Indirect Fired Heater

Indirect Fired Heater

Uploaded by

Joshua CollierCopyright:

Available Formats

Indirect Fired Heater

Indirect Fired Heater

Uploaded by

Joshua CollierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Indirect Fired Heater

Indirect Fired Heater

Uploaded by

Joshua CollierCopyright:

Available Formats

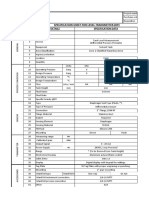

INDIRECT HEATER SPECIFICATION SHEET

Project Number : Revision: Customer Location FLUID TO BE HEATED TOTAL FLUID ENTERING Gas Flow Rate LIQUID - Water LIQUID - Condensate Oil Gas Temperature Gas Density/Spec. Grav. Liquid Water Density o Oil Density/ API/Sp. Gr. Gas Viscosity Liquid Water Viscosity Oil Viscosity Water Therm Conductivity Oil Therm Conductivity Oil Specific Heat Water Specific Heat A

THERMAL DESIGN Well Head Natural Gas

INLET 5.00 40.00 2.5 100 0.6 1 52 OUTLET 5.00 40.00 2.5 100 0.6 1 52 Gas Coils Data: Intermediate Choke Post Choke Temperature Choke Inlet Pressure Pressure Drop (allowable) Type of Fuel LHV / HHV of Fuel Bath Medium Design Bath Temperature

MMScfd Bpd Bpd o F Sp. Grav. Sp. Grav. oAPI Centipoises Centipoises Centipoises Btu/Hr-Ft2/oF Btu/Hr-Ft2/oF Btu/Lb-oF Btu/Lb-oF

Yes o F 80 1,000 Psig 750 Psi Natural Gas 980 Btu/Scf Water+Ethylene Glylcol o F 190

MECHANICAL DESIGN Design Pressure: First Coil Pressure Second Coil Pressure Design Temperature: First Coil Inlet Temp. Second Inlet Coil Temp Crossion Allowance Design Code (ASME, API, DOT) ENVIRONMENTAL DESIGN Allowable Noise Allowable Emissions: NOX CO2 HydroCarbons H2S BURNER TYPE Yes No

6,170 Psig 6,170 Psig

o F 100 o F 80 0.250 inch. ASME

85

dba Lb/hr Lb/hr Lb/hr Lb/hr

ELECTRICAL DESIGN / AREA CLASSIFICATION Power Available: Voltage N/A Phase N/A Hertz N/A Area Classification: Class II Division 2 Group D Temperature T4A CIVIL DESIGN Elevation, ASL Unk. feet Ambient Temperature Wind Speed OnShore / OffShore Seismic Zone 95 - 110 100 OnShore 4

o

F Mph (0 - 4)

Natural Draft Forced Draft

Skid Mounted Stack Type Control Type

MISCELLANEOUS Yes Ell Pneumatic

ACCESSORIES Standard Supply Custom Design Options: Bath Low Level Switch Fuel Meter Stack High Temp Switch Flame Arrestor

No Yes Yes Yes Yes Yes Page 1 of 2

CONTROL PANEL Required Yes NEC / NEMA Rating Type Ignitor Yes Burner Management Unkn. PLC w/B.M. & Temp Control Unkn. PLC W/ DCS Communications Unkn.

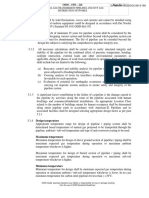

In-Line Heater Sketch:

Gas inlet

E

B

Gas outlet

C D G

Nozzles' Schedule:

A B C D E F G H I J Wellhead Gas Inlet Gas Outlet Fuel gas inlet Fuel gas outlet Temperature Indicator Water bath Fill Drain Thermostat Choke inlet Choke outlet Size 4" 4" 2" 2" " Unk. 2" " 4" 4" Facing Raised Face Raised Face Raised Face Raised Face N/A N/A N/A N/A Raised Face Raised Face Type Flanged Flanged Flanged Flanged Screwed N/A Screwed Screwed Flanged Flanged Class 2500 # 150 # 150 # 150 # 3000 # N/A 150 # 3000 # 2500 # 150 #

ADDITIONAL NOTES: 1. All process coils are to be removable 2. Designer / Fabricator to state max. design heating Flux on fire tube 3. Unit to be skid mounted and complete for field installation and hook up. 4.Unit shall have pre-piped ability to be flow by-passed with exception that built in heater choke shall remain in service. 5. Heater Choke valve shall be Long-nose (if possible) adjustable choke (manual handwheel). 6. Heater shell shall be insulated and protected by corrugated metal 7. Heater will have auxilliary coil for heating fuel and instrument natural gas

Page 2 of 2

You might also like

- Htri B51GUHXEReport PDFDocument42 pagesHtri B51GUHXEReport PDFjesus_manrique2753No ratings yet

- Air Cooled Heat Exchanger CourseDocument2 pagesAir Cooled Heat Exchanger Courserodrigoperezsimone100% (1)

- Smith Industries WaterBath Indirect Heater PDFDocument29 pagesSmith Industries WaterBath Indirect Heater PDFcassindromeNo ratings yet

- Data Sheet Indirect Fired Heater NapkjsDocument12 pagesData Sheet Indirect Fired Heater Napkjsahmad santosoNo ratings yet

- Indirect Fired HeaterDocument3 pagesIndirect Fired Heatermatteo2009No ratings yet

- QB Johnson Water Bath HeaterDocument3 pagesQB Johnson Water Bath HeaterSantosh AdadaNo ratings yet

- Effect of Various Parameters On Indirect Fired Water Bath Heaters' Efficiency To Reduce Energy LossesDocument8 pagesEffect of Various Parameters On Indirect Fired Water Bath Heaters' Efficiency To Reduce Energy LossesInternational Journal of Science and Engineering Investigations100% (1)

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresNo ratings yet

- Thermal Design Well Head Natural GasDocument3 pagesThermal Design Well Head Natural GaskodeesNo ratings yet

- Tema Style HX DatasheetDocument1 pageTema Style HX Datasheet404FileNotFoundNo ratings yet

- Water Bath HeaterDocument3 pagesWater Bath Heaterbinhlam_dlNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- Cascade Data Sheet PDFDocument28 pagesCascade Data Sheet PDFvisutsiNo ratings yet

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- Relief Valve CalculationsDocument9 pagesRelief Valve CalculationssegunoyesNo ratings yet

- Calculation and Design of Separators (VS)Document18 pagesCalculation and Design of Separators (VS)Bhuran Akshay100% (1)

- Double Pipe Heat Exchanger Design - ChE GuideDocument6 pagesDouble Pipe Heat Exchanger Design - ChE GuideNastaran BagheriNo ratings yet

- 40863-001 Calc - Inline Heater PDFDocument3 pages40863-001 Calc - Inline Heater PDFomar equihua0% (1)

- CAMERON Indirect HeatingDocument4 pagesCAMERON Indirect Heatingأصلان أصلان100% (1)

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- Induction Water Bath HeaterDocument2 pagesInduction Water Bath Heatermahboob_qayyum100% (2)

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- M07 PDFDocument48 pagesM07 PDFAdrian GuzmanNo ratings yet

- PE-D-ln10-422.002-PS-DAS-002-D0-E WTIS - DATA SHEET FOR CLOSED DRAIN ...Document6 pagesPE-D-ln10-422.002-PS-DAS-002-D0-E WTIS - DATA SHEET FOR CLOSED DRAIN ...widhisaputrawijayaNo ratings yet

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDocument3 pagesBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloNo ratings yet

- Sweetening ProcessDocument20 pagesSweetening ProcessMuhammad Sajid100% (1)

- Vacuum Insulated CO2Document13 pagesVacuum Insulated CO2dragosm78No ratings yet

- BPCL CGD Booster Compressor SpecsDocument82 pagesBPCL CGD Booster Compressor SpecsVMNo ratings yet

- High Performance Trays PDFDocument9 pagesHigh Performance Trays PDFAlan ChewNo ratings yet

- AX5 Vaporizer Electric Water Bath Type LPG VaporizerDocument2 pagesAX5 Vaporizer Electric Water Bath Type LPG VaporizerRicky DermawanNo ratings yet

- BDVDocument3 pagesBDVJason ThomasNo ratings yet

- 1 Temp MeasurementDocument26 pages1 Temp Measurementnarendra_nucleusNo ratings yet

- The Panhandle A and B Equations For Natural Gas Flow: ParametersDocument3 pagesThe Panhandle A and B Equations For Natural Gas Flow: Parametersbryandown0% (1)

- PSV Design-Practical Case StudyDocument10 pagesPSV Design-Practical Case StudyVishnuVarthan ImayavarambanNo ratings yet

- CGD Report 12Document63 pagesCGD Report 12Saurabh Dubey50% (2)

- Testing of Generic Differential Pressure Cone Meters To MPMS API 22.2Document21 pagesTesting of Generic Differential Pressure Cone Meters To MPMS API 22.2Philip A Lawrence EUR Ing , C.Eng. F. Inst M.C.No ratings yet

- Basics of High-Pressure Measuring and Regulating Station DesignDocument8 pagesBasics of High-Pressure Measuring and Regulating Station DesignMirling MirelesNo ratings yet

- Shell Entrance Area Calculation-R0Document2 pagesShell Entrance Area Calculation-R0nagtummalaNo ratings yet

- Process Storage Tank Lah & Lahh Level Calculation - 1551287770Document1 pageProcess Storage Tank Lah & Lahh Level Calculation - 1551287770wafaNo ratings yet

- Liquid Monopropellant CombustionDocument4 pagesLiquid Monopropellant Combustionherdi sutanto adigunaNo ratings yet

- Double - Pipe - Exchanger (Para o Lado Ar)Document4 pagesDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNo ratings yet

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- ESR0055024ACAL1004 0cDocument24 pagesESR0055024ACAL1004 0ckayaltharanNo ratings yet

- MySep Software Brochure PDFDocument7 pagesMySep Software Brochure PDFoverlord5555No ratings yet

- Foundation Option For LNG TanksDocument2 pagesFoundation Option For LNG TankssekarsanthanamNo ratings yet

- Dehydration Unit Sizing Chart - 12-13-13Document1 pageDehydration Unit Sizing Chart - 12-13-13Andres Crucetta100% (1)

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Dynamic Heat Transfer Analysis of Liquefied Natural Gas Ambient Air Vaporizer Under Frost ConditionsDocument9 pagesDynamic Heat Transfer Analysis of Liquefied Natural Gas Ambient Air Vaporizer Under Frost ConditionsabdoNo ratings yet

- Code Ref.Document155 pagesCode Ref.Selvakpm06No ratings yet

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDocument3 pagesBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNo ratings yet

- Engineering Services by KBR Technical Services, IncDocument12 pagesEngineering Services by KBR Technical Services, IncgfgfNo ratings yet

- EX Firetube Boiler Changed by Advances in Design TechnologyDocument7 pagesEX Firetube Boiler Changed by Advances in Design TechnologyXamir Suarez AlejandroNo ratings yet

- Ips - Indirect Fired HeatersDocument8 pagesIps - Indirect Fired HeatersjollyNo ratings yet

- Data Sheet Pressure Relief ValveDocument10 pagesData Sheet Pressure Relief ValveAnonymous UArnIExNo ratings yet

- LPG Compressor SpecsDocument11 pagesLPG Compressor SpecsabhishekNo ratings yet

- Process Presentation Shell and Tube Heat Exchanger GalfarDocument84 pagesProcess Presentation Shell and Tube Heat Exchanger GalfarKishore Sakhile100% (1)

- PIP Line ListDocument2 pagesPIP Line Listomgmatt100% (2)

- Refrigeration Process DataDocument2 pagesRefrigeration Process DataDavid LambertNo ratings yet

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument4 pagesChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallZoebairNo ratings yet