Segmental Construction

Segmental Construction

Uploaded by

manoj_mousamCopyright:

Available Formats

Segmental Construction

Segmental Construction

Uploaded by

manoj_mousamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Segmental Construction

Segmental Construction

Uploaded by

manoj_mousamCopyright:

Available Formats

Y.W.

Leung, Page 1

Construction of the Precast Segmental Approach Structures for Sutong Bridge

Xian Peng LIU, CHEC Wuhan Port Construction Corp, China Zong Ping QIN, CHEC Wuhan Port Construction Corp, China Y.W. LEUNG, YWL Engineering Pte Ltd, Singapore Dr. Lingling YUE, YWL Engineering Pte Ltd, Singapore

Abstract

The precast segmental approach structure of the Sutong Bridge with 75m span length was constructed using balanced cantilever method. This precast segmental viaduct was characterized by deep foundation in the riverbed, 60m high columns connecting the main bridge and relatively long end spans in the balanced cantilever deck. This paper covers the construction methods and logistics adopted to suit the particular site conditions. It discusses the casting yard selection and set up in the vicinity of the river bank, the design of the special equipment such as the short-line match casting moulds and two 160m long launching girders which were tailor-made for this project. The value engineering exercise in the post Contract award stage for facilitating construction is detailed. The geometry control method used in both the casting yard and erection front, the temporary works and stabilizing system are delineated. This paper also highlights the construction difficulties encountered and solutions to the problems.

Introduction

The Sutong Bridge is part of a traffic truck connecting cities Nantong and Suzhou (Changshu) across the Yangtze River in the south of Jiangsu Province (Figure 1). The total length of the highway is 32.4km. It consists of three parts: north bank link, central crossing and south bank link. The central crossing consists of a total length of 8.2km bridge structures with 6-lane dual carriageway. The main navigation channel is a cable-stayed bridge that has a central span of 1088m. Both the north and south approach structures consist of 30m, 50m or 75m long span prestressed concrete continuous single-cell box girder structure to be constructed by either cast in-situ or precast segmental method. The construction of the precast segmental approach structures commenced in April 2004 and completed in early 2007. Figure 1: Location Plan

Y.W.Leung, Page 2

The Sutong Bridge project is located at the downstream of the Yangtze River close to the estuary with strong tidal effects at about 110 km from the river mouth. The site conditions were characterized by snow, storm, typhoon, strong tide, variable riverbed and rapid flow rate. The observed 30-year returned wind speed was 35.5m/s. The maximum difference between high tide and low tide observed was more than 5m. The maximum water depth was about 12m and the section flow rate was over 4m/s. These environmental factors posed constraints and challenges to many construction activities in this project.

Bridge Characteristics

Being the first precast segmental bridge built using short-line match-casting method in China, the approach structure consisted of 52 spans of single cell box girders. The typical bridge units were formed by 5-span or 10-span continuous deck supported on the pot bearings (Figure 2). The total length of the box girder measured along its centerline was approximate 3.7km. The deck width of a single carriageway was 17.5m (Figure 3). Other than one end span that was adjacent to the in-situ box girder at Natong side was a 50m unit, all other spans had an equal span length of 75m. The reinforced concrete columns with 4.5m x 6.5m rectangular hollow section were adopted for the maximum height of 60m and supported on pile caps with bored pile foundation.

Figure 2: Bridge Elevation

Figure 3: Bridge Sectional View

Y.W.Leung, Page 3

Value Engineering

The Engineers original design of the precast segmental bridge deck was based on the balanced cantilever construction technique using long-line casting method with epoxy joints. A mixed prestressing system was employed. The cantilever and span tendons were internally prestressed while the continuity tendons were external. During the Tender stage, YWL Engineering was engaged by the Contractor (CHEC) to provide an alternative concept design for segment production using short-line match-casting method together with the associated value engineering exercise focusing on improving constructability. The detailed design was later executed by the original designer after award of the Contract. Some key aspects of the value engineering included the following: i) Setting out concept of the box girder the box girder soffit was always horizontal in the Engineers design; thus the cross section of the box was not symmetric about its centerline. The depth of two webs varied with respect to changes in super-elevation. The alternative setting out concept employed a constant depth section by allowing rotation in the box axis (Refer to Figure 4). This arrangement would simplify the mould design and casting operation in the production.

Figure 4: Box Girder Setting-Out Concept ii) Web transition details near the support, the web thickness was increased for shear resistance. The original design adopted a detail with continuous transition. The proposed alternative made use of a step discontinuity at segment joints so that the inner core form for the segment mould could be standardized and thus the casting operation would be simplified. See Figure 5.

Figure 5: Box Girder Web Variation

Y.W.Leung, Page 4

iii)

Second stage casting of segment there was a significant difference in self-weight between the typical and diaphragm segments (285 150 = 136 ton). The heavier diaphragm would demand extra capacity for all construction plants and equipment e.g. launching girder. The alternative construction concept involved re-design of the pier segment so that only a light weight shell segment was formed in the yard and the solid core was cast by insitu mean at a later stage after it was erected. Standardization of structural elements in the alternative proposal, many typical structural elements, such as, shear keys, blisters for cantilever tendons and diaphragm segments at end spans, were re-detailed and standardized in order to facilitate constructability. Closure segment at mid span the Engineers design at the mid span location consisted of a 3m long insitu cast closure segment. In the value engineering exercise, a precast option was proposed and adopted. The closure segment was 2.7m long with two 150mm insitu stitches.

iv)

v)

Foundation

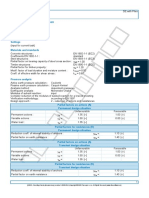

The project site is located in the alluvial plain of the Yangtze Delta, which is characterized by a thick layer of quaternary deposits. The bedrock is very deep ranging between 270m to 280m. In general, the upper layer of soil (-55m to -65m) consists of a loose to medium dense silty sand underlain by a layer of soft and compressible silty clay. Below the soft layer is the dense sandy deposits, which constitutes mainly the load bearing layers for the pile foundation. The foundation of the precast segmental approach bridge was composed of 330 bored piles of diameter 1.8m. Piers were supported by either 8 or 9 numbers piles with 11m x 12m x 3m or 12m x 12m x 3.2m pilecaps respectively. All the piles were designed as friction piles with the founding levels ranging from -87m to -95m. The temporary steel casings used for bored pile construction were formed by 12mm thick tubular section, and provided at the top portion from cap to -18m below seabed. The length varied from 21m to 33m depending on the geological condition. The casings were driven by a vibration hammer of 78 ton. The drilling of the bored pile was carried out using reverse-circulation drilling rig mounted on the temporary staging. Global position system (GPS) was employed in the setting out of the piles. The foundation of the pile staging consisted of 12 numbers of 0.8m x 6mm or 1.0m x 10mm tubular piles of about 30m long that were tied together on top in 2 layers with I sections and bailey trusses to form the staging platform of 30m x 15m for one pile group construction. Bentonite slurry was employed to stabilize the bored holes. The characteristics for Bentonite suspensions are given in Table 1. Table 1. Characteristics of the Proposed Bentonite Suspensions Property Fresh Ready for re-use Before concreting PH 10~12 8~10 7~9 Density (G/ml) <1.04 <1.08 1.06~1.10 Marsh viscosity (Sec) 26 ~ 35 25~26 20~24 Fluid loss (ml/30min) <10 <15 <10 Sand content (%) <0.3% 0.5~1.0% <0.5%

Y.W.Leung, Page 5

The bored hole was filled with slurry before drilling of the portion below the casing commenced. The head of the drilling fluid was kept constant at 1.5m above the water level so as to ensure sufficient stabilizing pressure in the uncased shaft area. After completion of drilling and initial base cleaning, the prefabricated reinforcement cages (8 numbers of 12m long per unit, 27 ton each) were installed by a 200 ton crane. Placement of concrete after final cleaning of the pile base was carried out using a 273mm diameter tremie pipe. For 95m long piles, it required a 3-7 day construction cycle from commencement of drilling to completion of concreting works. See Figure 6 for the temporary platform and equipment for the piling works.

Figure 6: Staging Platform for Piling

Figure 7: Pilecap Construction

Pilecap construction was executed using heavy duty cofferdams which consisted of 4 side forms and a soffit with a total weight of 75 ton (See Figure 7). This falsework system was designed for constructability. The maximum weight of each module was limited to 15 ton to facilitate easy handling. Initially, the cofferdams were overhang with temporary steelworks supported on the steel casing of the piles. After fine adjustment of cofferdam using hydraulic jacks, one meter thick layer of non-structural tremie concrete was poured in order to seal the base and stabilize the system prior to dewatering. The rest of the operations were carried out in dry. The typical cycle time for constructing a pile cap was 30-40 days.

Column

The reinforced concrete hollow columns were constructed using a self-climbing form with an integration of a working platform (See Figure 8). Hydraulic rams were employed for the climbing mechanism. A 70m high tower crane with a capacity of 120 ton-m was fixed on the pilecap for material handling. Concrete were supplied by a mixer barge and pumped via a pipe mounted on a scaffold system tied to the column. The slump of concrete was 150mm and each typical pour was 4m. The climbing form would be self-launched when the concrete reached a strength of 10 MPa. In general, a 4-day cycle time for a 4m pour height could be achieved. Figure 8: Column Construction

Y.W.Leung, Page 6

Segment Casting

The segments were fabricated in a casting yard located at the north bank of the project site (Natong side). The yard was chosen at a favorable location to facilitate easy transportation of the heavy segments by barge. The loading point was connected by a 240m long temporary bridge and a jetty. See Figure 9 for the layout of the yard.

Figure 9: Casting Yard Layout Plan In this project, a total of 1086 segments were fabricated in a period of 17 months. Due to the importance of the project, 6 sets of short-line casting cells were invested under a conservative assumption of 2.5-day casting cycle. The actual production characteristics, however, reached a typical cycle of 2 days for the standard segments after a brief initial learning period of 2 months. In the summer time, a 1-day cycle was achieved. The casting yard was about 40,000m2 and equipped with 2 numbers of 160 ton gantry cranes for segment handling and 2 numbers of 16 ton gantry cranes for light duty tasks, such as, manipulating the reinforcement cage. The casting yard had a storage capacity of 354 segments based on two-layer stacking (Figure 10). Concrete was mixed in the casting yard by using 2 numbers of batching plants of 50m3 /h capacity each.

Figure 10: Segment Storage

Figure 11: Segment Curing Chamber

The bridge segments were produced by short-line match-casting method. It was a new technology used in China as earlier concrete segmental bridges had always been built with multi-insitu joints in order to deal with the geometry variations from the bridge alignment. In this project, the classical precast segmental method was employed in which the overall

Y.W.Leung, Page 7

geometry of a bridge unit was captured in a casting cell in stages based on a given segmentation scheme. During each casting operation, the spatial relationship of a pair of conjugate segments in global coordinates was transformed to the local reference frame of the casting cell. Geometric errors that occurred during a casting operation were controlled and adjusted in the subsequent casting operations. Control points were fixed to the wet-cast segment before hardening of concrete for geometry controlling purposes. Survey was carried before and after casting a pair of conjugate segments. A proprietary computer software, GeomPro, developed by YWL, was used to control the geometry in the segment casting works. This software has a user-friendly interface equipped with a powerful databases and error detection checking system in order to minimize human errors during operation of the software. The casting cell was approximately 90 ton each. In the design, the stiffness and flexibility of the mould were properly balanced with due consideration of the geometry of the viaduct. In winter seasons, the ambient temperature in the Yangtze River area would drop below -10oC. In order to achieve the target production rate, the air-conditioned brick houses were constructed for all casting cells to accelerate the gain of concrete strength of segments. In side these curing chambers, the temperature was maintained at above 10oC during winter. See Figure 11.

Segment Erection

The total erection period was about 15 months. Two overhead launching girders (Figure 12) were employed. Since the Sutong Bridge was a signature structure over the Yangtze River, the aesthetics of both the main bridge and approach structures was an important aspect of the design. The pier spacing and the proportion of deck and column were carefully considered and approved by a national bridge committee. With the even pier spacing, the 75m long balanced cantilever articulation led to an end span exceeding 30m (Refer to Figure 13). This imposed a taxing condition to the design of the launching girder. The 160m long overhead girders weighted about 1000 ton each and functioned both somewhat as a cantilever and span-by-span (end span) girder at the same time. Each girder had two winches with lifting capacities of 180 ton and 150 ton respectively. The lifting height of the winches was allowed for 70m so that segments could be picked up at sea level. The launching girder had been designed to resist a maximum wind speed of 58 m/s. However, the maximum wind speed was limited to16m/s during self-launching, and 22 m/s during segment erection. At out of service condition, no special tie down system was needed when the wind speed was below 30 m/s, otherwise the typhoon tie-down device was to be engaged.

Figure 12: LG Assembling

Figure 13: End Span Erection

Y.W.Leung, Page 8

The diaphragm segments of the initial two spans were erected using a barge crane of 800 ton in advance in order to facilitate the launching girder assembling and testing (Figure 12). The remaining diaphragms were erected either by the barge crane or launching girder. All other segments in the balanced cantilevers and end spans were constructed using the launching girders. During erection of the end span, a careful investigation of the deck-girder interaction was conducted in order to avoid overstressing of the hangers in the load transfer process. The stabilization of the partially completed balanced cantilever was achieved by the use of vertical nailing consisted of 6 numbers of U shaped tendons (12@15.2mm) embedded in the column and preloaded to 50 ton each. The diaphragm segment was supported on 4 numbers of 100 ton temporary jacks (Figure 14). After geometry adjustment, the pier segment was fixed in position by concrete packers sandwiched with a layer (20mm) of sulphurous mortar that was later molten by the embedded electric arc for removal of the packers. Figure 14: Erected Diaphragm Segment After completion of the cantilever arms, the closure segment was lifted by the girder winch to the final position and supported by a pair of clamping beams mounted onto the erected cantilever tips. The launching girder could then be launched to the next span for continuing the erection works without completion of the stitches as all supports of the girder were rested on the pier segments. The insitu stitches were cast at the lowest temperature of the day. See The cantilever and span tendons were internally prestressed system consisted of 12, 15, 17 or 19 strands (15.2mm). The continuity tendons were externally prestressed system consisted of 25 strands and anchored at the diaphragm of every two spans. Figure 15a and 15b for the launching girder in action. The geometry control during erection was monitored at various stages. The theoretical profile of the deck, taking into consideration of the camber and stage effects, was compared with the observed results. Initially, some discrepancies were observed. After a thorough investigation, it was discovered that the problem was due to improper application of the temporary stressing system. Great improvement on the geometry accuracy was achieved for the remaining works.

Figure 15a, 15b: Partially Erected Bridge Deck

Y.W.Leung, Page 9

Conclusions

The precast segmental approach structure of the Sutong Bridge was a pilot project of this type of balanced cantilever construction in China. It was the result of the leadership and entrepreneur spirit of Jiangsu Provincial Sutong Bridge Commanding Department (STB). With close cooperation with many parties and experts, the project was successfully completed in a timely manner. The end product is a high quality signature structure over the Yangtze River and shall serve the public for many coming years.

Acknowledgment

For a project of this scale and complexity, there are always many individuals who have contributed to the works; their names, however, would be too long to be all listed. Special thanks are to those few who have immediate and significant help and influence on the authors works, namely, Mr. Qingzhong YOU (STB), Mr. Yadong LIU (CHEC) and Ms Tujing (YWL). Their efforts made this project happen.

You might also like

- DK CHING SUMMARY NOTES - Building Construction IllustratedDocument70 pagesDK CHING SUMMARY NOTES - Building Construction IllustratedManny InocencioNo ratings yet

- Engineering Structures: Hadi Panahi, Aikaterini S. GenikomsouDocument20 pagesEngineering Structures: Hadi Panahi, Aikaterini S. GenikomsouBayuAgungGilangWibowo100% (1)

- 111 - The Design and Construction of Cliffsend UnderpassDocument4 pages111 - The Design and Construction of Cliffsend UnderpassYash SinghNo ratings yet

- VSL Jordan Wadi Abdoun Curved Cable Stayed Bridge PDFDocument2 pagesVSL Jordan Wadi Abdoun Curved Cable Stayed Bridge PDFrrkkffNo ratings yet

- 1 VBC BasicsDocument46 pages1 VBC BasicsBenedetto La FauciNo ratings yet

- Saxton MillauDocument10 pagesSaxton MillauBilalABasheerNo ratings yet

- Bai Chay 2Document3 pagesBai Chay 2Anh NguyenNo ratings yet

- Ismailia Road Tunnel Crossing The Suez Canal PDFDocument8 pagesIsmailia Road Tunnel Crossing The Suez Canal PDFRonald HeijmansNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Cable Stays of Cable-Stayed Bridges (T 5140.25)Document9 pagesCable Stays of Cable-Stayed Bridges (T 5140.25)Mohamed BahgatNo ratings yet

- SSRN Id3694237Document14 pagesSSRN Id3694237BALRAJNo ratings yet

- Evolution of Bridge TechnologyDocument17 pagesEvolution of Bridge TechnologyPaniraju Narayanappa BellurNo ratings yet

- Analysis and Design of Prestressed Concrete Box Girder BridgeDocument16 pagesAnalysis and Design of Prestressed Concrete Box Girder BridgeDidier D. Boko-hayaNo ratings yet

- Provided by Universiti Teknologi Malaysia Institutional RepositoryDocument8 pagesProvided by Universiti Teknologi Malaysia Institutional RepositoryDyeri FloresNo ratings yet

- Extradosed Bridges in Poland-Design and Constructi PDFDocument10 pagesExtradosed Bridges in Poland-Design and Constructi PDFFitsum AbebeNo ratings yet

- Composite Structures Full Notes Part 7 PDFDocument25 pagesComposite Structures Full Notes Part 7 PDFsvnNo ratings yet

- Construction Process of Segmental BridgesDocument47 pagesConstruction Process of Segmental BridgesmnsawantNo ratings yet

- BridgesDocument3 pagesBridgesShah KhanNo ratings yet

- Post Tensioned Segmental Bridge PDFDocument7 pagesPost Tensioned Segmental Bridge PDFAnonymous Gd0PTUQNo ratings yet

- The Staggered Truss System-Structural Considerations: John B. ScalziDocument6 pagesThe Staggered Truss System-Structural Considerations: John B. Scalzisaber javidNo ratings yet

- Land Viaduct Design Dynamic Behaviour-CompletedDocument23 pagesLand Viaduct Design Dynamic Behaviour-CompletedPatrick Augustin100% (1)

- Queensferry Crossing Presentation by DawidDocument11 pagesQueensferry Crossing Presentation by Dawidmlynarczykdawid0No ratings yet

- Bridge Design NewDocument46 pagesBridge Design NewAdheesha BandaraNo ratings yet

- Staggered Truss Frames SEAOC BlueDocument4 pagesStaggered Truss Frames SEAOC BlueHirad GrivaniNo ratings yet

- A Critical Analysis of The Donghai Bridge, ShanghaiDocument10 pagesA Critical Analysis of The Donghai Bridge, ShanghaiPunithan PunithanNo ratings yet

- Construction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su ChengDocument6 pagesConstruction Control of The Yamen Cable-Stayed Bridge: Han Dajian Su Chengarindam1508No ratings yet

- Creep Calculation of Extradosed BridgeDocument9 pagesCreep Calculation of Extradosed Bridgesiva_ascinfratechNo ratings yet

- Design of Segmental Bridges For Thermal GradientDocument18 pagesDesign of Segmental Bridges For Thermal GradientRAIMUNDO SUHERDINNo ratings yet

- Mask EllDocument10 pagesMask EllYap Wen KhongNo ratings yet

- Shear Lag EffectDocument2 pagesShear Lag Effectmedhat145No ratings yet

- 4.3 - K F Tam, Gammon - PDFDocument11 pages4.3 - K F Tam, Gammon - PDFsouthchayNo ratings yet

- Effect of Torsion On Externally Prestressed Segmental Concrete BridgeDocument7 pagesEffect of Torsion On Externally Prestressed Segmental Concrete Bridgepmullins_11No ratings yet

- San Francisco Oakland East Bay Bridge Seiblefib2003Document20 pagesSan Francisco Oakland East Bay Bridge Seiblefib2003mapasabcNo ratings yet

- Surrey ENGM030 Unit 9 Presentation1aDocument26 pagesSurrey ENGM030 Unit 9 Presentation1aPhilip YapNo ratings yet

- Recent Technology of Prestressed Concrete Bridges in Japan PDFDocument10 pagesRecent Technology of Prestressed Concrete Bridges in Japan PDFYuli Ana Fransisca SantanaNo ratings yet

- Field Performance of Twin Bored Tunnelling in Different Geological Conditions Construction of MRT Downtown Line 3 in SingaporeDocument4 pagesField Performance of Twin Bored Tunnelling in Different Geological Conditions Construction of MRT Downtown Line 3 in SingaporethirisuNo ratings yet

- Medway Bridge DesignDocument10 pagesMedway Bridge DesignTamaduianu IoanNo ratings yet

- Using Fracture Grouting To Lift Structures in Clayey SandDocument8 pagesUsing Fracture Grouting To Lift Structures in Clayey SandxheurtauxNo ratings yet

- Arup Journal - Oresund BridgeDocument8 pagesArup Journal - Oresund BridgeNikT1111No ratings yet

- Fulltext01 PDFDocument180 pagesFulltext01 PDFAlin SalageanNo ratings yet

- Compensation GroutingDocument37 pagesCompensation GroutingPablo RincónNo ratings yet

- Cable-Stayed Bridge - Wikipedia, The Free EncyclopediaDocument14 pagesCable-Stayed Bridge - Wikipedia, The Free EncyclopediasunnymaniaggarwalNo ratings yet

- VSL China PRC Ching Chau Min Jian BridgeDocument2 pagesVSL China PRC Ching Chau Min Jian BridgeblaqhaqarNo ratings yet

- Recent Evolution of Cable-Stayed Bridges: Michel VirlogeuxDocument19 pagesRecent Evolution of Cable-Stayed Bridges: Michel VirlogeuxprakharNo ratings yet

- Study On Extradosed Bridge and It's Structural Behavior.: Conference PaperDocument7 pagesStudy On Extradosed Bridge and It's Structural Behavior.: Conference Papervivek kasatNo ratings yet

- Seminar Document - EIT - IRR Cable-Stayed Bridge - 13 October 2007Document35 pagesSeminar Document - EIT - IRR Cable-Stayed Bridge - 13 October 2007DrPadipat ChaemmangkangNo ratings yet

- A Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberDocument5 pagesA Review On Design and Analysis of Foot Over Bridge Using Plated Fabricated Steel MemberIJRASETPublicationsNo ratings yet

- 0 6729 1Document192 pages0 6729 1lamkinpark3373No ratings yet

- Train A Grande VitesseDocument5 pagesTrain A Grande VitesseEditor IJRITCCNo ratings yet

- Dubai Metro Footbridge DesignDocument17 pagesDubai Metro Footbridge DesignCharles Wong100% (2)

- Bridge Introduction 8th CivilDocument56 pagesBridge Introduction 8th Civilsamrudh kamalapurkarNo ratings yet

- Track (Rail Transport) : Navigation Search Merged Discuss Improve This Article Reliable Sources Challenged RemovedDocument15 pagesTrack (Rail Transport) : Navigation Search Merged Discuss Improve This Article Reliable Sources Challenged RemovedParthiban GuruNo ratings yet

- Precast Segmental Bridges in Riyadh Metro Project - Lines 1 & 2Document10 pagesPrecast Segmental Bridges in Riyadh Metro Project - Lines 1 & 2kutticute_877110165No ratings yet

- Analysis of Full Depth Precast Concrete Bridge Deck PanelsDocument12 pagesAnalysis of Full Depth Precast Concrete Bridge Deck PanelsMedi EyobNo ratings yet

- Bridge EngineeringDocument139 pagesBridge Engineeringmurad alahdalNo ratings yet

- Precast Segmental ApproachStrForSutongBridgeDocument9 pagesPrecast Segmental ApproachStrForSutongBridgeJayaraman RathnamNo ratings yet

- BridgeDocument12 pagesBridgeIAhoeNo ratings yet

- Sutong Bridge FoundationsDocument16 pagesSutong Bridge FoundationsDimitris PantelakisNo ratings yet

- Sutong BridgeDocument8 pagesSutong BridgeDhindeM100% (1)

- The Design of Langqi Min River Bridge, Fuzhou, China: Min Zhang Tianbo Wan Yingliang WangDocument6 pagesThe Design of Langqi Min River Bridge, Fuzhou, China: Min Zhang Tianbo Wan Yingliang WangmasteriragaNo ratings yet

- Gba 0809 QLD RoadsDocument11 pagesGba 0809 QLD RoadsJimmy Villca SainzNo ratings yet

- Triangular Pile Cap StructvilleDocument13 pagesTriangular Pile Cap Structvillemanoj_mousamNo ratings yet

- 2700 0 29 6 137 Rectangular Column (Reinf. On 2 Sides) : Short Column Slender ColumnDocument1 page2700 0 29 6 137 Rectangular Column (Reinf. On 2 Sides) : Short Column Slender Columnmanoj_mousamNo ratings yet

- Floor Vibration - Machinery Input Data:-WmachineDocument2 pagesFloor Vibration - Machinery Input Data:-Wmachinemanoj_mousamNo ratings yet

- Simply Supported Beam With UDL Simply Supported Beam With Point LoadDocument2 pagesSimply Supported Beam With UDL Simply Supported Beam With Point Loadmanoj_mousamNo ratings yet

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Document19 pagesACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014manoj_mousamNo ratings yet

- Column DesignDocument1 pageColumn Designmanoj_mousamNo ratings yet

- Design of 3-Cell Box Culvert: 1. Base Pressure CheckDocument2 pagesDesign of 3-Cell Box Culvert: 1. Base Pressure Checkmanoj_mousam67% (3)

- Section 3.5: Design Calculation of ColumnDocument2 pagesSection 3.5: Design Calculation of Columnmanoj_mousamNo ratings yet

- Construction Design Report Project: Hanoi Pilot Light Metro Line Section Nhon - Hanoi Railway StationDocument26 pagesConstruction Design Report Project: Hanoi Pilot Light Metro Line Section Nhon - Hanoi Railway StationXuannguyen1001No ratings yet

- Thermal Spray Coating Procection Steel PilingDocument169 pagesThermal Spray Coating Procection Steel Pilingdevancdm100% (1)

- Piling in Ireland Current PracticesDocument35 pagesPiling in Ireland Current Practicesthakrarhits100% (1)

- Building Control ActDocument73 pagesBuilding Control ActzixiangNo ratings yet

- Rebar Arrangement and Construction CarryoutDocument113 pagesRebar Arrangement and Construction CarryoutSamitha Harshani88% (8)

- Design of Monopile Foundation For Offshore Wind TurbineDocument7 pagesDesign of Monopile Foundation For Offshore Wind TurbineAbdullah Kürşat DemirNo ratings yet

- 281 Design and Installation of Micropiles and Ground Anchors For OHL Support FoudationsDocument67 pages281 Design and Installation of Micropiles and Ground Anchors For OHL Support FoudationsNaomi PurbaNo ratings yet

- Technical Journal: Plan Design EnableDocument16 pagesTechnical Journal: Plan Design EnableAkshay SakhujaNo ratings yet

- VSL Catalogue For Stressbars - 2012Document18 pagesVSL Catalogue For Stressbars - 2012Khoa Lê ViếtNo ratings yet

- LVS 1046 - 2017 - EngDocument41 pagesLVS 1046 - 2017 - EngAlekh HazarikaNo ratings yet

- AUST Civil SyllabusDocument33 pagesAUST Civil Syllabusmurad_ceNo ratings yet

- Ce2033 Ground Improvement Techniques L T P CDocument2 pagesCe2033 Ground Improvement Techniques L T P Camma832No ratings yet

- Method Statement For Micropiling Works-Jbt. Kedua Sg. YongDocument2 pagesMethod Statement For Micropiling Works-Jbt. Kedua Sg. YongKelvin LauNo ratings yet

- Sheeting Structure Verification Input DataDocument26 pagesSheeting Structure Verification Input DataanonimusazNo ratings yet

- Construction Methology and Requirements For Bored Piling WorksDocument2 pagesConstruction Methology and Requirements For Bored Piling WorksREYNo ratings yet

- 1 (CCE.M) 1: Total No. of Printed Pages: 8 Roll No. ...........................Document4 pages1 (CCE.M) 1: Total No. of Printed Pages: 8 Roll No. ...........................TarunNo ratings yet

- Optimized Skid Design For Compressor PackagesDocument9 pagesOptimized Skid Design For Compressor PackagesjdfdfererNo ratings yet

- Shallow Foundation Deep FoundationDocument39 pagesShallow Foundation Deep FoundationBmssa 2017BNo ratings yet

- Bridge Detailing Guide Taxes DoT (April 2022)Document578 pagesBridge Detailing Guide Taxes DoT (April 2022)farhanNo ratings yet

- Gate Way BoqDocument5 pagesGate Way BoqSothea BornNo ratings yet

- Lateral Load PileDocument21 pagesLateral Load PileCarlos FilipusNo ratings yet

- BHT 2cDocument54 pagesBHT 2chailuNo ratings yet

- 2022 - 12 - 29 - JN - Main HT Panel Foundation GA & Details - R4 - ApprovedDocument1 page2022 - 12 - 29 - JN - Main HT Panel Foundation GA & Details - R4 - ApprovedHemal PatelNo ratings yet

- Design and Construction of Excavation Works For Klang Valley Mass Rapid Transit Underground Station at Cochrane, Kuala Lumpur, MalaysiaDocument4 pagesDesign and Construction of Excavation Works For Klang Valley Mass Rapid Transit Underground Station at Cochrane, Kuala Lumpur, Malaysiajinwook75No ratings yet

- Guidelines For Offshore Wind Farm Infrastructure InstallationDocument52 pagesGuidelines For Offshore Wind Farm Infrastructure InstallationBooraj Duraisamy100% (3)

- Safety Concept in Codified Design of Piled Raft Foundation: NtroductionDocument10 pagesSafety Concept in Codified Design of Piled Raft Foundation: NtroductionNadim527No ratings yet

- Pullout TestDocument3 pagesPullout TestAvinash Lal100% (1)

- ACI 336.2R-88 R02 Suggested Analysis and Design Procedures For Combined Footings and Mats - MyCivil - IrDocument11 pagesACI 336.2R-88 R02 Suggested Analysis and Design Procedures For Combined Footings and Mats - MyCivil - IrRenjith S AnandNo ratings yet

- Dimensional Solutions Mat3DDocument32 pagesDimensional Solutions Mat3DpravinNo ratings yet