Installation-And Instruction Manual: Software Version 1.3-2.56

Installation-And Instruction Manual: Software Version 1.3-2.56

Uploaded by

Ema RussiCopyright:

Available Formats

Installation-And Instruction Manual: Software Version 1.3-2.56

Installation-And Instruction Manual: Software Version 1.3-2.56

Uploaded by

Ema RussiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Installation-And Instruction Manual: Software Version 1.3-2.56

Installation-And Instruction Manual: Software Version 1.3-2.56

Uploaded by

Ema RussiCopyright:

Available Formats

Installation- and Instruction manual

Software version 1.32.56

0-

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

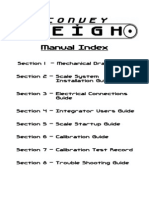

Table of contents:

0. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Introduction Daily use Quick guide Calibration Configuration Protecting your setup Electrical installation Air-sensor installation SG Sensor installation Optional sensors installation OBC serial output 11. 12. 13. 14. Accessories Frequently asked questions Technical specifications Appendix

This manual is edited for Kimax 2 radio and Kimax 2 sensor, menus and diagrams are referring to layout of Kimax 2 radio. However Kimax 2 universal have equal function and menus as Kimax 2 radio. When connection diagrams or layouts are different, additional diagrams are present for Kimax 2 universal. Warranty Kimax 2 radio, Kimax 2 universal, Kimax 2 sensor are all covered by Sense-Tech Weighing Systems ApS guarantee. Electronic failure and broken components caused by normal use are repaired or exchanged when nessecary, when send to the factory. Damage to your vehicle caused by installation of Kimax instruments or loss of time caused by recalibration or repairments of Kimax instruments are not covered by Sensetech Weighing Systems ApS in any case. Basic safety rules: Before you start the installatation procedure, make sure that the instruments has not suffered any damage during transport. Note that the KIMAX 2 instruments must be installed and connected in accordance with the regulations valid for the vehicle and country in question. The KIMAX 2 instruments must be protected from gravel, water spray from wheels and other factors that may damage the instruments. We recommend to mount the instruments in a position where it is protected from water jets and rinse water. Once you have decided where the instrument is to be mounted in the cabin, you have to consider the cable routing. Special attention should be given to potential damaging factors such as e.g. hinging point for tilting the cab. Once you have decided where the instrument is to be mounted on the chassis, you have to consider the cable routing. Special attention should be given to tensile forces, cuts and other factors that may damage the cables and hoses. Connection of compressed air. Before you carry out any installation work related to the air suspension, make sure that the suspension has been brought to the lowest possible position. Electrical connection Always disconnect the battery before you perform any installation work on the system of the vehicle.

KIMAX 2 - Installation- and Instruction manual

0-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

How does it work

The KIMAX 2 on board scale is an axle pressure meter that measures the pressure on the air suspension system to indicate the load on each axle for the entire vehicle. The KIMAX 2 has a 3-digit display indicating the actual weight of the vehicle or the weight of the individual axles. LEDs warns the driver in case of overload.

KIMAX 2

A mechanical system on the vehicle maintain a fixed level of the chassis height through a level valve which add or subtract compressed air to the bellows according to the actual load on the vehicle. Top of bellows, shock absorber and level valve are fixed on the chassis of the vehicle.

Air-pressure for KIMAX Level valve Shock absorber Storage tank Bellow Maintain level

0-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Each axle has to be calibrated after installation, before you can rely on your new onboard scale. The calibration is carried out by weighing each axle of the vehicle on a weighing bridge. While you truck is standing on the weighing bridge you must give in the empty (Lo) weight and loaded (Hi) weight, when the vehicle is empty respective loaded.

Kimax 2 - calibration diagram (example)

14 12 10

Tonne

Front Rear Lo - front Hi - front Lo - rear Hi - rear 0,00 1,00 2,00 3,00 Bar 4,00 5,00 6,00 7,00

8 6 4 2 0

Air pressure are measured on right and left side on each axle and routed to the Kimax instrument, due to get the most accuracy weighing results under different circumstances.

KIMAX 2 - Installation- and Instruction manual

0-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Daily use

When you switch on your KIMAX 2 system, it will show the total weight of the entire vehicle in the 3-digit display measured in tonne. The active axle LEDs as well as the load LED are on too. When a trailer is connected to your vehicle, the active axle LEDs and load LED for the trailer is turned on too. When you disconnect the trailer from your vehicle, the axle and load indications for the trailer disappear after a few seconds, as well as the displayed weight is reduced by the weight of the trailer.

Enter

Roll

When you switch on the power for your Kimax 2, you read a 3-digit number in the display for about 3 seconds. The number equals the software version of your instrument. Next read out is an indication of your degree of the protection of the setup and calibration of your instrument. A - L- indicates that the instrument is protected against changing the setup and calibration, a -U-means your unit is unlocked, calibration and setup can be changed.

Save

KIMAX 2

KIMAX 2

KIMAX 2

By use of the Roll button and the +/- buttons, you can display the individual weight of each axle, the load you are carrying and the total weight of your vehicle. The following pages show a short walk through the buttons, it shows you the easy way of reading and printing values from your KIMAX 2.

1-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

When you press the Roll button once, the KIMAX 2 display the actual weight of axle #1 and only the axle LED #1 is lit up.

KIMAX 2

Pressing the + button once, change the axle LED to the next active axle on the right. In this case axle LED #2 is lit up and the display reads the actual weight of axle #2.

Pressing the + button once again, the axle LEDs changes to the next active axle, which are the boogie axle #3 and #4. The common weight of axle #3 and #4 is displayed. Pressing the + button once again, change the axle LED to the next active axle on the right, in this case axle #5, which is the 1. axle on the trailer. The belonging weight is read out on the display. Pressing the + button once again, the axle LED changes to the next active axle, which are the boogie axle #6 and #7. The common weight of axle #6 and #7 is displayed. Pressing + button once again return the display to #1 axle, pressing the button returns the display to axle #5. Pressing the - button reverse the axle LED to the next active axle on the left, in this case axle #3 and #4.

KIMAX 2

KIMAX 2

KIMAX 2

KIMAX 2 - Installation- and Instruction manual

1-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

When you press the Roll button in any of the single axle modes, you go to display the load on your vehicle, indicated by litting up the load LED. Press the + or - button, and you toggle between the load on your vehicle and the load on your trailer. When no trailer is present, pressing the + or - button will not affect the displayed value. When you press the Roll button in any of the load modes, you will go to display the total weight of your vehicle. This mode is displayed by litting both the load LED and the axle LEDs on the vehicle. Press the + or - button, and you toggle between the total weight of your vehicle and the total weight of your trailer. When no trailer is present, pressing the + or - button will not affect the displayed value. When you press the Roll button in any of the total weight modes, you will go to display the load on your vehicle + trailer.

KIMAX 2

KIMAX 2

KIMAX 2

KIMAX 2

KIMAX 2

Pressing the Roll button once again return you to the total weight of your vehicle + trailer.

S

KIMAX 2

In any display mode, - pressing the Enter button shortly, blank your display, - pressing Enter once again turn on your display. While the display is blanked during your ride, the alarm output A2 and the OBC signal is still active and broadcasted.

KIMAX 2

1-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Main menu:

Run Mode

Light OFF

> 5 sec

PPP

OAA

Sub-menu

VER

Sub-menu

CAL

Sub-menu section 3

COF

Sub-menu section 4

ALA

Sub-menu

OFF

KIMAX 2 - Installation- and Instruction manual

1-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Entering the Kimax 2 sevice menu

Through an easy to use menu, you have access to print out actual weight of your vehicle on a printer. Further more you can read some additional setup values on the display, helping you understand how your weighing system works. By pressing the Enter button for 5 seconds, you will get access to the service menu in your Kimax 2, - while you are in the menus, the LED next to the Enter button is lit. By pressing the Roll button once or several times, when you are in menu mode, you can scroll through the following sub-menus. You can leave the service menu when you continue scrolling until the display reads OFF, then you can leave the menu by pressing Enter.

PPP - print-out

The first position is the printing menu, press the Enter button once again shortly and you will get a printed copy of your actual load, when a printer is connected to the Kimax 2. The Kimax 2 leaves the menu and returns to normal read out.

KIMAX 2

OAA - diagnostic menu

Press Enter shortly and you get a relative value, ranging from 0,5% to 99,5%, displaying the actual load on your 1. axle. In this position you can rotate between your active axles #1 to #8 by pressing Roll. You leave the OAA menu by pressing Enter shortly.

S

KIMAX 2

VER - software version

Press Enter shortly and you get a 3 digit code for your currently software version in the Kimax instrument. Pressing Roll button in this menu, will show the software version of the trailer, when a trailer is present in your system.

S

KIMAX 2

CAL - calibration

Press Enter shortly and you will get access to the LO - HI - ADL - ADH - OFF submenus. Rotate between readings by pressing Roll. Press Enter once again when LO / HI / ADL / ADH is displayed and you get an axle LED indication and a 3-digit value, which equals the value which was save previously. In this position you can rotate between your active axles #1 up to #8 by pressing Roll. You leave actual menu by pressing Enter shortly, rotate by Roll to OFF and press Enter once again.

S

KIMAX 2

KIMAX 2

2-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

COF - configuration

Press Enter shortly and you will get access to the configuration menu CF - HFA - ID - OFF submenu. Rotate between readings by pressing Roll. Press Enter once again when CF / HFA / ID is displayed.

KIMAX 2

CF - configuration

Press Enter once again in the CF menu, Kimax 2 displays which axle LEDs are assigned to which input. You can rotate between your active axles #1 to #8 by pressing Roll. You leave the CF menu by pressing Enter shortly.

KIMAX 2

HFA - configuration

Press Enter once and the Kimax 2 displays the HFA setting: 000, 010, 020 or 030. Change this setting by pressing either + or - button and save it by pressing the S button. Leave the HFA menu by pressing Enter shortly.

KIMAX 2

ID - configuration

Press Enter once and the Kimax 2 displays the ID setting: 000255. Change this setting by pressing either + or - button and save it by pressing the S button. Leave the ID menu by pressing Enter shortly.

KIMAX 2

ALA - alarms

Press Enter shortly and you get access to the A1 - A2 - OFF sub-menus. Rotate between readings by pressing Roll. Press Enter once again when A1 is displayed and you get a 3-digit value and one or more of the axle LEDs will be lit. By pressing either + or - you can change the value and save it by pressing the S button. If the Kimax 2 exceeds this value for the chosen axle the axle LEDs will flash. By pressing the roll button the display reads the value for axle LED number 2, which can be altered like axle LED number 1. You leave actual submenu by pressing Enter shortly, rotate by Roll to A2. Press Enter shortly and the Kimax 2 displays a 3-digit value, change this value by pressing either + or and save it by pressing the S button. If the Kimax 2 exceeds this value a relay will activate. You leave actual submenu by pressing Enter shortly, rotate by Roll to OFF and press Enter once again.

KIMAX 2

KIMAX 2

OFF - leave Menu

You leave this menu by pressing Enter when you read OFF in the display.

KIMAX 2

KIMAX 2 - Installation- and Instruction manual

2-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Calibration

Once you have finished the installation and setup of your Kimax system, you must calibrate it, this means you link an actual unloaded weight of an axle together with a LO reading on this axle, - and you link a loaded weight of an axle together with a HI reading on this axle. LO and HI calibration has to be carried out on all axles or axle groups. The actual weight of each axle on your vehicle has to be measured on a weighing bridge. LO weighing For calibration of the LO values on each individual axle, you have to weigh a unloaded vehicle in the following positions on a weighing bridge, showed in the table. The table is showing a example for a 3 axle vehicle.

LO

Weighing bridge Reading

Position Axle #1 3,1 T Axle 1: 3,1 T

Position Axle #1 + 2 5,2 T Axle 1: 3,1 T

Type here the LO weight value for axle 1

Position Axle #1 + 2 + 3 7,2 T Axle 1: 3,1 T

Type here the LO weight value for axle 1

Axle 1

Axle 1 LO weight value Axle 1 = Weighing bridge Axle #1

Axle 2: 2,1 T Axle 2

Axle 2 LO value. To find the LO value for Axle 2 (Weighing bridge Axle #1+2) Axle 1 = Axle 2

Axle 2: 2,1 T

Type here the LO weight value for axle 2

Axle 3: 2,0 T Axle 3

Axle 3 LO value. To find the LO value for Axle 3 (Weighing bridge axle #1+2+3) (Axle 1 + Axle 2) = Axle 3

The measured values for the axles must be given in right away in the Kimax instrument while the vehicle is carrying the actual measured weight and is parked on an even surface without any brakes active.

3-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Access menu

CAL Main Menu

Access menu

Change to the next Axle LED

Change to the next Axle LED

LO

Axle 1 Value

Axle "n" 1<n<8

Adjust

Adjust

S

Change setting

Low Cal weight

Leave menu

S

Change setting

Low Cal weight

Leave menu

Change to the next Axle LED

Change to the next Axle LED

Entering Menu and saving LO Weight values for each Axles.

HI

Press enter for 5 sec. PPP is showed, Press the RollButton until CAL i shown, Press Enter. LO is shown, Press Enter Change the value if needed, shift between the Axle with Roll-button, press S to save the new value. When done press Enter.

ADL

ADH

OFF

Leave menu

CAL Main Menu

KIMAX 2 - Installation- and Instruction manual

3-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

HI weighing For calibration of the HI values on each individual axle, you have to weigh a loaded vehicle in the following positions on a weighing bridge, showed in the table. The table is showing a example for a 3 axle vehicle.

HI

Weighing Bridge Reading

Position Axle #1 3,6 T Axle 1: 3,6 T

Position Axle #1 + 2 6,7 T Axle 1: 3,6 T

Type here the HI weight value for axle 1

Position Axle #1 + 2 + 3 9,7 T Axle 1: 3,6 T

Type here the HI weight value for axle 1

Axle 1

Axle 1 HI weight value Axle 1 = Weighing bridge Axle #1

Axle 2: 3,1 T Axle 2

Axle 2 HI value. To find the HI value for Axle 2 (Weighing bridge Axle #1 + 2) Axle 1 = Axle 2

Axle 2: 3,1 T

Type here the HI weight value for axle 2

Axle 3: 3,0 T Axle 3

Axle 3 HI value. To find the HI value for Axle 3 (Weighing bridge Axle #1+2+3) (Axle 1 + Axle 2) = Axle 3

The measured values for the axles must be given in right away in the Kimax instrument while the vehicle is carrying the actual measured weight and is parked on an even surface without any brakes active.

3-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Access menu

CAL Main Menu

LO

Entering Menu and saving HI Weight values for each Axles Press enter for 5 sec. PPP is showed, Press the RollButton until CAL i showed, Press Enter. LO is showed, Press the RollButton until HI is showed Press Enter Change the value if needed, shift between the Axle with Roll-button, press S to save the new value. When done press Enter.

Change to the next Axle LED

Change to the next Axle LED

HI

Axle 1 Value

Axle "n" 1<n<8

Adjust

Adjust

S

Save Value

High Cal weight

Leave menu

S

Save Value

High Cal weight

Leave menu

ADL

Change to the next Axle LED Change to the next Axle LED

ADH

OFF

Leave menu

CAL Main Menu

KIMAX 2 - Installation- and Instruction manual

3-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Communication setup

Configuration is a one time customizing of your Kimax 2 instrument making it specific for your vehicle. This has to be done to make the system work proberly. Through the HFA menu you can set up your Kimax 2 radio panel up for either a display with or without sensors. Through the BCD rotary switch you can set up your Kimax 2 Sensorbox up for working on a truck or on a trailer. The Kimax 2 Universial display unit you can set up with either the HFA menu or with the BCD rotary switch. Through the COF menu you can assign certain axle LEDs to each of the 8 analogue channels. The factory setting for the instruments is that each channel lights up one LED. Example 1: You have a 3 axle truck with air suspension as shown in scenario 1. In this example you do not have to change a thing. Factory setting is HFA 0.10 and channel 1 lights up Axle-LED 1, channel 2 lights up Axle-LED 3 and channel 3 lights up Axle-LED 4.

Example 2: You own a 3 axle truck with air suspension and a 3 axle trailer also with air suspension. You would like to be able to read out the load on your trailer outside the cabin and therefore you have decided to buy instruments like scenario 3. As in example 1 you do not have to change a thing in the MMS instrument. When you change the HFA setting in the SL2 instrument to HFA 0.30 you also have to change the Axle-LED settings. The instruments will look like this after HFA change:

1 2 3 4 5 6 7 8

Enter the CF-submenu and and press the roll button until the display reads 4. Now Axle -LED 1 will be lit press either + or - button to make the Axle-LED flash. When the AxleLED flashes you can change its setting by pressing S-button, now the instrument only reads 4 in the display. Press either + or - to make the first Axle-LED of the trailer flash and press S to change its setting. Press the roll button and the display now reads 5 and Axle-LED 3 will be lit. Press either + og - to make it flash and press S to change its setting. Press either + or - to make Axle-LED 7 on the trailer flash and press S to change its setting. Press the roll button and the display now reads 6 and Axle-LED 4 will be lit. Press either + og - to make it flash and press S to change its setting. Press either + or - to make Axle-LED 8 on the trailer flash and press S to change its setting. Now leave the menu by pressing Enter and Roll until the display reads OFF. Press Enter and Roll until the display reads OFF and press Enter. The instruments should look like this:

4-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Find your combination of instruments below. MUS is a master instrument without sensors. MMS is a master instrument with sensors. SL1 is a slave instrument, it only works properly when a MUS is also installed on the vehicle. SL2 is a slave instrument

Scenario 1

MMS

Optional

Scenario 2

MMS SL2

Scenario 3

MMS SL2

Scenario 4

MUS SL1 SL2

Scenario 5

MUS SL1 SL2

Scenario 6

MUS SL1 SL2

Scenario 7

MUS SL1 SL2

Setup Scenario 1 Scenario 2 Scenario 3 Scenario 4 Scenario 5 Scenario 6 Scenario 7

MUS

MMS HFA 0.10 HFA 0.10 HFA 0.10

SL1

SL2 (Optional) BCD 2 HFA 0.30 or BCD 2

HFA 0.00 HFA 0.00 HFA 0.00 HFA 0.00

BCD 1 HFA 0.20 or BCD 1 BCD 1 HFA 0.20 or BCD 1

BCD 2 BCD 2 HFA 0.30 or BCD 2 HFA 0.30 or BCD 2

Once you have made the communication setup you are ready to customize the instrument(s) to your vehicle. This has to be done in order to make the system work properly.

KIMAX 2 - Installation- and Instruction manual

4-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Configuration menu

Access menu

COF Main Menu

Access menu

Change to the next Axle LED

Change to the next Axle LED

CF

Axle LED Channel 1

Channel "n" 1<n<8

Adjust

Adjust

S

Change setting

Axle LED flash

Leave menu

S

Change setting

Axle LED flash

Leave menu

Change to the next Axle LED

Change to the next Axle LED

Access menu

HFA

HFA setting

Adjust

S

Change setting

HFA setting

Leave menu

Access menu

This menu is only visible if the instrument is either HFA 0.00 or HFA 0.10

ID

ID setting

Adjust

S

Change setting

ID setting

Leave menu

OFF

Leave menu

COF Main Menu

4-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

How to set up HFA and the BCD rotary switch

Enter the HFA-menu to make sure the setting is correct otherwise change it. Enter the menu and change the setting, remember to save the setting by pressing S. To change the BCD rotary switch you must turn off the power and remove the front of the Kimax 2 instrument. Locate the BCD rotary switch on the printed circuit board and change the setting. Put the front back on and switch the power on. When you have finished setting up these settings you must continue to the next part Setting up the LEDs

Access menu

HFA

HFA setting

Adjust

S

Change setting

HFA setting

Leave menu

Setting up the Axle-LEDs

Enter the CF-menu to assign LEDs to the individual inputs: When the LED is flashing you can change its settings by pressing the S-button, to make a LED flash press either + or button. Change to the next input by pressing the rollbutton. You can assign several LEDs to one input but you cannot assign one LED to two or more inputs. LED 1-4 is available on the truck instrument and LED 5-8 is available on the trailer instrument.

Access menu

Change to the next Axle LED

Change to the next Axle LED

CF

Axle LED Channel 1

Channel "n" 1<n<8

Adjust

Adjust

S

Change setting

Axle LED flash

Leave menu

S

Change setting

Axle LED flash

Leave menu

Change to the next Axle LED

Change to the next Axle LED

KIMAX 2 - Installation- and Instruction manual

4-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Protecting your setup and calibration

When your setup, configuration and calibration is done, you can protect these settings and values by activating a software lock on Kimax 2 radio, Kimax 2 universal and Kimax 2 sensor. In the locked position you are able to read all measured values from your Kimax instrument. Further more you can read the values in the service menus, - you are not able to change the setup, configuration or calibration by accident. The software lock is not hacker proof protection, you can easily (decide to) unlock your instrument in order to modify the calibration. Locking Kimax 2 radio and universal The factory setting is unlocked when you get a new instrument, you read a - U when you power your instrument up. After the setup, configuration and calibration is done you can lock your Kimax 2 radio and Kimax 2 universal by powering up the instrument once again while you press Enter and Roll button. Unlocking Kimax 2 radio and universal When you decide to recalibrate your system, you need to unlock the Kimax 2 radio or universal. A locked instrument is displayed as a - L when you power it up. Pressing both Enter and Roll button while you are powering the instrument up once again will unlock the menus, and you will have access to all setup, configuration and calibration menus again.

KIMAX 2

KIMAX 2

You can lock and unlock your Kimax instrument as often as you like. When your Kimax 2 radio or Kimax 2 universal is connected to a Kimax 2 sensor, you need to lock your Kimax 2 sensor separately, as described on the next page. The Kimax instruments is a reliable instrument, which show you the real weight of your vehicle when it is properly calibrated. However it is your responsibility to maintain the calibration of your instrument. Sense-tech Weighing Systems ApS do not in any case take over the responsibility for the accuracy of your calibration.

5-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

When you setup your Kimax 2 sensor, you have decided is it a Slave 1 or a Slave 2 instrument (described in section 4 of this manual). Locking a Kimax 2 sensor is carried out by setting the rotary switch located on the lower left corner on the PCB inside the sensor box.

Locking Kimax 2 sensor The factory setting is unlocked SL 2 when you get a new Kimax 2, this means it is intended for a trailer or a semitrailer. When your trailer or semitrailer is set up, configurated and calibrated you can lock it by rotating the switch from unlocked position 2 to locked position 4. In order to rotate the switch you need to open the box by means of untighten the 4 screws on the top and remove the cover.

When you are using your Kimax 2 sensor as a Slave 1 instrument, typical application is on your truck in combination with a display in your cabin, the rotary switch has to be in position 1 for unlocked set up configuration and calibration and in position 3 for locked position. All sensor boxes has to be locked individually by rotary switch, you can not lock them through your Kimax 2 radio and Kimax 2 universal.

SL1

SL 2

6 54

6 54

6 54

32

32

10 9

10 9

Unlocked

6 54

32

locked

KIMAX 2 - Installation- and Instruction manual

5-2

87

87

87

32

10 9

10 9

87

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Electrical installation

Electrical connection Always disconnect the battery before you perform any installation work on the system of the vehicle. Do not route the cables next to ignition cables or other cables carrying large current. Make sure that the cables are not exposed to tensile or shearing forces. Protect the cables with rubber grommet if you route the cables through holes. For connecting cables use crimp connectors or another approved method. Avoid shortcircuting the system by faulty connections or Squeezed cables. Fasten the cables at suitable intervals. Basic installation When you use your Kimax 2 radio instrument on a single vehicle, you only need to connect the brown wire from pin 1 in the cable set to chassis (- supply) and the black wire from pin 2 to +24 V through a (ignition) switch and a fuse and you are done. Unused wires in the cable set are kept insulated from chassis and any other conducting circuits.

Fuse

Switch

+

Black

Kimax 2

Standard installation trucktrailer Kimax 2 in the cabin: In a standard truck trailer installation the brown wire to chassis (- supply) and the black wire to the +24 V through switch and fuse. The communication circuit is established by connecting the white wire to chassis together with the brown wire and by routing the red and green wire as a new wire from truck to trailer. This new wire is conducting both the supply and communication for the sensor on the trailer. The new supply through the red wire, has a limited capacity of 200 mA and must not be used for anything else than Kimax sensor boxes. Unused wires in the cable set are kept insulated from chassis and any other conducting circuits.

24 V bus

Fuse

Switch

Kimax 2

24 V bus

Supply and communication for sensor on trailer

6-1

KIMAX 2 - Installation- and Instruction manual

Black Red Green White Brown

Brown

S

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Kimax 2 on the trailer: In a standard truck trailer installation the brown wire to chassis (- supply) and the gray and green wire to the new +24 V. The communication circuit is established by connecting the white wire to chassis together with the brown wire and by routing the grey and green wire as a new wire from trailer to truck.

Kimax 2

Unused wires in the cable set are kept insulated from chassis and any other conducting circuits. Getting your system to work: When you have connected your Kimax 2 radio and your Kimax 2 sensor to the electrical system on your vehicle, you need to go to section 4 of this manual for instruction on setting up the communication between Kimax 2 radio and Kimax 2 sensor and learn how to customize the Kimax system to fit exactly to your vehicle. When you have finished the setup of your system, you need to go to section 3 of this manual for instruction on calibrating the Kimax system. When you have finished the calibration of your Kimax system, you can go to section 5 of this manual learning how to protect your setup, configuration and calibration. The Kimax 2 radio is calibrated together with the bellows and the actual weight of the truck. The sensor on the trailer is calibrated together with the bellows and the actual weight of the trailer. In this way you can swap from one trailer to another trailer and you still can read the actual weight of the entire vehicle on the Kimax 2 radio (both trailers have to be equipped with a Kimax sensor). When you have finished your electrical installation, you need to go to section 4 in order to arrange the setup and configuration of the system. Some CAN-bus systems are very sensitive and respond immediately when you load circuits with additional power consumption. In these cases we recommend the standard truck - trailer installation. The power consumption of one Kimax 2 equals the consumption of a 3 W lamp on a 24 Volt system. Advanced trucktrailer installation: On a lot of trucks you are able to use the existing electrical wires routed in-between the truck and on the trailer, which means you do not have to add an extra connector to the truck and trailer.

KIMAX 2 - Installation- and Instruction manual

6-2

Brown

White

This new wire is conducting both the supply and communication for the sensor on the trailer. The new supply through the red wire, has a limited capacity of 200 mA and must not be used for anything thing else as Kimax sensors.

Grey Green Supply and communication for sensor on trailer

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Advanced trucktrailer installation version: On some trucks it is possible to install a Kimax 2 radio as display only without sensors, when you do not want to route air tubes in your cabin or when you have limited available space behind your dashboard.

Kimax 2 radio without sensors in the cabin

Fuse

Switch

+

DCfilter

Black

Kimax 2

Green

Supply and communication for sensor on trailer

+

Kimax 2 sensor as slave 1 on the truck chassis

Battery

White Brown

Kimax 2 Kimax 2

Grey Green Supply and communication for sensor on trailer

Kimax 2 sensor as slave 2 on the trailer chassis

Grey Green Supply and communication for sensor on trailer

6-3

KIMAX 2 - Installation- and Instruction manual

Brown

White

Brown

White

Black Green

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

KIMAX 2 - Installation- and Instruction manual

6-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Air-sensor installation

Connection of compressed air. Before you carry out any installation work related to the air suspension, make sure that the suspension has been brought to the lowest possible position and all compressed air are released. It is important to install the hoses in such a way that they are not affected by other components. The hoses must be fixed at suitable intervals Route the hoses in such a way that they are not exposed to exhaust heat and other heating sources that may lead to the permissible temperature being exceeded. Avoid damages from gravel, friction and contact with sharp edges. Avoid excessive tension of the hoses. Make sure that the smallest bending radius is not exceeded. Basic installation:

Air-pressure for KIMAX Level valve Shock absorber Storage tank Bellow Maintain level

First of all you have to identify the supply hoses for the bellows. Depending on the layout of your vehicle you can have one or two bellows each side on each axle. Your air suspension system can be deviated in a left-hand side and a right-hand side with individual air circuits and individual level controlling valves due to minimizing rolling. In all cases you will get the best accuracy and the fasted response, when you use Kimax 2 Instruments with double air-inlet for each axle. In cases of steering axles or rear axles with common air circuit you can use a single input Kimax 2 instrument in order to save cost in installation and investment.

7-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Cut the supply hose between the level valve and the bellow, assemble the hose again by using a T-piece. Connect the instrument to the air bellows by means of an approved 6 x 1 mm polyurethane hose. A throttle has to be put in every 6 mm hose at the T-piece end. It is important to mount the throttle in T-piece end of the hose, it will not work i the correct way, when you put it in the sensor end of the connecting hose. The throttles protect the pressure sensors in the Kimax 2 instruments against burstpressure. Further more the throttles protect the air circuit against unexpected leakage when one of the 6 mm hoses has a damage. Unexpected loss of compressed air may affect your breaking and steering capability.

Air inlet 1

Air inlet 2

Air inlet 3

6 mm

throttle 8 mm

Minor airflow towards pressure sensor 8 mm T-piece Major airflow to/from bellows

7-2

All air-inlets on Kimax instruments and all belonging fittings are quick-release type. You need to make a clean cut in a right angle with a sharp knife before you connect a new tube to a Kimax instrument. You can release the locking mechanism by push-in the releasing ring on the air-inlet. (An 7 mm open-ended spanner is a suitable tool for pushing-in the release ring meanwhile you slightly pull out the tube).

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Air-sensor installation on your vehicle When you suspension system is deviated in a left hand side and in a right hand side by use of a level control valve in both left and right side, you can connect a KIMAX instrument by using the standard fitting you get together with your instrument according to the below diagram. Basic layout

When your lift-axle is engaged, the pressure in air 3 left equals air 2 left and the pressure in air 3 right equals air 2 right, axle 2 and 3 share the weight of the rear of your vehicle. When your lift-axle is disengaged (lifted from the road) the pressure in air 3 right and air 3 left is 0 bar and all the weight of the rear-end of your vehicle is carried and weighed by axle 2.

Rearsite

AMP male connector 929505-5 (14-pos.) L

Air inlet 3 Air inlet 2

L

Air inlet 1

7-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Optional layout

You can find additional layout on different vehicles in the appendix to this manual section 14 and on www.kimax.com.

KIMAX 2 - Installation- and Instruction manual

7-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

SG-sensor installation

Front axle installation On vehicles with steel spring suspension (parable springs or leave springs) e.g. on front axles, we recommend SG sensors. The SG sensor senses the bending of the front axle caused by load of the vehicle. The SG sensor has to be glued on the front axle in order to read the bending of the front axle (more preciseto read the strain in the front axle). Gluing the SG Sensor to the front axle has to be done with a lot of care, when it is carried out. Both the SG sensor and the front axle needs to be at 20 C at least, not only on the surface of the axle, but the entire axle needs to be at 20 C ! - Typically that means that the vehicle has to stay in the workshop one night over before you start the gluing process. The surface of the front axle, where you are going to fit the SG sensor must be extremely clean and without of any dust, oil and grease. Cleaning: The very best way to clean the axle from dust and spots of oil, is to wash it with warm water and soap, and then you clean the axle surface with a oil removing chemical. The optimal position for fitting the SG sensor is on the top of the centreline in the middle of the axle, as indicated on the drawing below. You have to remove all paint and corrosion protecting materials from the axle in an area at least with the dimension as described in the below drawing. This area has to be even, dry and clean. The easiest way to make the surface even is to use a grinding machine with emery paper first grain 80-120 later grain 180220.

SG sensor

Center

Sense-Tech

Weighing Systems

Surface has to be even and rughened by emery paper 220 grain

Scale 1 : 1

8-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

All dust from grinding the front axle, has to be remove by washing the grinded area with cleaning solvent and white cleaning paper. You have to continue the wiping process until you does not pick up any dirt by using white cleaning paper. The SG sensor itself has to be grinded slightly by emery paper grain 220 and wiped off with cleaning solvent and cleaning paper on the 12 x 18 mm pad on the bottom side immediately before gluing the sensor to the axle. Gluing: Apply a tiny drop of Z70 on the 12 x 18 mm pad on the bottom side of the SG sensor and put it immediately in position upon the axle and press it with your thumb for 2 minutes until the glue has cured. The position of the SG sensor has to be like it is in the drawing below. After curing the SG sensor fix the flex tube shielding of the cables to the axle by mean of cable strips. Now you are ready to connect and test the SG sensor.

Scale 1 : 1

Testing: Connect the SG sensor to the KIMAX 2 instrument through the SG extension cable according to the circuit diagram. You will get a waterproof junction when you connect the SG sensor and the SG extension with the adapter. Switch on the KIMAX 2 instrument and go to the OAA reading for the relevant axle (in most cases the front axle) you will typically get a reading in the range 5.00 to 15.0 which is a relative value, ranging up to 99.9 %. Load the axle (when testing a front axle make some people enter the cabin, 4 adults ~ 300 kg) and you read an increasing OAA value100 kg ~ 0,1 % increasing OAA value. Protecting the SG sensor

KIMAX 2 - Installation- and Instruction manual

8-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Electrical installation SG sensor

KIMAX 2 SG version

AMP male connector 929505-5 (14 - pos.)

Rearsite

+ 10 V supply for SG sensor Red -Battery Brown Brown White - sensor signal

Red Brown White

SG sensor Extension cable

10 - 30 V +Battery

Crimp splice 1 mm# Black

2,7 m cable from SG sensor

Connector SG sensor

Adapter housing

Connector SG extension 4,9 m Extension cable

Black

Violet Blue Yellow

optional

signal 3 signal 4

optional optional

optional

Black

Violet Blue Yellow

Sense-Tech

Weighing Systems

Connection diagram for a single SG sensor

+ 10 V supply for SG sensor Red -Battery Brown Brown White - sensor signal 1 SG sensor 1 Extension cable

Red Brown White

Red 10 - 30 V +Battery Brown signal 2 White

SG sensor 2 Extension cable

Crimp splice 1,5 mm#

Connection diagram for multiple SG sensors on individual axles

+ 10 V supply for SG sensor Red Brown Brown White - sensor signal 1 SG sensor axle 1 Extension cable Red Brown White

Crimp splice 1,5 mm# Red Brown signal 2 left White

SG sensor axle 2 left Extension cable

Red Brown signal 2 reight White

SG sensor axle 2 reight Extension cable

Connection diagram for 1 SG sensor on front axle and 2 SG sensors on one rear axle

8-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

The steel cover is glued to the axle and to the flextube in the shaded area with Tunap 3040 (black)

Ventilation opening

Inlet 4 Sense-Tech

Weighing Systems

Ventilation opening 3

Cavity in flex tube and underneath steel cover is molded by Tunap 3020 (grey)

2 unit Plastic plug 3 mm 1 unit Plastic plug 4 mm

Step 1 The steel cover is glued to the axle and to the flex tube in the shaded area with Tunap 3040 (black), the curing time is 24 hours at 20 C, the cover can be fixed with two cable strips around the axle. Step 2 The steel cover is moulded completely with Tunap 3020 (gray) through 4 mm opening, until the Tunap 3020 is floating out of the 3 ventilation openings and the flex tube stub is filled too. When you have moulded the steel cover completely with Tunap and have cut away all surplus Tunap from the axle and the steel cover and protect all grinded and blank surface by use of your normal anti corrosion paint and protection system. Typical application: SG sensor on front axle combined with air suspension on rear axles.

KIMAX 2 - Installation- and Instruction manual

8-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Optional sensor installation

Hydraulic suspension is often used on heavy load low bed trailers. In order to measure the load on this kind of vehicles, hydraulic sensors are used in cooperation with Kimax instruments, which can be Kimax 2 radio, Kimax 2 sensor as well as Kimax 3 sensor.

Kimax 2

2 wire 4 - 20 mA current loop Hydraulic transmitter

When you use Kimax 2 radio for hydraulic sensors, you have to connect the sensor(s) as indicated on the below circuit diagram. The 2-wire hydraulic sensor has to be supplied either from Kimax 2 sensor supply (pin 9) or from the 24 V supply net directly.

Green - Communication I Orange - OBC Red -Battery Brown White signal 1 + sensor Hydraulic sensor 1

2 1 1

Hydraulic sensor 2

2 1

Blue Yellow

10 - 30 V +Battery Black

Hydraulic sensor 3

2

signal 2 signal 3

Yellow - Alarm OC (NPN) Grey - Printer Tx White - Communication II

When you use Kimax 2 universal or Kimax 2 sensor, each unit is equipped with a cable and belonging connector, which fits directly to the hydraulic sensor.

9-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

The hydraulic sensor is connected as indicated in this diagram.

3 2 1 2

Brown

Black

+ 24 V

The hydraulic sensor act as a 2-wire current loop sensor, which is connected to the Kimax instrument by means of an internal pull down resistor. When you are supplying the hydraulic sensor directly from the 24 V net on your vehicle, please make sure this net is referring to the same ground potential (chassis) as the Kimax instrument does.

1

Kimax 2 radio

2

Hydraulic sensor

+ 68 ohm pull down

0 - 20 mA current loop

KIMAX 2 - Installation- and Instruction manual

9-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

OBC serial output

The Kimax II radio panel offers you a RS-232 serial output, displaying the measured values you can read on the display. The string of data is broadcasted every 3 second and can be picked up by a GPRS unit e.g. a FM 300 unit. For test you can set up a HyperTerminal on your laptop with the below parameters: Bit pr sec 9.600 Data bit 8 Parity N Stopbit 1 Flowcontrol N and you can read the broadcasted values as numeric characters. You need to set up your GPRS or FM300 to receive on the above parameters too. In order to retransmit the Kimax values through your GPRS unit, or receive the data in a FM300, you can set up a mask: UUUUww ..... SSS framing 10 x 3 digits. When you want to retransmit the total weight of the truck and the trailer, you need to pick up digit 10+11+12 for the truck and digit 25+26+27 for the trailer. Protocol: UUUUww111222333777999444555666888AAASSS SSS end of message AAA value for payload trailer 888 value for total weight of trailer 666 value for axle #6 555 value for axle #5 444 value for axle #4 999 value for payload truck 777 value for total weight truck 333 value for axle #3 222 value for axle #2 111 value for axle #1 UUUUww start of message Connection diagram for On Board Computer signals:

Kimax 2 - Radio Rearside

11 13

AMP male connector 929505-5 (14 - pos.)

10 12

14

-Battery

Brown Green - Communication I Orange - OBC

1 3 5 7 9 11 13

RS-232

10 12 14

10 - 30 V +Battery

Red - Supply for sensorbox Yellow - Alarm OC (NPN) Grey - Printer Tx White - Communication II Black

10-1

KIMAX 2 - Installation- and Instruction manual

FM300

GPRS

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Printer serial output

The Kimax 2 radio panel offers you a RS-232 serial output, for printers. The string of data is broadcasted every time you access the printer function in the menu. For test you can set up a HyperTerminal on your labtop with the below parameters, Bit pr sec 4.800 Data bit 8 Parity N Stopbit 1 Flowcontrol N and you can read the broadcasted values as numeric characters. You need to set up your printer for receiving on the above parameters too. Most common printer with serial input can be used with Kimax II. Connection diagram for serial printer:

Kimax 2 - radio Rearsite

11 13

AMP male connector 929505-5 (14 - pos.)

10 12

Printer

14

-Battery

Brown Green - Communication I Orange - OBC

1 3 5 7 9 11 13

10 12 14

10 - 30 V +Battery

Red - Supply for sensorbox Yellow - Alarm OC (NPN) Grey - Printer Tx White - Communication II Black

RS-232

Alarms

Kimax 2 offers you two different alarm levels. A1 which is an individual alarm level for each axle, when the A1 level is exceeded, the associated axle diode starts flashing. A2 is an external vehicle alarm. When the A2 level is exceeded the output on the yellow wire is switched to ground through a NPN open collector output. The A2 output has a 10 K pull up resistor and is protected by a diode. The load of A2 output is limited to 200 mA DC. Typical external alarms are warning lamps mounted in such a way that they are visible from outside the vehicle. You will need a lamp on the truck and a lamp on the trailer.

KIMAX 2 - Installation- and Instruction manual

10-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Connection diagram for external alarms and DTCO: The A2 alarm output can be connected to a DTCO to log when and for how long you exceed the A2 level.

Kimax 2 - radio Rearsite

11 13

AMP male connector 929505-5 (14 - pos.)

10 12

14

-Battery

Brown Green - Communication I Orange - OBC

1 3 5 7 9 11 13

10 12 14

10 - 30 V +Battery

Red - Supply for sensorbox Yellow - Alarm OC (NPN) Grey - Printer Tx White - Communication II Black

External warning lamp

Connection diagram Kimax 2 Universal:

1R Air inlet

OBC +12 to 30 V DC Ground Communication 1 Communication 2 Alarm OC (NPN) Printer

1L

2R Air inlet

Blue Grey Brown Green White Yellow Pink

2L

3R Air inlet

3L

10-3

KIMAX 2 - Installation- and Instruction manual

DTCO

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Kimax 2 Universal has equal functionality as the Kimax 2 Radio have. The Kimax 2 Universal is build in another box and has different type of cable for electrical connection as the Kimax 2 Radio have. For connection diagram please reefer to drawing above. Basically all menus are identical with the menus on Kimax 2 Radio. Kimax 2 Universal is able to communicate with Kimax 2 Radio and with Kimax 2 Sensor. For communication setup details please reefer to section 4.

Connetion diagram Kimax 2 Sensor:

1R Air inlet

1L

2R Air inlet

2L

3R Air inlet

3L

+12 to 30 V DC Ground Communication 1 Communication 2 Alarm OC (NPN)

Grey Brown Green White Yellow

Kimax 2 Sensor is able to communicate with Kimax 2 Radio and Kimax 2 Universal. For communication setup details please reefer to section 4. Kimax 2 Sensor is build in the same box as Kimax 2 Universal. For connection diagram please reefer to the drawing above.

KIMAX 2 - Installation- and Instruction manual

10-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Accessories

Kimax 2 wireless Optional your Kimax 2 radio and Kimax 2 universal can be equipped with a wireless terminal, making it possible to read all the weight readings on a portable display in a distance of 30100 m from your Kimax 2 instrument. You can easily code the wireless terminal for your individual Kimax 2 radio, by means of 255 individual ID codes.

KIMAX 2

S

KIMAX 2

Kimax 2 radio is broadcasting the measured actual axle loads and total weights every 6 seconds through a 433 MHz. Displayed menus When you activate your wireless terminal, it starts displaying the axle position like it was displaying when it powered off last. Until a valid reading is received, it displays Axle #. - - . Individual weight for axle #1 is displayed as 1.04.5, - first digit is the actual axle no, the next 3 digits is formatted as xx.x tonne When an axle is not present, the read out is displayed as Axle #.00.0 Your wireless terminal has to be coded with exactly the same ID code as the actual Kimax 2 radio you want to monitor. In normal run mode the wireless terminal powers off automatic after approx 2 minutes without any activation of buttons. In the ID mode the wireless terminal do not power off until you leave the menu by pressing the Roll button. When you do not get a readout after pressing Roll for a second, - then check the battery.

11-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

3

5 sec 1.xx.x Axle No 1

3

+ -

I .xxx 2.xx.x Axle No 2

ID code Nr

3.xx.x Axle No 3

Increase ID code Nr

-

Decrease ID code Nr

3

4.xx.x Axle No 4 Run mode

5.xx.x Axle No 5

6.xx.x Axle No 6

-

7.xx.x

Truck total

8.xx.x

Trailer total

9.xx.x

Truck + Trailer total

KIMAX 2 - Installation- and Instruction manual

11-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Frequently Asked Questions:

Q Q Q Q Q Q Q 1: 2: 3: 4: 5: 6: 7: Why is configuration and calibration not done by the manufacture? What is HFA and why is it changeable? (HFA = Trailer/Truck Addressing) Why do I have to configure CF? (CF = Configuration of axles) Why do I have to calibrate both LO and HI? (LO = Low weigh, HI = High weigh) Why do I have to calibrate each axle? What is the OAA values? What is the ADL and the ADH values? It is because the manufacture cannot know which type or brand the system will be installed on, when all types or brands are unique in there suspension and they have different number of axles. HFA id an address, it tells the instrument where it is installed, so it can know which axles there belongs to it. Plus it tells the other instruments which axles it has connected. HFA is changeable, because a box can mount on either a truck or a trailer. The only thing the manufacture have decided is that a master must be mounted on a truck and it has to be set at HFA = 1 or HFA = 0. To adapt the instrument for your special vehicle, with the consideration of axles and there placement. Plus it will give you a visual sight of how your vehicle looks like on the display of the instrument and it tell the instrument which axles it has to measure. It is to adapt the instrument for your special vehicle, so it will measure the right pressure. The reason that there are two menus for this is purely mathematics. The axle load indicator functions by calculating a straight line and to do this it needs to get two set of coordinates existing of (x,y), and that is what you tell the instrument in LO and HI. It is because each vehicle is unique; in both weight and the air bellows in your suspension can vary among the other axles. The OAA values is a value in percent (0,00-100%). This value tells you if the sensor is working properly, when the pressure is increasing the OAA value must also go up. If not, the sensor could be defect. The ADL and the ADH values are bit values (0.00-65.5). These values are the ones that the instrument is using when it calculates the axle pressure. The values emergence when you calibrate LO and HI. Test a Kimax 2 in the workshop How do I refit my Kimax on a new vehicle Why is my measured values very unstable Why is my Kimax 2 not responding when I try to save new values

A 1:

A 2:

A 3:

A 4:

A 5: A 6:

A 7:

Q Q Q Q

1: 2: 3: 4:

12-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Frequently Asked Questions:

KIMAX 2 - Installation- and Instruction manual

12-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Technical specifications

How to build Kimax 2 radio in: Kimax 2 radio is designed to fit directly into one of your free DIN radio slots. Your kit contains a mounting frame which can be placed in your free DIN radio slot when no frame is present already. Connect the cable set to the electrical circuit on the vehicle and connect the Kimax 2 radio to the cable set connector before you snap it in into the frame.

In order to replace the Kimax 2 radio, you need to use the two belonging forks for releasing the snaps before you can pull the instrument out of the frame.

How to build Kimax 2 universal and sensor in: Kimax 2 universal and sensor is designed for panel mounting through 4 screws. In order to access the slots for the mounting screws, you need to open the box by means of loosen the 4 plastic screws you see on the front of the instruments. Be carefully and do not harm the rubber gasket between case and cover. Behind the cover of the instrument you find 4 slots, one in each corner of the case, through these slots you can mount the instrument to your panel by means of 4 pieces of 4 mm or 5 mm screws. You find detailed drawings on next page. Even through the Kimax casing is basically IP67 proof when the cover is properly installed, we recommend you to install your Kimax instrument in dry conditions on your truck or trailer.

13-1

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

How to build Kimax 2 universal and sensor in:

Please notice: this drawing is out of scale, - do not copy and paste to your panel !

KIMAX 2 - Installation- and Instruction manual

13-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Technical specification Kimax 2 radio:

Supply voltage Current consumption Alarm 1 Alarm 2 Display Measuring accuracy Air connection Maximum pressure Operating pressure SG Sensor Printer On-Board Computer Device bus Operating temperature Storage temperature Dimensions(DIN format) Weight Approval 10 ... 30 Volt direct current max. 90 mA Flashing display Output open collector NPN max. 0.2 A/ 50 VDC Three-digits 7-segment LED, character height 20.3 mm 2 % of maximum load at 0 C - +50 C Quick release connection, 6 mm hose 15.5 bar (225 psi ) range 0 to 10.5 bar (0 to 150 psi ) 0-20 mA input RS-232 serial RS-232 serial Power line communication -25 C...+70 C -40 C...+70 C 182 x 53 x 75 mm approx. 550 g CE and E1

Set includes:

Kimax 2 radio 1 + 1 x 2 sensors

Part number 10167 1 x display unit, cabin 1 x mounting frame + connection cable 3 x angle fittings 3 x air pressure throttle dia. 6mm 3 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 radio 2 x 2 sensors

Part number 10169 1 x display unit, cabin 1 x mounting frame + connection cable 4 x angle fittings 4 x air pressure throttle dia. 6mm 4 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 radio 3 x 2 sensors

Part number 10171 1 x display unit, cabin 1 x mounting frame + connection cable 6 x angle fittings 6 x air pressure throttle dia. 6mm 6 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 radio 1SG + 2 x 2 sensors

Part number 10173 1 x display unit, cabin 1 x mounting frame + connection cable 1 x SG Sensor + extension cable 4 x angle fitting 4 x air pressure throttle dia. 6mm 4 x T-fitting dia. 8mm / 6mm / 8mm

Technical specification Kimax 2 universal:

Supply voltage Current consumption Alarm 1 Alarm 2 Display Measuring accuracy Air connection Maximum pressure Operating pressure Printer On-Board Computer Device bus Operating temperature Storage temperature Dimensions Weight Approval 10 ... 30 Volt direct current max. 90 mA Flashing display Output open collector NPN max. 0.2 A/ 50 VDC Three-digits 7-segment LED, character height 20.3 mm 2 % of maximum load at 0 C - +50 C Quick release connection, 6 mm hose 15.5 bar (225 psi ) range 0 to 10.5 bar (0 to 150 psi ) RS-232 serial RS-232 serial Power line communication -25 C...+70 C -40 C...+70 C 180 x 135 x 52 mm approx. 750 g CE and E1 You find more details on sensor layout in section 14 of this manual and on www.kimax.com

Set includes:

Kimax 2 universal 3 x 2 sensors

Part number 10107 1 x display unit, universal 6 x air pressure throttle dia. 6mm 6 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 universal 2 x 2 sensors

Part number 10109 1 x display unit, universal 4 x air pressure throttle dia. 6mm 4 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 universal 3 sensors

Part number 10110 1 x display unit, universal 3 x air pressure throttle dia. 6mm 3 x T-fitting dia. 8mm / 6mm / 8mm

13-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Technical specification Kimax 2 sensor:

Supply voltage Current consumption Alarm 2 Measuring accuracy Air connection Maximum pressure Operating pressure Device bus Operating temperature Storage temperature Dimensions Weight Approval 10 ... 30 Volt direct current max. 90 mA Output open collector NPN max. 0.2 A/ 50 VDC 2 % of maximum load at 0 C - +50 C Quick release connection, 6 mm hose 15.5 bar (225 psi ) range 0 to 10.5 bar (0 to 150 psi ) Power line communication -25 C...+70 C -40 C...+70 C 180 x 135 x 60 mm approx. 750 g CE and E1

Set includes:

Kimax 2 sensor 3 x 2 sensors

Part number 10113 1 x sensor unit, sensor 6 x air pressure throttle dia. 6mm 6 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 sensor 2 x 2 sensors

Part number 10115 1 x sensor unit, sensor 4 x air pressure throttle dia. 6mm 4 x T-fitting dia. 8mm / 6mm / 8mm

Kimax 2 sensor 1 x 2 sensors

Part number 10117 1 x sensor unit, sensor 2 x air pressure throttle dia. 6mm 2 x T-fitting dia. 8mm / 6mm / 8mm

Technical specification Kimax 2 wireless:

Supply voltage Display Device bus Range No of individual ID codes Operating temperature Storage temperature Dimensions Weight 2 x 1,5 V AA battery Four-digits 7-segment LCD, character height 12.7 mm 433,92 MHz - FM coded 30100 m 255 -10 C...+50 C -25 C...+50 C 200 x 95 x 35 mm approx. 230 g

Set includes:

Kimax 2 wireless

Part number 10119 1 x wireless terminal 1 x transmitter module 1 x Dashboard bracket 2 x 1,5 V AA battery

Additional technical information you get from www.kimax.com

Tools and parts you can need for proper installation: Gluing Set STWS part nr 10139 T-piece 868 mm STWS part nr 10124 Elbowe 6 mm STWS part nr 10126 4 mm throttles for 6 mm PA hose STWS part nr 10126 T-piece 666 mm 6 mm Polyurethane (PA) hose 10 bar manometer with 6 mm tubing Manual air pump Hose cutting knive Cable strips

KIMAX 2 - Installation- and Instruction manual

13-4

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Basic test setup:

To test two instruments with pressure sensors at all channels (e.g. 10147 and 10116) you can connect them as shown here:

24 V supply

+

Black Red

Kimax 2 Brown Green White

Kimax 2

Grey Green Brown White Supply and communication for sensor on trailer

If the instruments are configured as the ones described in chapter 4 page 2 and calibrated to show 0,00 when no pressure is applied to the individual channels and 10,0 when 10 bar is applied to the channels you can apply e.g. 6 bar to all channels and you will get a total reading of 6 times 6,00 equal 36,0 on the display of the radio panel. If you disconnect the white wire from ground the communication between the two instruments will stop and the reading on the radio panel will be 3 times 6,00 equal 18,0. Connect the white wire again and the reading will be 36,0 again.

Air inlet 3

1 3 5 7 9 11

Air inlet 2

Air inlet 1

10

12

Air inlet 3

Air inlet 2

Air inlet 1

Kimax 2

Air inlet 1

Bar

Adjustable air supply 0 - 10 bar

If the reading is not as you expected you may recalibrate the instruments see chapter 3.

14-1

KIMAX 2 - Installation- and Instruction manual

Air inlet 2

Air inlet 3

10

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Appendix:

KIMAX 2 - Installation- and Instruction manual

14-2

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

14-3

KIMAX 2 - Installation- and Instruction manual

Introduction

Sensor installation

Electrical installation

Setup

Calibration

Protecting Calibration

Daily use

Additional information

Your notes:

KIMAX 2 - Installation- and Instruction manual

14-4

Introduction

Kimax 2 calibration

Axle #2 Axle #3 Axle #4 Axle #5 Axle #6 Axle #7

Appendix:

Axle #1

Sensor installation

0,00-99,9

OAA empty

Electrical installation

0,00-99,9

OAA loaded

0,00-99,9 Ton

Setup

LO

HI

0,00-99,9 Ton

14-5

Calibration

ADL

0,00-65,5

0,00-65,5

ADH

Protecting Calibration

0,00-99,9 Ton

A1

Daily use

CF

KIMAX 2 - Installation- and Instruction manual

HFA tractor: Date:

HFA trailer:

Rotary switch trailer: Calibrated by:

Additional information

Vehicle ID:

Sense-Tech Weighing Systems ApS Bygade 43 A DK 7173 Vonge Tel +45 7670 3001 Fax +45 7670 3002 mail@sense-tech.com www.sense-tech.com

14-6

You might also like

- Operating Manual of Disomat TersusDocument204 pagesOperating Manual of Disomat TersusDan Bal100% (3)

- Troublesshooting Manual 3b6 PDFDocument50 pagesTroublesshooting Manual 3b6 PDFAugusto Oliveira86% (22)

- w220 Airmatic Service Manual.Document47 pagesw220 Airmatic Service Manual.Kenny Sanhueza100% (1)

- Lmi OperationDocument24 pagesLmi OperationMohamed Rashed100% (2)

- ALIMARK - User ManualDocument60 pagesALIMARK - User ManualfayasibrahimkuttyNo ratings yet

- Sullair Supervisor Controller Manual - 02250146-049Document32 pagesSullair Supervisor Controller Manual - 02250146-049martin_jaitman82% (11)

- W221 en PDFDocument13 pagesW221 en PDFalirio0% (1)

- Applications Manual: Honda/Acura Immobiliser SystemDocument17 pagesApplications Manual: Honda/Acura Immobiliser Systemaoh1226No ratings yet

- Scania Diagnos & Programmer 3 2.28Document13 pagesScania Diagnos & Programmer 3 2.28scania100% (3)

- KK 2.1 Multi-Rotor Control Board: User GuideDocument14 pagesKK 2.1 Multi-Rotor Control Board: User GuideSandal MasjidNo ratings yet

- Technical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangerDocument9 pagesTechnical Data Sheet 3RW33 Soft Starter For Carrier NGC Iv: DangervickersNo ratings yet

- Liftt Control Manual, ALC II PDFDocument70 pagesLiftt Control Manual, ALC II PDFFikret Davudov100% (1)

- PWS CARICO 24Vdc - en PDFDocument22 pagesPWS CARICO 24Vdc - en PDFchaladsch100% (1)

- Suspension AirmaticDocument83 pagesSuspension AirmaticAnonymous N4swcSNo ratings yet

- Suspension AirmaticDocument83 pagesSuspension AirmaticAnonymous N4swcSNo ratings yet

- DEC2 Tuning and Calibration PDFDocument18 pagesDEC2 Tuning and Calibration PDFbagus100% (3)

- General SchenckDocument211 pagesGeneral Schenckingecontrol100% (2)

- Product Sensor Web-UKDocument2 pagesProduct Sensor Web-UKEma RussiNo ratings yet

- Installation & Calibration: Ed2-2X-Sm Series Skidweigh SystemDocument12 pagesInstallation & Calibration: Ed2-2X-Sm Series Skidweigh SystemTed JurcaNo ratings yet

- Installation & Calibration: Ed2-Sll Series Skidweigh SystemDocument12 pagesInstallation & Calibration: Ed2-Sll Series Skidweigh SystemTed JurcaNo ratings yet

- SkidWeigh Plus, Freight Weight Print Out TicketsDocument11 pagesSkidWeigh Plus, Freight Weight Print Out TicketsTed JurcaNo ratings yet

- Manual Xk3190 A12Document17 pagesManual Xk3190 A12Paul Cabrera0% (1)

- enDocument31 pagesenRegistr Registr100% (4)

- 1K 2K In-Chassis Maintenance 4th GenDocument86 pages1K 2K In-Chassis Maintenance 4th GenMuhammad Fahmi Mahmud100% (1)

- SkidWeigh Series, ED2-SM Installation & Calibration InstructionsDocument9 pagesSkidWeigh Series, ED2-SM Installation & Calibration InstructionsTed JurcaNo ratings yet

- Auto TraDocument84 pagesAuto TraAjnmalNo ratings yet

- ED3-AT - Barakat Version SkidWeigh Plus Installation & CalibrationDocument12 pagesED3-AT - Barakat Version SkidWeigh Plus Installation & CalibrationTed JurcaNo ratings yet

- BIM-01-1 Bus Interface Module For OBD-II Vehicle Interface: MAN #650341:CDocument4 pagesBIM-01-1 Bus Interface Module For OBD-II Vehicle Interface: MAN #650341:CSeshadri VenkatNo ratings yet

- Average Responding RMS: Firmware Upgrade For Model 2001-M Release NotesDocument3 pagesAverage Responding RMS: Firmware Upgrade For Model 2001-M Release Notesblack11111No ratings yet

- ED2-SM-OSHA Installation & CalibrationDocument10 pagesED2-SM-OSHA Installation & CalibrationTed JurcaNo ratings yet

- Instrument PanelDocument30 pagesInstrument Panelglazing.skulls.00No ratings yet

- Alimak Alc - IIDocument62 pagesAlimak Alc - IImoiburNo ratings yet

- 672089481X667872X37 PDFDocument15 pages672089481X667872X37 PDFPablo SchamberNo ratings yet

- PAT DS150H 2 (Consolas Service Manual)Document13 pagesPAT DS150H 2 (Consolas Service Manual)diomiraNo ratings yet

- Body Repair: SectionDocument27 pagesBody Repair: SectionFSR1407No ratings yet

- KK 2.1 Multi-Rotor Control Board: User GuideDocument15 pagesKK 2.1 Multi-Rotor Control Board: User GuideSagar DeshpandeNo ratings yet

- 30-6030 Series 2 Plug & Play EMSDocument17 pages30-6030 Series 2 Plug & Play EMSebetts0206No ratings yet

- Link 5Document38 pagesLink 5emanueltorres.traderNo ratings yet

- Jolly2: Installation User's ManualDocument16 pagesJolly2: Installation User's ManualCuong NguyenNo ratings yet

- Over load VK3-Control-Operating-ManualDocument8 pagesOver load VK3-Control-Operating-ManualMohamed YousupNo ratings yet

- RSUDocument12 pagesRSUtomallor101100% (1)

- Penta ManualDocument61 pagesPenta ManualDouglas SantosNo ratings yet

- Webco ABS Sensor TestsDocument4 pagesWebco ABS Sensor TestsДмитрий Пупкин0% (1)

- Installation Instructions For 3-3/8" Programmable Speedometer Before You StartDocument2 pagesInstallation Instructions For 3-3/8" Programmable Speedometer Before You Startjulio797No ratings yet

- 1K 2K In-Chassis Maintenance 4th GenDocument80 pages1K 2K In-Chassis Maintenance 4th GenJohn MichaelNo ratings yet

- MEG1000 ManualDocument17 pagesMEG1000 ManualKostas TressosNo ratings yet

- Precor 9.27 ServiceManualDocument58 pagesPrecor 9.27 ServiceManualAdrian Garcia FrancoNo ratings yet

- Zero Point CalibrationDocument4 pagesZero Point CalibrationMike Tsai100% (1)

- Irc Blipper Non Ride by Wire Quickshifter InstructionsDocument5 pagesIrc Blipper Non Ride by Wire Quickshifter InstructionstweencupNo ratings yet

- IM Checkout Procedure EM2127Document7 pagesIM Checkout Procedure EM2127Jose ZorrillaNo ratings yet

- SoftwareDocument39 pagesSoftwarepetsamo_m100% (5)

- Y62 Patrol: 17 Digit Vin LocationsDocument22 pagesY62 Patrol: 17 Digit Vin LocationsAlexandr Taranenko100% (1)

- DP6011 Jeep CJ Digital Dash 1955-1986 8292022Document5 pagesDP6011 Jeep CJ Digital Dash 1955-1986 8292022Eduar AcvdoNo ratings yet

- k9 AlarmDocument18 pagesk9 AlarmChristianHernandezNo ratings yet

- Controlador de EmpilhadeiraDocument76 pagesControlador de EmpilhadeiraJosias100% (5)

- 10-1002 For EMS - 30-1002Document7 pages10-1002 For EMS - 30-1002Javier RojasNo ratings yet

- LMI НС3926 PDFDocument45 pagesLMI НС3926 PDFГригорий Григорян100% (4)

- Lan System: SectionDocument54 pagesLan System: SectiontsudsingNo ratings yet

- ALC 2 ManualDocument68 pagesALC 2 ManualBudi SatriaNo ratings yet

- Electronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesFrom EverandElectronic Automotive Transmission Troubleshooter Nissan-Infinity VehiclesNo ratings yet

- Stories from the Road 6: An Automotive Case Studies SeriesFrom EverandStories from the Road 6: An Automotive Case Studies SeriesNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- CAN Newsletter: Hardware + Software + Tools + EngineeringDocument42 pagesCAN Newsletter: Hardware + Software + Tools + EngineeringAlex Dinu100% (1)

- Biniam TesfayDocument76 pagesBiniam TesfayCiise Cali HaybeNo ratings yet