Tennin HAZOP

Tennin HAZOP

Uploaded by

Mohamed SamirCopyright:

Available Formats

Tennin HAZOP

Tennin HAZOP

Uploaded by

Mohamed SamirOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Tennin HAZOP

Tennin HAZOP

Uploaded by

Mohamed SamirCopyright:

Available Formats

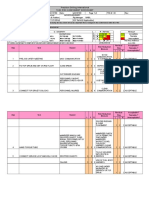

HAZOP Analysis Well Test WORK SHEET

No. Activity Description of task step

JOB 1. PREPA RATIO NS Security/Emergencies Community threat Robbery Attacks Vandalization Petty Stealing On-site accident Personnel Equipment LTI/LTA H H H L L M

Tennin W 1

Threats Who or What might be harmed S L R Control Measures Recovery Measures

IEOC

Action Party

Hazard Potential Incident

L L L

2.

Job Preparation/ execution

Job failure

Well Asset Cost over run

H H

L L

M M

3. 4.

Communication During job preparation Communication during Job

Mis-communication Mis- or lack of communication

LTI Health/Safety LTI

H H

H M

L H

Ensure Community has been settled and no record of conflicting factions or hostilities in the area. Employ enough security personnel preferably from host community. Secure any loose equipment or item during low activity period. Be on the alert for unfamiliar faces and report accordingly to security personnel. Have communication with IEOC offices installed. Have all personnel aware of agreed Muster point in case of emergencies. PRO to be on site Adequate Planning and preparation for Job prior to mobilizing to site. Use pre-audited and have adequate equipment for the Job. Have equipment back-up on the ready. Use only qualified manpower. Job supervisor and SLB Base staff involved in pre-job meetings with IEOC staff. Pre job meeting to address this problem. Line of communication to be identified and followed. 3 or 4 Walkie talkie to be provided for Crew

Alliance Management All Alliance Job Supervisors

Alliance Management All Alliance Job Supervisors SLB- Saipem,SE SLB-Saipem Job supervisor man Company

Consequence Category:

Health/Safety

Public Disruption

Environmental Impact Financial Impact

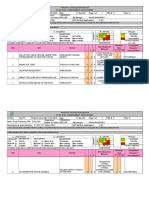

HAZOP Analysis Well Test WORK SHEET

No. Activity Description of task step

DST/TCP PERFO. 1. Picking up tools/guns Damage to tools Health/Safety LTI Cost LTI LTI Health/Safety LTI Health/Safety LTI LTI Health/Safety Health/Safety H H H M H M M L H H M H H L M M H L H M

Tennin W 1

Threats Who or What might be harmed S L R Control Measures Recovery Measures

IEOC

Action Party

Hazard Potential Incident

M M M L H M M L H H

2. 3. 4. 5. 6. 7.

Running in hole Packer Integrity check Test String integrity check Displacing string to required Cushion type Guns failed to fire Guns miss- fire

Obstruction in string Packer leak Unable to set packer Leak in string Circulating valve malfunction Bar not reaching firing head. Retrieve Gun String out of Hole

- Only essential people on rig floor while making up firing head. - Hold Safety meeting on rig floor prior to picking up tools/guns. - Follow SLB handling procedures Rabbit all tubular while tripping in hole Make scrapper run prior to run test string. Pick up 10 ft up or down and reset packer Pressure test string at surface prior to RIH. Pressure test as required while RIH with TFTV. Inspection/Certification of equipment. Function test tools at surface prior to RIH Secondary firing System Pressure delay (HDF) Use clear filtered brine or sea water solid free for casing Rabbit all tubular while RIH Ensure drop bar is retrieved before POOH. Follow SLB live gun handling procedure during POOH Clear non essential personnel from rig floor.

DST/TCP Engineer Company man

Driller Company man DST/TCP Supervisor Company man DST/TCP Supervisor DST/TCP Supervisor Company man DST/TCP Supervisor Company man DST/TCP Supervisor

Consequence Category:

Health/Safety

Public Disruption

Environmental Impact Financial Impact

HAZOP Analysis Well Test WORK SHEET

No Activity Description of task step Hazard potential Incident Threats Who or What might be harmed? S L

Tennin W 1

R

IEOC

Control Measures recovery-measures Action Party

WIRELINE OPERATIONS

1 Rigging up hydraulic hoses for Well Head Pressure Control Pressure Testing Escape of high pressure hydraulic oil.. Incorrect equipment operation Uncontrolled release of pressure Heavy weights Lifting Heavy weights lifting Spillage Guns fire with Slick line in Hole Personnel Equipment H M L L L L Quick union connections should engage without difficulty otherwise carry out a thorough check for trapped pressure. Match hoses correctly using indication rings to opposite and corresponding connections. Ensure pressure lines are tied down and secured. Monitor Gauges and lines at start of pressuring of lines. Use certified banded Chiksans lines and pre-audited equipment. Seal off area and indicate operation with warning signs. Adopt safe lifting posture. Request for assistance when lifting load beyond capability. Use PPE Adopt safe lifting posture. Request for assistance when lifting load is beyond capability. Flush lines clean with fresh water before disconnection. Use PPE Slickline lubricator rated for 10k service Flow head valves can cut Slickline if required for well control. WT Supervisor Wireline Engineer and Personnel WT Supervisor Pumping Supervisor Wireline Engineer WT Supervisor Wireline Personnel Wireline Personnel WT Supervisor SL Operator DST/TCP Supervisor

Personnel

3 4 5

Rigging down Equipment Rigging down lines Retrieve bar

Personnel Personnel Environment Equipment damage Health/Safety

H H H L

M M L L

L L L L

Consequence Category:

Health/Safety

Public Disruption

Environmental Impact Financial Impact

HAZOP Analysis Well Test WORK SHEET

WELL KILL/POOH 1. 2. Open circulating valve Rig down Flow head Mal function of reverse valves Damage to equipt. Injury to personnel 3. Pull out of hole with Test String POOH with test String Stuck with Test String after test Fluid loss to well Health /Safety LTI Equipment Health/safety Equipment LTI Health/Safety L L S L L L L L

Tennin W 1

IEOC

L L L M

Kill well by bull heading Use Secondary system available Follow SLB handling Procedure Discuss procedure in safety meeting prior to rig down Un necessary personnel to leave work area -Jar a couple of times -Wash over guns and try jarring again -Call town for advise -Can back out from Safety joint -Spot fluid loss pill -Reset packer and observe well

Company man DST/TCP Supervisor Test supervisor Company man DST/TCP Supervisor Company man Company man DST/TCP Supervisor

4.

JHA Team Members ..

IEOC

SLB TESTING

..

Consequence Category:

Health/Safety

Public Disruption

Environmental Impact Financial Impact

You might also like

- Airway and Ventilatory ManagementDocument27 pagesAirway and Ventilatory ManagementEvert Salazar OyolaNo ratings yet

- Revised Manual Ligament Therapy - FoundationDocument38 pagesRevised Manual Ligament Therapy - FoundationKleberBattaglia100% (6)

- May and September 2022Document123 pagesMay and September 2022Aminur Rahman Alif100% (2)

- Boyus Engineering Nigeria LimitedDocument26 pagesBoyus Engineering Nigeria LimitedBurak KucukkelesNo ratings yet

- Japl-F-Wi-008-Journey Management Log Sheet 1Document1 pageJapl-F-Wi-008-Journey Management Log Sheet 1Ali HassanNo ratings yet

- Health, Safety & EnvironmentDocument27 pagesHealth, Safety & EnvironmentbilouNo ratings yet

- Majnoon Oil Field - HSSE Plan 2020-2021Document29 pagesMajnoon Oil Field - HSSE Plan 2020-2021amjed naama0% (1)

- Kai Greene-Biceps CompressedDocument17 pagesKai Greene-Biceps CompressedYoussef MehrezNo ratings yet

- Stage Combat HandoutDocument3 pagesStage Combat HandoutkevoyNo ratings yet

- Isand Drilling HSE Case Nov 08 Rev A02lDocument310 pagesIsand Drilling HSE Case Nov 08 Rev A02lSalim Muftah100% (5)

- Road & Traffic Safety Procedure: Pars Oil & Gas CompanyDocument29 pagesRoad & Traffic Safety Procedure: Pars Oil & Gas CompanyKostan Abdillah100% (1)

- Shell Safety in Drilling ManualDocument147 pagesShell Safety in Drilling ManualNicolae MarinNo ratings yet

- Well Operations Crew Resource ManagementDocument2 pagesWell Operations Crew Resource ManagementJassieNo ratings yet

- Emergency Response Plan: (For Makori Early Production Facility Project)Document13 pagesEmergency Response Plan: (For Makori Early Production Facility Project)waqarahmedogarNo ratings yet

- Apprisk Assessment HAZOPDocument1 pageApprisk Assessment HAZOPHakim YahiaouiNo ratings yet

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDocument1 pageRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig74No ratings yet

- Emergency Response & Contigency Planning StandardDocument15 pagesEmergency Response & Contigency Planning Standardbilou100% (1)

- Hazards On An Offshore Platform A ReviewDocument8 pagesHazards On An Offshore Platform A ReviewWendy Tie Kai SingNo ratings yet

- ENI Drilling HSE ManagementDocument104 pagesENI Drilling HSE Managementnurwinanto0175% (4)

- NB2 HSE Case Part 5 - Emergency Response Rev 1Document36 pagesNB2 HSE Case Part 5 - Emergency Response Rev 1George MedeirosNo ratings yet

- KOC - PS.019 - Guidelines For Escape, Evacuation and Rescue Assessment (EERA)Document23 pagesKOC - PS.019 - Guidelines For Escape, Evacuation and Rescue Assessment (EERA)Sampath Kumar KandasamyNo ratings yet

- Change Out Rig Tong DiesDocument1 pageChange Out Rig Tong DiesAbdul Hameed OmarNo ratings yet

- HSERequirementsfor ContractsDocument21 pagesHSERequirementsfor ContractsSachin GanvirNo ratings yet

- Eni Pakistan HSE Risk Register 2021Document9 pagesEni Pakistan HSE Risk Register 2021saad_ur_rehman_ghouri100% (1)

- RM-001 Rig Move TRADocument7 pagesRM-001 Rig Move TRAcenim2004No ratings yet

- Well Handover DocumentDocument1 pageWell Handover DocumentCadiffNo ratings yet

- Precision Drilling International Task Risk Assessment WorksheetDocument2 pagesPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- HSE Bridging PlanDocument22 pagesHSE Bridging PlansergioNo ratings yet

- Saudi Aramco: RHSEI FindingsDocument2 pagesSaudi Aramco: RHSEI FindingsaswinNo ratings yet

- Process Safety ManagementDocument7 pagesProcess Safety ManagementsantoshjayantiNo ratings yet

- Risk Assessment Pc4dp-A (Draft)Document11 pagesRisk Assessment Pc4dp-A (Draft)HSE PULAI ANo ratings yet

- SR 65-19-01 ToR PSM AuditDocument17 pagesSR 65-19-01 ToR PSM AuditMuhammad.SaimNo ratings yet

- Well Services QHSE Standard 23 Guideline 12: Bull Plugs, Sensors, Sensor Wings, and Other Unions Inspection and TestDocument13 pagesWell Services QHSE Standard 23 Guideline 12: Bull Plugs, Sensors, Sensor Wings, and Other Unions Inspection and TestCiprianHnNo ratings yet

- 08 - OP - Permit To Work - I07 R06Document54 pages08 - OP - Permit To Work - I07 R06learningzabatNo ratings yet

- Standard Major Emergency ManagementDocument80 pagesStandard Major Emergency ManagementnizartounsiNo ratings yet

- 4.01 IOEC Rigs Commisioning Project HSE PlanDocument59 pages4.01 IOEC Rigs Commisioning Project HSE Planhshobeyri100% (2)

- Drilling HSE Audit - Base Questionnaire: 1 4.1 Well Control 2Document58 pagesDrilling HSE Audit - Base Questionnaire: 1 4.1 Well Control 2MartahanManurungNo ratings yet

- Safety Performance Indicators - Motor Vehicle Crash Data - 2008-2019Document56 pagesSafety Performance Indicators - Motor Vehicle Crash Data - 2008-2019TFattahNo ratings yet

- 01.01. HSE ManagementDocument64 pages01.01. HSE ManagementHussainNo ratings yet

- 5 - Contractors HSE ForumDocument49 pages5 - Contractors HSE ForumDheeraj MenonNo ratings yet

- Risktec Drilling Soc 0.3Document16 pagesRisktec Drilling Soc 0.3mashanghNo ratings yet

- Part 4 Risk and Hazard ManagementDocument19 pagesPart 4 Risk and Hazard Managementalex.kollosovNo ratings yet

- 89 Gas and Oilfield Safety Inspection ChecklistDocument14 pages89 Gas and Oilfield Safety Inspection Checklistdilip matalNo ratings yet

- PN3-PRO-HSE-038 Offshore Drilling Safety Case - Rev 01Document180 pagesPN3-PRO-HSE-038 Offshore Drilling Safety Case - Rev 01aymenmoataz100% (5)

- Bow TieDocument2 pagesBow TieAnonymous ocCa18R100% (1)

- Precision Drilling International Task Risk Assessment WorksheetDocument2 pagesPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- Dropped Object Awareness and Prevention SPSDocument54 pagesDropped Object Awareness and Prevention SPSahmadNo ratings yet

- Lay Down Drill PipeDocument2 pagesLay Down Drill PipeAbdul Hameed OmarNo ratings yet

- #39 Drawworks and HydromaticDocument1 page#39 Drawworks and HydromatickhurramNo ratings yet

- JSA HEMP Well Services Pg11-15Document5 pagesJSA HEMP Well Services Pg11-15Ashok SureshNo ratings yet

- UBD-MPD Well Control Risk AssessmentDocument27 pagesUBD-MPD Well Control Risk AssessmentAli BoubeniaNo ratings yet

- Parker Drilling HSE IADC Rig CoursesDocument8 pagesParker Drilling HSE IADC Rig CoursesDanciulescu Mircea GabrielNo ratings yet

- PR-IMS-006-Dropped Object Preventive Scheme (DROPS)Document10 pagesPR-IMS-006-Dropped Object Preventive Scheme (DROPS)Blister PatchNo ratings yet

- Hubbard 2010Document12 pagesHubbard 2010SofiaNo ratings yet

- CHESM Questionnaire GuidanceooDocument15 pagesCHESM Questionnaire GuidanceooWale OyeludeNo ratings yet

- BGA-HSSE-SAF-ST-1526 Safety Case Rev 02Document27 pagesBGA-HSSE-SAF-ST-1526 Safety Case Rev 02TFattahNo ratings yet

- PR-2352 - Greater Birba Emergency Response PlanDocument173 pagesPR-2352 - Greater Birba Emergency Response PlanSHRISH SHUKLANo ratings yet

- 2 - Robuste Risikoanalyser - Linda Fløttum Og Tore Andre SvidalDocument33 pages2 - Robuste Risikoanalyser - Linda Fløttum Og Tore Andre SvidalNurhayati Muhamad NorNo ratings yet

- BOP Nipple Down 17-May-2010Document1 pageBOP Nipple Down 17-May-2010HAMDI RAFIEK100% (2)

- HEMP-Leader Engagement SOPAF GM-1Document64 pagesHEMP-Leader Engagement SOPAF GM-1ashveen_peddadu100% (2)

- Ep 950100Document62 pagesEp 950100Ram1zNo ratings yet

- Illegal Drugs and Alcohol StandardDocument28 pagesIllegal Drugs and Alcohol Standardrahul kavirajNo ratings yet

- Creating A Culture Of Safety A Complete Guide - 2020 EditionFrom EverandCreating A Culture Of Safety A Complete Guide - 2020 EditionNo ratings yet

- ECE R29 Safety Analysis of The New Actros Megaspace CabinDocument14 pagesECE R29 Safety Analysis of The New Actros Megaspace CabinGirish Raj100% (1)

- Functional NeuroanatomyDocument23 pagesFunctional NeuroanatomyDaniela GrigoraşNo ratings yet

- Articular Step-Off and Risk of Post-Traumatic OsteoarthritisDocument10 pagesArticular Step-Off and Risk of Post-Traumatic Osteoarthritisashut1100% (1)

- Spinal Injury RehabitationDocument13 pagesSpinal Injury Rehabitationheavysky1No ratings yet

- Product Safety InformationDocument112 pagesProduct Safety InformationJose Enrique Mendoza RodriguezNo ratings yet

- Penyaji: Ayu Iswandari Raharjo Pembimbing 1:Dr. Dr. M. Zafrullah Arifin, SP - Bs (K) Dr. Ahmad Faried, SP - Bs (K) PHDDocument14 pagesPenyaji: Ayu Iswandari Raharjo Pembimbing 1:Dr. Dr. M. Zafrullah Arifin, SP - Bs (K) Dr. Ahmad Faried, SP - Bs (K) PHDayuNo ratings yet

- Avatar The Last Airbender (Zuko Fanfiction)Document3 pagesAvatar The Last Airbender (Zuko Fanfiction)koulakoukoulaNo ratings yet

- Scope of Legal MedicineDocument2 pagesScope of Legal MedicineCherlene TanNo ratings yet

- Arthroscopic Osseous Bankart Repair For Chronic Recurrent TraumaticDocument12 pagesArthroscopic Osseous Bankart Repair For Chronic Recurrent TraumaticdrjorgewtorresNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Komplikasi - Compartment Syndrome-A Very Rare Complication Where The Fluid That Is Used To Irrigate TheDocument3 pagesKomplikasi - Compartment Syndrome-A Very Rare Complication Where The Fluid That Is Used To Irrigate TheNanang YuliantoNo ratings yet

- Mnemonics Definitions PDFDocument6 pagesMnemonics Definitions PDFsaquib eqbalNo ratings yet

- Batangas Transportation Company vs. CaguimbalDocument2 pagesBatangas Transportation Company vs. Caguimbaldonnamariebollos50% (2)

- Comma Incision For Impacted Mandibular Third MolarsDocument4 pagesComma Incision For Impacted Mandibular Third MolarsSukhvinder Singh RanaNo ratings yet

- JSA 45 - Valve BoxupDocument18 pagesJSA 45 - Valve BoxupgolusinghdataNo ratings yet

- List of Ailments Approved by Abs PDFDocument3 pagesList of Ailments Approved by Abs PDFVineet Upadhyay100% (1)

- 1 Understanding PhlebotomyDocument6 pages1 Understanding PhlebotomyRogelio JuanNo ratings yet

- The Water Circle and Power Principles HapkidoDocument0 pagesThe Water Circle and Power Principles HapkidonitrofrogNo ratings yet

- Management of Dog Bites: Thorough History TakingDocument6 pagesManagement of Dog Bites: Thorough History TakingElvisNo ratings yet

- DEGENERATIVE SPINE DISEASE and HomeopathyDocument21 pagesDEGENERATIVE SPINE DISEASE and Homeopathypawajee100% (3)

- Gardner-Wells TongsDocument11 pagesGardner-Wells TongsDimas PrasetyoNo ratings yet

- Chapter 3 ThePearlDocument6 pagesChapter 3 ThePearlA. A. SuleimanNo ratings yet

- Dlungwane Thebelihle 2010Document92 pagesDlungwane Thebelihle 2010Usha CNo ratings yet

- Brighter Futures - Orthodontics and Dental TraumaDocument2 pagesBrighter Futures - Orthodontics and Dental TraumaEastma MeiliNo ratings yet

- Headaches: Prof. Dr. Basjiruddin Ahmad, SP.S (K) Fakultas Kedokteran Universitas Andalas RS. Dr. M. Djamil PadangDocument44 pagesHeadaches: Prof. Dr. Basjiruddin Ahmad, SP.S (K) Fakultas Kedokteran Universitas Andalas RS. Dr. M. Djamil PadangPutri MiraaNo ratings yet