100%(2)100% found this document useful (2 votes)

2K viewsAssignment 1

This document contains solutions to operations and quality control assignment problems. It analyzes productivity increases and decreases based on changes in labor hours, raw materials, capital investment, energy usage, and demand. Key findings include: 1) Increasing labor hours from 40 to 120 per day increased productivity from 3 to 3.125 units per labor hour. 2) Decreasing labor hours, raw materials, capital investment, and energy usage resulted in productivity increases between 0.3-11.1%. 3) To meet a 25% increase in demand, one additional worker working 160 hours per month is needed. 4) It is more cost effective to invest $100 in a new blender than hire another worker to increase output. 5) Increasing

Uploaded by

meray8Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100%(2)100% found this document useful (2 votes)

2K viewsAssignment 1

This document contains solutions to operations and quality control assignment problems. It analyzes productivity increases and decreases based on changes in labor hours, raw materials, capital investment, energy usage, and demand. Key findings include: 1) Increasing labor hours from 40 to 120 per day increased productivity from 3 to 3.125 units per labor hour. 2) Decreasing labor hours, raw materials, capital investment, and energy usage resulted in productivity increases between 0.3-11.1%. 3) To meet a 25% increase in demand, one additional worker working 160 hours per month is needed. 4) It is more cost effective to invest $100 in a new blender than hire another worker to increase output. 5) Increasing

Uploaded by

meray8Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

You are on page 1/ 2

Operations and quality control

Assignment #1

Page 21

Prob 1.1

John Lucy makes wooden boxes in which to ship motorcycles. John and his three

employees invest 40 hours per day making the 120 boxes

a) Productivity = 120/40 = 3 units/labor-hour

b) New productivity = 1125/40 = 3.125 units/labor-hour

c) Increase in productivity = 0.125 units/ labor-hour

Prob 1.6

Units produced remain the same

Decrease in labor hours spent for 8.33% (from 300 to 275)

Old Productivity = 1000/300=3.33 units per labor hour

New productivity = 1000/275=3.63 units per labor hour

The difference is an increase in units per labor hour for 0.3 or 0.9%

Decrease in use of (raw material) Resin for 10 % (from 50 to 45)

Old Productivity= 1000/50=20 units per pounds resin

New productivity=1000/45=22.22 units per pounds resin

Productivity difference= 0.22 or 11.1%

Increase in capital invested for 10 % (from 10000 to 11000)

Old Productivity=1000/10000=0.1 units per dollar

New productivity= 1000/11000=0.09 units per dollar

Productivity difference= 0.01 or 11.1%

Decrease in use of energy for 5 % (from 3000 BTU to 2850 BTU)

Old Productivity=1000/3000=0.33 units per BTU

New productivity=1000/2850=0.35 units per BTU

Productivity difference= 0.02 or 0.6%

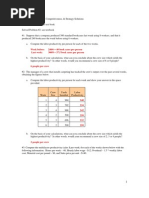

Prob 1.13

25% increase in demand

How many workers should be added?

Productivity = 2.344 = 1500/labor-hours used

Labor-hour used= 640 hours (considered per month)

It is given that the worker works 160 hours per month then the bakery has

640/160=4 workers,

In order to increase the output by 25%, one more worker should be added:

25% of 4 is =1 or

25% + 1500= 1875 loaves to be produced then 375 loaves to be added

These 375 loaves how many hours they need to be produced?

375/2.344= 160hours (this is the hours spent by one worker per month)

We need just one more worker to perform these 160hours of productivity

Prob 1.14

What to choose: to add one labor or add a blender

a) productivity in loaves per dollar with an increase in labor cost:

With 4 workers: 640 hours and $8 per hour:

Productivity = 1500/5120= 0.29 loaves per dollar

With 5 workers: 800hours and $8/hour:

Productivity=1875/6400= 0.29 loaves per dollar

b) productivity change with only an increase in investment ($100 / month)

Without the increase:

1500/5120=0.29 loaves per dollar

With the increase:

1875/5120+100= 0.359 loaves per dollar

The decision would be better to invest $100 in a blender than to employ a worker

Prob 1.15

I am supposing 1 loaf takes 1 pound of ingredients

For 1500 loaves produced:

Productivity = 1500/500 + 640*8 + 0.35*1500 = 1500/6145=0.244 loaves per

dollar

For 1875 loaves produced:

Productivity = 1875/500 + 800*8 + 0.35*1875= 1875/7556.25=0.248 loaves per

dollar

The increase in productivity is 0.004 or 1.6%

You might also like

- Case Study (Weemow Lawn Service) : Presented ToNo ratings yetCase Study (Weemow Lawn Service) : Presented To52 pages

- Ergonomics Solutions To Sample Problems: Cie Review 2017 Iexcel Review and Training CenterNo ratings yetErgonomics Solutions To Sample Problems: Cie Review 2017 Iexcel Review and Training Center7 pages

- Introduction To Operations Management: Final ProjectNo ratings yetIntroduction To Operations Management: Final Project10 pages

- Practice Problems: Supplement 7, Capacity Planning: Problem 1No ratings yetPractice Problems: Supplement 7, Capacity Planning: Problem 14 pages

- CHAPTER 1: Productivity Measurement and Improvement: Learning ObjectivesNo ratings yetCHAPTER 1: Productivity Measurement and Improvement: Learning Objectives58 pages

- C Productivity Problems and Solutions To Students 20140% (2)C Productivity Problems and Solutions To Students 20142 pages

- Name: Syed Wajahat Abbas Reg#: 10466 Operation Management100% (1)Name: Syed Wajahat Abbas Reg#: 10466 Operation Management4 pages

- Quiz On Understanding of Lean & Six Sigma SC LeongNo ratings yetQuiz On Understanding of Lean & Six Sigma SC Leong3 pages

- Exercise 1.1 Graph The Given Inequalities. 1. y 2xNo ratings yetExercise 1.1 Graph The Given Inequalities. 1. y 2x30 pages

- Practice... Work Sampling Asynchronous ActivityNo ratings yetPractice... Work Sampling Asynchronous Activity7 pages

- 01 Activity 1 - Productivity and Project ManagementNo ratings yet01 Activity 1 - Productivity and Project Management2 pages

- LESSON 4 - Contribution of TQM by W.E. Deming, Joseph M. Juran & Philip CrosbyNo ratings yetLESSON 4 - Contribution of TQM by W.E. Deming, Joseph M. Juran & Philip Crosby27 pages

- Operations & Productivity-Practice Problems50% (2)Operations & Productivity-Practice Problems3 pages

- Waiting Lines and Queuing Theory ModelsNo ratings yetWaiting Lines and Queuing Theory Models49 pages

- Revised NIOSH LiftinG Equation Examples Ans ExplanationsNo ratings yetRevised NIOSH LiftinG Equation Examples Ans Explanations17 pages

- Problem Statements Chapter 1 - Productivity100% (1)Problem Statements Chapter 1 - Productivity2 pages

- Types of Construction Wood Frame - Type VNo ratings yetTypes of Construction Wood Frame - Type V2 pages

- Goods and Services Tax " Future in India": by - Joe Suhas Thambi Rahul Aurade MET Institute of Management, Nasik100% (1)Goods and Services Tax " Future in India": by - Joe Suhas Thambi Rahul Aurade MET Institute of Management, Nasik33 pages

- Vocabulary: Flying Away - Typical SituationNo ratings yetVocabulary: Flying Away - Typical Situation6 pages

- Senior High School Department: Quarter 3 - Module 5: The Books of Accounts100% (2)Senior High School Department: Quarter 3 - Module 5: The Books of Accounts10 pages

- Module 9 - Earnings and Market Approach ValuationNo ratings yetModule 9 - Earnings and Market Approach Valuation46 pages

- Position Paper: Republic Act No. 9003-Ecological Solid Waste Management ACT OF 2000No ratings yetPosition Paper: Republic Act No. 9003-Ecological Solid Waste Management ACT OF 20002 pages

- IDFCFIRSTBankstatement 10137207542 183527367No ratings yetIDFCFIRSTBankstatement 10137207542 18352736711 pages

- DLSU REVDEVT - TOA Revised Reviewer - Answer Key PDFNo ratings yetDLSU REVDEVT - TOA Revised Reviewer - Answer Key PDF16 pages

- Semester 1 FEB2016 Final Examination Timetable (Listing)No ratings yetSemester 1 FEB2016 Final Examination Timetable (Listing)69 pages

- Chapter 1 2 Cost Accounting and Control by de Leon 201950% (2)Chapter 1 2 Cost Accounting and Control by de Leon 201910 pages