Automated Storage Systems

Automated Storage Systems

Uploaded by

Khoerul UmamCopyright:

Available Formats

Automated Storage Systems

Automated Storage Systems

Uploaded by

Khoerul UmamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Automated Storage Systems

Automated Storage Systems

Uploaded by

Khoerul UmamCopyright:

Available Formats

Unit 9.

Automated Storage Systems

9.1 Unit Introduction

9.2 Unit Learning Objectives

9.3 Storage Systems

9.4 Conventional Storage

9.5 Automated Storage Systems

9.6 Automated Storage and Retrieval Systems

9.7 Carousel Storage Systems

9.8 Unit Review

9.9 Self-Assessment Questions

9.10 Self-Assessment Answers

9.1 Unit Introduction

Storage is an essential function in an automation system. The material storage

system allows materials to be stocked for a specified period of time, before they

are re-introduced, or are introduced for the first time, into the automation system.

The sorts of stored material are related to the product (e.g. raw materials,

purchased parts, work-in-process, finished products, and scrap and rework), the

process (e.g. process refuse, such as process waste products; and tooling), and

the overall support functions in the factory (e.g. maintenance spare parts, office

supplies, and plant records). Each of these material types is typically stored

under different conditions and controls.

KEYPOINT

A material storage system allows materials to be stocked for a specified period of

time, before they are re-introduced, or are introduced for the first time, into the

automation system.

END KEYPOINT

In this unit storage equipment is described, alongside appropriate methods in

both conventional and automated storage systems. Storage system performance

and location strategies examine the operating characteristics associated with

storage systems, and where best to place and organise them in the plant layout.

Conventional storage methods and equipment turns to an investigation of how

storage is regularly accomplished, and the pieces of equipment that is used to

achieve storage aims. Automated storage systems, which reduce or eliminate

human intervention in the system, are subsequently described. This is followed

by an engineering analysis of storage systems, in their various guises. A case

study completes the material of the unit, followed by the review of the unit and

the self-assessment questions and answers.

9.2 Unit Learning Objectives

After completing this unit you will be able to:

BULLET LIST

Explain the meaning of a material storage system, and issues that affect its

operating characteristics

Determine performance measures used to assess storage system performance

List methods and equipment used for storage purposes

List the types of automated storage categories that can be examined

Define automated storage/retrieval systems (AS/RS) and their associated

equipment

Define carousel storage systems and their construction

List the determinants of aisle capacity and system throughput for AS/RS

List the determinants of size and capacity for carousel systems

ENDLIST

9.3 Storage Systems

Storage systems are used to store materials related to the product (e.g. raw

materials, purchased parts, work-in-process, finished products, and scrap and

rework), the process (e.g. process refuse, such as process waste products; and

tooling), and the overall support functions in the factory (e.g. maintenance spare

parts, office supplies, and plant records). Storage systems can be classified into

conventional storage systems and automated storage systems (Figure 9.1).

Figure 9.1: Conventional and Automated Storage Systems

We can specify two sets of operating characteristics and issues when it comes to

storage systems; these are:

BULLETLIST

Storage system performance

Storage location strategies

ENDLIST

KEYPOINT

Storage system operating characteristics can be examined on two sets of issues:

storage system performance; and storage location strategies.

END KEYPOINT

9.3.1 Storage System Performance

A respective storage system must justify itself in terms of investment and

operating expense, by providing an adequate level of performance. Performance

measures used to assess this performance are detailed in Table 9.1.

Table 9.1: Storage system performance

Performance

measure

Description

Storage capacity Defined in two ways: the total volumetric space available; and the total

number of storage compartments in the system available for holding

items or loads. Use is often made of the unit load principle to

standardise storage in the storage system; the number of unit loads that

may be stored is a convenient metric that can be quickly captured. The

physical capacity of the storage system must be greater than the

maximum number of loads that can be stored, to allow for additional,

emergency, storage requirements, as and when they are necessary.

Storage density Defined as the volumetric space available for actual storage relative to

the total volumetric space in the storage facility. Aisle space and wasted

overhead space are two examples of unutilised storage space; these

often take up more space than actual usable storage capacity itself.

Often measured by means of the floor area of the storage facility;

although volumetric density is a more accurate metric.

High densities should be aimed at.

Accessibility Defined as the capability to access any desired item or load stored in

the system. Density often has an inverse relationship with accessibility

to the storage facility, so a trade-off may ensue here.

System throughput Defined as the hourly rate at which the storage system either receives

and puts loads into storage, and/or retrieves and delivers loads to the

output station. Storage system must be design to meet maximum

throughput requirements, as variations in the levels of throughput

should be expected throughout the working day.

Storage throughput is limited by the time to perform a storage or

retrieval transaction. Storage consists of: picking up a load at the input

station; travel to a storage location; placement of the load in the storage

location; and travel back to the input station. Retrieval consists of: travel

to the storage location; picking up the item from storage; travel to the

output station; and unloading at the output station. The some of each of

these element times (for either operation) determines the throughput for

the storage system.

A dual command cycle reduces throughput by combining storage and

retrieval functions. The ability to perform such a cycle is dependent on

demand and scheduling issues. It more easily performed by automated

storage systems, than manual systems.

Utilisation Defined as the proportion of time that the system is actually being used

to perform storage/retrieval operations compared with the time it is

available. Used in mechanised and automated storage system analysis.

Desirable utilisation patterns see ranges between 80-90%. If system

utilisation is too low, then it is probably over-designed; if it is too high,

then there will be no allowance for rush periods or system breakdowns.

Availability Defined as the proportion of time that the system is capable of

operating compared with the normal schedule shift hours. System

breakdowns cause downtimes in the system. Reasons for downtime

include: computer failures, mechanical breakdowns, load jams,

improper maintenance, and incorrect operating procedures.

KEYPOINT

Performance measures used to assess storage system performance include:

storage capacity, storage density, accessibility, system throughput, utilisation,

and availability.

END KEYPOINT

9.3.2. Storage Location

Storage location strategies try to organise stock in a storage system, with chosen

location strategies having a direct impact upon the performance measures

outlined in Table 9.1. Two basic strategies that are deployed are: randomised

storage, and dedicated storage; these are outlined further in Table 9.2. It should

be noted that both strategies take advantage of stock-keeping-units (SKUs),

which uniquely identifies an item type. Inventory records keep a count on the

quantities of each type of SKU that has a place in the storage system.

KEYPOINT

Storage location strategies organise stock in a storage system, and have a

considerable impact upon storage system performance.

END KEYPOINT

Table 9.2: Strategies for storage location

Strategy Description

Randomised storage Items are stored in any available location in the storage system,

typically in the nearest available open location. For retrieval, SKUs

are taken from storage on a first-in-first-out policy so that the items

held in storage the longest are moved out first.

Less storage space is generally required for randomised storage

systems, although this affects throughput rates by reducing them,

sometimes significantly.

Dedicated storage SKUs are assigned to specific locations in the storage facility, so

that pre-defined reservation of SKUs can take place, and the

system may be designed to accommodate maximum levels of

particular SKUs held in inventory. The basis for specifying the

storage locations is usually done by: storing items in part number,

or product number sequence; storing items as per activity level,

with more active SKUs being placed closer to input/output stations;

or storing items according to their activity-to-space ratios, with

higher ratios being located closer to input/output stations.

More storage space is generally required for dedicated storage

systems, although with the consequent advantage of higher

throughput times being achieved.

KEYPOINT

The two basic strategies that may be deployed for storage location are:

randomised storage, and dedicated storage.

END KEYPOINT

The two strategies may also be mixed; for example, in a system that uses

dedicated storage at a general level, but which is further divided into several

classes according to activity level, andwithin each classwith randomised

storage being deployed. This effectively tries to take the benefits of both strategy

sets, and to deploy them for the overall advantage of the storage system.

9.4 Conventional Storage

Conventional storage methods and equipment to support the various strategies

outlined above, are detailed in Table 9.3.

Table 9.3: Storage equipment

Methods and Equipment Description

Bulk storage using pallet trucks

and powered forklifts

Used for the storage of stock in an open floor area,

generally in unit loads on pallets or similar containers. Unit

loads may be stacked on top of each other to achieve

higher storage densities. Highest densities achieved when

unit loads placed next to each other, but the formation of

rows and blocks in bulk storage can also improve

accessibility. Depending on the materials being stacked,

there may be restrictions on how high they can be loaded;

sometimes materials cannot be stacked owing to physical

characteristics or limited compressive strength of the

individual loads.

Rack systems that use pallet

trucks and powered forklifts

Rack systems provide bulk storage facilities with adequate

support to aid safe stacking, by means of various methods,

such as : pallet racksconsisting of a frame to support unit

loads stacked one over the other, without the weight of the

top-most loads resting on loads lower down: it consists of a

frame with horizontal load-supporting beams; cantilever

rackssame as pallet racks, except the horizontal beams

are cantilevered from the vertical central frame: this

provides for unobstructed storage spans; portable racks

consisting of portable box-frames that hold a single pallet

load, and can be stacked on top of each other safely; drive-

through racksconsisting of a framework with open aisles

down the middle of two vertical beam-columns, on each

side of whichas we progress in forklifts down the aisle

are supporting horizontal rails for pallet loads, thus

providing for unobstructed storage spanning; and flow-

through racksconsisting of conveyor tracks capable of

supporting a row of unit loads, which replace conventional

horizontal rack beams; unit loads are loaded on one side of

the rack, and are unloaded on the other side, thus providing

first-in-first-out stock rotation.

Shelving and Bins for manual

attendants or powered forklift use

Shelving is one of the most common types of storage

equipment. Steel shelving sections are manufactured in

standard sizes, and may be fitted as and where they are

needed. Bins may be attached to shelves; these consist of

compartments or boxes that hold loose items.

Shelf storage must be applicable to the storage situation

required: sometimes may be improperly placed, or contain

material which would be stored more efficiently in other

storage equipment

Drawer storage for manual

attendants

Storage drawers solve the problem of shelving, where

materials may often be overlooked, by allowing the

attendant to pull the drawer out to reveal fully its contents.

Modular drawer storage cabinets are available with a variety

of drawer depths for different item sizes, and are widely

used to store maintenance tools and other items.

KEYPOINT

Storage methods and equipment include: bulk storage for use by pallet trucks

and powered forklifts; rack systems for use by pallet trucks and powered forklifts;

shelving and bins for use by manual attendants or powered forklifts; and drawer

storage for use by manual attendants.

END KEYPOINT

9.5 Automated Storage Systems

Automationwhen applied to storage systemstends to minimise human

interaction with the storage function; this, in turn, requires an examination of the

level of automation that may be required for a particular storage system, and the

methods of application that must be used to achieve a successful amalgamation

of storage capabilities, coupled to automation processes. Less automated

systems, still with a considerable level of human interaction (for example, to

handle storage/retrieval transactions), may also be utilised: in such cases,

automation must be built around the human element remaining in the system.

Highly automated storage systems, meanwhile, usually relegate the operator to

the role of data management, whilst automation carries-out the rest of the work-

load of the system.

KEYPOINT

When automation is applied to storage systems it tends to minimise human

interaction with the manual elements of the storage function.

END KEYPOINT

Automated storage can be divided into the following headings: automated

storage/retrieval systems, and carousel storage systems.

9.6 Automated Storage/Retrieval Systems

An automated storage/retrieval system (AS/RS) is a storage system that

performs storage and retrieval operations with speed and accuracy under a

defined degree of automation. Different levels of automation may be applied. At

one extreme, the AS/RS is completely automated. This can include a full

compliment of totally automated, computer-controlled storage functions that are

integrated into overall factory or warehouse operations. At the other extreme it

may use human workers to control equipment and perform storage/retrieval

transactions. Using modular components, available from AS/RS vendors, the

AS/RS system is custom-designed to fit the requirements of the plant in which it

is installed.

KEYPOINT

An automated storage/retrieval system (AS/RS) is a storage system that

performs storage and retrieval operations with speed and accuracy under a

defined degree of automation.

END KEYPOINT

The basic equipment of the AS/RS include a rack structure used for storing

loads, plus a storage/retrieval (S/R) mechanism with three dimensions of motion

(x, y, z). Additionally, the AS/RS maintains one or more storage aisles that are

serviced by the S/R mechanism. The S/R mechanism is used to deliver materials

to the storage racks and to retrieve materials from the racks. Each aisle has an

input/output station where storage deliveries are transferred into the system, or

out-of the system; these stations are known as pickup-and-deposit (P&D)

stations. P&D stations may be manually operated or connected to an automated

transport system, such as a conveyor or an AGVS (see Figure 9.2).

Figure 9.2: Automated Storage and Retrieval System (AS/RS)

KEYPOINT

An AS/RS consists of a rack structure and storage/retrieval mechanism that

operates to deliver materials into and out-of the storage system, via pickup-and-

deposit stations.

END KEYPOINT

Different types of AS/RS may be specified as in Table 9.4.

Table 9.4: AS/RS types

Type Description

Unit load AS/RS A large automated system designed to handle unit loads stored on

pallets or other containers. Computer-controlled, with automated

S/R customised for unit load handling. Basic form of AS/RS, with all

those below being variations of this initial type.

Deep-lane AS/RS High-density unit load storage system. Used with large quantities of

stock, but where the number of separate stock types (SKUs) is

relatively small. Loads are stored one behind another, with up to ten

loads in a single rack, in the deep-lane system. Access is ensured

by the flow-through system, whereby loads are input on one side

of the rack by an S/R machine, and retrieved on the other side by

another S/R machine.

Mini-load AS/RS Used to handle small loads that are contained in bins or drawers in

the storage system. The S/R machine retrieves the bin and delivers

it to a P&D station at the aisles end, so that individual items may be

withdrawn. The P&D station is usually operated manually. The bin

is then returned to its location in the storage system.

Man-on-board AS/RS In this system a human operator rides on the carriage of the S/R

machine, so as to allow for the manual retrieval of items directly

from their storage locations. This allows for increases in system

throughput.

Automated item retrieval

system

Have the same functionalities as mini-load AS/RS, but the items are

stored in lanes rather than bins or drawers. When an item is

retrieved, it is pushed from its storage position so that it drops onto

a conveyor for delivery to the pickup station. Replenishment of the

storage system is accomplished using a first-in/first-out inventory

rotation policy.

Vertical lift storage

modules (VLSM)

Also known as vertical lift automated storage/retrieval systems (VL-

AS/RS). Here the same principles as the above AS/RS types are

followed, except that instead of a horizontal aisle, the aisle is

vertical.

KEYPOINT

Different types of AS/RS include: unit load AS/RS; deep-lane AS/RS; mini-load

AS/RS; man-on-board AS/RS; automated item retrieval system; and vertical lift

storage modules.

END KEYPOINT

9.6.1 AS/RS Applications

AS/RS technology has generally been associated with warehousing and

distribution operations, although it can also be used for raw material storage, and

storage of work-in-process in manufacturing. Three application areas of interest

are:

BULLETLIST

Unit load storage and handling

Order picking

Work-in-process storage

ENDLIST

KEYPOINT

The application areas for AS/RS technology are: unit load storage and handling;

order picking; and work-in-process storage.

END KEYPOINT

Unit load storage and retrieval applications have been represented above in the

discussion on the unit load AS/RS and deep-lane storage system; so here we

focus upon work-in-process applications. Work-in-process (WIP) is desirable for

balancing work loads throughout the factory and in order to meet the demands

for short term fulfilment of customer orders. WIP is inherently inefficient and

needs to be minimised. WIP cannot be eliminated entirely: hence the

requirement for WIP management, and the use of AS/RS for this application.

For high-production operations large-capacity AS/RS technologies may be used

for staging and sequencing the work units as per the production schedule, to

achieve increased production efficiencies. General reasons for the

implementation of WIP automated storage systems are outlined in Table 9.5.

Table 9.5: Reasons to introduce WIP automated storage systems

Reason Comments

Buffer storage in production The automated storage system can be used as a buffer

storage zone between two processes whose production

rates differ.

Support of just-in-time delivery To reduce the chance of stock-out, owing to the failure of

deliver by suppliers in the just-in-time system, automated

storage systems may be installed as storage buffers for

incoming materials.

Kitting of parts for assembly The storage system is used to store components for

assembly of products or subassemblies. When orders are

received from storage they are put together into kits and

deliver to production.

Compatible with automatic

identification systems

The systems can be interfaced with other automated

systems throughout production, such as automatic

identification devices.

Computer control and tracking of

materials

Automated WIP storage system allows the location and

status of WIP to be known.

Support of factory-wide automation Given the need for some storage of WIP in batch

production, an appropriately-sized automated storage

system is an important subsystem in a fully automated

factory.

KEYPOINT

Reasons for the implementation of WIP automated storage systems include:

buffer storage in production; support of just-in-time delivery; kitting of parts for

assembly; compatibility with automatic identification systems; computer control

and tracking of materials; and support of factory-wide automation.

END KEYPOINT

9.6.2 Components and Operating Features

The components of an AS/RS are illustrated in Figure 9.3 and outlined in Table

9.6.

Figure 9.3: Major Components of an AS/RS

Table 9.6: Components of an AS/RS

Component Description

Storage structure Consists of the rack framework used to support loads contained in the

AS/RS; made from fabricated steel of sufficient strength and toughness

to support typical AS/RS loads. May have individual storage

compartments to hold storage modules, which hold the stored material.

May be built into the plant building itself, as a building support structure.

It also supports aisle hardware required to align the S/R machines with

the storage compartments of the AS/RS.

S/R machine Used to accomplish storage transactions, both delivering loads to

storage, and retrieving loads as required. To do this, the S/R machine

must be able to move horizontally and vertically with the load along the

front of the rack structure. Components consist of a rigid mast on which

is mounted an elevator system for vertical motion; all of which is

attached to a base with wheels for horizontal motion along a rail system

that traverses the storage aisle. A parallel rail at the top of the storage

structure ensures alignment of mast and carriage with the rack

structure.

Storage modules The unit load containers of the stored materials, including pallets, steel

wire baskets and containers, plastic tote pans, and special drawers.

The storage modules are standardised in size so that can be handled

easily by the carriage shuttle of the S/R machine; it also fits the storage

compartments of the rack structure.

Pickup-and-deposit

station

This is where loads are transferred into and out of the AS/RS. It is

generally found at the aisle end for convenient access to external

handling equipment. The two functions may be divided such that pickup

functions occur at one end of the aisle, and deposit functions may

happen at the other end; alternatively they may be combined at just one

aisle end, depending on the layout of the AS/RS. The pickup-and-

deposit station must be compatible with both the S/R machine used,

and the external handling system in place.

KEYPOINT

Typical components of an AS/RS include: a storage structure; an S/R machine;

storage modules; and one or more pickup-and-deposit stations.

END KEYPOINT

Each compartment in the storage structure may be identified by its horizontal and

vertical position, and whether it is on the left or right side of the aisle; all of which

information can be coded in an alphanumeric coding scheme that is executed by

the S/R machine. Using this location reference system, each unit of material in

the storage system can be referenced to a particular location in the aisle. The

record of these locations is called the item location file.

S/R machine and shuttle positioning is ensured either by means of a counting

procedure positioning method in which the number of bays and levels are

counted in the direction of travel; or by means of a numerical identification

procedure in which each compartment has a unique binary-coded location

identification tag. These tags can be read by the S/R machine by deploying an

optical scanner that reads the target and positions the shuttle to deliver or

retrieve stored material. Computer controls and programmable logic controllers

are used to determine the required location and guide the S/R machine to its

destination.

LEARNING ACTIVITY 9.1

Visit www.youtube.com and look up videos that illustrate the design and

operation of various types of AS/RS outlined in Table 9.4. Make a note of the

manufacturers names and country of origin.

END LEARNING ACTIVITY 9.1

9.6.3. AS/RS Analysis

The methods outlined here for AS/RS can also be used for analysis of traditional

storage facilities. The total capacity of one storage aisle depends on the number

of its storage compartments and their horizontal and vertical arrangement. This is

expressed as:

z y

n n AisleCap 2 . =

where n

y

is the number of load compartments along the length of the aisle; and

n

z

is the number of load compartments that make up the height of the aisle. This

is multiplied by two because there are loads contained on both sides of the aisle.

Assuming a standard size for storage compartments, then compartment size

facing the aisle must be larger than the unit load size to be slotted-into it. If x and

y are set as the depth and width dimensions of a unit load, respectively, and z is

set as the height of the unit load; then the following equations hold for the width

(W), length (L), and height (H) of one aisle of the rack structure of the AS/RS:

) ( 3 a x W + =

) ( b y n L

y

+ =

) ( c z n H

z

+ =

where x, y, and z are the dimensions of the unit load; and a, b, and c are

allowances designed into each load compartment to provide clearance for the

unit load and to account for the size of the supporting beams in the rack

structure.

KEYPOINT

Aisle capacity depends on the number of its storage compartments and their

horizontal and vertical arrangement.

END KEYPOINT

EXAMPLE 9.1

A unit load AS/RS is being designed to store 1000 pallet loads in a distribution

center located next to the factory. Pallet dimensions are: x =1000 mm, y =1200

mm; and the maximum height of a unit load =1300 mm. The following is specified:

(1) the AS/RS will consist of two aisles with one S/R machine per aisle, (2) length

of the structure should be approximately five times its height, and (3) the rack

structure will be built 500 mm above floor level. Using the allowances a =150 mm,

b =200 mm, and c =250 mm, determine the width, length, and height of the

AS/RS rack structure.

Solution: Assumption: the L/H ratio does not include the 500 mm foundation.

1000 pallets/ 2 aisles =500 pallets/aisle. 500 pallets/aisle 250 pallets per aisle

side.

Thus n

y

n

z

=250 Eq. (1)

L =n

y

(y +b) =n

y

(1200 +200) =1400 n

y

(n

y

in mm) =1.4 n

y

(n

y

in m)

H =n

z

(z +c) =n

z

(1300 +250) =1550 n

z

(n

z

in mm) =1.55 n

z

(n

z

in m)

Given the specification L/H =5

1.40

1.55

y

z

n

n

=0.9032n

y

/ n

z

=5 0.9032 n

y

=5.0 n

z

; n

y

=5.536 n

z

Eq.(2)

Combining Eqs. (1) and (2): n

y

n

z

=(5.536 n

z

) n

z

=250

n

z

2

=250/5.536 =45.161 n

z

=6.72 use n

z

=7

n

y

=250/n

z

=250/7 =35.71 use n

z

=36

W =3(1000 +150) =3450 mm =3.45 m/aisle.

With 2 aisles, W =2(3.45) =6.9 m

L =1.4 n

y

=1.4(36) =50.4 m

H =1.55 n

z

=1.55(7) =10.85 m

Given that the rack structure is built 500 mm above floor level, H =10.85 +0.5 =

11.35 m

Check on specifications: Capacity =2 x 2 x 36 x 7 =1008 pallets.

L/H =50.4/10.85 =4.645

END EXAMPLE

LEARNING ACTIVITY 9.1

Given the rack structure dimensions computed in Example 9.1. Assuming that only

80% of the storage compartments are occupied on average, and that the average

volume of a unit load per pallet in storage =0.75 m

3

, compute the ratio of the total

volume of unit loads in storage relative to the total volume occupied by the storage

rack structure.

END LEARNING ACTIVITY 9.1

System throughput is defined as the hourly rate of S/R transactions that the

automated storage system can perform. A transaction involves depositing a load

into storage, or retrieving a load from storage. These two separate transactions

may be combined into a dual command cycle, which accomplishes both

transaction types in one cycle. There are, in fact, several methods for the

computation of AS/RS cycle times, for the estimation of throughput performance;

only one of which is outlined here.

The method makes these assumptions:

BULLETLIST

There is randomised storage of loads in the AS/RS

There are storage compartments of equal size

The pick-up and deposit station is located at the aisles end

The S/R machine travels at constant horizontal and vertical speeds

There is simultaneous horizontal and vertical travel

For a single command cycle the load to be deposited/retrieved is assumed to be

in the centre of the rack structure

ENDLIST

From these assumptions we can show that the S/R machine must travel half the

length and height of the AS/RS, and it must return the same distance. The single

command cycle time is, therefore:

pd

z y

pd

z y

cs

T

v

H

v

L

Max T

v

H

v

L

Max T 2 , 2

5 . 0

,

5 . 0

2 +

)

`

= +

)

`

=

where T

cs

is the cycle time of a single command cycle; L is the length of the

AS/RS rack structure; v

y

is the velocity of the S/R machine along the length of the

AS/RS; H is the height of the rack structure; v

z

is the velocity of the S/R machine

in the vertical direction of the AS/RS; and T

pd

is the pickup-and-deposit time. Two

pickup-and-deposit times are required per cycle, representing load transfers to

and from the S/R machine.

For dual command cycles, the S/R machine is assumed to travel to the centre of

the rack structure to deposit a load, and then to three quarters the length and

height of the AS/RS to retrieve a load. The total distance travelled by the S/R

machine is the length and the height of the rack structure, and back. Cycle

time is:

pd

z y

pd

z y

cd

T

v

H

v

L

Max T

v

H

v

L

Max T 4

5 . 1

,

5 . 1

4

75 . 0

,

75 . 0

2 +

)

`

= +

)

`

=

where terms as defined above; and T

cd

is the cycle time for a dual command

cycle.

System throughput depends upon the above analysis of single and dual

command cycles; so that R

cs

may be set as the number of single command

cycles performed per hour, while R

cd

may be set as the number of dual command

cycles per hour at a specified or assumed utilisation level. Thus, the amounts of

time spent in performing single command and dual command cycles each hour,

is:

U T R T R

cd cd cs cs

60 = +

where U is the system utilisation during the hour; and all other terms as defined

above. For this equation we need to determine the relative proportions of both

R

cs

and R

cd

; once known, the total hourly cycle rate is given by:

cd cs c

R R R + =

where R

c

is the total S/R cycle rate. The total number of storage and retrieval

transactions per hour will be greater than this value unless R

cd

is zero, since

there are two transactions accomplished in each dual command cycle. If R

t

is the

total number of transactions performed per hour, then:

cd cs t

R R R 2 + =

EXAMPLE 9.2

An AS/RS is used for work-in-process storage in a manufacturing facility. The

AS/RS has five aisles, each aisle being 120 ft long and 40 ft high. The horizontal

and vertical speeds of the S/R machine are 400 ft/min and 50 ft/min, respectively.

The S/R machine requires 12 sec to accomplish a pick and deposit operation. The

number of single command cycles equals the number of dual command cycles. If

the requirement is that the AS/RS must have a throughput rate of 200 S/R

transactions per hour during periods of peak activity, will the AS/RS satisfy this

requirement? If so, what is the utilization of the AS/RS during peak hours.

Solution: T

cs

=2 Max

05120

400

05 40

50

. ( )

,

. ( ) |

\

|

.

|

+2(12/60) =1.2 min/cycle

T

cd

=2 Max

075120

400

075 40

50

. ( )

,

. ( ) |

\

|

.

|

+4(12/60) =2.0 min/cycle

1.2 R

cs

+2.0 R

cd

=60

Given R

cs

=R

cd

, 1.2 R

cs

+2.0 R

cs

=3.2 R

cs

=60 R

cs

=18.75 cycles/hr.

R

cd

=R

cs

=18.75 cycles/hr.

R

t

=5(R

cs

+2R

cd

) =5(3 x 18.75) =281.25 S/R transactions/hr

U =200/281.25 =0.711 =71.1%

END EXAMPLE

LEARNING ACTIVITY 9.3

An automated storage/retrieval system installed in a warehouse has five aisles.

The storage racks in each aisle are 10m high and 50m long. The S/R machine for

each aisle travels at a horizontal speed of 100 m/min and a vertical speed of 30

m/min. The pick and deposit time =0.25 min. Assume that the number of single

command cycles per hour is equal to the number of dual command cycles per hour

and that the system operates at 75% utilization. Determine the throughput rate

(loads moved/hour) of the AS/RS.

END LEARNING ACTIVITY 9.3

KEYPOINT

System throughput depends upon an analysis of single and dual command

cycles in the AS/RS.

END KEYPOINT

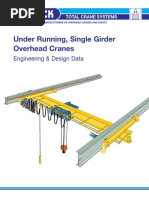

9.7 Carousel Storage Systems

A carousel storage system is one with a series of bins or baskets suspended

from an overhead chain conveyor that revolves around a long oval rail system.

The chain conveyor positions the bins/baskets at load/unload stations at each

end of the oval, the whole system being operated by human workers positioned

at the load/unload stations (See Figure 9.4). The worker activates the system,

and the powered carousel delivers the desired bin to its desired station; one or

more parts are removed, or added-to, the bin at this station; and then the bin is

moved by the powered carousel from the station to another location. Once

completed, the process cycle can be repeated. Transfer mechanisms from

load/unload stations to carousel bins may also be automated.

Figure 9.4: Carousel Systems

KEYPOINT

A carousel storage system is one with a series of bins or baskets suspended

from an overhead chain conveyor that revolves around a long oval rail system.

END KEYPOINT

9.7.1 Carousel Technology

Carousels are classified as horizontal or vertical, with the former being more

common in practice. Horizontal carousels consist of a welded steel framework for

the oval rail system, which can be either mounted overhead (a top-driven unit), or

from below (a bottom-driven unit). In the top-driven structure, a motorised pulley

system drives the overhead trolley system, attached to which are suspended

bins. In the bottom-driven structure, the pulley drive system is mounted at the

base of the frame, and the trolley system rides on a rail in the base. Carousel

bins and baskets are designed to be consistent with the loads they are to carry.

Standard bins are made of steel wire to increase operator visibility.

KEYPOINT

Carousels are either horizontal or vertical in construction.

END KEYPOINT

Vertical carousels operate around a vertical conveyor loop. They operate in less

floor space than horizontal carousel designs, but take up as much space again in

the vertical plane, which means that they can be limited by the size of the

building that houses them. Because of this, storage capacity is general lower for

vertical carousels than for horizontal carousel designs.

KEYPOINT

Vertical carousels operate around a vertical conveyor loop that may be limited by

the height of the building in which they are implemented.

END KEYPOINT

Various control structures used in carousel systems are outlined in Table 9.7.

Table 9.7: Control structures for carousel systems

Control mechanism Comments

Manual controls Human-operated controls include foot pedals, hand switches, and

specialised keyboards.

Foot control allows the carousel to be rotated in either direction as

the operator requires; similarly for hand control, which is facilitated

by a hand-operated switch that projects from the frame of the

carousel to within easy reach of the operator. Keyboard control is

even more flexible: it allows a greater amount of control features to

be implemented on the bins in the carousel system; for example,

keyboard control can allow the system to be programmed to take

the shortest route for the delivery of bins to stations.

Computer controls These increase the opportunities for automation of the mechanical

carousel and for management of the inventory records. For

example, automatic loading and unloading is available on modern

carousel storage systems, which allows the carousel to be

interfaced with automated handling systems without the need for

human intervention. Additionally, data management facilities

provide computer control over bin locations, bin inventories, and

inventory control records.

KEYPOINT

Both manual and computer control mechanisms may be used in conjunction with

horizontal and vertical carousel systems.

END KEYPOINT

9.7.2 Carousel Applications

Carousels are sometimes seen as an attractive alternative to AS/RS, especially

mini-load systems, in some manufacturing contexts. Typical applications include:

BULLETLIST

Storage and retrieval operationsparticularly where individual items must be

selected from groups of items in storage

Transport and accumulationwhereby the carousel is used to transport and/or

sort materials as they are stored

Work-in-processwhereby carousels may compete with automated storage and

retrieval systems for applications where work-in-process is to be temporarily

stored

Specialised usesfor example, the use of carousels during the electrical testing

of products, such that the carousel is used to store the item during the test for a

specified period of time

ENDLIST

KEYPOINT

Typical applications of carousels include their use in: storage and retrieval

operations; transport and accumulation functions; work-in-process storage; and

other specialised use areas.

END KEYPOINT

9.7.3. Carousel Systems Analysis

Similar relationships can be developed for carousel systems. The size and

capacity of a carousel consists of individual bins suspended in columns from

carriers that revolve around an oval rail with a circumference given by:

W W L C t + = ) ( 2

where C is the circumference; L is the length; and W is the width of the track

oval. Capacity of the system depends on the number and size of the bins in the

system (See Figure 9.5). Assuming standard-sized bins are used, each with a

fixed volumetric capacity, then the number of bins can be used as our measure

of capacity. The number of bins that may hang in a column, one below another,

from each carrier may be set as n

b

, and n

c

may be set as the number of carriers

supported by the rail; then the total number of bins is given by:

b c

n n Tot = .

Each carrier is separated by a distance from the preceding carrier, and the next

carrier, to avoid interference as it operates. If s

c

is the centre-to-centre spacing

from one carrier to the next carrier, then:

C n s

c c

=

with terms as defined above.

KEYPOINT

The size and capacity of a carousel system depends upon the number individual

bins that revolve around an oval rail with a given circumference, and by a set

centre-to-centre spacing from one carrier to the next.

END KEYPOINT

Figure 9.5: Major Components of Carousel

Carousel systems have higher throughput rates than an AS/RS. The following set

of assumptions must be made when calculating storage/retrieval cycle times for

carousel systems:

BULLETLIST

Only single command cycles are performeda bin is accessed in the carousel

either to put items into storage or to retrieve one or more items from storage

The carousel operates at constant speedacceleration and deceleration effects

are ignored

Random storage is assumedany location around the carousel is equally likely

to be selected for an S/R transaction

The carousel can move in either direction

ENDLIST

Upon the last assumption, the mean travel distance between the load/unload

station and a bin randomly located in the carousel is C/4. Thus, the S/R cycle

time is given by:

pd

c

c

T

v

C

T + =

4

where T

c

is the S/R cycle time; C is the carousel circumference; v

c

is the carousel

velocity; and T

pd

is the average time required to pick or deposit items each cycle

by the operator at the load/unload station. The number of transactions

accomplished per hour is the same as the number of cycles and is given by the

following:

c

c t

T

R R

60

= =

KEYPOINT

Carousel systems have higher throughput rates than an AS/RS.

END KEYPOINT

EXAMPLE 9.2

A single carousel storage system is located in a factory making small assemblies.

It is 20 m long and 1.0 m wide. The pick and deposit time is 0.25 min. The speed

at which the carousel operates is 0.5 m/s. The storage system has a 90%

utilization. Determine the hourly throughput rate.

Solution: C =2(L - W) +tW =2(20 - 1) +1t =41.14 m

T

c

=

4

c

C

v

+T

pd

=

4114

4 05

.

( . )

+0.25(60) =35.57 sec =0.593 min, R

t

=60/0.593 =101.2

transaction/hr

END EXAMPLE

LEARNING ACTIVITY 9.3

A carousel storage system is to be designed to serve a mechanical assembly

plant. The specifications on the system are that it must have a total of 400 storage

bins and a throughput of at least 125 storage and retrieval transactions per hour.

Two alternative configurations are being considered: (1) a one-carousel system

and (2) a two-carousel system. In either case, the width of the carousel is to be

1.2m and the spacing between carriers =0.8m. One picker-operator will be

required for the one-carousel system and two picker-operators will be required for

the two-carousel system. In either system v

c

=25 m/min. For the convenience of

the picker-operator, the height of the carousel will be limited to 5 bins. The

standard time for a pick and deposit operation at the load/unload station =0.4 min

if one part is picked or stored per bin and 0.6 min if more than one part is picked or

stored. Assume that 50% of the transactions will involve more than one

component. Determine (a) the required length of the one-carousel system and (b)

the corresponding throughput rate; (c) the required length of the two-carousel and

(d) the corresponding throughput rate. (e) Which system better satisfies the design

specifications?

END LEARNING ACTIVITY

9.8 Unit Review

BULLETLIST

A material storage system allows materials to be stocked for a specified period of

time, before they are re-introduced, or are introduced for the first time, into the

automation system.

Storage systems operating characteristics can be examined on two sets of

issues: storage system performance; and storage location strategies.

Performance measures used to assess storage system performance include:

storage capacity, storage density, accessibility, system throughput, utilisation,

and availability.

Storage location strategies organise stock in a storage system, and have a

considerable impact upon storage system performance.

The two basic strategies that may be deployed for storage location are:

randomised storage, and dedicated storage.

Storage methods and equipment include: bulk storage for use by pallet trucks

and powered forklifts; rack systems for use by pallet trucks and powered forklifts;

shelving and bins for use by manual attendants or powered forklifts; and drawer

storage for use by manual attendants.

When automation is applied to storage systems it tends to minimise human

interaction with the storage function.

Depending on particular requirements and individual circumstances, storage

system automation can be set to different levels, so that human interaction is

included to a higher or lower degree.

Automated storage can be examined as either automated storage/retrieval

systems, or carousel storage systems.

An automated storage/retrieval system (AS/RS) is a storage system that

performs storage and retrieval operations with speed and accurate under a

defined degree of automation.

An AS/RS consists of a rack structure and storage/retrieval mechanism that

operates to deliver materials into and out-of the storage system, via pickup-and-

deposit stations.

Different types of AS/RS include: unit load AS/RS; deep-lane AS/RS; mini-load

AS/RS; man-on-board AS/RS; automated item retrieval system; and vertical lift

storage modules.

The application areas for AS/RS technology are: unit load storage and handling;

order picking; and work-in-process storage.

Work-in-process may be managed by either AS/RS systems or carousel

systems, for batch and job shop production.

Reasons for the implementation of WIP automated storage systems include:

buffer storage in production; support of just-in-time delivery; kitting of parts for

assembly; compatibility with automatic identification systems; computer control

and tracking of materials; and support of factory-wide automation.

Typical components of an AS/RS include: a storage structure; an S/R machine;

storage modules; and one or more pickup-and-deposit stations.

The item location file is the locational record of a particular material stored in the

storage system. The item location file is used as the basis for the retrieval and

deposit of materials in the storage system by the S/R machine.

A carousel storage system is one with a series of bins or baskets suspended

from an overhead chain conveyor that revolves around a long oval rail system.

Carousels are either horizontal or vertical in construction.

Horizontal carousels consist of a welded steel framework for the oval rail system,

which can be either mounted overhead (a top-driven unit), or from below (a

bottom-driven unit).

Vertical carousels operate around a vertical conveyor loop that may be limited by

the height of the building in which they are implemented.

Both manual and computer control mechanisms may be used in conjunction with

horizontal and vertical carousel systems.

Typical applications of carousels include their use in: storage and retrieval

operations; transport and accumulation functions; work-in-process storage; and

other specialised use areas.

Aisle capacity depends on the number of its storage compartments and their

horizontal and vertical arrangement.

System throughput depends upon an analysis of single and dual command

cycles in the AS/RS.

The size and capacity of a carousel system depends upon the number of

individual bins that revolve around an oval rail with a given circumference, and by

a set centre-to-centre spacing from one carrier to the next.

Carousel systems have higher throughput rates than an AS/RS.

ENDLIST

9.9 Self-Assessment Questions

NUMLIST

What do we mean by the phrase material storage system? What issues affect its

operating characteristics?

List performance measures that may be used to assess storage system

performance.

What methods and equipment are typically used for storage purposes?

What are the effects of automation on human intervention in storage systems?

What are the types of automated storage categories that can be examined?

What are automated storage/retrieval systems (AS/RS)? What is their associated

equipment?

What types of AS/RS construction are possible?

Why are WIP automated storage systems typically deployed?

What are carousel storage systems? Briefly describe their overall construction.

What are the typical applications of carousel storage systems?

What are the determinants of aisle capacity and system throughput for AS/RS?

What are the determinants of size and capacity for carousel systems?

ENDLIST

9.10 Answers to Self-Assessment Questions

NUMLIST

A material storage system allows materials to be stocked for a specified period of

time, before they are re-introduced, or are introduced for the first time, into the

automation system. Storage systems operating characteristics can be examined

on two sets of issues: storage system performance; and storage location

strategies.

Performance measures that may be used to assess storage system performance

include: storage capacity, storage density, accessibility, system throughput,

utilisation, and availability.

Methods and equipment that is typically used for storage purposes include: bulk

storage for use by pallet trucks and powered forklifts; rack systems for use by

pallet trucks and powered forklifts; shelving and bins for use by manual

attendants or powered forklifts; and drawer storage for use by manual

attendants.

When automation is applied to storage systems it tends to minimise human

interaction with the storage function. Depending on particular requirements and

individual circumstances, storage system automation can be set to different

levels, so that human interaction is included to a higher or lower degree.

Automated storage can be examined as either automated storage/retrieval

systems, or carousel storage systems.

An automated storage/retrieval system (AS/RS) is a storage system that

performs storage and retrieval operations with speed and accurate under a

defined degree of automation. An AS/RS consists of a rack structure and

storage/retrieval mechanism that operates to deliver materials into and out-of the

storage system, via pickup-and-deposit stations.

Different types of AS/RS construction include: unit load AS/RS; deep-lane

AS/RS; mini-load AS/RS; man-on-board AS/RS; automated item retrieval

system; and vertical lift storage modules.

Reasons for the implementation of WIP automated storage systems include: to

provide buffer storage in production; to support of just-in-time delivery; to allow

for the kitting of parts for assembly; to ensure the compatibility with automatic

identification systems; to enable computer control and tracking of materials; and

to support of factory-wide automation.

A carousel storage system is one with a series of bins or baskets suspended

from an overhead chain conveyor that revolves around a long oval rail system.

Carousels are either horizontal or vertical in construction.

Typical applications of carousels include their use in: storage and retrieval

operations; transport and accumulation functions; work-in-process storage; and

other specialised use areas.

The determinants of aisle capacity are the number of its storage compartments

and their horizontal and vertical arrangement. The determinants of system

throughput depend upon an analysis of single and dual command cycles in the

AS/RS.

The determinants of size and capacity for carousel systems are the number of

individual bins that revolve around an oval rail with a given circumference, and by

a set centre-to-centre spacing from one carrier to the next.

END LIST

You might also like

- Vibratory Bowl Feeder - WorkingDocument1 pageVibratory Bowl Feeder - WorkingKushal SinghNo ratings yet

- IBEW NMA AgreementDocument16 pagesIBEW NMA AgreementJoe RipplNo ratings yet

- ToyotaDocument8 pagesToyotaNikita BatuleNo ratings yet

- Basic FEA TestDocument6 pagesBasic FEA TestPagadala Sarath Chandra100% (2)

- Chapter 6 Storage SystemsDocument53 pagesChapter 6 Storage SystemsTú QuyênNo ratings yet

- ASRS With Input On Ground LevelDocument26 pagesASRS With Input On Ground LevelEusebiu PetuNo ratings yet

- Unit 4 Automated Storage/Retrieval Systems: StructureDocument11 pagesUnit 4 Automated Storage/Retrieval Systems: StructureRuby SmithNo ratings yet

- AsrsDocument43 pagesAsrsmkhairi91No ratings yet

- AUTOBASE Train WashingDocument18 pagesAUTOBASE Train WashingNeshvar DmitriNo ratings yet

- StandardsDocument19 pagesStandardsgaurav503050No ratings yet

- Manufacturing Material Handling Equipment: Profile No.: 225 NIC Code: 28162Document11 pagesManufacturing Material Handling Equipment: Profile No.: 225 NIC Code: 28162Vikram PhalakNo ratings yet

- Belt Conveyor Project 03-07-2013Document57 pagesBelt Conveyor Project 03-07-2013Shashikala Kollipara0% (1)

- Report On Anti Lock Braking SystemDocument12 pagesReport On Anti Lock Braking SystemParth RathoreNo ratings yet

- Mechanical DesignDocument34 pagesMechanical DesignNiki LaudaNo ratings yet

- Unit Load ConceptsDocument5 pagesUnit Load ConceptsProf C.S.Purushothaman100% (1)

- Definition of Material HandlingDocument12 pagesDefinition of Material HandlingAnkur MahteNo ratings yet

- Artificial IntrlligenceDocument28 pagesArtificial IntrlligenceAnkita SinhaNo ratings yet

- Bulox Equipment CatalogDocument24 pagesBulox Equipment CatalogIulian MurariuNo ratings yet

- Seminar ReportDocument15 pagesSeminar ReportRuhan Madni NaqashNo ratings yet

- Systems For Production Have Existed Since Ancient TimesDocument30 pagesSystems For Production Have Existed Since Ancient TimesSurya PratapNo ratings yet

- Material-handling equipment The Ultimate Step-By-Step GuideFrom EverandMaterial-handling equipment The Ultimate Step-By-Step GuideNo ratings yet

- MMH1105Sorting CompaniesDocument4 pagesMMH1105Sorting CompaniessachinNo ratings yet

- Reverse Vending Machine Pilot ProjectDocument4 pagesReverse Vending Machine Pilot ProjectICT WalaNo ratings yet

- Open CIM Practice Report-Group 3Document13 pagesOpen CIM Practice Report-Group 3Hong Nhung Bui Le0% (1)

- ISM Toyota With Work FlowDocument9 pagesISM Toyota With Work FlowAvnit kumarNo ratings yet

- Brake System BleedingDocument2 pagesBrake System BleedingToua YajNo ratings yet

- Cad Cam and AutomationDocument21 pagesCad Cam and AutomationSumit KumarNo ratings yet

- Principles of Air ConditioningDocument3 pagesPrinciples of Air ConditioningAljon AnarioNo ratings yet

- Mechanical Braking System of Mine WindersDocument54 pagesMechanical Braking System of Mine Windersanirudh subbuNo ratings yet

- Flexsim Basics TutorialDocument91 pagesFlexsim Basics TutorialThe Wolf 507No ratings yet

- A Conveyor System Is A Common Piece of Mechanical Handling Equipment That Moves Materials From One Location To AnotherDocument9 pagesA Conveyor System Is A Common Piece of Mechanical Handling Equipment That Moves Materials From One Location To AnotherDinesh SainiNo ratings yet

- 6.design and Fabrication of Length Adjustable Belt Conveyor-1Document3 pages6.design and Fabrication of Length Adjustable Belt Conveyor-1Chockalingam AthilingamNo ratings yet

- 15 Integrated Manufacturing Systems Lecture #15 HandoutDocument2 pages15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeNo ratings yet

- Mech 499 Project Virtual and Physical Prototyping of Mechanical Systems Web-Controlled Dog Ball LauncherDocument26 pagesMech 499 Project Virtual and Physical Prototyping of Mechanical Systems Web-Controlled Dog Ball LauncherParesh GoelNo ratings yet

- Simulation Study For ASRSDocument67 pagesSimulation Study For ASRSSuvin NambiarNo ratings yet

- Introduction To Material Handling Siddharta RayDocument1 pageIntroduction To Material Handling Siddharta RayPrathamesh NaikNo ratings yet

- 8.5 Chute, Charging Hopper Deep Mining General (Steep Formation) Underground Mining LoadingDocument6 pages8.5 Chute, Charging Hopper Deep Mining General (Steep Formation) Underground Mining LoadingJuan MontufarNo ratings yet

- Four Main Types of Plant LayoutDocument3 pagesFour Main Types of Plant LayoutSikakolli Venkata Siva KumarNo ratings yet

- BernoullisDocument19 pagesBernoullisSelwah Hj AkipNo ratings yet

- Classification of RobotDocument2 pagesClassification of RobotSourabh Angural83% (6)

- Computer Aided Process Planning (Capp)Document17 pagesComputer Aided Process Planning (Capp)sivaNo ratings yet

- Material Handling: Material Handling Involves Short-Distance Movement Within The Confines of A Building orDocument7 pagesMaterial Handling: Material Handling Involves Short-Distance Movement Within The Confines of A Building orNidhi EnterprisesNo ratings yet

- Mato Belt Cleaner CatalogueDocument12 pagesMato Belt Cleaner Catalogueleeyod100% (1)

- Metal Process Technology (Meng) : Rolling and Ring Rolling Design of Roll Passes in Shape RollingDocument35 pagesMetal Process Technology (Meng) : Rolling and Ring Rolling Design of Roll Passes in Shape RollingRavichandran GNo ratings yet

- Manual HoistsDocument71 pagesManual Hoistsfuat0804No ratings yet

- Conveyor System - WikipediaDocument32 pagesConveyor System - WikipediaEndhy Wisnu NovindraNo ratings yet

- Robot Cell Layouts and InterlocksDocument44 pagesRobot Cell Layouts and InterlocksAnshul SharmaNo ratings yet

- How To Remove Autorun Inf Virus OpenDocument6 pagesHow To Remove Autorun Inf Virus OpenIsaac TataNo ratings yet

- Pan Conveyors PDFDocument24 pagesPan Conveyors PDFRaji SuriNo ratings yet

- Metal Forming Machines: PressesDocument35 pagesMetal Forming Machines: PressesMohammed Alnashar0% (1)

- Vacuum Conveyor For Industrial ApplicationDocument4 pagesVacuum Conveyor For Industrial Applicationkrishna100% (1)

- CEMA GuidelinesDocument2 pagesCEMA GuidelinesasnandyNo ratings yet

- Types of Packaging Machines and There FunctionsDocument5 pagesTypes of Packaging Machines and There Functionsbottlingplant indiaNo ratings yet

- Hydraulic Press MachineDocument18 pagesHydraulic Press MachineJunior Azeumo100% (1)

- Case Study On Supply Chain Management RajDocument5 pagesCase Study On Supply Chain Management RajGhule VinayakNo ratings yet

- Application of Robotics in Manufacturing Industry Group 7Document9 pagesApplication of Robotics in Manufacturing Industry Group 7Sathriyan SathiNo ratings yet

- Under Running Single Girder PDFDocument8 pagesUnder Running Single Girder PDFWissam JarmakNo ratings yet

- Development of Robotic Automated Storage and Retrieval System (AS/RS)Document5 pagesDevelopment of Robotic Automated Storage and Retrieval System (AS/RS)International Journal of computational Engineering research (IJCER)No ratings yet

- UNIT-6 Storage Systems PVPSIT 2014: Function of Storage Systems and Definition of AS/RSDocument7 pagesUNIT-6 Storage Systems PVPSIT 2014: Function of Storage Systems and Definition of AS/RSSravanth KondetiNo ratings yet

- Implementation of An Automatic Storage and Retrieval System PDFDocument9 pagesImplementation of An Automatic Storage and Retrieval System PDFAlvaro GonzNo ratings yet