Welding Checklist 9195

Welding Checklist 9195

Uploaded by

Michael PenaCopyright:

Available Formats

Welding Checklist 9195

Welding Checklist 9195

Uploaded by

Michael PenaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Welding Checklist 9195

Welding Checklist 9195

Uploaded by

Michael PenaCopyright:

Available Formats

Date:

Inspector(s): Signature:

Job Title:

Chair:

THOMPSON RIVERS UNIVERSITY

WELDING HAZARD CHECKLIST

This list is not exhaustive and over time new hazards may come to be. The space at the bottom is for you to add your own identified hazards. Please notify the OH&S department so the checklist can be updated with these additions. Answering 'no' to any of the following questions indicates a need for corrective action to be taken.

PERSON DATE ACTION RESPONSIBLE COMPLETED FOR ACTION

YES 1. Hazard & Location

General safety are electrical safety procedures posted and enforced? Are protocols in place for PPE? Are there signs of safety rules posted? Is there adequate training? Are there any no food or drink signs? Is there an eyewash station located there? (272) Fumes (welding booths)-Is ventilation in the welding booths in good condition? Has ventilation system been tested within the last year? (272) Brake- Are the safety stickers posted? Is foot controls in good condition? Is there an ESD installed? Shear- Are there safety stickers posted? Are guards in place and in good condition? Is there an ESD installed? Are all guides in good condition? Is the mirror in good condition and positioned properly? (272)

NO

COMMENTS

1.

2.

3.

4.

Workplace Safety Inspection Checklist

YES

Drill Press - Are there safety stickers on the drill? Are guards in place? (272) Storage - Are all materials safely and properly stored? (272, outside) Grinder Is tool rest gap set correctly? What condition is the grinder stone in? Is a face shield provided? (272C) Floors- Are floors clean and free of grease and spills? Are all walkways clear? Gas cylinders-Are all gas cylinders clearly labeled? Are gas cylinders stored in a proper secure storage? Is MSDS available for all gas cylinders? Is there safety training and supervision? (272, outside) Cutting station- is safety training provided? Are all PPE used? (outside) Iron Worker- Are all guards in place and in good condition? (outside) Chop Saw- Are all required PPE used? Is wheel guard in place and in good condition? (outside) Belt Sander- Are safety stickers posted? Is the guard in place and in good condition? (outside) Roller- Is there safety training in the operation of the roller? (outside) Gantry Crane-Is there adequate training and supervision? Are safe work procedures in place? Has the crane been inspected within the last month? Is the crane inspected before use? Are wheel blocks used? (outside)

NO

COMMENTS

PERSON DATE ACTION RESPONSIBLE COMPLETED FOR ACTION

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Page 2

Workplace Safety Inspection Checklist

General Issues to Always Look For

Cords: Damaged extension cords, chains of extension cords, Male prong missing, proper wire size Lockouts: when doing work on any piece of power equipment, proper precautions must be taken to ensure the power source has been eliminated and locked out. If its just a matter of unplugging the cord from the wall, the individual doing the work must have a constant view of the unplugged cord. Safe work procedures: safe work procedures must be readily available at all times Spills: ensure anything spilled has been cleaned up to avoid slipping hazards and exposure, a procedure should be in place to remedy accidental spills Work benches: work space on benches should be adequate to work safely Walkways: designated walk ways and safety areas should be clearly marked Combustibles: a collection of combustible materials such as oil rags, cardboard or garbage should be eliminated Equipment: equipment used must be certified and in good working condition. Anything broken should be flagged and not used. PPE: requirement signs should be posted on doors to shops and requirements MUST be enforced Training: all students need to be trained on any safety issues and equipment they are expected to use. It is a good idea to also do a follow up refresher training mid term. Eyewash: eyewashes should be flushed often to avoid dirt build up and to ensure they are working adequately Distraction: it is crucial to ensure students are totally focused on their tasks. All distractions should be avoided. Containers: any container that holds chemicals MUST be properly labeled and stored High hazard areas should be clearly marked and identified, either with signs or floor taping A program for servicing and preventive maintenance should be in place Signs: relevant warning signs relating to ALL workshop hazards should be displayed Waste: waste materials should be stored appropriately, and a procedure should be in place to legally dispose of the waste Housekeeping if upon inspection you notice that lighting is not adequate, doors dont close properly, or something is damaged, make note of it to ensure the right people are informed Clutter walkways, doorways and places where hazardous materials are stored should be free of clutter to avoid trips etc

Page 3

You might also like

- TLB Daily ChecklistDocument1 pageTLB Daily ChecklistDuvan Bence100% (1)

- Ladder Inspection ChecklistDocument1 pageLadder Inspection ChecklistzulfactNo ratings yet

- Portable Electrical Equipment Register and InspectionDocument1 pagePortable Electrical Equipment Register and Inspectionsalman100% (2)

- Forklift Safety Policy and ProcedureDocument3 pagesForklift Safety Policy and ProcedureChristian Auditor Rivera100% (4)

- Backhoe ChecklistDocument1 pageBackhoe ChecklistSajid Hussain100% (1)

- Safety Audit ChecklistDocument20 pagesSafety Audit ChecklistDeep Narayan Jaiswal0% (1)

- Truck Load-Out ChecklistDocument3 pagesTruck Load-Out ChecklistIsaac Anthony100% (2)

- 07 Hand Tool RegisterDocument1 page07 Hand Tool RegisterZodwaNo ratings yet

- Emergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTDocument3 pagesEmergency Response Plan Tank Cleaning: - Safety & SPV - Safety & Ert PTSyifa Ula HamidyaNo ratings yet

- Hand Tool ChecklistDocument1 pageHand Tool Checklistsivasri999100% (1)

- Weekly Hazardous Waste Inspection Checklist PDFDocument1 pageWeekly Hazardous Waste Inspection Checklist PDFOM SUTARNo ratings yet

- Tool Box Talk - 8 Lifting EquipmentDocument2 pagesTool Box Talk - 8 Lifting EquipmentMoaatazz Nouisri100% (1)

- The New BMW 5 Series Touring Price List March 2017 v1Document24 pagesThe New BMW 5 Series Touring Price List March 2017 v1petruNo ratings yet

- Laydown Yard ChecklistDocument6 pagesLaydown Yard Checklistjonathan camba100% (1)

- Hse Team Tour Checklist Workshop Welding AreaDocument2 pagesHse Team Tour Checklist Workshop Welding Areaf.B100% (3)

- Health and Safety Inspection ChecklistDocument10 pagesHealth and Safety Inspection ChecklistlilaraharjoNo ratings yet

- Workplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredDocument7 pagesWorkplace Transport Checklist: Management of Workplace Transport Safety Yes No Action RequiredUlviyye ElesgerovaNo ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistshahidNo ratings yet

- Daily Safety Inspection ChecklistDocument2 pagesDaily Safety Inspection ChecklistNeil Ian CalambaNo ratings yet

- Shovel ChecklistDocument2 pagesShovel Checklistjamal motaNo ratings yet

- CM-510.5 Tractor Loader Back ChecklistDocument1 pageCM-510.5 Tractor Loader Back ChecklistHSE Heryginting100% (1)

- HSE 05-015a Ladder Inspection RegisterDocument1 pageHSE 05-015a Ladder Inspection RegisterQuentin KlynsmithNo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- Hse Team Tour Checklist GeneralDocument2 pagesHse Team Tour Checklist Generalf.B100% (1)

- Fire Safety Inspection ChecklistDocument3 pagesFire Safety Inspection Checkliste cubeNo ratings yet

- Hydra Safety Inspection Checklist.Document1 pageHydra Safety Inspection Checklist.Mohamed KamalNo ratings yet

- Checklist For Tools On Site in QatarDocument3 pagesChecklist For Tools On Site in QatarBishop Ojonuguwa AmehNo ratings yet

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDocument1 pageHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNo ratings yet

- Workplace-Safety - Inspection - ChecklistDocument2 pagesWorkplace-Safety - Inspection - ChecklistNaba majead100% (3)

- JobSite Safety Inspection ChecklistDocument8 pagesJobSite Safety Inspection ChecklistBisaya ni BaiNo ratings yet

- Daily Inspection Heck List: HSE General DepartmentDocument3 pagesDaily Inspection Heck List: HSE General DepartmentFaris WahedNo ratings yet

- WorkSafeBC - Forklift Inspection ChecklistDocument0 pagesWorkSafeBC - Forklift Inspection ChecklistjohnzepolNo ratings yet

- 4 Plant & Equipment Checklist - Docx-1Document2 pages4 Plant & Equipment Checklist - Docx-1REHAN IQBALNo ratings yet

- 25 - Welding, Cutting and Hot WorkDocument16 pages25 - Welding, Cutting and Hot WorkRicardo DalisayNo ratings yet

- General Chemical Safety Inspection ChecklistDocument6 pagesGeneral Chemical Safety Inspection ChecklistWaqas Saeed100% (1)

- Work at Heights Self Assessment SheetDocument4 pagesWork at Heights Self Assessment SheetBalogun Isaac100% (1)

- HLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistDocument1 pageHLG HSE SPI FM 051A Rev 00 Lifting Equipment Audit ChecklistLemuel Petronio100% (3)

- Weekly Checklist Truck VehicleDocument1 pageWeekly Checklist Truck VehicleSatya Naidu100% (1)

- Cradle Inspection Weekly ChecklistDocument1 pageCradle Inspection Weekly ChecklistFaizan SarwarNo ratings yet

- S-OS-21-01 Hand Tool Inspection RegisterDocument1 pageS-OS-21-01 Hand Tool Inspection RegisterCharles Lamb100% (1)

- Safety Checklists: Accident Investigation, Analysis & ReportingDocument48 pagesSafety Checklists: Accident Investigation, Analysis & Reportingnatas100% (1)

- Accident Witness Statement FormDocument4 pagesAccident Witness Statement FormVictorNo ratings yet

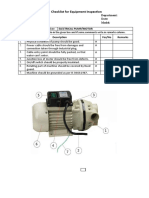

- Checklist For Equipment Inspection Electrical Pump MotorDocument1 pageChecklist For Equipment Inspection Electrical Pump MotorKaif Siddique100% (1)

- Camp Inspection ChecklistDocument12 pagesCamp Inspection ChecklistNoufal Pattambi100% (2)

- Grating Control ProcedureDocument25 pagesGrating Control ProcedureMuneeb Rehman100% (1)

- 4A dm253461 Project Premobilization Safety Meeting Checklist PDFDocument19 pages4A dm253461 Project Premobilization Safety Meeting Checklist PDFRheNo ratings yet

- Aug Toolbox Talks Confined Spaces 0517Document2 pagesAug Toolbox Talks Confined Spaces 0517WaSim AKramNo ratings yet

- Crane Inspection Checklist RevDocument1 pageCrane Inspection Checklist RevMuhammadHaziqHaiqalNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument1 pageEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Monthly HSE Report - January 2022Document13 pagesMonthly HSE Report - January 2022adeniyi abiolaNo ratings yet

- Portable Power Tools Inspection ChecklistDocument2 pagesPortable Power Tools Inspection Checklistengrabbas75100% (1)

- Permit To Work ProceduceDocument4 pagesPermit To Work ProceduceQuý Hoàng ChuNo ratings yet

- Drilling Machine Inspection ChecklistDocument1 pageDrilling Machine Inspection ChecklistKevin MichaelNo ratings yet

- ESA Daily Check ListDocument2 pagesESA Daily Check ListTarique SaifullahNo ratings yet

- HOUSEKEEPINGDocument2 pagesHOUSEKEEPINGFRONTLINE ASSOCIATESNo ratings yet

- Warehouse Cleaning Checklist Daily TasksDocument6 pagesWarehouse Cleaning Checklist Daily TasksDanaNo ratings yet

- Generic Safety Checklist: Truck Mounted CraneDocument3 pagesGeneric Safety Checklist: Truck Mounted Cranepawan pandey100% (1)

- Sample: Excavator Inspection & Maintenance RecordDocument3 pagesSample: Excavator Inspection & Maintenance RecordbangladragosNo ratings yet

- Angle-Grinder Inspection Check ListDocument1 pageAngle-Grinder Inspection Check ListThein Myint OoNo ratings yet

- Construction Industry Inspection Checklist (Long Version)Document6 pagesConstruction Industry Inspection Checklist (Long Version)Usman ShahidNo ratings yet

- All Safety Inspection ChecklistsDocument30 pagesAll Safety Inspection ChecklistsSagar Sharma67% (3)

- SS-C111 - Rev 7 - Fabrication and Erection of Structural SteelDocument35 pagesSS-C111 - Rev 7 - Fabrication and Erection of Structural SteelcraigNo ratings yet

- Plan Silopate PL5Document17 pagesPlan Silopate PL5Lotfi NEILINo ratings yet

- Next Generation 802.11ac SOLUTION: Fact SheetDocument2 pagesNext Generation 802.11ac SOLUTION: Fact Sheetducquang89No ratings yet

- Alarm System AlstomDocument16 pagesAlarm System AlstomRebecca TerryNo ratings yet

- Circuit Theory Experiment 2 Lab Report DONE Jen HahnDocument10 pagesCircuit Theory Experiment 2 Lab Report DONE Jen HahnPei Ing100% (1)

- Application For Lateral Entry Technical Officers 1Document2 pagesApplication For Lateral Entry Technical Officers 1arthur asparelaNo ratings yet

- Fundamental of Mechanical Engineering Bihar 1st Semester Model Set-1Document9 pagesFundamental of Mechanical Engineering Bihar 1st Semester Model Set-1mohitrajputttttNo ratings yet

- VibrationsDocument125 pagesVibrationsFariq AdlawanNo ratings yet

- AC AMMETER / Moving Iron: Model AECDocument33 pagesAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaNo ratings yet

- Assignment 1 Tutor Marking GuidelinesDocument3 pagesAssignment 1 Tutor Marking GuidelinesNick JthnNo ratings yet

- GPS KLN 900Document210 pagesGPS KLN 900zeeshanshaNo ratings yet

- CSC206Document15 pagesCSC206Chunduru Devi AnushaNo ratings yet

- Tecsun Pl310et English Instruction Manual PDFDocument30 pagesTecsun Pl310et English Instruction Manual PDFjewws100% (1)

- Information On Epidata 3.0: Introduction To Epidata Whats New in V3Document1 pageInformation On Epidata 3.0: Introduction To Epidata Whats New in V3Lian ElvaniNo ratings yet

- An Evaluation of A Small Scale Hydropower Development Project in Sri Lanka: A Case Study in SripadagamaDocument11 pagesAn Evaluation of A Small Scale Hydropower Development Project in Sri Lanka: A Case Study in SripadagamatanujaayerNo ratings yet

- Thought Parallels - The Skew HouseDocument21 pagesThought Parallels - The Skew Housebkc246No ratings yet

- Resato Check ValveDocument4 pagesResato Check ValveSam LarismaNo ratings yet

- BRANDED BOOSTERDocument6 pagesBRANDED BOOSTERAYUSH KUMAR SINGHNo ratings yet

- Dbms NotesDocument71 pagesDbms Notessanyasirao183% (12)

- vị trí kiểm tra động cơ 1240-1250veDocument35 pagesvị trí kiểm tra động cơ 1240-1250veNguyễn Văn HùngNo ratings yet

- Installing SolidWorks 2016 On Your PC Jan 2017 (Stand Alone)Document6 pagesInstalling SolidWorks 2016 On Your PC Jan 2017 (Stand Alone)Jignesh ChauhanNo ratings yet

- Libble EuDocument1 pageLibble EuMihael SusaNo ratings yet

- Sesv8002 PDFDocument97 pagesSesv8002 PDFali100% (2)

- Plastics Presentation Teacher NotesDocument4 pagesPlastics Presentation Teacher NoteslauferwNo ratings yet

- 12 Theory Tofd FCBDocument77 pages12 Theory Tofd FCBNDTInstructorNo ratings yet

- FAN7602C Green Current Mode PWM Controller: Features DescriptionDocument19 pagesFAN7602C Green Current Mode PWM Controller: Features DescriptionAmjad ZaidNo ratings yet

- Understanding Linear Feedback Shift Registers - The Easy WayDocument3 pagesUnderstanding Linear Feedback Shift Registers - The Easy WayrockymaxdeemannNo ratings yet

- Design Portfolio ExampleDocument15 pagesDesign Portfolio ExampleAmoghaNo ratings yet

- KSR Job Mix DBM II - pdf-1Document6 pagesKSR Job Mix DBM II - pdf-1Ankur BarsainyaNo ratings yet