009-12 Fy12

009-12 Fy12

Uploaded by

aladinsaneCopyright:

Available Formats

009-12 Fy12

009-12 Fy12

Uploaded by

aladinsaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

009-12 Fy12

009-12 Fy12

Uploaded by

aladinsaneCopyright:

Available Formats

NAVSEA

STANDARD ITEM

FY-12

ITEM NO: 009-12

DATE: 30 JUL 2010

CATEGORY: II

1. SCOPE:

1.1 Title: Welding, Fabrication, and Inspection Requirements; accomplish

2. REFERENCES:

2.1 Standard Items

2.2 MIL-STD-1689, Fabrication, Welding, and Inspection of Ships Structure

2.3 American Bureau of Shipping (ABS) Rules for Building and Classing

Steel Vessels

2.4 0900-LP-060-4010, Fabrication, Welding, and Inspection of Metal Boat

and Craft Hulls

2.5 T9074-AQ-GIB-010/248, Requirements for Welding and Brazing Procedure

and Performance Qualification

2.6 0900-LP-001-7000, Fabrication and Inspection of Brazed Piping Systems

2.7 S9074-AR-GIB-010/278, Requirements for Fabrication Welding and

Inspection, and Casting Inspection and Repair for Machinery, Piping,

and Pressure Vessels

2.8 MIL-STD-22, Welded Joint Design

2.9 MIL-STD-2035, Nondestructive Testing Acceptance Criteria

2.10 T9074-AS-GIB-010/271, Requirements for Nondestructive Testing Methods

2.11 DOD-STD-2185, Requirements for Repair and Straightening of Bronze

Naval Ship Propellers

2.12 S9221-C1-GTP-010/020, Repair and Overhaul, Main Propulsion Boilers

2.13 S9AAO-AB-GOS-010, General Specifications for Overhaul of Surface

Ships (GSO)

2.14 MIL-STD-2191, Repair, Welding, Weld Cladding, Straightening, and Cold

Rolling of Main Propulsion Shafting

1 of 18 ITEM NO: 009-12

FY-12

2.15 S9FFG-AG-SRM-010, Superstructure Cracking Repair; FFG7 Class, Ship

Repair Manual

2.16 DM 10-612 Rev A, SERMC, FFG7 Class Aluminum Deckhouse Critical Welds

and Critical Weld Regions

2.17 S9CGO-BP-SRM-010/CG-47CL, Technical Manual for CG-47 Class,

Superstructure Cracking Repair

2.18 DM 10-623, SERMC, Quality Assurance Requirements for Welding 5XXX

Series Aluminum Structures for CG-47 Class

│

3. REQUIREMENTS:

3.1 Utilize specific requirements of 2.2 through 2.12 listed in Tables

One, 2, 3, and 4 of this item for determining the welder and brazer

qualifications, electrodes, weld design, welding requirements, brazing

requirements, welding procedures, brazing procedures, welding parameters and

controls, inspection standards, and acceptance criteria.

3.2 Weld bell-end fittings in accordance with Section 505c8 of 2.13.

Nondestructive testing inspection shall comply with Class P-2 piping systems

as defined by 2.7.

3.3 Ground welding machines, for purposes of providing a return path for

welding current, using a grounding bar or lead which shall be connected

directly from the machine ground return connection to the ship's hull, sized

on the basis of 1,000,000 Circular Mils per 1,000 amps per 100 feet, but in no

event using less than a Number One cable (85,037 Circular Mils).

3.3.1 Welding machines used for welding on machinery, pressure

vessels, or piping, rotating ordnance, electronic, or fire control equipment

shall have the ground return connection in the immediate vicinity of the work

to ensure that current does not flow through bearings, pipe hangers, or other

areas where arcing or high resistance paths exist. For ships constructed of

non-magnetic materials, the ground return cables shall be connected directly

to the component being welded - as close to the weld zone as feasible.

3.3.2 Shipboard power distribution system shall not be used as the

power source for welding equipment. External power source shall be used.

3.4 Accomplish the requirements of 009-09 of 2.1 for specific welding,

brazing, and inspection operations as follows:

3.4.1 Class A-F, A-1, A-2, A-3, A-LT, P-1, P-LT, M-1, and T-1

welding, as defined by 2.7. These procedures shall include, as a minimum, the

information required by Paragraph 4.1.3 of 2.7 and supporting data such as a

sketch of the weld repair areas and associated ship components. Joint numbers

shall not be duplicated on ship during the availability.

2 of 18 ITEM NO: 009-12

FY-12

3.4.2 Class P-3a special category silver brazing, as defined by 2.6.

The procedure shall include, as a minimum, the information required by

Sections 4, 5, 6, 7, 8, and 9 of 2.6.

3.4.2.1 All brazing of steam piping shall conform to 2.6,

Class P-3a special category, including ultrasonic inspection, regardless of

pipe size, including any (existing) copper to (new) copper-nickel transition

joints.

3.4.2.2 In steam systems, where brazed piping and fittings

are to be reused, or piping has to be sized to achieve proper fit-up, the

option for a 5X visual inspection for cracks listed in Sections 5.5.3, 5.10.1,

and 5.10.2 of 2.6 shall not be used; liquid penetrant inspection shall be

required.

3.4.3 For propellers other than bronze, using 2.7 for guidance.

3.4.4 For propulsion shafting and rudder stocks, using 2.14 for

guidance.

3.4.5 For titanium-based materials, using 2.7 for guidance.

3.4.6 Accomplish aluminum welding and nondestructive testing for

FFG-7 Class ships in accordance with 2.15 and 2.16.

3.4.7 Accomplish aluminum welding and nondestructive testing for

CG-47 Class ships in accordance with 2.17 and 2.18.

│

(I) or (I)(G) “NONDESTRUCTIVE TESTING”

3.5 Accomplish nondestructive testing in accordance with the following:

3.5.1 Manufacture, installation, and repair (welding, brazing,

machining, or lapping) of Level I fittings or components:

3.5.1.1 Nondestructive Testing Visual Inspection - (I)

3.5.1.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant and Ultrasonic Testing (Final Only) - (I)(G)

3.5.1.3 Nondestructive Testing Radiographic - (I)

3.5.2 Welding/brazing of P-1, P-LT, P-3a piping systems or Class

A-F, A-1, A-2, A-3, A-LT, M-1, T-1 welding, and P-2 steam service:

3.5.2.1 Nondestructive Testing Visual Inspection - (I)

3.5.2.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant and Ultrasonic Testing (Final Only) - (I)(G)

3.5.2.3 Nondestructive Testing Radiographic - (I)

3 of 18 ITEM NO: 009-12

FY-12

3.5.3 Welding on ship/craft listed in Attachment A hull or structure

when required by the fabrication document:

3.5.3.1 Nondestructive Testing Visual Inspection - (I)

3.5.3.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant and Ultrasonic Testing (Final Only) - (I)(G)

3.5.3.3 Nondestructive Testing Radiographic - (I)

3.5.4 Weight handling equipment manufacture and repair:

3.5.4.1 Nondestructive Testing Visual Inspection - (I)

3.5.4.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant - (I)(G)

3.5.4.3 Ultrasonic Testing (Final Only) - (I)(G)

3.5.4.4 Nondestructive Testing Radiographic - (I)

3.5.5 Corrective maintenance within the certified boundaries of

cranes (as defined in NSTM 589):

3.5.5.1 Nondestructive Testing Visual Inspection - (I)

3.5.5.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant - (I)(G)

3.5.5.3 Ultrasonic Testing (Final Only) - (I)(G)

3.5.5.4 Nondestructive Testing Radiographic - (I)

3.5.6 Maintenance on aircraft launch and recovery equipment:

3.5.6.1 Nondestructive Testing Visual Inspection - (I)

3.5.6.2 Nondestructive Testing Magnetic Particle, Liquid

Penetrant and Ultrasonic Testing (Final Only) - (I)(G)

3.5.6.3 Nondestructive Testing Radiographic - (I)

(I)(G) "EVALUATION OF RT FILMS"

3.6 Accomplish RT film interpretation.

3.6.1 Provide the cognizant Government representative designated by

the SUPERVISOR the evaluated radiographs and records within 2 working days of

the (G) point.

4 of 18 ITEM NO: 009-12

FY-12

3.7 Do not deposit ferritic welds on welds made with austenitic or

non-ferrous electrodes. Where the base material is ferrous and the existing

weld is austenitic or non-ferrous, that weld shall be completely removed prior

to welding with ferritic electrodes. The welding shall be accomplished in

accordance with 2.2.

3.8 Utilize Attachment A to define combatant and non-combatant vessels

and applicable table.

3.9 Where requirements in the repair and testing instructions for

propulsion boilers conflict, 2.12 shall take precedence.

4. NOTES:

4.1 None.

5 of 18 ITEM NO: 009-12

FY-12

TABLE 1

WELDING, FABRICATION, AND INSPECTION OF PIPING, PRESSURE VESSELS, PROPELLERS, AND MACHINERY

COLUMN A B C D E

L CLASS A

I SITUATION CLASS P-1, P-2 AND P-LT CLASS P-3a SPECIAL HARD FACING PRESSURE ** PROPULSION *PROPELLERS

N EVOLUTION PIPING CATEGORY, OTHER VALVE PARTS VESSEL BOILERS (BRONZE)

E CLASS P-3a, AND P-3b

PIPING

S9221-C1-GTP-010/020

1 WELDER AND S9074-AQ-GIB-010/248, 0900-LP-001-7000, S9074-AQ-GIB-010/248, PARAGRAPH 5

BRAZER PARAGRAPH 5 SECTION 4

QUALIFICATION

S9221-C1-GTP-010/020 DOD-STD-2185,

2 WELDING S9074-AQ-GIB-010/248, NOT APPLICABLE S9074-AQ-GIB-010/248, PARAGRAPH 4 PARAGRAPH 4

PROCEDURE PARAGRAPH 4

3 BRAZING NOT APPLICABLE 0900-LP-001-7000, NOT APPLICABLE

PROCEDURE SECTION 4

4 WELDING S9074-AR-GIB-010/278, NOT APPLICABLE S9074-AR-GIB-010/278, MIL-STD-2185,

REQUIREMENTS PARAGRAPH 6 PARAGRAPH 6 PARAGRAPH 5

5 FILLER MATERIAL S9074-AR-GIB-010/278, 0900-LP-001-7000, S9221-C1-GTP-010/020

PARAGRAPH 5 SECTION 5 S9074-AR-GIB-010/278, PARAGRAPH 5

DOD-STD-2185,

PARAGRAPH 5

6 JOINT DESIGN S9074-AR-GIB-010/278, 0900-LP-001-7000, NOT APPLICABLE S9074-AR-GIB- S9221-C1-GTP-010/020

PARAGRAPH 9 SECTION 5 010/278,

PARAGRAPH 9

MIL-STD-22

MIL-STD-22

* - PARAGRAPH 3.3.3 APPLIES

** - PARAGRAPH 3.7 APPLIES 6 of 18 ITEM NO: 009-12

FY-12

TABLE 1

WELDING, FABRICATION, AND INSPECTION OF PIPING, PRESSURE VESSELS, PROPELLERS, AND MACHINERY

COLUMN A B C D E

L CLASS A

I SITUATION CLASS P-1, P-2 AND P-LT CLASS P-3a SPECIAL HARD FACING PRESSURE ** PROPULSION *PROPELLERS

N EVOLUTION PIPING CATEGORY, OTHER VALVE PARTS VESSEL BOILERS (BRONZE)

E CLASS P-3a, AND P-3b

PIPING

7 HEAT TREATMENT S9074-AR-GIB-010/278, 0900-LP-001-7000, S9074-AR-GIB- S9221-C1-GTP-010/020 S9074-AR-GIB-

PARAGRAPH 6 SECTION 5 010/278, 010/278,

PARAGRAPHS 6 PARAGRAPH 6

AND 11.6 S9074-AR-GIB-

010/278, DOD-STD-2185,

PARAGRAPH 6 PARAGRAPH 5

S9221-C1-GTP-010/020

8 WORKMANSHIP S9074-AR-GIB-010/278, 0900-LP-001-7000, S9074-AR-GIB- S9074-AR-GIB- S9074-AR-GIB-

REQUIREMENTS PARAGRAPH 7 SECTION 5 010/278, 010/278, 010/278,

PARAGRAPHS 7 PARAGRAPH 7 PARAGRAPH 7

AND 11.6

S9221-C1-GTP-010/020

9 VISUAL INSPECT S9074-AR-GIB-010/278, 0900-LP-001-7000, NOT APPLICABLE S9074-AR-GIB- DOD-STD-2185,

JOINT FIT-UP PARAGRAPH 9 SECTION 7 010/278, PARAGRAPH 5

MIL-STD-22 PARAGRAPH 9

FOR CLASS P-3a MIL-STD-22

SPECIAL CATEGORY

10 VISUAL INSPECTION S9074-AR-GIB-010/278, 0900-LP-001-7000, S9074-AR-GIB- S9074-AR-GIB-010/278,

PARAGRAPH 10 SECTION 7 AND 8 010/278, PARAGRAPH 10

PARAGRAPH 11.6.3 MIL-STD-2035,

MIL-STD-2035, FOR CLASS P-3a MIL-STD-2035, PARAGRAPH 4

PARAGRAPH 4 SPECIAL CATEGORY MIL-STD-2035, PARAGRAPH 4

PARAGRAPH 4

* - PARAGRAPH 3.3.3 APPLIES

** - PARAGRAPH 3.7 APPLIES 7 of 18 ITEM NO: 009-12

FY-12

TABLE 1

WELDING, FABRICATION, AND INSPECTION OF PIPING, PRESSURE VESSELS, PROPELLERS, AND MACHINERY

COLUMN A B C D E

L CLASS A

I SITUATION CLASS P-1, P-2 AND P-LT CLASS P-3a SPECIAL HARD FACING PRESSURE ** PROPULSION *PROPELLERS

N EVOLUTION PIPING CATEGORY, OTHER VALVE PARTS VESSEL BOILERS (BRONZE)

E CLASS P-3a, AND P-3b

PIPING

11 RADIOGRAPHIC S9074-AR-GIB-010/278 S9074-AR-GIB-010/278

INSPECTION (RT) PARAGRAPH 10 T9074-AS- PARAGRAPH 10

GIB-010/271, PARAGRAPH 3 NOT APPLICABLE T9074-AS-GIB-010/271,PARAGRAPH 3 NOT APPLICABLE

MIL-STD-2035, MIL-STD-2035, PARAGRAPH 5

PARAGRAPH 5 (NORMALLY

ONLY P-1 AND P-LT)

12 ULTRASONIC NOT APPLICABLE 0900-LP-001-7000, NOT APPLICABLE S9245-AR-TSM-

INSPECTION (UT) SECTIONS 6,7,8 AND 9 010/PROP,

FOR CLASS P-3a PARAGRAPH

SPECIAL CATEGORY 5-7.5.2

PIPING ONLY

13 LIQUID PENETRANT S9074-AR-GIB-010/278, 0900-LP-001-7000, S9074-AR-GIB- S9074-AR-GIB-010/278, PARAGRAPH 10 MIL-STD-2035,

INSPECTION (PT) PARAGRAPH 10 SECTION 7 AND 8 010/278, T9074-AS-GIB-010/271, PARAGRAPH 5 PARAGRAPH 7

PARAGRAPH 11.6.3

T9074-AS-GIB-010/271, T9074-AS-GIB-

FOR CLASS P-3a MIL-STD-2035, PARAGRAPH 7

PARAGRAPH 5 010/271,

SPECIAL CATEGORY MIL-STD-2035,

PARAGRAPH 5

PARAGRAPH 7

MIL-STD-2035,

PARAGRAPH 7 (NORMALLY SEE 3.4.2.2

ONLY P-1 AND P-LT)

14 MAGNETIC S9074-AR-GIB-010/278, NOT APPLICABLE S9074-AR-GIB-010/278, PARAGRAPH 10 NOT APPLICABLE

PARTICLE PARAGRAPH 10 T9074-AS-GIB-010/271, PARAGRAPH 4

INSPECTION (MT)

T9074-AS-GIB-010/271,

MIL-STD-2035

PARAGRAPH 4

PARAGRAPH 6

MIL-STD-2035,

PARAGRAPH 6 (NORMALLY

ONLY P-1 AND P-LT)

* - PARAGRAPH 3.3.3 APPLIES

** - PARAGRAPH 3.7 APPLIES 8 of 18 ITEM NO: 009-12

FY-12

TABLE 1

WELDING, FABRICATION, AND INSPECTION OF PIPING, PRESSURE VESSELS, PROPELLERS, AND MACHINERY

COLUMN F G H I J

L REDUCTION AND

I SITUATION EVOLUTION MACHINERY CLASS M TURBINE PARTS CASTINGS FORCED DRAFT STEAM TURBINE

N BLOWERS DRIVEN AUXILIARY

E GEARS

1 WELDER AND BRAZER

QUALIFICATIONS S9074-AQ-GIB-010/248, PARAGRAPH 5

2 WELDING PROCEDURE S9074-AQ-GIB-010/248, PARAGRAPH 4

3 BRAZING PROCEDURE NOT APPLICABLE

4 WELDING REQUIREMENTS S9074-AR-GIB-010/278, PARAGRAPH 6

5 FILLER MATERIAL S9074-AR-GIB-010/278, PARAGRAPH 5

6 JOINT DESIGN S9074-AR-GIB-010/278, PARAGRAPH 9, AND MIL-STD-22

7 HEAT TREATMENT S9074-AR-GIB-010/278, PARAGRAPHS 6 AND 8

8 WORKMANSHIP S9074-AR-GIB-010/278, PARAGRAPH 7

REQUIREMENTS

9 VISUAL INSPECT JOINT FIT- S9074-AR-GIB-010/278, PARAGRAPH 10, AND MIL-STD-22

UP

10 VISUAL INSPECTION S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB- S9074-AR-GIB-010/278, S9074-AR-GIB-

PARAGRAPH 10 PARAGRAPH 14 010/278, PARAGRAPH 16 010/278,

PARAGRAPH 13 PARAGRAPH 15

MIL-STD-2035, PARAGRAPH 4

MIL-STD-2035,

PARAGRAPH 4

11 RADIOGRAPHIC S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB- S9074-AR-GIB-010/278, NOT APPLICABLE

INSPECTION (RT) PARAGRAPH 10 PARAGRAPH 14 010/278, PARAGRAPH 16

T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, PARAGRAPH 13 T9074-AS-GIB-010/271,

PARAGRAPH 3 PARAGRAPH 3 PARAGRAPH 3

MIL-STD-2035, MIL-STD-2035, MIL-STD-2035,

PARAGRAPH 5 PARAGRAPH 5 PARAGRAPH 5

9 of 18 ITEM NO: 009-12

FY-12

TABLE 1

WELDING, FABRICATION, AND INSPECTION OF PIPING, PRESSURE VESSELS, PROPELLERS, AND MACHINERY

COLUMN F G H I J

L REDUCTION AND

I SITUATION EVOLUTION MACHINERY CLASS M TURBINE PARTS CASTINGS FORCED DRAFT STEAM TURBINE

N BLOWERS DRIVEN AUXILIARY

E GEARS

12 ULTRASONIC INSPECTION S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278,

(UT) PARAGRAPH 10 PARAGRAPH 14 PARAGRAPH 13 PARAGRAPH 16 PARAGRAPH 15

T9074-AS-GIB-010/271,

PARAGRAPH 6

MIL-STD-2035, PARAGRAPH 8

13 LIQUID PENETRANT S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278,

INSPECTION (PT) PARAGRAPH 10 PARAGRAPH 14 PARAGRAPH 13 PARAGRAPH 16 PARAGRAPH 15

T9074-AS-GIB-010/27,1 T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, T9074-AS-GIB-010/271,

PARAGRAPH 5 PARAGRAPH 5 PARAGRAPH 5 PARAGRAPH 5 PARAGRAPH 5

MIL-STD-2035, PARAGRAPH 7 MIL-STD-2035, MIL-STD-2035, MIL-STD-2035, MIL-STD-2035,

PARAGRAPH 7 PARAGRAPH 7 PARAGRAPH 7 PARAGRAPH 7

14 MAGNETIC PARTICLE S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278, S9074-AR-GIB-010/278,

INSPECTION (MT) PARAGRAPH 10 PARAGRAPH 14 PARAGRAPH 13 PARAGRAPH 16 PARAGRAPH 15

T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, T9074-AS-GIB-010/271, T9074-AS-GIB-010/271,

PARAGRAPH 4 PARAGRAPH 4 PARAGRAPH 4 PARAGRAPH 4 PARAGRAPH 4

MIL-STD-2035, MIL-STD-2035, MIL-STD-2035, MIL-STD-2035, MIL-STD-2035,

PARAGRAPH 6 PARAGRAPH 6 PARAGRAPH 6 PARAGRAPH 6 PARAGRAPH 6

10 of 18 ITEM NO: 009-12

FY-12

TABLE 2

WELDING, FABRICATION, AND INSPECTION OF SURFACE SHIP HULLS (COMBATANT)

COLUMN A B C D E F

L *HIGH STRENGTH STEEL

CARBON STEEL (MS) CHROMIUM NICKEL COPPER AND/OR

I MATERIAL EVOLUTION (HY-80/100, HSLA-80 AND ALUMINUM ALLOY SILICONE BRONZE

AND (HTS) STEEL (STAINLESS) NICKEL BASE

N STS) ALUMINUM BRONZE

ALLOYS

E

1 WELDER QUALIFICATION S9074-AQ-GIB-010/248, PARAGRAPH 5

2 WELDING PROCEDURE S9074-AQ-GIB-010/248, PARAGRAPH 4

3 ELECTRODE MIL-STD-1689, MIL-STD-1689, MIL-STD-1689, MI-STD-1689, MIL-STD-1689, S9074-AR-GIB-

PARAGRAPH 10 PARAGRAPH 10 PARAGRAPH 10 PARAGRAPH 10 PARAGRAPH 10 010/278, TABLE II

TABLE X TABLE XI TABLE XVI TABLES XII AND XIII TABLES XIV AND XV

4 JOINT DESIGN MIL-STD-22

MIL-STD-1689, PARAGRAPH 11

5 WELDING REQUIREMENTS

MIL-STD-1689, PARAGRAPH 13

6 WORKMANSHIP

REQUIREMENTS MIL-STD-1689, PARAGRAPHS 12 AND 14

7 VISUAL

MIL-STD-1689, PARAGRAPHS 6, 7, AND 8

MIL-STD-2035, PARAGRAPH 4

T9074-AS-GIB-010/271, PARAGRAPH 8

8 RADIOGRAPHIC

MIL-STD-1689, PARAGRAPHS 6, 7, AND 8

INSPECTION (RT)

MIL-STD-2035, PARAGRAPH 5

T9074-AS-GIB-010/271, PARAGRAPH 3

* - PARAGRAPH 3.5 APPLIES

11 of 18 ITEM NO: 009-12

FY-12

TABLE 2

WELDING, FABRICATION, AND INSPECTION OF SURFACE SHIP HULLS (COMBATANT)

COLUMN A B C D E F

L

CARBON STEEL (MS) CHROMIUM NICKEL COPPER AND/OR

I MATERIAL EVOLUTION *HIGH STRENGTH STEEL ALUMINUM ALLOY SILICONE BRONZE

AND (HTS) STEEL (STAINLESS) NICKEL BASE

N (HY-80/100, HSLA-80 AND ALUMINUM BRONZE

ALLOYS

E STS)

9 ULTRASONIC INSPECTION MIL-STD-1689, PARAGRAPHS 6, 7, AND 8

(UT) MIL-STD-2035, PARAGRAPH 8

T9074-AS-GIB-010/271, PARAGRAPH 6

10 LIQUID PENETRANT MIL-STD-1689, PARAGRAPHS 6, 7, AND 8

INSPECTION (PT) MIL-STD-2035, PARAGRAPH 7

T9074-AS-GIB-010/271, PARAGRAPH 5

11 MAGNETIC PARTICLE MIL-STD-1689, PARAGRAPH 6

INSPECTION (MT) MIL-STD-2035, PARAGRAPH 6 NOT APPLICABLE

T9074-AS-GIB-010/271, PARAGRAPH 4

* - PARAGRAPH 3.5 APPLIES

12 of 18 ITEM NO: 009-12

FY-12

TABLE 3

WELDING, FABRICATION, AND INSPECTION OF SURFACE SHIP HULLS (NON-COMBATANT) * **

COLUMN A B C D E F

L *** CHROMIUM SILICONE

ALUMINUM COPPER

I MATERIAL EVOLUTION CARBON STEEL (MS) HIGH STRENGTH STEEL NICKEL STEEL BRONZE

ALLOY AND/OR NICKEL

N (HY-80/100) (STAINLESS) ALUMINUM

BASE ALLOYS

E BRONZE

1

WELDER QUALIFICATION ABS RULES, PART 2, CHAPTER 4, SECTION 1

2 ABS RULES, PART 2, CHAPTER 4, SECTION 1

WELDING PROCEDURE

3 ABS RULES, PART 2, CHAPTER 4, SECTION 1

ELECTRODE

4 ABS RULES, PART 2, CHAPTER 4, SECTION 1

JOINT DESIGN

5 WELDING

REQUIREMENTS ABS RULES, PART 2, CHAPTER 4, SECTION 1

6

WORKMANSHIP

ABS RULES, PART 2, CHAPTER 4, SECTION 1

REQUIREMENTS

7 VISUAL ABS RULES, PART 2, CHAPTER 4, SECTION 1

8 RADIOGRAPHIC

INSPECTION (RT) ABS RULES, PART 2, CHAPTER 4, SECTION 1

13 of 18 ITEM NO: 009-12

FY-12

TABLE 3

WELDING, FABRICATION, AND INSPECTION OF SURFACE SHIP HULLS (NON-COMBATANT) * **

COLUMN A B C D E F

L *** CHROMIUM SILICONE

ALUMINUM COPPER

I MATERIAL EVOLUTION CARBON STEEL (MS) HIGH STRENGTH STEEL NICKEL STEEL BRONZE

ALLOY AND/OR NICKEL

N (HY-80/100) (STAINLESS) ALUMINUM

BASE ALLOYS

E BRONZE

9 ULTRASONIC

INSPECTION (UT) ABS RULES, PART 2, CHAPTER 4, SECTION 1

10 LIQUID PENETRANT

INSPECTION (PT) ABS RULES, PART 2, CHAPTER 4, SECTION 1

11 MAGNETIC PARTICLE

INSPECTION (MT) ABS RULES, PART 2, CHAPTER 4, SECTION 1 NOT APPLICABLE

*- IDENTIFICATION OF "SURVEYOR" IN ABS RULES SIGNIFIES SUPERVISOR OF SHIPBUILDING (SUPERVISOR) ACTION. THE SUPERVISOR MAY USE MIL-STD-1689 FOR GUIDANCE

WHERE ADDITIONAL DIRECTION IS NECESSARY. SUCH GUIDANCE MAY BE USED TO: ESTABLISH NDT REQUIREMENTS, ESTABLISH WELDING/NDT PROCEDURE AND

PERSONNEL QUALIFICATION REQUIREMENTS, OR TO DEFINE OTHER ATTRIBUTES LISTED IN THE "MATERIAL EVOLUTION" LINE OF TABLE 3.

** - THE SUPERVISOR MAY ALSO ALLOW THE SHIPBUILDER TO CHOOSE FROM THE FOLLOWING OPTIONS, PROVIDING:

- THE SHIPBUILDER'S UTILIZATION OF THE FOLLOWING OPTIONS SHALL RESULT IN NO ADDITIONAL COST TO THE GOVERNMENT.

- THE SHIPBUILDER SHALL UTILIZE THE FABRICATION DOCUMENT SELECTED FOR THE ENTIRE AVAILABILITY AND SHALL NOT SWITCH BACK AND FORTH BETWEEN

DOCUMENTS.

- THE SHIPBUILDER SHALL NOTIFY THE SUPERVISOR OF WHICH FABRICATION DOCUMENT HAS BEEN SELECTED.

OPTIONS:

A) MIL-STD-1689 MAY BE UTILIZED BY THE SHIPBUILDER AT THE SHIPBUILDER'S DISCRETION. THE REQUIREMENTS OF TABLE 2 ABOVE WOULD THEN APPLY.

B) FOR DETERMINATION OF NDT METHOD(S) AND EXTENT OF NDT INSPECTION WHEN REPAIRS ARE TO BE ACCOMPLISHED, THE SHIPBUILDER MAY REQUEST TO UTILIZE

THE SAME NDT REQUIREMENTS THAT WERE INVOKED IN CONSTRUCTION OF THE VESSEL. IN SUCH CASES, THE SHIPBUILDER SHALL BE RESPONSIBLE TO DETERMINE

THE ORIGINAL NDT REQUIREMENTS AND SUBMIT EVIDENCE SUCH AS DRAWINGS OR SPECIFICATIONS WHICH DETAIL THE REQUIREMENTS TO THE SUPERVISOR ALONG

WITH A REQUEST FOR APPROVAL.

C) THE SHIPBUILDER MAY REQUEST TO UTILIZE PRE-ESTABLISHED WELDING AND/OR NDT PROCEDURES AND PERSONNEL QUALIFICATION PROGRAM(S) WHICH HAVE

BEEN PREVIOUSLY UTILIZED IN THE PERFORMANCE OF SIMILAR ABS-ACCEPTED WORK. IN SUCH CASES, THE SHIPBUILDER SHALL SUBMIT EVIDENCE OF SUCH ABS

ACCEPTABILITY TO THE SUPERVISOR ALONG WITH DESCRIPTIVE DETAILS AND SUPPORTING DOCUMENTATION FOR THE PROPOSED PROGRAM(S). SUCH

DOCUMENTATION SHALL INCLUDE THE WELDING/NDT PROCEDURES AND METHODS OF WELDING/NDT PERSONNEL QUALIFICATION THAT WERE UTILIZED IN FORMER

ABS-ACCEPTED WORK. THE SHIPBUILDER SHALL ALSO SUBMIT OTHER SUPPORTING EVIDENCE THAT MAY BE REQUESTED BY THE SUPERVISOR TO ESTABLISH THAT

THE PROPOSED PROGRAMS HAVE BEEN PREVIOUSLY UTILIZED FOR SIMILAR ABS-ACCEPTED WORK.

*** - PARAGRAPH 3.3 APPLIES.

14 of 18 ITEM NO: 009-12

FY-12

TABLE 4

WELDING, FABRICATION, AND INSPECTION OF METAL BOAT AND CRAFT HULLS

COLUMN A B C D E F

L COPPER AND/OR SILICONE

I MATERIAL *HIGH STRENGTH CHROMIUM NICKEL BRONZE

CARBON STEEL (MS) ALUMINUM ALLOY NICKEL BASE

N EVOLUTION STEEL (HY-80/100) STEEL (STAINLESS) ALUMINUM

ALLOYS

E BRONZE

1 WELDER

QUALIFICATION S9074-AQ-GIB-010/248, PARAGRAPH 5

2 WELDING

PROCEDURE S9074-AQ-GIB-010/248, PARAGRAPH 4

3 ELECTRODE 0900-060-4010, 0900-060-4010, 0900-060-4010, 0900-060-4010, 0900-060-4010 S9074-AR-GIB-

SECTION 10, TABLE SECTION 10, SECTION 10, TABLE SECTION 10, TABLE SECTION 10, 010/278, TABLE II

10-1 TABLES 10-2 AND 10-3 10-7 10-4 TABLES 10-5 AND 10-

6

4 JOINT DESIGN MIL-STD-22

0900-060-4010, SECTION 11

5 WELDING

REQUIREMENTS 0900-060-4010, SECTION 13

6 WORKMANSHIP

0900-060-4010, SECTION 14

REQUIREMENTS

7 VISUAL 0900-060-4010, SECTIONS 6, 7, AND 8

T9074-AS-GIB-010/271, PARAGRAPH 8

8 RADIOGRAPHIC 0900-060-4010, SECTION 6, TABLE 6-1 AND SECTIONS 7 AND 8

INSPECTION (RT) T9074-AS-GIB-010/271, PARAGRAPH 3

9 ULTRASONIC

INSPECTION (UT) T9074-AS-GIB-010/271, PARAGRAPH 6

10 LIQUID PENETRANT

INSPECTION (PT) 0900-060-4010, SECTIONS 6, 7, AND 8

T9074-AS-GIB-010/271, PARAGRAPH 5

11 MAGNETIC 0900-060-4010

PARTICLE SECTION 6 NOT APPLICABLE

INSPECTION (MT) T9074-AS-GIB-010/271, PARAGRAPH 4

* - PARAGRAPH 3.5 APPLIES

15 of 18 ITEM NO: 009-12

FY-12

ATTACHMENT A

COMBATANT SURFACE SHIPS

WARSHIPS TABLE

Aircraft Carriers:

Aircraft Carrier ...................................CV........... 2

Aircraft Carrier (nuclear propulsion) .............CVN........... 2

Surface Combatants:

Guided Missile Cruiser ............................CG........... 2

Guided Missile Destroyer ..........................DDG........... 2

Guided Missile Frigate ............................FFG........... 2

Littoral Combat Ship ..............................LCS........... 2

Patrol Combatants:

Patrol Coastal .....................................PC............2

AMPHIBIOUS WARFARE SHIPS

Amphibious Command Ship ...........................LCC........... 2

Amphibious Assault Ship (general purpose) .........LHA........... 2

Amphibious Cargo Ship .............................LKA........... 2

Amphibious Transport Dock .........................LPD........... 2

Dock Landing Ship .................................LSD........... 2

Amphibious Assault Ship (general purpose) .........LHD........... 2

AUXILIARY SHIPS

Ammunition Ship ....................................AE........... 2

Combat Store Ship .................................AFS........... 2

Oiler ..............................................AO........... 2

Fast Combat Support Ship ..........................AOE........... 2

Replenishment Oiler ...............................AOR........... 2

MINE WARFARE SHIPS

Mine Countermeasures Ship .........................MCM........... 2

Coastal Minehunter ................................MHC............2

16 of 18 ITEM NO: 009-12

FY-12

ATTACHMENT A

(Con't)

COMBATANT SURFACE CRAFT

AMPHIBIOUS WARFARE CRAFT TABLE

Landing Craft, Air Cushion .........................LCAC......... 4

Landing Craft, Mechanized ...........................LCM......... 4

Landing Craft, Personnel, Large ....................LCPL......... 4

Landing Craft, Utility ..............................LCU......... 2

Landing Craft, Vehicle, Personnel ..................LCVP......... 4

Light Seal Support Craft ...........................LSSC......... 4

Amphibious Warping Tug ..............................LWT......... 4

Medium Seal Support Craft ..........................MSSC......... 4

Swimmer Delivery Vehicle ............................SDV......... 4

Side Loading Warping Tug ...........................SLWT......... 4

Special Warfare Craft, Light .......................SWCL......... 4

Special Warfare Craft, Medium ......................SWCM......... 4

PATROL CRAFT

Mini-Armored Troop Carrier ..........................ATC......... 4

Patrol Boat ..........................................PB......... 4

River Patrol Boat ...................................PBR......... 4

Patrol Craft (fast) .................................PCF......... 4

Fast Patrol Craft ...................................PTF......... 4

NON-COMBATANT SURFACE SHIPS

AUXILIARY SHIPS

Auxiliary Crane Ship ..............................ACS........... 3

Missile Range Instrumentation Ship ................AGM........... 3

Oceanographic Research Ship ......................AGOR........... 3

Ocean Surveillance Ship ..........................AGOS........... 3

Surveying Ship ....................................AGS........... 3

Hospital Ship ......................................AH........... 3

Cargo Ship .........................................AK........... 3

Auxiliary Cargo Barge/Lighter Ship ................AKB........... 3

Auxiliary Cargo Float-On/Float-Off Ship ...........AKF........... 3

Transport Oiler ...................................AOT........... 3

Barracks Craft ....................................APL........... 3

Cable Repairing Ship ..............................ARC........... 3

Salvage Ship ......................................ARS........... 3

Submarine Tender ...................................AS........... 3

Fleet Ocean Tug ...................................ATF........... 3

Aviation Logistic Support Ship ....................AVB........... 3

17 of 18 ITEM NO: 009-12

FY-12

ATTACHMENT A

(Con't)

NON-COMBATANT SURFACE CRAFT

SERVICE CRAFT TABLE

Small Auxiliary Floating Dry Dock (non-self-propelled) ...AFDL... 3

Medium Auxiliary Floating Dry Dock (non-self-propelled) ..AFDM... 3

Medium Auxiliary Repair Dry Dock (non-self-propelled) ....ARDM... 3

Causeway Section, Powered .................................CSP... 3

Causeway Section (non-self-propelled) ....................CSNP... 3

Unclassified Miscellaneous .................................IX... 3

Open Lighter (non-self-propelled) ..........................YC... 3

Aircraft Transportation Lighter (non-self-propelled) ......YCV... 3

Cargo Semi-Submersible Barge .............................YCSS... 3

Floating Crane (non-self-propelled) ........................YD... 3

Diving Tender (non-self-propelled) ........................YDT... 3

Ferryboat or Launch (self-propelled) ......................YFB... 3

Covered Lighter (non-self-propelled) ......................YFN... 3

Large Covered Lighter (non-self-propelled) ...............YFNB... 3

Dry Dock Companion Craft (non-self-propelled) ............YFND... 3

Lighter (special purpose) (non-self-propelled) ...........YFNX... 3

Floating Power Barge (non-self-propelled) .................YFP... 3

Salvage Lift Craft, Light .................................YLC... 3

Gasoline Barge (non-self-propelled) ......................YOGN... 3

Fuel Oil Barge (non-self-propelled) .......................YON... 3

Oil Storage Barge (non-self-propelled) ....................YOS... 3

Patrol Craft (self-propelled) ..............................YP... 4

Floating Workshop (non-self-propelled) .....................YR... 3

Repair and Berthing Barge (non-self-propelled) ............YRB... 3

Repair, Berthing and Messing Barge (non-self-propelled) ...YRBM.. 3

Floating Dry Dock Workshop (hull) (non-self-propelled) ....YRDH.. 3

Floating Dry Dock Workshop (machine) (non-self-propelled) .YRDM.. 3

Radiological Repair Barge (non-self-propelled) .............YRR.. 3

Seaplane Wrecking Derrick (self-propelled) .................YSD.. 3

Large Harbor Tug ...........................................YTB.. 4

Small Harbor Tug ...........................................YTL.. 4

Torpedo Trials Craft .......................................YTT.. 4

Water Barge (non-self-propelled) ...........................YWN.. 3

NOTES:

Letter prefixes to classification symbols may add identification:

E -- Prototype ship or craft in an experimental or developmental status.

T -- Assigned to MSC (Military Sealift Command)

F -- Being Constructed for a foreign government.

X -- Often added to existing classifications to indicate a new class whose

characteristics have not been defined.

18 of 18 ITEM NO: 009-12

FY-12

You might also like

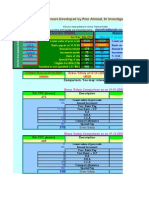

- Box Culvert Design LRFD 2x2m, 2m Filling by Excel SheetDocument4 pagesBox Culvert Design LRFD 2x2m, 2m Filling by Excel Sheetfaridhassani56% (9)

- Emm3812 - Static and Dynamic BalancingDocument7 pagesEmm3812 - Static and Dynamic Balancingsyamil100% (4)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Field Welding Procedures Manual - Contractor VersionDocument102 pagesField Welding Procedures Manual - Contractor Versionlaz_k100% (2)

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderDocument10 pagesRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (2)

- 02 Samss 012Document9 pages02 Samss 012slan79bisNo ratings yet

- BS 5892-3 1992 Railway Rolling Stock Materials - Part 3 Specification For Monobloc Wheels For Traction and Trailing Stock PDFDocument30 pagesBS 5892-3 1992 Railway Rolling Stock Materials - Part 3 Specification For Monobloc Wheels For Traction and Trailing Stock PDFPhillip Miller100% (1)

- 01 Samss 035 API LinepipeDocument28 pages01 Samss 035 API Linepipemdsazidalam100% (2)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Plate A516 and A387 - Pressure Vessel SteelsDocument16 pagesPlate A516 and A387 - Pressure Vessel SteelsaladinsaneNo ratings yet

- 009-12 FY21 PKGDocument30 pages009-12 FY21 PKGyasserdlggroupNo ratings yet

- Guidelines For Preparation of Qap Undercarriage NDDocument44 pagesGuidelines For Preparation of Qap Undercarriage NDhardeep SinghNo ratings yet

- Materials System SpecificationDocument13 pagesMaterials System SpecificationAbdullahNo ratings yet

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Smi 225Document3 pagesSmi 225Greshy FieldNo ratings yet

- 8382 3504 LG 8001 1 - APEM Vendor Data Register List - Rev ADocument6 pages8382 3504 LG 8001 1 - APEM Vendor Data Register List - Rev AAlphaEcc EngineeringTeamNo ratings yet

- Structural Fabrication SpecificationDocument18 pagesStructural Fabrication Specificationravirawat15No ratings yet

- Product Manual 398 5 - V2Document7 pagesProduct Manual 398 5 - V2Puneet ChaurasiaNo ratings yet

- 02 ACSR ZEBRA ConductorDocument37 pages02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Irst 19Document12 pagesIrst 19krischaeverNo ratings yet

- Product Manual Is 398 Part 5Document7 pagesProduct Manual Is 398 Part 5MTIWARINo ratings yet

- Asme U Comparison QaDocument21 pagesAsme U Comparison QajksankarNo ratings yet

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- Class Result: of DefenseDocument12 pagesClass Result: of DefenseJay MillerNo ratings yet

- AMS2175ADocument20 pagesAMS2175AKanikannan SamyduraiNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- Mil-Std-1580b Not 1Document3 pagesMil-Std-1580b Not 1arielaparicioNo ratings yet

- JG2P1-107000291285-IR-002Document16 pagesJG2P1-107000291285-IR-002kaushik21185No ratings yet

- Spec 6a E21 en Add3Document16 pagesSpec 6a E21 en Add3LiLiNo ratings yet

- 5318 2001 WeldingDocument9 pages5318 2001 WeldingminhnnNo ratings yet

- RG6-S-00-1360-231 - 0001 - 3 Technical Specification For Dual Plate Check ValvesDocument12 pagesRG6-S-00-1360-231 - 0001 - 3 Technical Specification For Dual Plate Check ValvesShivashankar Durga MedisettiNo ratings yet

- FAA 2022 1295 0005 - Attachment - 1Document19 pagesFAA 2022 1295 0005 - Attachment - 1Ahmad Ghazi EliasNo ratings yet

- Piping Welding General Specification Consortium) Rev-3Document48 pagesPiping Welding General Specification Consortium) Rev-3rvsreddy1972No ratings yet

- JP-001 Job Procedure For Ag Piping Fabrication & ErectionDocument14 pagesJP-001 Job Procedure For Ag Piping Fabrication & ErectionMakhan MaanNo ratings yet

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- GM6442MDocument5 pagesGM6442MFelipao DelacruzNo ratings yet

- Overhaul Ac Electrical Motors: 1. ScopeDocument16 pagesOverhaul Ac Electrical Motors: 1. ScopemersiumNo ratings yet

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduNo ratings yet

- 01 Samss 333Document34 pages01 Samss 333Jinliang Liu100% (1)

- Inspection Record and Report Master List As On 8.3.18Document32 pagesInspection Record and Report Master List As On 8.3.18Gomathyselvi100% (1)

- Itp For SSDP Project Rev CDocument9 pagesItp For SSDP Project Rev CRachel FloresNo ratings yet

- TSCDocument17 pagesTSCmailbkraoNo ratings yet

- Lethal ServiceDocument4 pagesLethal Servicesajalkk25No ratings yet

- UFGS Welding Pressure PipeDocument20 pagesUFGS Welding Pressure PipeDeclanNo ratings yet

- Manual For Glued Insulated Rail Joint (ACS - 01)Document43 pagesManual For Glued Insulated Rail Joint (ACS - 01)Ashutosh TripathiNo ratings yet

- PM-IS-6419Document9 pagesPM-IS-6419arun.zenithNo ratings yet

- 6A E21 Addendum 3 2022Document16 pages6A E21 Addendum 3 2022shamir_ahmedabadNo ratings yet

- JHDocument14 pagesJHghome123No ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- ADA383002Document4 pagesADA383002이승진No ratings yet

- Is-903 Couplings, Branch Pipe, NozzlesDocument13 pagesIs-903 Couplings, Branch Pipe, NozzlesCharls JamesNo ratings yet

- 12 SAMSS 018 - HighlightedDocument14 pages12 SAMSS 018 - HighlightedDhaval PatelNo ratings yet

- Asme Q&aDocument57 pagesAsme Q&amsraja7767% (3)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- Flat Panel Display ManufacturingFrom EverandFlat Panel Display ManufacturingJun SoukNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Heat, The Mechanical UniverseDocument2 pagesHeat, The Mechanical UniversealadinsaneNo ratings yet

- Research Notes On Sulfide Stress CrackingDocument5 pagesResearch Notes On Sulfide Stress CrackingaladinsaneNo ratings yet

- TTC - Dark Matter, Dark Energy, Dark Side of The UniverseDocument6 pagesTTC - Dark Matter, Dark Energy, Dark Side of The UniversealadinsaneNo ratings yet

- Foma NDT System PDFDocument16 pagesFoma NDT System PDFaladinsaneNo ratings yet

- Builder 3 and 2 Vol 2Document342 pagesBuilder 3 and 2 Vol 2Dan JohnsonNo ratings yet

- Research Notes On Sulfide Stress CrackingDocument5 pagesResearch Notes On Sulfide Stress CrackingaladinsaneNo ratings yet

- Grigull, Ulrich - Fahrenheit, A Pioneer of Exact Thermometry (Article)Document10 pagesGrigull, Ulrich - Fahrenheit, A Pioneer of Exact Thermometry (Article)aladinsaneNo ratings yet

- Comparisons of Steel Water Storage Tanks (Tim Guishard Enterprises)Document11 pagesComparisons of Steel Water Storage Tanks (Tim Guishard Enterprises)aladinsaneNo ratings yet

- Pub BDC Codeti2014 Div3 GB x2xDocument4 pagesPub BDC Codeti2014 Div3 GB x2xaladinsaneNo ratings yet

- A Fracture Mechanics Approach For Analyzing Spiral Weld Pipes Containing CracksDocument9 pagesA Fracture Mechanics Approach For Analyzing Spiral Weld Pipes Containing CracksaladinsaneNo ratings yet

- Met Preparation of Zinc Coatings (Struers)Document6 pagesMet Preparation of Zinc Coatings (Struers)aladinsaneNo ratings yet

- XRF Analytical TechniquesDocument83 pagesXRF Analytical Techniquesaladinsane100% (5)

- Eddy Current Array Technology For The Inspection of Aircraft and EngineDocument37 pagesEddy Current Array Technology For The Inspection of Aircraft and Enginealadinsane100% (1)

- Moment Redistribution - Principles and Practice Using Aci 318-02Document19 pagesMoment Redistribution - Principles and Practice Using Aci 318-02aladinsaneNo ratings yet

- T5 Camping EquipmentDocument2 pagesT5 Camping Equipmentpha3tOn100% (3)

- A Review On Design and Development of Frame Structure For CNG Tank in Two Wheeler SI EngineDocument9 pagesA Review On Design and Development of Frame Structure For CNG Tank in Two Wheeler SI EngineIJAMTESNo ratings yet

- Airborne Review - Katana MiniDocument3 pagesAirborne Review - Katana Minigeronimo101No ratings yet

- Honeywell Sensing Ss42r Series Product Sheet 005854 1 enDocument4 pagesHoneywell Sensing Ss42r Series Product Sheet 005854 1 encuco777No ratings yet

- Cable & Busbar - LegrandDocument2 pagesCable & Busbar - LegrandAshish MulikNo ratings yet

- Dubai IndustrialDocument16 pagesDubai Industrialsunil duttNo ratings yet

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTANo ratings yet

- Vibration Analysis of Production Unit by Using Mechanical StethoscopeDocument67 pagesVibration Analysis of Production Unit by Using Mechanical Stethoscopek eswariNo ratings yet

- Temperature Sensor: SeriesDocument2 pagesTemperature Sensor: SeriesyasincanNo ratings yet

- A 272Document1 pageA 272AnuranjanNo ratings yet

- CV-Awadhesh Kumar ChaudhuryDocument3 pagesCV-Awadhesh Kumar Chaudhurytrinadha raoNo ratings yet

- A2 Arch Design Elements & Principles in KLDocument3 pagesA2 Arch Design Elements & Principles in KLsyrifah syahiraNo ratings yet

- UntitledDocument1 pageUntitledapi-54659510No ratings yet

- How To Design Your Perfect Kitchen in Just 15 Minutes Using Microsoft WordDocument46 pagesHow To Design Your Perfect Kitchen in Just 15 Minutes Using Microsoft WordSunil Salathia100% (1)

- Saab 2000 MTA Proposal To IAFDocument13 pagesSaab 2000 MTA Proposal To IAFShiv Aroor100% (1)

- Premix Concrete Supplier - Company ProfileDocument7 pagesPremix Concrete Supplier - Company ProfileSolomon BalemeziNo ratings yet

- Cortez Rose ResumeDocument2 pagesCortez Rose Resumeapi-405469343No ratings yet

- Request For Project Supervision FormDocument4 pagesRequest For Project Supervision FormAhmed AbokorNo ratings yet

- Repair & Retrofitting of National Highway Bridge by Using Carbon Fiber Reinforced Composites - A Case StudyDocument4 pagesRepair & Retrofitting of National Highway Bridge by Using Carbon Fiber Reinforced Composites - A Case StudyAbhishek KumarNo ratings yet

- PFD Hazira NewDocument1 pagePFD Hazira NewJagan BoseNo ratings yet

- Automotive Chassis 2Document360 pagesAutomotive Chassis 2Mohammmed Farooq100% (1)

- Mature Field Revitalization: Technology FocusDocument1 pageMature Field Revitalization: Technology FocusSahib QafarsoyNo ratings yet

- ST 00 BD 001 - CDocument29 pagesST 00 BD 001 - CUALU333No ratings yet

- Industrial InstrumentationDocument2 pagesIndustrial InstrumentationAbhijeeth BabuNo ratings yet

- Differences Between Besmm 3 4Document14 pagesDifferences Between Besmm 3 4ishaq kazeemNo ratings yet

- From Gordian III To The Gallic Empire ADDocument24 pagesFrom Gordian III To The Gallic Empire ADGiacomo BondarelliNo ratings yet

- DGS 1016D DatasheetDocument3 pagesDGS 1016D DatasheetrznajibNo ratings yet