50%(2)50% found this document useful (2 votes)

604 views08 - Ignition System

08 - Ignition System

Uploaded by

captoyota starlet and corolla k series engine factory service manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

08 - Ignition System

08 - Ignition System

Uploaded by

cap50%(2)50% found this document useful (2 votes)

604 views26 pagestoyota starlet and corolla k series engine factory service manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

toyota starlet and corolla k series engine factory service manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

50%(2)50% found this document useful (2 votes)

604 views26 pages08 - Ignition System

08 - Ignition System

Uploaded by

captoyota starlet and corolla k series engine factory service manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 26

IGNITION SYSTEM

IGNITION SYSTEM CIRCUIT ............:c:e cere 82

DISTRIBUTOR ...............:ccecsccseceeecteeeene cette eneeeenee 8-7

HIGH TENSION CORD 8-23

SPARK PLUGS 8-24

8-2 IGNITION SYSTEM — Ignition System Circuit

IGNITION SYSTEM CIRCUIT

Fig. 84

USA & Canada

Distributor

Sional Rotor

Sional

Generator |!

(Prekeup Coil

a

1 pattery

+

To Starter Motor

(KP36 LHD)

Ignition

Switch

To Starter Motor

(KP36 LHO)

Ignition

Switch ah

Distributor

3

en i |

7 3

r

|

sary |

Spark Plug

IGNITION SYSTEM — Ignition System Circuit 8-3

Timing Light

Fig. 8-5

ON-VEHICLE INSPECTION

Spark Test

1, Seta timing light to the engine.

2. Crank the engine.

3. Check the spark condition with the timing

light.

Connector

Check the connector and

Turn on the ignition switch.

(But do not start engine)

2. Disconnect the ignition coil cover.

3. Check the battery voltage

Using a voltmeter, connect the positive (+)

probe to the resistor positive (+) terminal

and negative (—) probe to the body ground.

Voltage: Approx. 12V

Check the power transistor in igniter.

(1) Usinga voltmeter, connect the positive

(+) probe to the ignition coil negative

(—) terminal and negative (—) probe to

the body ground {power transistor

OND.

Voltage: Less than 3V

8-4 IGNITION SYSTEM — Ignition System Circuit

Fig. 86

a White

%

LA] (f |

evo 7

| ra |

Fig. 8-7

Fig. 88

(2) Unplug wiring connector from distri

butor.

(3) Using a voltmeter, connect the positive

(4) probe to the ignition coil negative

(=) terminal and negative (—) probe to

the body ground.

(4) Using a dry cell battery (1.5V), con:

nect the positive (+) pole to the white

wire terminal and negative (—) pole to

the pink wire terminal (power tran-

sistor OFF)

= Caution —

To avoid destroying the power transistor in the

do not apply voltage more than 5

(5) Check the voltage reading,

Voltage: Approx, 12V

Distributor

1. Distributor cap

Check for cracks, carbon tracks, burnt or

corroded terminals, and check the center

contact for wear.

2. Check the governor.

Turn the rotor counterclockwise and release

it. The rotor should return smoothly to its

original position.

IGNITION SYSTEM — Ignition System Circuit 8-5

Fig. 89

USA & Canada

3. Check the air gap.

Check the air gap between the timing rotor

and pick up coil projection with a thickness

gauge.

Air gap: 0.2—0.4mm

(0.008 — 0.016 in.)

Air Gap

Fig. 8-10

aap aon 4, Check the signal generator.

Check the resistance of the signal generator

with an ohmmeter.

n Resistance: 140 — 180 2

Q

Fig. 8-11

Except USA & Canada

3. Check the rubbing block gap.

Rubbing block gap: 0.45 mm.

(0.017 in.)

Fig, 812

Resistor

‘Check the resistor resistance with an ohmmeter.

8-6

Fig. 8-13

IGNITION SYSTEM — Ignition System Circuit

Fig. 815

Ignition Coil

1, Check the ignition coil resistances with an

ohmmeter,

(1) Primary coil resistance: between Posi-

tive (+) and negative (~) terminals

Resistance:

with Igniter 1.31.79

without Igniter 1,2— 1.5.2

(2) Secondary coil resistance: between

positive (+) terminal and high tension

terminal,

Resistance:

with Igniter 10 — 15k

without Igniter 8 — 12k

2. Check the insulation resistance between the

positive (+) terminal and coil case with an

ohmmeter

Resistance: Infinity

IGNITION SYSTEM — Distributor 8-7

DISTRIBUTOR

DISASSEMBLY

Disassemble the parts in the numerical order

shown in the figure.

Fig. 8.16

General Destinations

Cop, Rotor & Cover

Terminal

Breaker Point

Vacuum Advancer

Breaker Plate

Cam

8-8 IGNITION SYSTEM — Distributor

Fig. 8-17

General Destinations.

Breaker Plate

Stationary Plate

nar

=

a

HR snap Ring

Bg rere sins

|

Ce overncr Weight

=

Steel Washer

Bakelite Washer

‘Stoel Washer

Governor Shaft

| Ring:

Stare

Fig. 8-18

Sweden 4K-C

n

IGNITION SYSTEM — Distributor 8-9

Disassemble the parts in the numerical order

shown in the figure.

Cap, Rotor, Cover & Packing

Terminal

Breaker Point

Damping Spring

Ground Wire

‘Vacuum Advancer

Breaker Plate

Cam

8=10 IGNITION SYSTEM — Distributor

Fig. 8-19

‘Sweden 4K-C

SGovenor Soring erg

IGNITION SYSTEM — Distributor 8-11

Disassemble the parts in the numerical order

shown in the figure.

Fig. 8-20

USA & Canada

nd

wp

y

ap, Rotor & Packing 8. Governor Weight

Dustproof Cover & Signal Generator 9. Cord Clamp

Steel Plato Washer 10, Vacuum Advancer

Breaker Plate 11. Pin

Grease Stopper 12. Spiral Gear & Washer

Governor Spring 13. Governor Shaft

Signal Rotor 14, Stee! Washer

seeeepe

8-12 IGNITION SYSTEM — Distributor

reas INSPECTION & REPAIR

Cap

Inspect for cracks, carbon wacks, burnt or

corroded terminals and check the center contact,

for wear

Rotor

Inspect for cracks, carbon tracks, burnt or

corroded terminals.

Breaker Plate

Check the breaker plate for smooth rotation.

Governor Weight & Pin

Check the fitting portions of the governor

weights with support pins for binding.

IGNITION SYSTEM — Distributor 8-13

Fig. 8-25

Vacuum Advancer Diaphragm

The diaphragm should move when you inhale

through the port.

Cam & Shaft

Inspect cam for wear, damage and fit between

‘cam and shaft,

Governor Shaft & Housing

1, Check shaft thrust clearance.

Thrust clearance: 0,15 — 0.50 mm

(0,006 — 0,020

2. Remove gear and pin

Grind off the pin end and remove the pin

and gear.

8-14 IGNITION SYSTEM — Distributor

Fig. 8-29

3. Inspect the governor shaft for wear or

damage.

Fig. 8-30

Inspect housing bushings, and O ring for

wear, deformation or damage.

Fig. 8-31

General Destinations

5. Insert the washers onto the governor shaft

and plate in the following order.

(1) 2mm (0.08 in.)

(2) 0.2 mm (0,008 in.)

(3) Bakelite washer

(4) 0.2 mm (0.008 in.)

(5) 0.2mm (0,008 in)

Adjust to standard clearance by varying the

number of washers 2, 4 and 5 listed above.

Steel Washer

. Except General Destinations

+! 5-1 Assemble the washer as shown in the figure

Washer (for adjustment)

Thickness mm (in)

2.5 (0.098)

2.7 (0.106)

2.9 (0.114)

2.3 (0.091)

90099-01385

90099-01386

90099-01387

90099-01412

IGNITION SYSTEM — Distributor e15

Fig. 8-33

5-2 Assemble the bearing between the pin and

weight.

Fig. 834

Assemble the washers and gear in order as

shown in the figure and check the thrust

clearance.

Fig. 8:35

a 7. Peen both pin ends with a vise.

8-16 IGNITION SYSTEM — Distributor

ASSEMBLY

Assemble the parts in the numerical order shown

in the figure.

Fig. 836

General Destinations

i

| fants pss :

‘

. Se

“8B

| --- xy O

> Ww 9

Cam

Advancer

Point

7

Cover, Rotor & Cap

IGNITION SYSTEM — Distributor 8-17

Assemble the parts in the numerical order shown

in the figure.

Fig. 8.37

Sweden 4K-C

cam

Breaker Plate

‘Vacuum Advancer

Damping Spring

Cover, Rotor, Cap & Packing

Presson

8-18 IGNITION SYSTEM — Distributor

Assemble the parts in the numerical order shown

in the figure.

Fig. 8-38

USA & Canada

7—__———_

1. Governor Weight Governor Spring

2. Stee! Washer Breaker Plate

3. Governor Shaft ‘Steel Plate Washer

4. Spiral Gear & Washer Signal Generator & Dustproot Cover

5. Pin ‘Vacuum Advancer

6. Signal Rotor Cord Clamp

7 Gre ‘& Packing

Stopper

IGNITION SYSTEM — Distributor 8-19

|. 8:39

General Destinations

Install the governor springs in the direction

shown in the figure.

USA, Canada & Sweden

1. Insure installation of the E ring into the

groove.

2. Match the mark 14 with the stopper and

install the cam.

Fig. 8-42

be] 3. Insure proper installation of the governor

spring.

8-20 IGNITION SYSTEM — Dist

itor

Fig. 8.43

Center Line |

Setting farie

Setting

ADJUSTMENT

1. Adjust the air gap.

(Except USA & Canada)

Rubbing block gap: 0.45 mm

(0.0177 in.)

(USA & Canada)

Airgap: 0.2—0.4mm

(0.008 — 0.016 in.)

2. Set the octane selector at the standard line,

(2K, 3K-H & 4K)

3. Check the breaker plate for smooth rotation,

Fig. 8-47

IGNITION SYSTEM — Distributor 8-21

INSTALLATION

1. Set the crankshaft pulley to No. 1 cylinder

ition timing.

Ignition timing (BTDC):

8° at

Align the center line of the slot at the top

end of the oil pump shaft against the mark

(il hole) at the top side of the oil pump

body.

Fig. 8-50

Position the distributor rotor toward the

right side of No. 3 plug tube, and insert the

distributor housing.

3

+

4, When the housing is inserted, the rotor

should be positioned near the center of

No, 2 plug tube.

be]

8-22

Fig. 851

IGNITION SYSTEM — Distributor

A?

ON Position

Turn ignition switch to the ON position.

Do not turn the starter motor.

Rotate the distributor body counterclock-

wise until there is a spark between the

points, and tighten the clamp bolt in that

position. (Except USA & Canada)

Adjust the housing by moving it so that the

signal rotor will just begin to cut the lines of

the flux, and then tighten the set bolt.

(USA & Canada)

7. Check ignition timing during idling.

Ignition timing (BTDC):

8° at idle speed

If necessary, align the timing marks by

turning the distributor body.

IGNITION SYSTEM — High Tension Cord 8-23

Fig. 8:55 HIGH TENSION CORD

— Note —

Carefully remove the high tension cords by

pulling on the rubber boots.

Fig. 856

2. Do not bend the cords as the conductors will

Wrong Correct break.

eer INSPECTION

1. Check the condition of the cord terminals. If

any terminal is corroded, clean it. If broken

. or distorted, replace the cord

N

Fig. 8-58

Check the resistance of each cord between

both ends. If the reading exceeds the limit,

replace the cord.

Resistance: Less than 25 k®/cord

IGNITION SYSTEM — Spark Plugs

SPARK PLUGS

INSPECTION

Inspect for the following. Clean or replace the

plugs if necessary.

1, Cracks or damages in the threads or in-

sulator.

2. Damaged or deteriorated gaskets.

‘Wear on the electrodes.

Burnt electrode and the amount of carbon

deposit.

Fig. 8-61 GAP ADJUSTMENT

Check the plug gap with plug gap gauge.

If not to specified value, adjust by bending the

ground (outer) electrod

‘Spark plug gap:

USA (ex. Calif.) & Canada 1.1 mm

(0.043 in.)

General, Europe & Calif. 0.8 mm

(0.031 in.)

MEMO

MEMO:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5935)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1106)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (879)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (598)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (925)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (545)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (353)

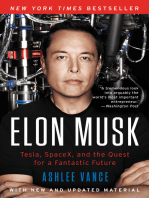

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (476)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (831)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (274)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (419)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2271)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (99)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (270)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Toyota Starlet KP6 - Series Body Style Wiring DiagramsDocument13 pagesToyota Starlet KP6 - Series Body Style Wiring Diagramscap67% (6)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (235)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (232)

- 50 Chairs That Changed The WorldDocument57 pages50 Chairs That Changed The Worldcap97% (32)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (75)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 07 - Starting SystemDocument32 pages07 - Starting SystemcapNo ratings yet

- 05 - Cooling SystemDocument10 pages05 - Cooling SystemcapNo ratings yet

- MR Gasket Instructions Micro Electric Fuel Pump 12S 42SDocument4 pagesMR Gasket Instructions Micro Electric Fuel Pump 12S 42ScapNo ratings yet

- Krups Espresso Machine TipsDocument14 pagesKrups Espresso Machine TipscapNo ratings yet

- Electric Fuel Pump Installation InstructionsDocument4 pagesElectric Fuel Pump Installation InstructionscapNo ratings yet

- Human Bartonellosis Caused By: Bartonella BacilliformisDocument29 pagesHuman Bartonellosis Caused By: Bartonella BacilliformiscapNo ratings yet

- Walmart-Four Dollar Generic Drug ListDocument5 pagesWalmart-Four Dollar Generic Drug ListcapNo ratings yet