Flange Leakage Check Sheet

Flange Leakage Check Sheet

Uploaded by

Ehtisham AndrAbiCopyright:

Available Formats

Flange Leakage Check Sheet

Flange Leakage Check Sheet

Uploaded by

Ehtisham AndrAbiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Flange Leakage Check Sheet

Flange Leakage Check Sheet

Uploaded by

Ehtisham AndrAbiCopyright:

Available Formats

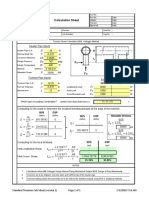

Flange Leakage Check

Sr.

No.

Line No.

Node

No.

Nozzle Details

Size

(Inch)

Rating

(#)

Pressure

Temperature

Axial Force

Resultant

Moment

Mean Dia. of

Gasket Contact

face

Equivalent

Pressure

Allowable

Pressure

Condition /

Case

Result

(Flange Leakage

Check)

(Kg/cm2g)

(Deg F)

(N)

(N-m)

(mm)

(psig)

(psig)

10

14

150

11.6

368

2021

2256

389

195

210

Case -1

PASS

10

14

150

9.6

341

1798

2021

389

164

218

Case -2

PASS

10

14

150

0.5

374

2098

2325

389

39

208

Case -3

PASS

100

10

150

11.6

368

5940

4965

302

309

410

Case -1

PASS

100

10

150

9.6

341

5284

6011

302

307

218

Case -2

FAIL

100

10

150

0.5

374

5679

4822

302

147

208

Case -3

PASS

150

10

150

11.6

368

17

851

302

187

210

Case -1

PASS

150

10

150

9.6

341

10

760

302

157

218

Case -2

PASS

150

10

150

0.5

374

337

848

302

30

208

Case -3

PASS

Notes :

1) Gasket dimensions are as per ANSI B 16.20

2) Allowable Pressure is as per "Pressure-Temperature" Chart from ANSI B16.5.

3) This table is prepared based on ASME Section III, Paragraph NC-3658.1.

4) All values of Static output results (Force & Moments) for different cases are considered for the calculation.

6) The formula used to calculate the Equivalent Pressure is as follows :

Peqv = Pd + 4*F/3.14*G2 + 16*M/3.14*G3

Pd = Internal Pressure

where ;

F = Axial Force

G = Mean Diameter of Gasket

M = Resultant Bending Moment

7) Units have been converted suitably.

Case -1

Case -2

Case -3

Design Case

Operating Case

Occasional Case

You might also like

- ASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelDocument16 pagesASME V111 Div2 APP 3 Flanges Stress Calculation in ExcelPanya Purahong100% (1)

- Flange LeakageDocument48 pagesFlange LeakageAnjani Prabhakar83% (6)

- ASME B31.3 Area ReplacementDocument2 pagesASME B31.3 Area ReplacementJahsbuck100% (1)

- Weldstrength Calc ProgDocument10 pagesWeldstrength Calc ProgSajal KulshresthaNo ratings yet

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- Modeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368Document5 pagesModeling of Internal Pressure and Thrust Load On Nozzles Using WRC 368m5416No ratings yet

- Ring Flange CalculationDocument3 pagesRing Flange CalculationLuizNo ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- Stud Bolts CalculatorDocument2 pagesStud Bolts CalculatorEhtisham AndrAbiNo ratings yet

- B - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersDocument22 pagesB - 4.5 - 44LK-5100-00-V.02-0102-A4-General Spec For Heat ExchangersAnitNo ratings yet

- Ozone - Calif. Laws PDFDocument6 pagesOzone - Calif. Laws PDFRicardo Alberto AhrensNo ratings yet

- Technical Specification 1420288037Document51 pagesTechnical Specification 1420288037gaurao nasare100% (1)

- ISA 75.19.01 Hydrostatic Testing of Control Valves PDFDocument34 pagesISA 75.19.01 Hydrostatic Testing of Control Valves PDFChristianGuerrero100% (1)

- Flange Leakage Check SheetDocument1 pageFlange Leakage Check SheetLimin ZhangNo ratings yet

- Pge Sa 000 PD SP 0015 02Document30 pagesPge Sa 000 PD SP 0015 02sajadranjbaranNo ratings yet

- Special Pipe SupportsDocument293 pagesSpecial Pipe SupportsVijay_Damam100% (3)

- Trunnion & Shoe Temp. Calculation.Document27 pagesTrunnion & Shoe Temp. Calculation.Bharat Bellad100% (1)

- Nozzle Movement CalculationDocument23 pagesNozzle Movement CalculationPriyanathan Thayalan80% (5)

- Calculation For Reinforced PadDocument4 pagesCalculation For Reinforced Padjsridhar_34750% (2)

- Stress Sample Calculation On Base EllDocument1 pageStress Sample Calculation On Base EllLionel Torrado0% (1)

- Texas FlangeDocument76 pagesTexas FlangeDANIEL JIMENEZNo ratings yet

- ASME B16.5 2013 FlangeRating 1.0Document4 pagesASME B16.5 2013 FlangeRating 1.0sanjaysyNo ratings yet

- Flange Leakage CheckDocument1 pageFlange Leakage CheckPhornlert WanaNo ratings yet

- Line Stop Welded To Shoe CalculationDocument16 pagesLine Stop Welded To Shoe Calculationmohdnazir100% (1)

- Thickness Analysis ReportDocument9 pagesThickness Analysis ReportEhtisham AndrAbiNo ratings yet

- ShoeDocument1 pageShoePhornlert Wana100% (1)

- Zinq - AnalysisDocument116 pagesZinq - AnalysisAimiNo ratings yet

- Piping Isometric ChecklistDocument21 pagesPiping Isometric ChecklistNguyen Anh Tung75% (4)

- Hydraulic Analysis Versus Piping Stress Analysis ApproachDocument1 pageHydraulic Analysis Versus Piping Stress Analysis Approachalan172081100% (1)

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- FRP Flange DesignDocument29 pagesFRP Flange DesignSubhadip RoyNo ratings yet

- Hot Tap/Stopple & Reinforcement Calculation Request: SECTION 1 (To Be Completed by The Initiating Engineer)Document2 pagesHot Tap/Stopple & Reinforcement Calculation Request: SECTION 1 (To Be Completed by The Initiating Engineer)aqisNo ratings yet

- Flange CalculationsDocument3 pagesFlange CalculationssanjaysyNo ratings yet

- Nozzle Movement CalculationDocument23 pagesNozzle Movement Calculationdjole112No ratings yet

- Design Sheet As Per ASME 31.8 2012 For 12inch TeeDocument3 pagesDesign Sheet As Per ASME 31.8 2012 For 12inch TeechethanNo ratings yet

- Nozzle Pipe Length CalculatorDocument5 pagesNozzle Pipe Length CalculatorRyan Goh Chuang HongNo ratings yet

- 2 PVElite NotesDocument19 pages2 PVElite NotesZAKI1983No ratings yet

- Pipe Load CalculationDocument6 pagesPipe Load CalculationSuthan SelvarajNo ratings yet

- Guideline For GRE Pipe Stress Analysis - T SrinivasanDocument5 pagesGuideline For GRE Pipe Stress Analysis - T Srinivasansri06No ratings yet

- Design of Flanges - Full-Face Gasket 2010Document29 pagesDesign of Flanges - Full-Face Gasket 2010bakelly100% (2)

- N-318-5 Lug Local StressDocument3 pagesN-318-5 Lug Local StresscohenfuNo ratings yet

- Pipe Size Flange Rating Operating Condition: E F SFDocument4 pagesPipe Size Flange Rating Operating Condition: E F SFvivekpec100% (1)

- NC Method: Bolt Circle Dia Diameter Bolts Number BoltsDocument5 pagesNC Method: Bolt Circle Dia Diameter Bolts Number BoltsJ A S JASNo ratings yet

- External Pressure Calculation ResultsDocument8 pagesExternal Pressure Calculation ResultsAndika DearsonNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Load Cases For Typical Piping System Using CAESAR IIDocument4 pagesLoad Cases For Typical Piping System Using CAESAR IIsj22100% (1)

- PSV Reaction Forces and DirectionDocument29 pagesPSV Reaction Forces and Directionpvmsson100% (1)

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Nozzle Load CheckDocument4 pagesNozzle Load CheckpipestressNo ratings yet

- ASME Code Calculations and DrawingsDocument2 pagesASME Code Calculations and DrawingsRicardo Paz SoldanNo ratings yet

- Stress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPDocument23 pagesStress Analysis Specification: CONT. NO.: 1032/GC-GN/CON-EP09-00 DOC. NO.: 3607/34-78-ED-PI-SPhamedpdms100% (1)

- Pipe Wall THK Calc For External PressureDocument2 pagesPipe Wall THK Calc For External PressurektejankarNo ratings yet

- SIF CalculatorDocument4 pagesSIF CalculatorKannaphat Wattanaphan100% (1)

- Nozzle Loading - EILDocument5 pagesNozzle Loading - EILSanthosh Dhinakaran P100% (1)

- Pressure Vessel ExampleDocument48 pagesPressure Vessel ExamplemohamedNo ratings yet

- Stress and Displacement Analysis of Aerial Oil GasDocument17 pagesStress and Displacement Analysis of Aerial Oil GasDaniel Gómez100% (1)

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDocument12 pagesFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNo ratings yet

- Flange Leakage - NC 3658.3Document4 pagesFlange Leakage - NC 3658.3gharsallah mounaNo ratings yet

- Pumps Head Calculation SheetDocument2 pagesPumps Head Calculation Sheethasanadel88100% (1)

- VDR 715 Ag 9C: BS 1868 Trim MaterialsDocument1 pageVDR 715 Ag 9C: BS 1868 Trim Materialshalim_kaNo ratings yet

- Enginnering DemandsDocument23 pagesEnginnering Demandswaqas_asad3081No ratings yet

- Fuseal PP Corrosive WasteDocument56 pagesFuseal PP Corrosive WasteFrancisco Javier AguilarNo ratings yet

- Whirlpool Polar PDT 839 Service ManualDocument14 pagesWhirlpool Polar PDT 839 Service ManualAnonymous 2GVabYh40WNo ratings yet

- VF SFOA Ss 3 Description of Service Features and Charges v16 2019 10 14Document14 pagesVF SFOA Ss 3 Description of Service Features and Charges v16 2019 10 14Ehtisham AndrAbiNo ratings yet

- Volunteer Tutor Scheme Faqs 1Document2 pagesVolunteer Tutor Scheme Faqs 1Ehtisham AndrAbiNo ratings yet

- Carla Algie Portfolio PDFDocument11 pagesCarla Algie Portfolio PDFEhtisham AndrAbiNo ratings yet

- GPT 1-3 PGE Tech SpecificationsDocument4 pagesGPT 1-3 PGE Tech SpecificationsEhtisham AndrAbiNo ratings yet

- Branch Reinforcement Per Asme B31.4 PipelineDocument1 pageBranch Reinforcement Per Asme B31.4 PipelinegateauxboyNo ratings yet

- Materials Used in Process PlantsDocument8 pagesMaterials Used in Process PlantsEhtisham AndrAbiNo ratings yet

- GCCTariff enDocument560 pagesGCCTariff enEhtisham AndrAbiNo ratings yet

- Thickness Analysis ReportDocument9 pagesThickness Analysis ReportEhtisham AndrAbiNo ratings yet

- Hydraulic Bolt TensionDocument24 pagesHydraulic Bolt TensionEhtisham AndrAbi100% (1)

- Service Letter 0229ADocument4 pagesService Letter 0229A412 BellNo ratings yet

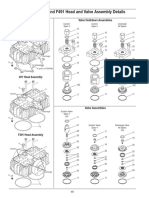

- F1 Crankcase Assy.: NOTES: V5 Engine Model:172MMDocument17 pagesF1 Crankcase Assy.: NOTES: V5 Engine Model:172MMryan FosterNo ratings yet

- Tamd162c-C, Tamd163a-A, Tamd163p-A, Tamd165a-A, Tamd165c-ADocument482 pagesTamd162c-C, Tamd163a-A, Tamd163p-A, Tamd165a-A, Tamd165c-AJACK BacksNo ratings yet

- Fis190 en A5Document8 pagesFis190 en A5andhucaosNo ratings yet

- Weight & Measurement Data 11627 4th Jan 2019 (IN KGS)Document530 pagesWeight & Measurement Data 11627 4th Jan 2019 (IN KGS)Prateek SehgalNo ratings yet

- Technical Manual: VanessaDocument7 pagesTechnical Manual: VanessaAnonymous LLLK3pqNo ratings yet

- Dodge 054153 CatalogDocument214 pagesDodge 054153 CatalogRicardo PerezNo ratings yet

- Elring GasketsDocument28 pagesElring GasketsSergio Valente (PY1ZA)No ratings yet

- VSAT Satcom Equipment Install HandbookDocument45 pagesVSAT Satcom Equipment Install Handbookraymund12345No ratings yet

- PP67 PE GEN 00 DOR SP Q 004 - Rev06 Piping Material ClassesDocument45 pagesPP67 PE GEN 00 DOR SP Q 004 - Rev06 Piping Material ClassesHEINER_P100% (1)

- Flange Facings: ContentDocument11 pagesFlange Facings: ContentcemalNo ratings yet

- 2015 Outlander-Renegade-XMR Service ManualDocument826 pages2015 Outlander-Renegade-XMR Service ManualDiego Garagem P7No ratings yet

- Pages From Iom LPG Comp - Ie101hDocument8 pagesPages From Iom LPG Comp - Ie101hRamius HamdaniNo ratings yet

- Catalog DIESEL Engine SCANIADocument221 pagesCatalog DIESEL Engine SCANIAquocsimarineNo ratings yet

- PV Elite Report-4 CODE A - CompressedDocument219 pagesPV Elite Report-4 CODE A - Compressedmech1No ratings yet

- Fisherr HP and HPA Control Valves: Scope of ManualDocument56 pagesFisherr HP and HPA Control Valves: Scope of ManualMK MKNo ratings yet

- Dragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198Document16 pagesDragon 178 Series Pumps: Installation, Operation and Maintenance Instructions For 1-800-231-8198jesus alfonso fragozo calderonNo ratings yet

- Fuel Feed Pump: Wärtsilä Vasa 32 Engine SPC 174-0019ADocument4 pagesFuel Feed Pump: Wärtsilä Vasa 32 Engine SPC 174-0019ASaasiNo ratings yet

- TempoDocument4 pagesTempoAbdul Majid ShabbirNo ratings yet

- Service Manual: AXSM0057Document90 pagesService Manual: AXSM0057guillermoNo ratings yet

- Power Steering Vane Pump (2Jz Ge) : ComponentsDocument2 pagesPower Steering Vane Pump (2Jz Ge) : ComponentsMoh DeBrNo ratings yet

- Metal Jacketed Gaskets: Picture 1Document7 pagesMetal Jacketed Gaskets: Picture 1surendharNo ratings yet

- Technical Specification PTP Ennore Part2-2024-02!19!06!07!41Document239 pagesTechnical Specification PTP Ennore Part2-2024-02!19!06!07!41trilokNo ratings yet

- PNSMV027Document11 pagesPNSMV027Philippe AlexandreNo ratings yet

- Horizontal Pressure Vessel Designe Project One: AcknowledgementDocument7 pagesHorizontal Pressure Vessel Designe Project One: Acknowledgementshibabw worknehNo ratings yet

- Lamons Gasket PDFDocument8 pagesLamons Gasket PDFisrar khanNo ratings yet