Ign Timing 101

Ign Timing 101

Uploaded by

jeivolCopyright:

Available Formats

Ign Timing 101

Ign Timing 101

Uploaded by

jeivolCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ign Timing 101

Ign Timing 101

Uploaded by

jeivolCopyright:

Available Formats

Ignition Timing 101 Getting Beyond the 009

Part I: Ignition Theory and Distributor Operation

best ones for your application.You may have also taken great care in properly jetting and adjusting your induction system,whether its a single carb,dual carbs or fuel injection.Then,to top it off,its likely that you slapped on a cheap, easy, clean-looking and nearly ubiquitously recommended 009 distributor.

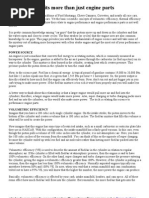

Too good to be true? You bet. It works, but it is not the greatest thing, especially for a street car. The lack of performance is not limited to applications using the Solex PICT-34/3. Although not commonly known, it is cheap and not too difficult to set up a proper distributor for your modified engine. However, to understand what to do requires a little bit of reading. Unfortunately, I have not found much definitive literature on the subject in the aircooled VW realm. I hope that this series of tech articles will begin to erase the great fallacy: The 009 is best for all engines. This article will focus on ignition timing theory and give you a good background on understanding timing needs of an engine. restricted to VWs. In fact, every reciprocating engine is based on the same theory, and if you look under the hood of most nonengine management cars, youll find the same mechanisms Im describing. What do we Here is a centrifugal advance want from our mechanism. Note how the weight assembly splits the spark plug? Well, upper and lower halves. wed like the spark plug to start a flame front across the highly explosive fuel mixture in the On the left, the weights are all cylinder. the way in, like at idle speed. On the right, the weights have But, when pulled out, like at high RPM. should this hapNote the change in the pen? Its not as angleif you were precise simple as more and measured it, then doubled the difference, youd find advance is more the difference in timing from power, but you idle speed to high RPM. IGNITION BASICS run hotter and First, I am not going to delve more retarding is deeply into technical stuff. Ill give a simplified less power, but you run cooler. explanation to give you a basic understanding. This flame front is similar to a Also, note that except for the VW-specific comwave moving outward from a pebble dropped ments, this discussion of ignition timing is not in a pond. We want this wave to gently press the

STORY AND PHOTOGRAPHY BY SHAD LAWS

piston downward. So, we want the spark plug to spark at the right time so the flame front it creates meets the piston on its downward stroke at the right time to cause a gentle push. If we spark too soon (too advanced), the flame front will reach the piston crown too soon, causing damage to the piston crown and unwanted reverberations because of the wave reflecting in the cylinder. This is pinging and its a great way to lose power and destroy your engine. If we fire too late (too retarded), the waves push on the piston is not as strong. This will cause the piston to move, but not as effectively, reducing the potential power output and therefore thermal efficiency (i.e. amount of work done per amount of energy liberated by burning fuel). Although being slightly retarded is mostly innocuous, being a great deal retarded reduces power, increases fuel consumption, causes hesitation and contributes to the incomplete combustion of the fuel mixture. How do we measure the ignition timing? We measure it by the position of the crankshaft at the start of the spark in cylinder No. 1 in relation to TDC. The number of crankshaft degrees before TDC is called the amount of advance. Retarding is the opposite of advancing. So, if the spark plug for cylinder No. 1 fires 8 degrees before TDC, we say it is advanced 8 degrees. If it fires 5 degrees after TDC, we say that it is 5 degrees retarded. As youll see, this convention was adapted because of the operation of a distributor.

ouve decided to build or modify an aircooledVW engine so that it no longer has a stock configuration.While doing so,youve probably given yourself a basic education on many different engine components to choose the

Courtesy of

VW Trends

March 2001

FACTORS THAT EFFECT TIMING

Ignition timing isnt a constant. Engine temperature, mixture temperature, mixture composition, engine speed and current volumetric efficiency effect when this spark should happen to get maximum performance. Volumetric efficiency (VE) is the amount of mixture drawn in during the intake stroke as compared to the displacement of the cylinder.

Here are the qualitative plots of what our approximations look like.

When 200cc worth of mixture under normal conditions in a cylinder with a swept volume of 400cc (like a 1600), the VE is 50 percent. In other words, this means LOAD, as a throttle at less than WOT (wide-open throttle) does an excellent job of reducing VE. Likewise, for you turbo buffs, you can think of boost as a way to increase VE beyond 100 percent, giving you a high load. Controlling timing on a constantly running, constant-speed, constant-throttle engine is simple, it gets a bit harder for a typical automotive engine. Now, how does each of the factors I listed effect timing? Leaner mixtures and high temperatures cause the wave to move faster, therefore, they need less advance. Common belief dictates that VW advanced cylinder No. 3 is 4 degrees less than the others on some cars to keep No. 3 cool. This isnt quite truethey did it to keep a hot No. 3 from pinging on long hauls.

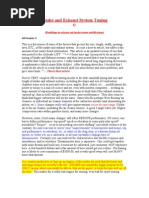

The biggest two influences on ignition timfiguring an aircooled VW engine. ing are engine speed and load. Not only is timWe are approximating this timing. If we go ing highly dependent on these conditions, but too retarded, we reduce power and consume a the conditions themselves are constantly more fuel. If we go too advanced, we reduce changing! Determination of the exact timing is power and destroy the engine. The perfora difficult task, which typically requires a labomance difference between dead-on accurate ratory and many tests to get perfect. and a couple of degrees retarded from the ideal However, good approximations are often is nearly negligible. adequate enough. Here is the set of approximations well use for engine speed: As engine PROPER MECHANICAL IGNITION TRIGGERING speed increases, so does advance. Then, at some engine speed, advance levels off and Mechanical control revolves around the use remains constant. of a distributor. In a distributor, a shaft spinning Our approximation for desired timing with at 1/2 the speed of the crankshaft has a rotor engine load (or current VE) is as follows: At idle on it that carries the spark current from the censpeed, we dont want much advance. As you ter of the rotor to the outer edge, whose varymove off idle, wed like advance to increase ing position serves to distribute the spark cursomewhat steeply to a point and level off. Then, rent to the proper spark plug. as load increases beyond the The rotor doesnt have anymid-range, we want advance to OK,now for a brief disthing to do with triggering the die back down, so that near WOT cussion on fluid (i.e. liqspark and one distributor it has returns to where it was at uid or gas) flow. Fluid degree equals two crankshaft idle. flow from one place to degrees. These two things dont change another is highly depenThe triggering is accomindependently, but simultanedent on the pressure difplished by other means inside ously. When approximating, we ference between the two the distributor. Two methods are can think of the contributions to places. When the intake magnets and points. For points, advance these factors give as sepvalve opens, the cylinder the shaft of the distributor has arate, with the total of advance pressure is quite low.If the cam lobes one for each cylinbeing the sum of the two. pressure of the manifold der. Then, the points ride on the AN OVERVIEW: TWO is also relatively low,there shaft, and when a cam lobe TYPES OF IGNITION CON- isnt much flow into the comes along, it opens the conTROL cylinders and you have a tacts, signaling the coil to release For relatively modern multilow VE. How is the presits charge that the rotor then ple-cylinder automobiles, there sure of the manifold conassigns to the proper cylinder. I are two main types of ignition trolled? When the throttle wont go into detail on the eleccontrol: mechanical and elecis nearly closed, the prestric theory behind points, but tronic. Electronic is more sure of the manifold is you should know that they also advanced, accurate and often quite low. require a condensor, regular includes a knock sensor to detect So, does it make sense adjustment and/or replacethe onset of pinging, i.e. they can that manifold pressure ment, and are subject to failure. be closed-loop systems. A system can be seen as a measure Hall effect sensors are much incorporating this type of control of load? Low pressure = betterthey use magnets that is typically paired with a closedlow load and high presspin on the shaft of the distribloop fuel injection system and sure = high load. utor over a sensor to trigger the they are collectively called an spark. These require no mainteengine management system. nance, minimal adjustment and rarely fail. A I will focus on the former methodmechanfew companies make points replacement units. ical control. Mechanical control uses non-elecThe end result is that both contact points and tronic means to alter ignition timing based on hall effect sensors serve the same functionto some approximations. Do not confuse this with send a signal to the rest of the ignition system the term mechanical-only distributor, which to fire. Both are dependent on the relationship is a misnomer commonly used to describe a between the distributor shaft and the points/ distributor like the 009 that lacks vacuum module. advance. This is the method to use when con-

Courtesy of

VW Trends

March 2001

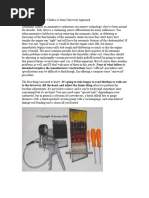

ALTERING WHEN TRIGGERING OCCURS

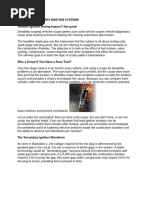

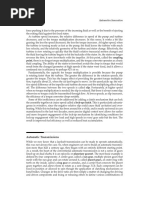

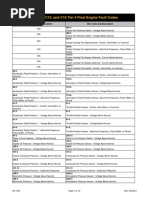

For a four-cylinder engine, you put the lobes or magnets 90 degrees apart and theyll trigger the spark for each cylinder. Now, These are different vacuum canisters, from left, a late model dual vacuum unit, a by altering the relationship late model single vacuum unit and a 36-hp fully adjustable single vacuum unit. between the sensing unit and the A close up of a 36-hp fully adjustable single vacuum canister. Note how maximum shaft, you can change when this SUMMARY vacuum advance is controlledthe nut on the arm only allows the arm to move spark happens! This is how to Ignition timing is dependent on so far before hitting the canister. control ignition timing. the relationship between the top How do we use this? If we have a springAn old Model A has a control on the steering half of the shaft and the points/module. Cenloaded diaphragm with ambient pressure on column to change this relationship manually. trifugal weights twist the top half of the shaft one side and this sensed pressure on the other, Along came the idea of using a centrifugal forward so they trigger the points/module it will push against the spring as the sensed system of weights and springs. The shaft of the soonerthis causes more advance for a highpressure decreases. Now, put an arm on this distributor was broken into an upper half, which er rpm. diaphragm and have it move the triggering controlled timing, and the lower half, which was A vacuum advance canister has an arm that mechanism in the distributor controlled by the speed of the moves the position of the points/module itself to advance more when it sees a engine. At a lower speed, the backward so that it is triggered by the shaft Here are different types lower pressure. This is the basis springs hold the weights in and soonerthis causes more advance for low/mid of distributors: of a vacuum advance system, keep the relationship between the throttle. Does this make sense? If not, go look Centrifugal-only (or which was the second big two halves constant. As speed at the pictures or pop the cap off of a distributor incorrectly mechanicaldevelopment for mechanical increases, the weights move outand take a lookit really isnt complex once only): has centrifugal ignition timing control. As the ward, twisting the upper half of you get the hang of it. advance pressure to the port decreases, the shaft in relation to lower half. Now you should have a pretty good idea of Vacuum-only has vacthe arm pulls in until it hits a The amount of advance at this the timing needs of an engine, the conseuum advance stop. point is called the maximum quences for inadequate timing control, and SVDA:has both vacuum The points are mounted atop advance or total advance. Note how to get a pretty good mechanical approxiand centrifugal advance a pair of plates called the that this operation mimics our mation for timing using a distributor. Be sure (i.e. single vacuum, dual advance plates. The lower one approximation for engine speed to check out VW Trends next month when I put advance) is fixed to the distributor body exactly. Because proper ignition this knowledge to practice and show you how DVDA: has vacuum and the upper one floats atop timing was so dependent on to tune a stock Bosch distributor for modified advance, centrifugal the lower one. Attached to the engine speed, this centrifugal engines, resulting in greater (and cheaper) peradvance, and vacuum upper one is the points/ modadvance system was a help. formance than the off-the-shelf, poorly manretard (i.e. dual vacuum, ule and the arm from the vacuBut, what about load? ufactured 009. dual advance) um canister. Load is essentially the current From left, you One more thing to consider volumetric efficiency of the cylincan see how a vacuum retard. As the automotive industry ders, right? set of points is became more environmentally conscious, they How do we want to use this newly found opened by the cam lobes. Note quickly targeted deceleration. When you have a knowledge? Recall that wed like less advance the positioning somewhat high rpm and a closed throttle, your at idle, more advance at less load, and back to of the vacuum emissions are horrible. However, if you slow the less advance at high load. What if we sense the canister arm and closing of the throttle (those dashpot things on manifold pressure with a port positioned above the shaft and how moving the later Solex carbs) and retard the timing a the closed throttle plate, so that the opening of them would alter bit, emissions improve by a pretty good the plate makes the plate pass over the port? timing. An amount. (On a carburetor, this location is near the ports assembled late Well, when the throttle is closed and rpm is for the progression circuit.) At idle, the port model stock unit with a dual vacuhigh, manifold pressure is low. If we have a secwould see a pressure somewhat near ambient. um canister. An ond vacuum canister that takes its signal from Then, when the throttle opens a bit and passassembled below the throttle plate and has a large spring es over the port, the port is now nearer to man009 unit that lacks vaccum pre-load against the diaphragm, it will not kick ifold pressure and sees a low pressure. Also, advance. The last in until a very high manifold vacuum. since the air rushing through that small gap is distributor is not If we combine this setup with the advance going at a high velocity, it makes the vacuum advisable for a diaphragm into one unit, we have a dual vacsignal from the port greater. As throttle is street engine. uum canister. The arm on the canister pulls in opened further, the manifold pressure increasfor advance and pushes out for retard. es and the port sees a higher pressure. Next? In the April issue we will conclude with Part II, discussing several modifications of various VW distributors. 3 Courtesy of VW Trends March 2001

While the dashpot can be seen as disadvantageous to performance because of the loss of quick engine braking, the vacuum retard, in no way, shape or form harms the performance of your engine.

You might also like

- Paccar MX13 Service and Diagnostic 607 PáginasDocument607 pagesPaccar MX13 Service and Diagnostic 607 PáginasLUIS ALEJANDRO HURTADO QUIÑONES96% (50)

- Automotive Interview and ReviewerDocument20 pagesAutomotive Interview and ReviewerMichael Radan90% (10)

- Keihin CV Images and Diagrams - Tune UPDocument5 pagesKeihin CV Images and Diagrams - Tune UPНикола Карагьозов80% (5)

- Wartsila Tools Guide TCSPC PDFDocument159 pagesWartsila Tools Guide TCSPC PDFcengiz kutukcu50% (2)

- SPC Pulsar NS 160 EURO Single & Twin Disc (2019 01 31)Document89 pagesSPC Pulsar NS 160 EURO Single & Twin Disc (2019 01 31)Willy Mansilla A92% (13)

- EngineDocument83 pagesEngineAdolfo FuentealbaNo ratings yet

- ECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) InformationDocument4 pagesECM-641A Camshaft Control, Exhaust. Faulty Signal, B5254T2: Diagnostic Trouble Code (DTC) Informationapek1No ratings yet

- StatictimingDocument6 pagesStatictimingapi-232489155No ratings yet

- Catalogo de Peças d6kDocument933 pagesCatalogo de Peças d6kVictor Maia83% (6)

- Citaro CNGDocument12 pagesCitaro CNGPhilippine Bus Enthusiasts SocietyNo ratings yet

- A Brief Introduction To Automobile EngineeringDocument67 pagesA Brief Introduction To Automobile EngineeringSantanu ChakrabortyNo ratings yet

- Timing 101Document5 pagesTiming 101Juan MonNo ratings yet

- What Happens If Ignition Timing Is Too AdvancedDocument2 pagesWhat Happens If Ignition Timing Is Too Advancedayush shrotriya0% (1)

- Basic Spark Advance TableDocument9 pagesBasic Spark Advance Tablek07800702123No ratings yet

- Everyth Ing Flows Everyth Ing FlowsDocument3 pagesEveryth Ing Flows Everyth Ing FlowsDarwin FarinangoNo ratings yet

- Spark AdvanceDocument9 pagesSpark Advanceblackmailer hackNo ratings yet

- Camshaft AdvanceDocument5 pagesCamshaft Advancejameel babooramNo ratings yet

- Notes On Camshaft Selection - Gary LewisDocument4 pagesNotes On Camshaft Selection - Gary Lewisgaragepunkfan100% (3)

- Chain Saw GuideDocument22 pagesChain Saw GuideJoanne MowatNo ratings yet

- Afc TuningDocument4 pagesAfc TuningApril ChristopherNo ratings yet

- 1 SCOPING SECONDARY IGNITION SYSTEMSDocument11 pages1 SCOPING SECONDARY IGNITION SYSTEMSStylianos MetaxsNo ratings yet

- Choosing The Perfect Performance CamshaftDocument9 pagesChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Intake and Exhaust System TuningDocument15 pagesIntake and Exhaust System TuningAmir Izham100% (1)

- Valvetrain 101 - Education On The Engine Components and How They WorkDocument6 pagesValvetrain 101 - Education On The Engine Components and How They Workgiuseppe mazzeoNo ratings yet

- Technical: Engine Blueprinting 101 - Part OneDocument4 pagesTechnical: Engine Blueprinting 101 - Part OneJimmy ChaffaNo ratings yet

- TOPIC 3 -Fuel Induction and Ignition SystemDocument16 pagesTOPIC 3 -Fuel Induction and Ignition SystemesmamhossainemonNo ratings yet

- Automobile Electric IgnitionDocument35 pagesAutomobile Electric IgnitionPM50% (2)

- Abdul Samad Bin Abdullah (50216118377)Document5 pagesAbdul Samad Bin Abdullah (50216118377)Abdul SamadNo ratings yet

- Electronic Circuit For A Delphi Direct Fuel Injection System - Initial Approach - Malc's Blog PDFDocument9 pagesElectronic Circuit For A Delphi Direct Fuel Injection System - Initial Approach - Malc's Blog PDFMichael DavenportNo ratings yet

- E85 Tuning Tips1Document5 pagesE85 Tuning Tips1jameel babooramNo ratings yet

- Mpfi ManualDocument11 pagesMpfi ManualBalRam DhimanNo ratings yet

- MEO Class 2 Orals Function 4 & 6 Q & ADocument8 pagesMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- Rod Ratio KinematicsDocument6 pagesRod Ratio KinematicsJameel KhanNo ratings yet

- Exhaust ScavengingDocument6 pagesExhaust Scavengingtejashraj93No ratings yet

- Seaspan 3rd Engineer OralsDocument7 pagesSeaspan 3rd Engineer OralsVihanga VithanageNo ratings yet

- COMP Cams Valve Timing TutorialDocument3 pagesCOMP Cams Valve Timing TutorialJameel KhanNo ratings yet

- Harmonic Analysis of The Cam ShaftDocument3 pagesHarmonic Analysis of The Cam ShaftramsastryNo ratings yet

- Vibrator IGN 52Document20 pagesVibrator IGN 52KleberNo ratings yet

- AutoSpeed - Modifying Electric Power SteeringDocument6 pagesAutoSpeed - Modifying Electric Power SteeringgoundenaNo ratings yet

- Basic Introduction To TurbochargingDocument6 pagesBasic Introduction To TurbochargingAngelino Martini de LeonNo ratings yet

- Ignition Timing Explained - Timing An Unknown EngineDocument5 pagesIgnition Timing Explained - Timing An Unknown EngineMohsin Munawar100% (1)

- Kereta - Tuning Made Easy - Cars TuningDocument19 pagesKereta - Tuning Made Easy - Cars TuningemranosmanNo ratings yet

- Vacuum TestingDocument3 pagesVacuum TestingAnwar RamoNo ratings yet

- Brake CalculationsDocument15 pagesBrake CalculationsSaravanan Saran100% (2)

- AnalisticsDocument17 pagesAnalisticsWASSAABNo ratings yet

- Be The Camshaft ExpertDocument21 pagesBe The Camshaft ExpertRenan100% (1)

- Exit Guide Vanes of Gas TurbinesDocument7 pagesExit Guide Vanes of Gas TurbinesMuhammad Usman100% (1)

- Honda: Four-Stroke Internal Combustion EngineDocument10 pagesHonda: Four-Stroke Internal Combustion EnginetumimurNo ratings yet

- Automobile Ignition SystemDocument14 pagesAutomobile Ignition Systembalunkeswar ranaNo ratings yet

- Automatic TransmissionsDocument1 pageAutomatic Transmissionspkjhan1353No ratings yet

- Vacuum Gauge ExplorationDocument4 pagesVacuum Gauge ExplorationابوفاطمةاليساريNo ratings yet

- Tuning With Ve Volumetric EfficiencyDocument6 pagesTuning With Ve Volumetric EfficiencytcmracingNo ratings yet

- EdyJun Lemmiwinks For DummiesDocument9 pagesEdyJun Lemmiwinks For DummiesvijaydhandaNo ratings yet

- Final Draft Definition and - DescriptionDocument5 pagesFinal Draft Definition and - Descriptionswm5376No ratings yet

- Carburetor Tuning: Understanding CarburetionDocument11 pagesCarburetor Tuning: Understanding CarburetionMuhammad Rashid Jaidon ⎝⏠⏝⏠⎠80% (5)

- Auto Ignition System IntroDocument6 pagesAuto Ignition System IntroAustin BruceNo ratings yet

- Engine Science Its More Than Just Engine PartsDocument6 pagesEngine Science Its More Than Just Engine Partshsingh1990No ratings yet

- Tuning The DSM ECUDocument5 pagesTuning The DSM ECUccatlett1984No ratings yet

- A7 Ignition TimingDocument2 pagesA7 Ignition Timingswtdczj2c2No ratings yet

- Governing of Impulse TurbinesDocument3 pagesGoverning of Impulse TurbinesRich100% (3)

- Engine Value and PerformanceDocument5 pagesEngine Value and PerformanceM Umar ChatthaNo ratings yet

- Mechanical Interview QuestionsDocument30 pagesMechanical Interview Questionsamurugan_22No ratings yet

- 2.igniion SystemDocument42 pages2.igniion SystemMajaz AhmedNo ratings yet

- Carb AdjustmentDocument22 pagesCarb Adjustmentleleva13No ratings yet

- Counterp v7 I2 20031Document4 pagesCounterp v7 I2 20031Mauricio GarciaNo ratings yet

- How Automobile Ignition Systems WorkDocument13 pagesHow Automobile Ignition Systems WorkAbhishek DixitNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- NEF45SM1A.S500 Exploded Views (D66IST)Document17 pagesNEF45SM1A.S500 Exploded Views (D66IST)Daniel MuratallaNo ratings yet

- Seminar Application of Nitrous Oxide in AutomobilesDocument20 pagesSeminar Application of Nitrous Oxide in AutomobilesSaikat BadyakarNo ratings yet

- EdyJun Lemmiwinks For DummiesDocument9 pagesEdyJun Lemmiwinks For DummiesvijaydhandaNo ratings yet

- CAT C13, C15, and C18 Tier 4 Final Engine Fault CodesDocument14 pagesCAT C13, C15, and C18 Tier 4 Final Engine Fault CodesDamatNo ratings yet

- Troubleshooting Fuel Dilution of Engine Oil PDFDocument2 pagesTroubleshooting Fuel Dilution of Engine Oil PDFmanu luvungaNo ratings yet

- Perkins Update Katalog Agg & TideDocument4 pagesPerkins Update Katalog Agg & Tidehafid CJSPNo ratings yet

- 04 Engine ElectricalDocument39 pages04 Engine ElectricalFernando LedezmaNo ratings yet

- Pulsarns150as150 PDFDocument81 pagesPulsarns150as150 PDFBihan FernandoNo ratings yet

- Cross-Reference Information For Diagnostic CodesDocument9 pagesCross-Reference Information For Diagnostic CodesEdwin Alfonso Hernandez MontesNo ratings yet

- Repartitia Temelor de Casa PMRDocument3 pagesRepartitia Temelor de Casa PMRVlad SibiceanuNo ratings yet

- 2009 Mopar Perfomance PDFDocument351 pages2009 Mopar Perfomance PDFmacNo ratings yet

- 2252-1 Válvula de RetornoDocument2 pages2252-1 Válvula de RetornomjdeleoncNo ratings yet

- Design and Analysis of Chassis and Spring of A Load-Bearing TricycleDocument6 pagesDesign and Analysis of Chassis and Spring of A Load-Bearing TricycleMadhurjya DasNo ratings yet

- USE THIS PinVoltageChartsDocument9 pagesUSE THIS PinVoltageChartsPablo B. SoaresNo ratings yet

- M300-V 3001 Up Parts ManualDocument582 pagesM300-V 3001 Up Parts ManualCarlos ReyesNo ratings yet

- Nepal AirlinesDocument4 pagesNepal AirlinesAadarsh bhandariNo ratings yet

- Manual de Operacion Generador Multiquip DA7000SSA2 - SSA2GHDocument160 pagesManual de Operacion Generador Multiquip DA7000SSA2 - SSA2GHAlejandro Antonio Alvarez Balvero100% (1)

- SM 3TNV-4TNV-Yanmar EN PDFDocument216 pagesSM 3TNV-4TNV-Yanmar EN PDFjulianmataNo ratings yet

- Walkaround Exhaust Engine Brake Disadvantages: ClassicalDocument8 pagesWalkaround Exhaust Engine Brake Disadvantages: ClassicalBroCactusNo ratings yet

- Esquema Eléctrico - Motor C9.3Document11 pagesEsquema Eléctrico - Motor C9.3DavidNo ratings yet

- Catalog ZP Yamaha E55C-55BDocument77 pagesCatalog ZP Yamaha E55C-55BViktorNo ratings yet

- Mechanical EngineeringDocument19 pagesMechanical EngineeringhenoksolNo ratings yet