Mix BM & SDBC

Mix BM & SDBC

Uploaded by

hafsalCopyright:

Available Formats

Mix BM & SDBC

Mix BM & SDBC

Uploaded by

hafsalOriginal Description:

Copyright

Available Formats

Share this document

Read this document in other languages

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Mix BM & SDBC

Mix BM & SDBC

Uploaded by

hafsalCopyright:

Available Formats

JOB MIX FORMULA : BITUMINOUS MACADAM 5 CM THICK

Name of work : BM/SDBC works between Km 430 to 440 on NH-16 (Job No 1206/54)

i)Source and location of all materials :

CA No : CE (P) Hirak/23/2008-09

Type of material : Stone Agg for BM

Name of Contractor : M/S Sadanand Jha, Jagdalpur (C.G)

Date of Test : 04 Mar 2009

ii)Proportions of all materials expressed as follows where each is applicable:

Stone aggregates as per Table- 500-4 of MOSRTH specifacations

For BM 5 cm thick

Binder type, and percentage by weight of total mixture;

Bitumen Grade 60/70 @ 3.30% wt of total mix

(b) Coarse aggregate/Fine aggregate/Mineral filler as percentage by weight of total

aggregate including mineral filler;

S/Chips

20mm

S/Chips

10 mm

S/Chips

6mm

Sand

25% 35% 30% 10%

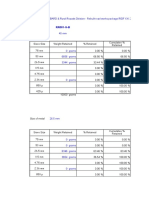

(iii) A single definite percentage passing each sieve for the mixed aggregate;

26.5 100.00 100

19 93.75 90-100

13.2 72.12 50-88

4.75 29.11 16-36

2.36 13.26 4-19

300mic 4.65 2-10

75mic 1.20 0-8

(iv) The individual gradings of the individual aggregate fractions, and the proportion of each in

the combined grading.

IS Sieve S/Chips

20mm

S/Chips

10 mm

S/Chips

6mm

Sand Combined

Aggregate proportion % 25 35 30 10 100

26.5 25 35 30 10 100 100

19 18.75 35 30 10 93.75 90-100

13.2 0.965 31.15 30 10 72.115 50-88

4.75 2.401 16.71 10 29.111 16-36

2.36 0.329 3 9.93 13.259 4-19

300mic 0.091 0.054 4.5 4.645 2-10

75mic 0 1.2 1.2 0-8

(v) The results of tests specimens

Minimum stability (kN at

600C) 9.2

Minimum flow (mm)

2.1

Maximum flow (mm)

3.83

Compaction level

(Number of blows)

75 Blows

faces of the specimen

MOSRTH

limits

MOSRTH

limits

Sieve

Desig

%age

passing

Per cent air voids

4.2

Per cent voids in mineral

aggregate (VMA) See

Table 500-12 below.

0

Per cent voids filled with

bitumen (VFB)

72

Where the mixer is a batch mixer, the individual weights of each type of aggregate, and

binder per batch,

NOT APPLICABLE

Test results of physical characteristics of aggregates to be used;

Test Results obtained MOSRTH limits

Cleanliness Grain size analysis1

Flakiness and Elongation Index

Aggregate Impact Value

Soundness

Sodium Sulphate

Magnesium Sulphate

Water Absorption

Stripping value

Retained tensile strength

(viii) Mixing temperature and compacting temperature.

Temp

Bitumen Mixing 160

Aggregate mixing 160

Laying 140

Rolling 120

While establishing the job mix formula, the Contractor

87

Max 5%

Max 30%

Max 40%

Max 12%

Max 18%

Max 2%

Min 95%

Min 80%

28.8

7.3

12.6

1.7

97

4.4 % passing 0.075

mm sieve

28.3

Aggregates & Binder required for BM 5 cm thick

Stone Agg 20mm = 25%

Stone Agg 10mm = 35%

Stone Agg 6mm = 30%

Stone Dust = 10%

2. Binder Content = 3.45%

3. Results Obtained

= 1.43gm/cc

= 2.23 gms/cc

= 0.076935 gm/cc

= 2.1531 gm/cc

= 2.15/1.3

= 1.503 Units

= 10x0.05x1.503 0.7515 Cum

Say 0.75 cum/10 sqm

Bitumen required

Area = 10 Sqm

Volume of mix = 10x0.050 = 0.50 Cum

Total Wt of mix = 0.50x2.23

= 1.115 MT

5. Weight of Bitumen = @ 3.45% of total mix

38.4 Kg Per 10 sqm

Stone chips 19mm 0.75 cum/10 Sqm

Bitumen 38.40 Kg/10 Sqm

Therefore combined aggregates

required for 10 Sqm area of 5cm thick

BM

Requirement of materials & stores

1. Proportion of Aggregate

Bulk density of combined aggregate

Bulk density of compacted mix

Quantity of binder@3.45%

Net aggregate density

Quantity of bulk aggregates required

for one unit of Mix

You might also like

- PQC Mix DesignDocument60 pagesPQC Mix DesignAshok amlapure70% (10)

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- Asme SB-443Document11 pagesAsme SB-443coronado777No ratings yet

- SDBC Design CalculationsDocument30 pagesSDBC Design Calculationsakst1976200095% (19)

- Test Report: Pavement Quality Concrete Mix Design of M-45 GradeDocument20 pagesTest Report: Pavement Quality Concrete Mix Design of M-45 GradeImran Khan100% (1)

- BC Mix Design G-2 STKKDocument99 pagesBC Mix Design G-2 STKKImran Khan100% (7)

- Grading Analysis For WMM, DBM, BM, BCDocument5 pagesGrading Analysis For WMM, DBM, BM, BCBilal Ahmed Barbhuiya91% (11)

- National Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Document37 pagesNational Highways Authority of India.: Design Mix Summary of Semi Dense Bituminous Concrete (Grade-2)Rahul Goyal100% (2)

- WMM Plant CalibrationDocument5 pagesWMM Plant CalibrationAnonymous zyIPjL9vNo ratings yet

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- GSB Mix Design NSK-66 PDFDocument63 pagesGSB Mix Design NSK-66 PDFJalgaon100% (3)

- WMM 1067-1Document14 pagesWMM 1067-1Imran Khan100% (1)

- QAP For Bitumen JobDocument2 pagesQAP For Bitumen JobSasanka SekharNo ratings yet

- Comparison of CBR Values For Different Grades of GSB Material As Per Morth Guidelines 2013Document40 pagesComparison of CBR Values For Different Grades of GSB Material As Per Morth Guidelines 2013Siddharth Borah100% (2)

- Design Mix GSBDocument1 pageDesign Mix GSBsoma100% (1)

- Methodology For Filter Media Behind The Structure MaterialDocument5 pagesMethodology For Filter Media Behind The Structure MaterialKunal Paul100% (2)

- Production of AcetaldehydeDocument173 pagesProduction of AcetaldehydeMuhammad Awais100% (1)

- Acidity of Tea LeavesDocument17 pagesAcidity of Tea LeavesAviral 1775% (20)

- DBM Mix DesignDocument22 pagesDBM Mix DesignImran Khan50% (10)

- Test Report: Consulting Engineers Group LTDDocument9 pagesTest Report: Consulting Engineers Group LTDImran Khan100% (1)

- m25 Mix DesignDocument7 pagesm25 Mix Design98675No ratings yet

- BC Mix Design SqmeDocument39 pagesBC Mix Design SqmePrasanna S Kulkarni0% (1)

- Trial 1 Analysis of Report (DBM 2)Document12 pagesTrial 1 Analysis of Report (DBM 2)JaneshaNo ratings yet

- DBMDocument29 pagesDBMEnd EndNo ratings yet

- Bitumen VG 30 & VG 40 Mix DesignDocument5 pagesBitumen VG 30 & VG 40 Mix DesignPoirei Zildjian50% (2)

- Annexure 5.14 BC Mix DesignDocument10 pagesAnnexure 5.14 BC Mix Designmiesty50% (2)

- Kship GVR: Sorce: Sankanur Cross CrusherDocument9 pagesKship GVR: Sorce: Sankanur Cross CrusherVijay Jamadar100% (1)

- GSB GR V 5th Rev - 1Document58 pagesGSB GR V 5th Rev - 1veevimalNo ratings yet

- PQC Mix Design 01 (Camp 01) 1Document120 pagesPQC Mix Design 01 (Camp 01) 1Imran Khan67% (3)

- Calibration of Pouring CylinderDocument16 pagesCalibration of Pouring CylinderAnonymous drBWfwhNo ratings yet

- 1 WMM Mix DesignDocument21 pages1 WMM Mix Designvikas kumar100% (1)

- DBM Mix Design No.-1Document81 pagesDBM Mix Design No.-1pujan patel100% (1)

- Source: Summary of CTSB Mix DesignDocument20 pagesSource: Summary of CTSB Mix DesignAbhishek pathakNo ratings yet

- WMM Plant CalibrationDocument13 pagesWMM Plant CalibrationDeepakNo ratings yet

- Mistake in Bitumen Content Assessment in OGPC and SC in APDocument14 pagesMistake in Bitumen Content Assessment in OGPC and SC in APPrakasam VemavarapuNo ratings yet

- Draft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenDocument3 pagesDraft Letter Regarding Source Approval For Bituminous Concrete Grade-1 With BPCL - VG - 30 BitumenAmol Jadhav50% (4)

- Recommended Revisions To MORTH Specifications Section 500 by Prof. Kandhal 18 May 2009Document44 pagesRecommended Revisions To MORTH Specifications Section 500 by Prof. Kandhal 18 May 2009Prof. Prithvi Singh Kandhal100% (1)

- BC Job MixDocument3 pagesBC Job MixSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Concrete Mix Design PQC M40Document5 pagesConcrete Mix Design PQC M40Pirpasha Ujede50% (2)

- GSB Design Mix Ashapuri CrusherDocument36 pagesGSB Design Mix Ashapuri Crushervikas kumarNo ratings yet

- Sieve Analysis of Wet Mix MacadamDocument2 pagesSieve Analysis of Wet Mix Macadamjitendra100% (3)

- WMM Mix DesignDocument12 pagesWMM Mix DesignSusanta Kumar DeyNo ratings yet

- M25 Mix Design & Trial SheetDocument3 pagesM25 Mix Design & Trial Sheetabir senguptaNo ratings yet

- Field Density Test by Sand Replacement MethodDocument1 pageField Density Test by Sand Replacement MethodMangeysh S. Chauhan100% (1)

- 40mm Aggregate For Concrete Flakiness Elongation IndicesDocument147 pages40mm Aggregate For Concrete Flakiness Elongation IndicesV Venkata Narayana100% (6)

- SDBC-Job Mix FinalDocument31 pagesSDBC-Job Mix FinalAchintya DasNo ratings yet

- M10 PDFDocument3 pagesM10 PDFranjeet Chikane67% (3)

- M 30 Concrete Mix Design FinalDocument10 pagesM 30 Concrete Mix Design FinalRakesh ReddyNo ratings yet

- Wet Mix Macadam (WMM) Quantity / Compaction Factor Value For WMMDocument31 pagesWet Mix Macadam (WMM) Quantity / Compaction Factor Value For WMMsuniljhilmilNo ratings yet

- SL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Document18 pagesSL - No. Name of Test Testing Method: Testing Frequency & Specification (As Per MORTH-5th Revision)Ashok amlapure100% (1)

- DLC Design Mix Stipulation1Document8 pagesDLC Design Mix Stipulation1abhishek negiNo ratings yet

- Mix Design of CTB As Per MORT&HDocument21 pagesMix Design of CTB As Per MORT&HSasanka SekharNo ratings yet

- Concrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Document13 pagesConcrete Trial Mix Calculations of Grade M-25 RCC: National Highway Authority of India (Nhai)Ashok amlapureNo ratings yet

- Concrete Mix Design 50Document6 pagesConcrete Mix Design 50Çhårū KêshNo ratings yet

- Laboratory Test Report: Faculty of Engineering & TechnologyDocument6 pagesLaboratory Test Report: Faculty of Engineering & TechnologySourav SahaNo ratings yet

- Test Frequency and Acceptance Criteria: Subgrade/Shoulder/MedianDocument6 pagesTest Frequency and Acceptance Criteria: Subgrade/Shoulder/MedianAshish yadav67% (3)

- Reclaimed Asphalt Pavement RapDocument10 pagesReclaimed Asphalt Pavement RapkomalNo ratings yet

- Specification For Additional Asphalt 302ADocument11 pagesSpecification For Additional Asphalt 302Amelinda bulosNo ratings yet

- Methodology 9.0 Bituminous Concrete (BC)Document12 pagesMethodology 9.0 Bituminous Concrete (BC)Eppili AdinarayanaNo ratings yet

- DBM Gupta ConstructionDocument24 pagesDBM Gupta Constructionimran khanNo ratings yet

- NH Training 4Document15 pagesNH Training 4Bilal Ahmed BarbhuiyaNo ratings yet

- A Study On Fractional Replacement of Bitumen With Crumb RubberDocument9 pagesA Study On Fractional Replacement of Bitumen With Crumb RubberMuhammad AliNo ratings yet

- DO - 013 - S2013 Generic Specs For SmaDocument7 pagesDO - 013 - S2013 Generic Specs For SmaAndrei AlidoNo ratings yet

- Group 6 - Activity 5 - Properties of CarbohydratesDocument6 pagesGroup 6 - Activity 5 - Properties of CarbohydratesJair Ezer AbaoNo ratings yet

- Wa0001.Document15 pagesWa0001.Thrivikram ArepalliNo ratings yet

- Acetic Acid - 010614Document1 pageAcetic Acid - 010614JESSICA PAOLA TORO VASCONo ratings yet

- Environmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaDocument9 pagesEnvironmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaRichardNo ratings yet

- Tosaf Polycarbonate Brochure FinalDocument9 pagesTosaf Polycarbonate Brochure FinalEsthikar khan0% (1)

- Vinh Tan 4 Thermal Power Plant Water Treatment System: Instructor: H. T. LEE (ATAI)Document34 pagesVinh Tan 4 Thermal Power Plant Water Treatment System: Instructor: H. T. LEE (ATAI)naturalgrace710No ratings yet

- Esnek Poliüretan Köpüğün Imalatı Için YöntemDocument11 pagesEsnek Poliüretan Köpüğün Imalatı Için YöntemahmetNo ratings yet

- Tribhuvan University Institute of Engineering: Thapathali CampusDocument10 pagesTribhuvan University Institute of Engineering: Thapathali CampusJeevan khatryNo ratings yet

- Automated Titration of The Hydroxyl Number According To ASTM E1899 and EN ISO 4629-2Document8 pagesAutomated Titration of The Hydroxyl Number According To ASTM E1899 and EN ISO 4629-2xibs2009No ratings yet

- McqsDocument5 pagesMcqsHuma Hameed Dogar100% (3)

- Genesys LFDocument1 pageGenesys LFvictorarnes100% (1)

- Zone Wise List of Vacant Industrial Land Parcels v1.1Document18 pagesZone Wise List of Vacant Industrial Land Parcels v1.1shivananda nayakNo ratings yet

- Indian Minerals Yearbook 2020: (Part-III: Mineral Reviews)Document7 pagesIndian Minerals Yearbook 2020: (Part-III: Mineral Reviews)k_pareshNo ratings yet

- The Chemistry of Thiocyanic EstersDocument68 pagesThe Chemistry of Thiocyanic EstersrajdewaanNo ratings yet

- Covalent - Bonding - Worksheet - Doc 2Document3 pagesCovalent - Bonding - Worksheet - Doc 2Zain AliNo ratings yet

- Selective Oxidation of Polysulfide Latexes To Produce Polysulfoxide and PolysulfoneDocument9 pagesSelective Oxidation of Polysulfide Latexes To Produce Polysulfoxide and PolysulfoneSimon LeluyerNo ratings yet

- Review Questions: Medicinal Chemistry 300550Document49 pagesReview Questions: Medicinal Chemistry 300550vanyarufusNo ratings yet

- HiTEC511TAW EPAgentDocument2 pagesHiTEC511TAW EPAgentGabriela Soares Viegas FerigatoNo ratings yet

- Corrosion Control of Reinforcement BarsDocument6 pagesCorrosion Control of Reinforcement BarsBhaskar ReddyNo ratings yet

- Chemistry Form 6 Chap 03 NewDocument92 pagesChemistry Form 6 Chap 03 Newbrandam0% (1)

- Appendix of Standard Thermodynamic QuantitiesDocument16 pagesAppendix of Standard Thermodynamic QuantitiesMawin ArabesNo ratings yet

- Evaluation of Non-Chemical Treatment Technologies For Cooling Towers at Select California FacilitiesDocument68 pagesEvaluation of Non-Chemical Treatment Technologies For Cooling Towers at Select California FacilitiesCarlos GamarraNo ratings yet

- Unit - I: Electron Beam WeldingDocument15 pagesUnit - I: Electron Beam Weldingapi-271354682No ratings yet

- How To Identify Geometrical Isomers by S.K.sinha See Chemistry Animations atDocument4 pagesHow To Identify Geometrical Isomers by S.K.sinha See Chemistry Animations atmyiitchemistry100% (4)

- The Chemistry of A Football Shirt: Polyester ElastaneDocument1 pageThe Chemistry of A Football Shirt: Polyester ElastaneJelenaNo ratings yet

- Recycling Rates of Metals: A Status ReportDocument48 pagesRecycling Rates of Metals: A Status ReportUnited Nations Environment ProgrammeNo ratings yet

- Material Descriere Dimensiuni Comercializare Culori UM: Pret Lista Din 03.01.2022 Euro (Fara TVA)Document16 pagesMaterial Descriere Dimensiuni Comercializare Culori UM: Pret Lista Din 03.01.2022 Euro (Fara TVA)cipos posNo ratings yet