Devicenet

Devicenet

Uploaded by

api-3754722Copyright:

Available Formats

Devicenet

Devicenet

Uploaded by

api-3754722Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Devicenet

Devicenet

Uploaded by

api-3754722Copyright:

Available Formats

Technical Overview

Behind each and every benefit realized in a new prioritization. DeviceNet systems can be

control system is a significant software configured to operate in a master-slave or a

engineering investment designed to deliver distributed control architecture using peer-to-

increased productivity through improved peer communication. DeviceNet systems offer a

process control and information flow. By single point of connection for configuration and

choosing DeviceNet™ products from ODVA’s control by supporting both I/O and explicit

member companies, users can protect this messaging. DeviceNet also has the unique

investment in several ways. feature of having power on the network. This

First, DeviceNet is a proven, stable network allows devices with limited power requirements

technology designed to meet the performance to be powered directly from the network,

and reliability requirements of the industrial reducing connection points and physical size.

environment. DeviceNet uses CAN (Controller DeviceNet follows the Open Systems

Area Network) for its data link layer, and CIP™ Interconnection (OSI) model, an ISO standard for

(Common Industrial Protocol) for the upper-

Network Size Up to 64 nodes

layers of the network, DeviceNet is an open

Network Selectable end-to-end network distance

standard managed by ODVA and accepted by Length varies with speed

international standards bodies around the world.

125 Kbps 500 m (1,640 ft)

In addition, users will appreciate the seamless 250 Kbps 250 m (820 ft)

bridging and routing provided by DeviceNet to 500 Kbps 100 m (328 ft)

other CIP-based networks which currently Data Packets 0-8 bytes

include EtherNet/IP™ and ControlNet™. Bus Linear (trunkline/dropline); power and

Second, DeviceNet is supported by vendors Topology signal on the same network cable

around the world. Over 700 Vendor IDs have Bus Peer-to-Peer with Multi-Cast (one-to-many);

been issued by ODVA. The fact that so many Addressing Multi-Master and Master/Slave special case;

polled or change-of-state (exception-based)

vendors have chosen to implement DeviceNet in

System Removal and replacement of devices from

their products allows users to employ best-in-

Features the network under power

class products from vendors around the world

who are best suited to support them based on Table 1: Summary of DeviceNet Features and Functionality

application expertise and geographic coverage.

network communications that is hierarchical in

Third, DeviceNet CONFORMANCE TESTED® nature. Networks that follow this model define all

products have been certified by ODVA to conform necessary functions from the physical

to the specification and operate in open, multi- implementation up to the protocol and

vendor systems by having passed conformance methodology to communicate control and

testing at one of ODVA’s authorized conformance information data within and across networks.

test service providers and having received an

official Declaration of Conformity from ODVA.

Here’s a look at the technology behind every The Physical Layer

DeviceNet product. DeviceNet uses a trunk-line/drop-line topology that

provides separate twisted pair busses for both

signal and power distribution. The possible

Introduction variants of this topology are shown in Figure 1.

DeviceNet is a digital, multi-drop network that Thick or thin cable can be used for either

connects and serves as a communication trunklines or droplines. End-to-end network

network between industrial controllers and I/O length varies with data rate and cable thickness

devices. Each device and/or controller is a node as shown in Table 2.

on the network. DeviceNet is a producer-

consumer network that supports multiple

communication hierarchies and message

©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA) 1

Technical Overview

Figure 1: Thick or Thin Cable can be used for either trunklines or droplines

DeviceNet supports both isolated and non-isolated physical layer design of devices. An opto-isolated

design option allows externally powered devices (e.g. AC Drives starters and solenoid valves) to share

the same bus cable. The DeviceNet Specifications contain additional information concerning

component requirements, protection from mis-wiring, and examples.

DATA RATES 125 KBPS 250 KBPS 500 KBPS

Thick Trunk Length 500 m 250 m 100 m

(1,640 ft) (820 ft) (328 ft)

Thin Trunk Length 100 m 100 m 100 m

(328 ft) (328 ft) (328 ft)

Flat Trunk Cable 380 m 200 m 75 m

(1,250 ft) (656 ft) (246 ft)

Maximum Drop Length 6m 6m 6m

(20 ft) (20 ft) (20 ft)

Cumulative Drop Length 156 m 78 m 39 m

(512 ft) (256 ft) (128 ft)

Table 2: The end-to-end network distance varies with data rate and cable thickness.

Several different connector types can be used on DeviceNet (see Figure 2). Both sealed and unsealed

connectors are available. Large (mini-style) and small (micro-style) sizes of pluggable, sealed connectors

are available. For products that do not require sealed connectors, open-style connectors can be used.

Screw or clamp connections can be made directly to the cable if a pluggable connection is not required.

Nodes can be removed or inserted from the network without powering-down the network. A unique

feature of DeviceNet is the ability to add power taps at any point on the network. This makes redundant

power supplies possible. The trunkline current rating is 8 amps.

2 ©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA)

Technical Overview

Figure 2: Open and Sealed Connectors are available on DeviceNet

The Data Link Layer it is the same. This allows detection of

The Data Link Layer of DeviceNet is defined by simultaneous transmission. If a node transmitting

the CAN specification and by the implementation a recessive bit receives a dominant bit while

of CAN Controller chips. The CAN specification sending the arbitration field, it stops transmitting.

defines two bus states called dominant (logic 0) The winner of arbitration between all nodes

and recessive (logic 1). Any transmitter can drive transmitting simultaneously is the one with the

the bus to a dominant state. The bus can only be lowest numbered 11-bit identifier. CAN also

in the recessive state when no transmitter is in specifies a data frame format with a 29-bit

the dominant state. This fact comes into play in identifier field that is not used by DeviceNet.

the bus arbitration scheme employed by CAN. The Control Field contains two fixed bits and a

Several frame types are defined by CAN: 4-bit length field. The length may be any number

from 0 to 8 representing the number of bytes in

• data frame • remote frame the Data Field. The 0–8 byte size is ideal for low-

• overload frame • error frame end devices with small amounts of I/O data that

Data is moved on DeviceNet using the data frame. must be exchanged frequently. With eight bytes,

The other frames are either not used on there is enough flexibility for simple devices to

DeviceNet or are for exception handling. The send diagnostic data, or to send a speed

DeviceNet data frame format is shown in Figure 3. reference and acceleration rate to a drive.

DeviceNet also defines a fragmentation protocol

CAN is a carrier sense network. Any node can

that provides a way for nodes to transmit larger

attempt to transmit a message when no other

amounts of data with minimal protocol overhead.

nodes are transmitting. This feature provides

inherent peer-to-peer capability. If two or more The CRC field is a cyclic redundancy check word

CAN nodes try to access the network which is used by CAN controllers to detect frame

simultaneously, a non-destructive, bit-wise errors. It is computed from the bits that come

arbitration mechanism resolves the potential before it. A dominant bit in the ACK slot means

conflict with no loss of data or bandwidth. All at least one receiver besides the transmitter

receivers on a CAN network synchronize to the heard the transmission.

transition from recessive to dominant represented CAN provides very robust error checking and

by a Start of Frame bit. The identifier and the fault confinement employing several types of

RTR (Remote Transmission Request – not used by error detection and fault confinement methods

DeviceNet) bit together form the Arbitration Field. including CRC and automatic retries. These

The Arbitration Field is used to facilitate media methods, which are mostly transparent to the

access priority. When a device transmits, it also application, prevent a faulty node from disrupting

monitors (receives) each bit it sends to make sure the network.

©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA) 3

Technical Overview

Figure 3. CAN Data Frame

The Network and Transport Layers would be the destination for Cyclic or Change-of-

DeviceNet requires that a connection with a State messages. Similarly, some connections in

device must first be established in order to either a Client or Server may only produce

exchange information with that device. To messages. These connections would be the

establish a connection, each DeviceNet product source for Cyclic or Changes-of-State messages.

will implement either an Unconnected Message The use of Cyclic and Change-of-State

Manager (UCMM) or a Group 2 Unconnected connections can substantially reduce bandwidth

Port. Both perform their function by reserving requirements. By design, nodes in a DeviceNet

some of the available CAN identifiers. When system are responsible for managing their own

either the UCMM or the Group 2 Unconnected identifiers. These identifiers are interleaved

Port is used to establish an Explicit Messaging (distributed) throughout the entire range. All

Connection, that connection is then used to nodes have a full range of message priorities

move information from one node to the other, or available to them regardless of their Media

to establish additional I/O Connections. Once Access Code Identifier (MAC ID). Through the

I/O connections have been established, I/O data duplicate MAC ID algorithm, the uniqueness of

may be moved among devices on the network. CAN identifiers is guaranteed without the need

At this point, all the protocol of the DeviceNet for a central tool or record for each network.

I/O message is contained within the 11-bit CAN Figure 4 shows the DeviceNet allocations within

identifier. Everything else is data. the 11-bit CAN Identifier.

The 11-bit CAN identifier is used to define the A related issue is detection of duplicate nodes.

connection ID. Uniqueness of connection IDs is Because DeviceNet uses a device address inside

strictly controlled, which is required to take full the CAN Identifier Field, it presents a mechanism

advantage of producer-consumer capabilities. for detecting nodes with duplicate addresses.

DeviceNet divides the 11-bit CAN identifier into Preventing duplicate addresses is better than

four groups. The first three defined groups trying to locate them after they occur —

contain two fields; one 6-bit field for MAC ID and something not taken into account in other CAN-

the other for Message ID. The combined fields based networks. Another key benefit to nodes

define the connection ID. Four messages are managing their identifiers is that a user can add

used for offline communications. and delete nodes and/or add additional peer-to-

Devices may be Clients or Servers or both. peer messages among existing nodes at any time

Clients and Servers may be producers, without having knowledge of the existing set-up.

consumers or both. In a typical Client device, its No centralized record must be located or

connection would produce requests and reconstructed. Since nodes know which IDs are

consume responses. In a typical Server device, already in use, a tool simply has to request an

its connections would consume requests and I/O connection be added between the two

produce responses. DeviceNet provides for devices, specifying priority level, the data path

several variations on this model. Some (class, instance, attribute) and the production

connections in either a Client or a Server may trigger (cyclic, poll, or change-of-state).

only consume messages. These connections

4 ©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA)

Technical Overview

Figure 4. DeviceNet Allocations of the 11-Bit CAN identifier field

The Upper Layers: the Common For a given device type, a minimum set of

Industrial Protocol (CIP) common objects will be implemented. The user

benefits from interoperability among devices

DeviceNet uses the Common Industrial Protocol,

regardless of the manufacturer or the device type.

called CIP, for its upper-layers. CIP is strictly

object oriented. Each object has attributes (data) Since CIP-based networks are based on a

and services (commands) and behavior (reaction common application layer, the application data

to events). Two different types of objects are remains the same regardless of which network

defined in the CIP specification: communication hosts the device. The application programmer

objects and application-specific objects. Vendor- doesn’t even need to know to which network a

specific objects can also be defined by product device is connected. Figure 5 provides an

makers for situations where a product requires overview of CIP within the context of DeviceNet

functionality that is not in the specification. and the OSI Model.

Figure 5: The CIP Object Model

©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA) 5

Technical Overview

CIP also defines device profiles, which identifies DeviceNet also has standard mechanisms for

the minimum set of objects, configuration vendors to incorporate their own features

options and the I/O data formats for different (objects, attributes, services beyond those

types of devices. Devices that follow one of the defined in the device profile) into their products

standard profiles will have the same I/O data and in addition to the minimum required objects.

configuration options, will respond to all the However, these additional features must be

same commands and will have the same implemented in strict accordance with the

behavior as other devices that follow that same DeviceNet specification in the manner

profile. A subset of the device profiles supported prescribed by the specification.

by CIP and DeviceNet are shown in Table 3. Another important feature that sets CIP-based

networks apart from other network architectures

Device Profile Device Type No. is the ability to originate a message on one CIP-

02hex based network such as DeviceNet, and then pass

AC Drives

it to another CIP-based network such as

Communications Adapter 0Chex

EtherNet/IP with no presentation at the

Contactor 15hex application layer. This seamless bridging and

DC Drives 13hex routing capability sets DeviceNet apart from

1Fhex

other field bus networks. It means that a set of

DC Power Generator objects included in the specification define the

General Purpose Discrete I/O 07hex mechanisms that a bridging device can use to

Generic Device 00hex forward the contents of a message from one

18hex network port to another without acting on the

Human-Machine Interface

contents of that message. When using bridging

Inductive Proximity Switch 05hex

devices that support these objects, the user’s

Limit Switch 04hex only responsibility is to describe the path that a

Mass Flow Controller 1Ahex message must follow. CIP ensures that the

message is handled correctly, independent of the

Motor Overload 03hex

networks involved.

Motor Starter 16hex

CIP is a producer/consumer-based model, rather

Photoelectric Sensor 06hex than a traditional source/destination model.

Pneumatic Valve(s) 1Bhex Producer-Consumer networks provide for more

10hex efficient use of networking bandwidth, A message

Position Controller

is produced onto the network, it is identified, not

Process Control Valve 1Dhex

by its destination address, but by connection ID.

Residual Gas Analyzer 1Ehex Multiple nodes may then consume the data to

Resolver 09hex which this connection ID refers. The result of

this dynamic connection approach provides two

Table 3: Device Types Supported by DeviceNet and CIP clear benefits in the efficiency of the network:

• If a node wants to receive data, it only needs

to ask for it once to consume the data each

time it is produced.

• If a second (third, fourth, etc.) node wants

the same data, all it needs to know is the

connection ID to receive the same data

simultaneously with all other nodes.

6 ©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA)

Technical Overview

The Predefined Master/Slave Connection Set The Predefined Master/Slave Connection Set

Fundamentally, DeviceNet employs a peer-to-peer provides connection objects that are almost

messaging model. However, it also provides for a entirely configured at the time the device

simplified communication scheme based on a powers-up. After powering up the network, the

Master/Slave relationship. This predefined only remaining step necessary to begin the flow

connection scheme is known as the Predefined of data is for a “master” device to claim

Master/Slave Connection Set. This connection ownership of this predefined connection set

method simplifies the movement of the I/O within its “slave(s).” Slave devices can produce

messages most often used in control applications. data using one or more of the following message

types, depending on how the device is

Many sensors and actuators are designed to configured and the requirements of the

perform some predetermined function in which application, as shown in Table 4.

the type and amount of data the device will

produce and/or consume is known at power-up.

Type Description of Operation

polled A slave configured for polled I/O will receive “output” data from the master device

in a sequential order that is defined by the master’s scan list. The master’s polling

rate is determined by the number of nodes in the scan list, the DeviceNet baud

rate, the size of messages produced by the master and each node in its scan list

and the internal timing of the master device. For a given system configuration, this

messaging method will provide deterministic behavior. Polled I/O “output” data can

be unicast or multicast.

cyclic A device configured to produce a cyclic I/O message will produce its data at a

precisely defined interval. This type of I/O messaging allows the user to configure

the system to produce data at a rate appropriate for the application. Depending on

the application this can reduce the amount of traffic on the wire and more

efficiently use the available bandwidth.

change-of-state A device configured to produce change-of-state (COS) message will produce data

whenever it changes, or at a base heartbeat rate. This adjustable heartbeat rate

provides a way for the consuming device to know that the producer is still alive

and active. DeviceNet also defines a user-configurable Production Inhibit Time that

limits how often COS messages are produced to prevent nodes from “flooding” the

bandwidth. Users can adjust these parameters to provide optimum bandwidth

utilization in a given application scenario.

Table 4: Slave I/O Message Types in the Predefined Master/Slave Connection Set

©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA) 7

Technical Overview

Conformance Testing DeviceNet™ System test verifies that the

ODVA Conformance Testing is designed to product operates in a multi-vendor DeviceNet™

validate that a product complies with relevant system. The product is installed in a 64-node,

aspects of the ODVA specification, from the multi-vendor environment and run in a variety

physical layer through the application layer. of situations specifically designed to identify

Devices that have passed ODVA DeviceNet potential interoperability and system problems.

conformance testing have passed all of the Products must successfully establish explicit

following tests at one of ODVA’s authorized test and I/O connections during various power-up

service providers: sequences, and they must survive the on-line

Control and Information Protocol (CIP) test removal and replacement of other nodes. The

verifies that a product meets requirements of test also confirms that the device will operate

CIP and the additional messaging and under heavy network traffic with scanners

services required for DeviceNet. It tests from multiple manufacturers and that the EDS

conformance at the device profile, file can be used to configure the device.

application layers. ODVA also offers specialized testing:

DeviceNet Electronic Data Sheet (EDS) test DeviceNet Power Supply test verifies that

verifies that the product’s EDS (an ASCII text network power supplies provide the

file supplied by the manufacturer) contains necessary voltage and currents, and operate

the correct grammar and all the required as the specification requires, under a variety

product information, including the device’s of loading conditions.

identity, supported message types, Semiconductor test is another level of testing

configuration parameters and parameter for DeviceNet products used on

enumeration. This file is used by network semiconductor manufacturing tools. Products

configuration software tools to help set up submitted for semiconductor-specific tests

devices on the network. must first pass the standard test suite. This

DeviceNet Physical Layer test verifies that a additional level of testing verifies

DeviceNet product’s physical layer is conformance of connectors, indicators,

designed and operating correctly. For switches, isolation, power, and object

example, it confirms that voltage and current behavior with the ODVA specification

levels remain in allowed ranges during supplement Interface Guidelines for

operation and that the connectors and DeviceNet Devices on Semiconductor

indicators meet ODVA specifications. Manufacturing Tools, including compliance

with CE and SEMI S2.

Once a product passes the appropriate conformance tests, ODVA grants the vendor the right to use its

conformance marks. A list <www.odva.org/10_2/04_products/04_prodtest.htm> of conformance-passed

products also appears on the ODVA web site. Users who wish to specify only products that have passed

conformance tests can find them listed online or identify them by these product marks.

www.odva.org

odva@odva.org

DeviceNet™ and CIP™ are trademarks of ODVA. DeviceNet CONFORMANCE TESTED® is a registered certification mark of

ODVA. EtherNet/IP™ is a trademark used under license by ODVA. ControlNet™ is a trademark of ControlNet International.

PUB00026R1

8 ©copyright 2004, Open DeviceNet™ Vendor Association, Inc., (ODVA)

You might also like

- Proces Um100 - en PDocument322 pagesProces Um100 - en PchinitomelianNo ratings yet

- Devicenet: HistoryDocument6 pagesDevicenet: HistoryNeftaly Fearless EssenceNo ratings yet

- DeviceNet Technical Overview PDFDocument2 pagesDeviceNet Technical Overview PDFThanh BaronNo ratings yet

- Control Logix ControllerDocument48 pagesControl Logix ControllerOscar Alberto Briones JorqueraNo ratings yet

- 1756L61Document2 pages1756L61cvchaudhariNo ratings yet

- Lecture PLCDocument30 pagesLecture PLCameer kannanNo ratings yet

- NEMA FrameDocument1 pageNEMA Frameriff100% (9)

- PLCLogixUserGuide PDFDocument27 pagesPLCLogixUserGuide PDFCldResendeNo ratings yet

- Unit1 2Document30 pagesUnit1 2CHETAN SETIYANo ratings yet

- Dozer Blade Parts Wiring Breakdown 1Document5 pagesDozer Blade Parts Wiring Breakdown 1Constantinescu BogdanNo ratings yet

- CompactlogixDocument56 pagesCompactlogixtazjuan1No ratings yet

- High Availability Systems: Selection GuideDocument16 pagesHigh Availability Systems: Selection GuideJeremiah CayondongNo ratings yet

- Iab - Projppd: Integrated Architecture BuilderDocument40 pagesIab - Projppd: Integrated Architecture BuilderRoman NaeemNo ratings yet

- Template Developer's Guide PDFDocument295 pagesTemplate Developer's Guide PDFMariangeles XitumulNo ratings yet

- Manual RslogixDocument132 pagesManual RslogixMárcio SantanaNo ratings yet

- Fieldbus I/O: Tactical BriefDocument25 pagesFieldbus I/O: Tactical BriefAlexander Ariza NadjarNo ratings yet

- Vendor Sample ProjectsDocument4 pagesVendor Sample ProjectsTiago da Silva PereiraNo ratings yet

- A Quick Tutorial On RSLogix..Document9 pagesA Quick Tutorial On RSLogix..hsnsbrNo ratings yet

- 1756 ControlLogix ControllersDocument40 pages1756 ControlLogix ControllersNguyễn Đăng QuýNo ratings yet

- L09 - Drive Configuration and Programming Lab: PublicDocument133 pagesL09 - Drive Configuration and Programming Lab: PubliccuongvcsNo ratings yet

- CoTMS-59 FactoryTalk Historian Site Edition Advanced LabDocument90 pagesCoTMS-59 FactoryTalk Historian Site Edition Advanced LabJose SierraNo ratings yet

- RSLogix 5000 Emulate Software - SIM Module ConfigurationDocument3 pagesRSLogix 5000 Emulate Software - SIM Module ConfigurationMarisolNo ratings yet

- List of Automation Protocols - Wikipedia, The Free EncyclopediaDocument5 pagesList of Automation Protocols - Wikipedia, The Free EncyclopediaArvind KumawatNo ratings yet

- Product Profile - Kinetix® 6500 - 2094-pp005 - En-P PDFDocument4 pagesProduct Profile - Kinetix® 6500 - 2094-pp005 - En-P PDFNicolás A. SelvaggioNo ratings yet

- 1756 td003 - en e PDFDocument40 pages1756 td003 - en e PDFRhys ShukerNo ratings yet

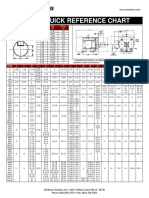

- Nema - Quick Reference Chart: ESR Motor SystemsDocument2 pagesNema - Quick Reference Chart: ESR Motor SystemsadolfNo ratings yet

- 03 PlantPAx 5.0 Early Adopter Labs - PlantPAx 5.0Document134 pages03 PlantPAx 5.0 Early Adopter Labs - PlantPAx 5.0pisoy30392No ratings yet

- Packml Implementation Guide: Part 6: Packml Hmis - User Interfaces, Stacklights, and Push-Button ControlsDocument8 pagesPackml Implementation Guide: Part 6: Packml Hmis - User Interfaces, Stacklights, and Push-Button Controlsddileo0% (1)

- Tutorial 01 PLC Basics1 PDFDocument21 pagesTutorial 01 PLC Basics1 PDFTete GoriNo ratings yet

- Powerflex Low Voltage Drives Selection Guide: Powerful Performance. Flexible ControlDocument178 pagesPowerflex Low Voltage Drives Selection Guide: Powerful Performance. Flexible ControlMr.K chNo ratings yet

- 8913 - Recovering A Project From The MER FileDocument4 pages8913 - Recovering A Project From The MER FileLalo De GanteNo ratings yet

- Cip Safety Pf527 Hott 2015 v1 - 2 Mar 18 2015Document16 pagesCip Safety Pf527 Hott 2015 v1 - 2 Mar 18 2015ipasa100% (1)

- Rockwell Automation TechED 2018 - SS07 - Lab Manual - Developing Safety Applications Using The Guardmaster 440C-CR30 PDFDocument106 pagesRockwell Automation TechED 2018 - SS07 - Lab Manual - Developing Safety Applications Using The Guardmaster 440C-CR30 PDFAlex RivasNo ratings yet

- Enet At007 - en PDocument94 pagesEnet At007 - en PAkshay AryaNo ratings yet

- Industrial Ethernet: A Control Engineer's Guide: White PaperDocument19 pagesIndustrial Ethernet: A Control Engineer's Guide: White PaperHamidreza Moaddeli100% (1)

- Panelview Plus 6 Terminals: User ManualDocument191 pagesPanelview Plus 6 Terminals: User ManualIsraelNo ratings yet

- 1756 Um543 - en PDocument152 pages1756 Um543 - en Pshijub_0010% (1)

- Recovering A Project From A MER FileDocument4 pagesRecovering A Project From A MER FileBryn WilliamsNo ratings yet

- P Alarm 2.0 Syslib Rm002c en eDocument40 pagesP Alarm 2.0 Syslib Rm002c en eBeto De HermosilloNo ratings yet

- KNX sg001 - en PDocument234 pagesKNX sg001 - en PNelsonNo ratings yet

- Industrial Automation Communication ProtocolsDocument7 pagesIndustrial Automation Communication ProtocolsNeshvar DmitriNo ratings yet

- Compactlogix P1Document20 pagesCompactlogix P1eumetallicaNo ratings yet

- Rockwell PLCDocument80 pagesRockwell PLCKamitkumar PatelNo ratings yet

- LAB Constructor de Arquitectura Integrada (IAB)Document249 pagesLAB Constructor de Arquitectura Integrada (IAB)Enrique RomeroNo ratings yet

- ControlLogix5000 MSG Instruction - 2.0Document13 pagesControlLogix5000 MSG Instruction - 2.0shijub_001No ratings yet

- Message From Micro800 To Logix On Ethernet - IPDocument3 pagesMessage From Micro800 To Logix On Ethernet - IPEdgardoNo ratings yet

- DSASW0052286Document746 pagesDSASW0052286ANIRUDDHA BARTAKENo ratings yet

- EW1ENDocument73 pagesEW1ENSaadullah SiddiquiNo ratings yet

- Flexi/O and Flex Ex: Selection GuideDocument144 pagesFlexi/O and Flex Ex: Selection GuideMaria MitaraNo ratings yet

- Allen Bradley JoystickDocument3 pagesAllen Bradley JoystickPankaj RamoleNo ratings yet

- Proces rm007 - en P PDFDocument108 pagesProces rm007 - en P PDFrodriggoguedesNo ratings yet

- Introduction To Logix Hands-On Lab Presenter: Liz Bahl Commercial EngineeringDocument84 pagesIntroduction To Logix Hands-On Lab Presenter: Liz Bahl Commercial EngineeringRaul Roque YujraNo ratings yet

- Motion Rm003 en PDocument707 pagesMotion Rm003 en PNelsonNo ratings yet

- Victor Tip Charts: Acetylene Cutting Tip ChartDocument3 pagesVictor Tip Charts: Acetylene Cutting Tip ChartahmedNo ratings yet

- Motion Rm003 en PDocument715 pagesMotion Rm003 en PSamuel OliveiraNo ratings yet

- Rockwell FactoryTalk Studio BasicsDocument7 pagesRockwell FactoryTalk Studio BasicsBryn WilliamsNo ratings yet

- Autocad ElectricalDocument24 pagesAutocad Electricalhhtemp195No ratings yet

- Instant PLC Programming with RSLogix 5000: Learn how to create PLC programs using RSLogix 5000 and the industry's best practices using simple, hands-on recipesFrom EverandInstant PLC Programming with RSLogix 5000: Learn how to create PLC programs using RSLogix 5000 and the industry's best practices using simple, hands-on recipesNo ratings yet

- Whatdev PDFDocument2 pagesWhatdev PDFIgidio PedroNo ratings yet

- NP243 DeviceBus CablesDocument6 pagesNP243 DeviceBus CablesAndy Kong KingNo ratings yet

- As Interface OverviewDocument1 pageAs Interface Overviewapi-3754722No ratings yet

- Controller Area Network (CAN)Document10 pagesController Area Network (CAN)api-3754722100% (3)

- Device NetDocument4 pagesDevice Netapi-3754722100% (1)

- NRZIDocument19 pagesNRZIapi-3754722100% (1)