ChecklistDocument1 pageAnnexure III - ChecklistNitin B maskeNo ratings yet

- Advanced Training Institute, Mumbai Draughtsman Mechanical: Nitin MaskeDocument67 pagesAdvanced Training Institute, Mumbai Draughtsman Mechanical: Nitin MaskeNitin B maskeNo ratings yet

- Lathe PDFDocument130 pagesLathe PDFNitin B maskeNo ratings yet

- AssyDocument17 pagesAssyNitin B maskeNo ratings yet

- D'man - Mech - CTS - NSQF-5 SyllabusDocument58 pagesD'man - Mech - CTS - NSQF-5 SyllabusNitin B maskeNo ratings yet

- DM-Intro 16.0 L03 Basics of DesignModelerDocument26 pagesDM-Intro 16.0 L03 Basics of DesignModelerNitin B maskeNo ratings yet

- NSQFDocument23 pagesNSQFNitin B maske100% (1)

- Advanced Training Institute: Draughtsman Mechanical CitsDocument36 pagesAdvanced Training Institute: Draughtsman Mechanical CitsNitin B maskeNo ratings yet

- Dvanced Training Institute Umbai: Draughtsman Mechanical CITSDocument39 pagesDvanced Training Institute Umbai: Draughtsman Mechanical CITSNitin B maske100% (1)