How To Troubleshoot Starting System

Uploaded by

rodrig15How To Troubleshoot Starting System

Uploaded by

rodrig15HOW TO TROUBLESHOOT YOUR

STARTING SYSTEM

Tech Tip

Tech Tip

HOW TO

TROUBLESHOOT YOUR

STARTING SYSTEM

ITEMS NEEDED: Haynes Manual For Your Vehicle

Battery Hydrometer

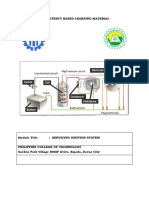

Your vehicle's starting system is made up of many components which,

when isolated, are really quite easy' to diagnose and repair. An easy way

to remember the system is to consider the battery as the power source the

starter as the power consumer, and the other components as paths for the

current to follow from the battery to the starter.

Loose

Connection

2. Many vehicles with manual transmissions are equipped with a

clutch pedal switch. Check to see if it is broken or has become

detached from the clutch pedal.

3. Turn on the headlights. They should be at normal brightness, indicating the battery has an adequate charge. Dimness or no headlights indicates a weak or discharged battery.

Figure 1

Figure 3

Fender Mounted

Solenoid

Positive Battery

Terminal

Relay-to-Starter

Cable

Figure 2

Ohmmeter

Starter Mounted Solenoid

Figure 5-A

Battery Terminal

S. Terminal

Solenoid

Ohmmeter

Jumper

Wire

Figure 4

Starting system components

The starting system consists of the battery, battery cables, wiring,

ignition switch, neutral safety switch, starter solenoid, and starter

motor. All of these components can be individually checked to pinpoint starting problems. To prevent burns on your hands, always

begin repairs with a cool engine. Starting system problems generally fall into the following two categories.

NO START ENGINE WILL NOT CRANK

1. If the vehicle has an automatic transmission, check to be sure the

gear shift selector is in park.

Corrosion

Starting

Motor

Digital Volt-ohmmeter(DVOM)

Jumper Wires and Cables

Figure 5-B

4. Check to see if any lights or accessories were left on that may

have run the battery down.

5. Inspect the battery cables and clamps. Look for corrosion at the

terminal and where the cable enters the terminal (figure 1). On side

post batteries, unbolt the terminal and examine the contact pads on

the battery and cable ends. Clean all corrosion, tighten loose connections, and replace any deteriorated parts. We recommend the

use of anti-corrosion pads or battery protectant spray to help minimize future corrosion. Inspect the wiring to the starter and/or solenoid. Some vehicles have a fender mounted solenoid; others have

the solenoid mounted on the starter (Figure 2). Look for broken,

burned, or loose wires and connections. Replace as needed.

6. Inspect the battery. If it has removable ventcaps, inspect each cell

to be sure it is not frozen or low on fluid.

7. Remove the cell caps and make sure the fluid covers the battery

plates. If it doesn't, add distilled water to raise the fluid level above

the plates and level with the filler ring. If distilled water was added,

fully charge the battery before checking the specific gravity of the

fluid.

8. Using the battery hydrometer, check each cell for specific gravity

(Figure 3). Insert the hydrometer into the first cell and draw out

enough fluid to float the balls. Record the reading and replace the

fluid. Go on to each cell in turn and repeat the procedure. The reading in each cell should be 1.250 or higher and should not vary more

than 10% from any other given cell. If one or more cells have a low

reading, charge the battery and retest. If the readings are still low,

replace the battery.

9. Next, by-pass the starter solenoid. This must be done on the vehicle.

Figure 6

Jumper

Wire

A. Starter Mounted Solenoids.

To by-pass the starter solenoid, place the transmission in "park" or "neutral" and set the parking brake.

Connect your jumper wire on the solenoid between the battery and "S" terminals (Figure 4). If engine

cranks, the ignition or neutral safety switches may be at fault (see step 20). If no sound is heard, the

solenoid is defective and must be replaced. A clicking sound indicates that the solenoid is operating

properly, and the problem may lie in the starting motor itself.

To test the solenoid off the car you will need an ohmmeter. Set the meter to the lowest scale and connect one lead to the starter terminal "1" and the other to the metal housing "G" (Figure 5-A). The reading should be between .7 and .9 ohms. If you observe a lower reading than .7 ohms, the solenoid has

a short circuit. If a reading higher than .9 ohms is observed, the solenoid has either loose internal connections or corrosion in the windings. In either case, the solenoid must be replaced. The test for a sticking internal contact that could cause the starter to stay engaged is simple. Connect one ohmmeter lead

to the terminal marked (1) and the other lead to the terminal marked (2) (Figure 5-B). The reading

should be infinity. If the reading indicates continuity, replace the solenoid.

B. Ford and AMC Fender-mounted Starter Relay

On Ford and AMC vehicles with a fender mounted starter relay, begin by removing the wire attached

to the "S" terminal. Connect a jumper wire from this terminal to the positive battery terminal on the relay

(Figure 6). If engine now cranks, the problem is in the wiring, ignition, or neutral safety switches. If

engine still will not crank, connect a heavy jumper cable between the positive and starter terminals on

the relay (Figure 7) If the engine now cranks, the relay is defective and must be replaced. If it still doesnt crank, the starter may be at fault.

Fender mounted starter solenoids can also be tested off the car using an ohmeter. With the ohmmeter

set at the lowest scale, connect the ohmmeter leads to the S terminal and the grounded case (Figure

8). The reading should be between 3.4 and 4.5 ohms. If you get a reading lower than 43.4 ohms, the

solenoid has shorted wingdings. If a reading higher than 4.5 ohms is observed, the solenoid either has

a bad internal wingding connection or corrosion in the wingdings. This occurs if the solenoid has been

on the vehicle for along time. Next, check to be sure the contact disc inside the solenoid is not stuck

to the battery or starter terminals. Referring to the dotted line in Figure 8, connect the ohmmeter leads

to the large terminals labeled From Battery and To Starter (Figure 8). The meter should show an

open circuit or infinity reading. If it does not, the contact disc is stuck in the cranking position. If the

solenoid fails any of the above tests, replace it.

C. Chrysler Relays

Chrysler vehicles use a relay to transfer power to the starter instead of the solenoid. On Chrysler vehicles, the relay can be found either on the firewall or the inner fender. To test, connect a Jumper wire

between the positive battery and solenoid terminals on the relay (Figure 9). If the engine cranks, the

relay is defective and must be replaced. If the engine still fails to crank, then the starter may be defective.

10. If no sound is heard when the key is turned to "start" and the battery and cables are okay, the ignition switch and neutral safety switch should be checked. To check the neutral safety switch, locate the

two wires going to the switch (Figures 10-11). The switch may be mounted on the steering column, in

the center console on some floor shift models and on others, it is threaded into the transmission.

Unplug the wires from the switch and connect your jumper wire between the two wires. Turn the ignition switch to start and if the engine now cranks, the neutral safety switch is defective and must be

replaced. For specific testing procedures on your vehicle, please contact a detailed repair manual.

Note: Ignition switches rarely fail only in the "start" mode. Check the ignition switch after all other components have been ruled out.

HARD START ENGINE CRANKS TOO SLOW

1. Follow instructions contained in 3 through 7 above.

2. Perform a cranking test. If the engine turns over, a voltmeter can be used to check the cranking voltage available from the battery. First, disable the ignition system by grounding the coil high tension lead

or by disconnecting the battery wire at the distributor cap on GM HEl systems. Set the voltmeter to 20

volt scale. Attach the black lead of the voltmeter to a good engine ground. Connect the red lead to the

positive battery terminal (Figure 12). Now turn ignition switch to "run" and check the meter reading. The

meter should read at least 12.5 volts. Next crank the engine for 15 seconds while observing the meter

reading. The voltage should not drop below 9.5 volts. If the voltage stays above 9.5 volts, the battery

has sufficient power. If the voltage drops below 9.5 volts, remove the starter and bring it to your Auto

Store. They'll be glad to test your battery or starter for free.

Jumper

Wire

Testing Wiring & Switches

on Fender Mounted

Solenoid

Figure 7

Tesiting Fender

Mounted Solenoid

Ohmmeter

S

Terminal

Grounded

Case

Figure 8

Jumper

Wire

Solenoid

Terminal

Figure 9

Battery

Terminal

Figure 10

Nuetral Starter

Switch

Removed Plug

Jumper Wire

Nuetral Safety

Switch

Steering

Column

Figure 11

Nuetral Switch

Column Shift Vehicles

Voltmenter

Figure 12

You might also like

- Intellitec Single Disconnect Battery Control Center Service Manual 5300635100No ratings yetIntellitec Single Disconnect Battery Control Center Service Manual 530063510012 pages

- Starter Motor Test Procedure: Exploded Diagram of A Starter Motor (Excluding The Housing)100% (4)Starter Motor Test Procedure: Exploded Diagram of A Starter Motor (Excluding The Housing)13 pages

- 5 Engine electrical systems 2 TroubleshootingNo ratings yet5 Engine electrical systems 2 Troubleshooting4 pages

- Testing The Starter On The Engine (1453,1450,1401)No ratings yetTesting The Starter On The Engine (1453,1450,1401)6 pages

- Sistema de carga(alternador) 3.8 mohave 2010No ratings yetSistema de carga(alternador) 3.8 mohave 201013 pages

- HCP9982 Battery Sensor Bypass Device: Installation Instruction SheetNo ratings yetHCP9982 Battery Sensor Bypass Device: Installation Instruction Sheet4 pages

- 79-83 Honda DOHC Charging System Procedure For Troubleshooting, Testing, and Performance VerificationNo ratings yet79-83 Honda DOHC Charging System Procedure For Troubleshooting, Testing, and Performance Verification5 pages

- Any High Resistance in Either The Power Side or Ground Side of The Starter Circuit Will Cause The Starter To Rotate Slowly or Not at AllNo ratings yetAny High Resistance in Either The Power Side or Ground Side of The Starter Circuit Will Cause The Starter To Rotate Slowly or Not at All4 pages

- Fluke - Troubleshooting Auto Electrical Systems0% (1)Fluke - Troubleshooting Auto Electrical Systems23 pages

- Auto-Lite, Delco, Ford Voltage Regulators PDFNo ratings yetAuto-Lite, Delco, Ford Voltage Regulators PDF1 page

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Stories from the Road 3: An Automotive Case Studies SeriesFrom EverandStories from the Road 3: An Automotive Case Studies SeriesNo ratings yet

- First aid for your car: - Your expert guide to common problems & how to fix themFrom EverandFirst aid for your car: - Your expert guide to common problems & how to fix themNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet