Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Uploaded by

Agus HermantoCopyright:

Available Formats

Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Uploaded by

Agus HermantoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Belchatow Poland Supercritical Steam Coal Power Plant Editorial

Uploaded by

Agus HermantoCopyright:

Available Formats

858 MWe supercritical extension for Belchatow: Poland's largest and most efcient lignite-red plant.

Belchatow

The Belchatow extension will be the largest generating unit ever built in Poland and also the most efficient lignite plant. Alstom is supplying the plant to utility BOT Elektrownia Belchatow SA under a full turnkey EPC (engineering, procurement, construction and commissioning) contract. This new power plant will allow to increase electricity production in full compliance with European environmental regulations.

to Oc r2 be 00 7

LIGNITE POWER

858 MWe supercritical extension for Belchatow

The supercritical unit under construction at Belchatow will be Poland's largest and most efficient lignite fired plant. Andrzej Twardowski, Alstom, Poland

rom the early 1990s onwards it was clear that major investment was needed to rehabilitate and/or replace Polish power plants, to improve operating performance and to address the effects of ageing and obsolescent technology. Furthermore, after a brief period when electricity consumption decreased, due to closure of obsolete production facilities and a decline in the power-intensive sectors of industry, over the past few years power demand has been increasing steadily in tandem with the country's GDP growth. The situation in the power sector was exacerbated by Poland's joining of the European Union in May 2005, which brought the burden of additional emissions reduction obligations, with limitations on emissions by Poland as a whole and by the Polish power sector specifically. All these factors created the necessity for the Polish power sector to embark on a very large

Supercritical boiler

investment programme to meet the requirements of growing power demand, increased market competition and tightening environmental regulations. Estimates suggest that to meet these requirements some 9 GW of new or radically rehabilitated generating capacity will need to be put in operation between now and 2015. Indigenous coal remains the mainstay of Polish power, accounting for about 152 TWh of the 162 TWh gross production in 2006 (some 94%, with oil, gas and hydro providing the rest). Lignite accounts for about a third of the coal generation. The first big project was rehabilitation of units 1-6 of the Turow lignite fired plant, a huge undertaking that started in 1994 (with the awarding to an Alstom-led consortium of a contract to rehabilitate all six LMZ-designed 200 MW units) and continued until 2005. The first three units were uprated to 235 MWe, and the subsequent three units to 262 MWe.

Another significant project was the construction of a 460 MW supercritical lignite fired plant at Patnow (replacing two old 200 MW LMZ designed oil fired units), for which Alstom was awarded the turbine island and boiler contracts in 2001 and which is currently under commissioning. The next key phase in the replacement of old generating capacity in Poland was the start of construction of the world's first supercritical CFB plant, at the Lagisza site of PKE (Southern Poland Power Company). Lagisza is scheduled to enter commercial operation in early 2009. The boiler for this 460 MW unit is being supplied by Foster Wheeler, while in December 2003 Alstom received an EPC contract covering the turbine island package (including civil works) and the cooling system, including cooling tower. The new 858 MWe lignite fired supercritical unit to be built at Belchatow represents a further key stage in the modernisation of Poland's power generation infrastructure.

LIGNITE POWER

Belchatow, pillar of Polish power a utility perspective

Piotr Szmaj, chief engineer, new unit, BOT Elektrownia Belchatow

Baltic Sea Even before the addition of the new 858 MWe supercritical unit (described in the Lithuania main article), Belchatow hosted the largest coal (lignite) fired plant in Europe with a current installed capacity of 4400 MWe (12 x 370 MWe) and has been called the capital of the Polish power generation industry. Following completion of the modernisation programme started in 1997, which added 120 MWe to the installed capacity (by modernisation of the turbine LP stages), the plant fulfils all Germany Poland EU requirements and standards. Indeed, BOT Elektrownia Belchatow was the first company in Poland to receive Belarus Warsaw a permit under the EU's Integrated Pollution Prevention Control (IPPC) scheme to Lodz run its installations in line with the IPPC directive. The power station being the lowest cost and the most efficient electricity Lodz producer in the country is a pillar of the Polish power generation industry, helping to stabilise the national energy market. Since the late 1990s, with an annual electricity output of about 28 TWh, Belchatow has provided some 20% of Poland's power, well ahead of any other power station. Belchatow Ukraine The design of the original Belchatow units was developed in the 1970s and did Piotrkow not anticipate any measures to limit emissions of sulphur oxides emissions because Trybunalski Slovakia at that time flue gas desulphurisation technologies were largely unknown and only in the development phase. However, in the years 1988 to 1990, BOT Elektrownia Belchatow turned its attention to developments in Polish desulphurisation technologies as well as those being applied worldwide, and subsequently fitted FGD to ten of the 12 Belchatow units (numbers 3 to 12). To maintain a leading position in the Polish electricity market BOT Elektrownia Belchatow has adopted a strategy for capacity development, which entails comprehensive modernisation of Belchatow units 3 to 12, starting in 2007 with the aim of enabling them to reach 320 thousand hours of operation, ie to operate until around 2035 plus construction of the new unit, as described in the main article. The strategy, which assumes maintenance of high power production capabilities in association with optimal utilisation of available coal deposits (about 1 billion tonnes of lignite) in the Belchatow and Szczercow open cast Belchatow site, showing mines, can be summarised as follows: the 12 existing units Construction of the new 858 MW power unit, with commercial operation scheduled for October 2010. This represents the largest investment of its kind yet in Poland. In 2001, official acceptance from the Ministry of the Treasury was obtained to commence a project to build a new 833 MW power unit. The capacity was subsequently increased to 858 MW, thanks to improved plant integration by EPC contractor Alstom. The tender procedure began in 2002 resulted in the selection of the Alstom consortium. The design was approved in 2005 and a construction permit issued. Construction work began in October 2006. The power plant will use best available technology (BAT), as required under IPPC, and will also fulfil the requirements of the EU Large Combustion Plant directive. First synchronisation with the Polish national grid is anticipated in February 2010. The project includes a new transmission link to the system switching station in Trebaczew. Reconstruction and modernisation programme. Refurbishment of units 1 and 2 Visualisation of the new 858 MWe unit at Belchatow, with (which do not have FGD) was done in 2004 and 2005, while modernisation of existing units, right units 3-12 will be done according to the following schedule: unit 3 in 2007, unit 4 in 2009, units 5 and 6 in 2010, units 7 and 8 in 2011, units 9 and 10 in 2012, and units 11 and 12 in 2013. The basic goals of the modernisation process include: extension of the operating lifetime of units 1 and 2 (to 2016) and of units 3-12 (to 2030-2035); improvement of operating performance; reduction in environmental impact, including compliance with EU Directive 2001/80/EC; and increase in turbine-generator unit power from 370 MW to 380 MW. The total investment cost (new build plus refurbishment) is 1.6 billion euro, with banks providing 880 million euro. The project won the Euromoney/Project Finance award for best European power deal of 2006. The new unit and the refurbishment programme are in line with BOT Elektrownia Belchatow's policy of striving to continuously upgrade and improve its power technology assets. The management system is also being continuously improved. The power plant holds a PCBC and IQNet certificate for an Integrated Management System for Quality, Environment, Occupational Safety and Information Security (IMS-ISO), compliant with the requirements of the PN-EN ISO 9001:2001, PN-N-18001:1999, PN-EN ISO 14001:1998 and PN-I-07799-2.

Poland's biggest

The Belchatow extension will be the largest generating unit ever built in Poland and also the most efficient lignite plant, expected to achieve almost 42%. Alstom is supplying the plant to utility BOT Elektrownia Belchatow SA (which is owned by the state power generation holding company BOT Gornictwo i Energetyka) under a full turnkey EPC (engineering, procurement, construction and commissioning) contract. The contract was signed in December 2004 and the pre-engineering phase started immediately. Financial close and the official launch of the project (notice to proceed) was obtained in October 2006. Commercial operation is scheduled for the last quarter of 2010.

There are already twelve 370 MWe lignite fired units at the Belchatow site, which started operation in the early 1980s and run in baseload mode. There was an urgent need to rehabilitate these units due to their age, emissions and economics. Ten of the units will be upgraded, over the period 2007 to 2013, while the oldest two will be shut down permanently before 2016, with the new plant more than making up the loss of power production. The end result will be increased electricity production in full compliance with European environmental regulations, including the Large Combustion Plant and Integrated Pollution Prevention and Control Directives. The total cost of the new plant plus the refurbishment of the existing units is estimated to be around 1.7 billion euros. The EBRD is

providing a loan of 125 million euros for the new plant. Other investors include EIB, 220 million euro, Nordic Investment Bank, 150 million euro, and ING and Citibank, which are providing various facilities totalling 604 million euro. BOT Elektrownia Belchatow decided to build the new 858 MWe unit as an extension of the existing unit in order to secure continuous deliveries of electricity to customers as well as maintaining a constant level of lignite consumption from the local open mine (a major cost factor for the power plant). Thanks to the project BOT Elektrownia Belchatow will: secure its income by maintaining electricity production;

LIGNITE POWER

Operating large coal and lignite plants in Poland

R Hard coal 4 Lignite

4 Elblag R Dolna Odra 8 x 200 MW R Ostrolka 3 x 200 MW

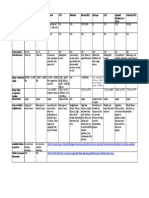

Main features of the new Belchatow 858 MWe supercritical unit

Fuel Cooling system Contract type Boiler Boiler type

Patnow

4 Patnow 7 x 120 MW 8 X 200 MW Turw 3 x 238 MW 1 x 265 MW 4 6 x 200 MW R Opole 4 x 360 MW R Kozienice 8 x 200 MW 4 Bechatw 2 x 500 MW 12 x 360 MW R Poaniec 8 x 200 MW

Lignite (domestic) Cooling tower (natural draft) Turnkey Tower, once through 2400 275 554 5 252 550/580 3000 1042 0.85 50 27 Alstom Static Excitation System P320 Hydrogen plus water

Turw

ayiska 2 x 120 MW R 4 x 200 MW

R Jaworzno III R Rybnik 6 x 200 MW 8 x 200 MW

Steam flow (t/h) Steam pressure (bar) Steam temperature (C) Turbine (STF100) Number of casings Steam pressure (bar) Steam temperature inlet/reheat (C) Speed (rpm) Generator (GIGATOP) Rating (MVA) Power factor Frequency (Hz) Terminal voltage (kV) Excitation system Cooling system Condensing plant Circulating water temperature (C) Condenser pressure (mbar) Tube material Feedwater heating plant Feedwater heaters Feedwater deaerating tank Feedwater temperature (C) Main pumps Condensate extraction pumps Feedwater pump

secure fuel costs by achieving constant lignite demand; secure extended lifetimes for the upgraded existing units; and meet all EU requirements relating to coal fired plants. The environmental performance of the new plant can be summarised as follows: NOx emissions below 200 mg/Nm3; particulate emissions below 30 mg/Nm3 thanks to ESP plus additional effect of wet desulphurisation; reduction of SOx emissions to below 200 mg/Nm3 with a removal efficiency of over 96 %, again thanks to the wet desulphurisation system; limitation of CO2 emissions thanks to high plant efficiency; reduction of raw cooling water consumption through measures such as reuse of cooling tower blowdown water and reuse of water from the nearby mine for ash slurry transport instead of using surface water resources; and noise abatement though use of protection systems and special attention to design of sensitive systems, such as coal handling equipment, boiler fans, and cooling tower. Solid waste consisting of fly and bottom ash will be transported as slurry to a new landfill in the nearby lignite mine. Waste gypsum from the new wet limestone FGD scrubbing system will be used commercially, a practice well established in Poland. In fact the use of power plant gypsum for plasterboard in Poland was pioneered by the existing Belchatow units.

Design features

The Alstom scope of supply includes: a tower type supercritical once through pulverised coal boiler (with low NOx combustion system); five-casing steam turbine with three double flow exhausts (STF100); hydrogen cooled generator (GIGATOP); water cooled condenser; feedheating system with seven heaters; milling system; wet flue gas desulphurisation system; coal

Five-casing steam turbine for Belchatow

and ash handling systems; control system based on Alstom ALSPA technology; and balance of plant. An important feature of the project has been careful integration of all these systems throughout all phases, from development of the concept, through the basic and detailed design up to erection and commissioning. The new 858 MW unit has been designed to achieve an operating life of about 200 000 hours, ie about 35 years. It will use local lignite from the existing Belchatow open cast mine, presently supplying fuel to the existing units, as well as from a new open cast lignite mine being constructed at Szczercow. The design of the unit as well as the equipment selected will allow the new plant to achieve an availability above 88% over the first two years of operation, with scheduled outages reduced to about two weeks for the annual overhaul, with a six week outage every three years. Thanks to its compact and modular design the new unit, with all auxiliary installations, will cover the relatively small area of 300 m long and 350 m wide, an extension to the area of the existing plant. The total height of the new turbine building will be 39 m and the boiler will be up to 150 m high. In addition to the new power block (boiler, turbine and generator) the project consists of: the new desulphurisation plant with auxiliary installations; recirculating cooling system with the cooling tower also used as a chimney; the complete electrical system with two unit transformers; new control system; water treatment system; coal handling system connecting the new unit with the lignite transportation system from the open mine to the existing units; hydraulic ash slurry transport systems; electrostatic precipitator; auxiliary systems and buildings, including administration building. The majority of deliveries and almost all the onsite work will be provided by Polish companies.

17.5 43 Stainless steel, DIN 1.4439 7 1 275

3 x 50% (first stage plus second stage) 1 x 100% main turbine driven feedwater pump plus 2 x 35% start-up motor driven feedwater pumps Circulating water pumps 2 x 50% Polishing plant Main transformer Rated output (MVA) Primary/secondary (kV) Unit transformers Rated output (MVA) Primary/secondary (kV) Standby transformer Rated output (MVA) Primary/secondary (kV) yes 2 x 700 420/27 80/40/40 27/10.5/10.5 80/40/40 115/10.5/10.5

Main components

The main data for the plant are summarised in the table, right. Key features of the main systems include the following: Boiler Supercritical once-through single pass boiler with circulating pump for start up and turn down capability to 40% of boiler load. There is one 100% boiler feedwater pump driven by an auxiliary steam turbine connected to steam extraction from the main steam turbine and two start up and reserve pumps (35% each) connected to electrical motors via hydrokinetic couplings.

Instrumentation and control system Logic control Alstom ALSPA Analog control Alstom ALSPA Data acquisition Alstom ALSPA

LIGNITE POWER

Process schematic of the new 858 MWe unit at Belchatow

Coal bunker Cooling tower Boiler Cold reheat steam from HP cylinder

Live steam to HP cylinder Absorber Generator Electrostatic precipitator Feedwater from feedwater pump Turbine

Transformer

Steam Cooling tower Feedwater Gypsum Limestone

GYPSUM COLLECTION

The design of the boiler has been done in Stuttgart, Germany, and production of most of the boiler components is being done in Raciborz, Poland. Turbine-generator The five-casing steam turbine (STF100) is of the reaction type and is being manufactured in Elblag, Poland. The GIGATOP generator is being produced in Wroclaw, Poland, and Birr, Switzerland. Control system The new unit will be equipped with an ALSPA P320 control system, which includes a CENTRALOG integrated monitoring and supervision system and CONTROBLOCK P320 control blocks.

Gypsum and limestone storage Cooling tower

Integration With Alstom the single EPC supplier, and through the use of its Plant Integrator capabilities, the project also provides a good example of the benefits of integration between systems, coupled with close co-operation between contractor and utility, during all phases of the project, from conceptual development of the concept, through basic and then detailed design up to erection and commissioning of the new plant. All major components of the new unit have been analysed as elements of the overall power plant system to achieve the best balance between technology, costs, power production etc. Also, all major systems and the interfaces between them have been optimised to arrive at

Water treatment

the most compact solution, matched to the limited area available for the new unit. In addition, integration combined with modularisation has contributed to reducing the expected project execution time to 48 months, from notice to proceed (October 2006) to obtaining of the provisional acceptance certificate (PAC) (October 2010).

New drivers

Ever more stringent environmental regulations and the emergence of open and competitive markets, with the need for increased productivity, are currently strong drivers in Central and Eastern European countries including Poland. The new Belchatow unit can be seen as a product of these combined forces. MPS

Fuel oil area

Switchyard

Twice gas desulphurisation

Turbine building Boiler Lignite crusher

ESP

Lignite conveyor

Site plan of the new 858 MWe unit at Belchatow

Construction underway on the new unit

www.power.alstom.com

Printed in England, TBC 1007E

You might also like

- QUIZ 1 - Geology 105Document10 pagesQUIZ 1 - Geology 105Danhy Nguyen100% (1)

- How To Check Earthing Using A MultimeterDocument6 pagesHow To Check Earthing Using A MultimeterNikhil GurawaNo ratings yet

- Mały Poradnik Mechanika - Tom 1Document345 pagesMały Poradnik Mechanika - Tom 1Marcin100% (1)

- Renewable Energy Snapshot: SlovakiaDocument4 pagesRenewable Energy Snapshot: SlovakiaUNDP in Europe and Central AsiaNo ratings yet

- LitGrid PDFDocument50 pagesLitGrid PDFkkkkNo ratings yet

- List of LNG Projects in Vietnam PDFDocument3 pagesList of LNG Projects in Vietnam PDFnguyencongoanhNo ratings yet

- KietlinskiDocument20 pagesKietlinskisenthil031277No ratings yet

- HK32 002 enDocument35 pagesHK32 002 enAaronNo ratings yet

- Budownictwo Zeszyt 1 B (11) 2015 7Document12 pagesBudownictwo Zeszyt 1 B (11) 2015 7EddySyahputraBenSyahrenNo ratings yet

- Dictionary - ElectricalDocument100 pagesDictionary - ElectricalSeb668No ratings yet

- EPLAN 5.50 Podręcznik Użytkownika cz.1Document604 pagesEPLAN 5.50 Podręcznik Użytkownika cz.1KonradNo ratings yet

- Falownik Inovance Md200 Wektorowy Broszura v2 3Document2 pagesFalownik Inovance Md200 Wektorowy Broszura v2 3Trak Bud100% (1)

- Tech Spec Ss - IIIDocument122 pagesTech Spec Ss - IIIkrcdewanewNo ratings yet

- Visit The Vehicle Buyer's Guide (HTTP://WWW - Ccities.doe - Gov/vbg/) To Learn More About Light and Heavy-Duty Alternative Fuel Vehicles AvailableDocument3 pagesVisit The Vehicle Buyer's Guide (HTTP://WWW - Ccities.doe - Gov/vbg/) To Learn More About Light and Heavy-Duty Alternative Fuel Vehicles Availablerushibmr19785604No ratings yet

- Air Liquide BS 50-3-2,5Document1 pageAir Liquide BS 50-3-2,5kuraimundNo ratings yet

- Power Plant Design Assignment-3 BELDocument14 pagesPower Plant Design Assignment-3 BELPRAKASH POKHRELNo ratings yet

- Tungsten Carbide Grades - WOKSALDocument1 pageTungsten Carbide Grades - WOKSALTaner DemirelNo ratings yet

- Tablice Mechanika Plynow PDFDocument24 pagesTablice Mechanika Plynow PDFMateusz SNo ratings yet

- JBL E150P, P10SW Subwoofers SMDocument31 pagesJBL E150P, P10SW Subwoofers SMalvhann_1No ratings yet

- Pressurized Water ReactorsDocument23 pagesPressurized Water ReactorsMario AndreiNo ratings yet

- Alstom Editorial Guide Thailand To Showcase Latest Upgrade of Alstom S Gt26 in Combined Cycle - Whitepaperpdf.renderDocument4 pagesAlstom Editorial Guide Thailand To Showcase Latest Upgrade of Alstom S Gt26 in Combined Cycle - Whitepaperpdf.renderEngr Jonathan O OkoronkwoNo ratings yet

- ReportplDocument27 pagesReportplMirek SzumowskiNo ratings yet

- Kilpilahti Combined Heat and Power ProjectDocument3 pagesKilpilahti Combined Heat and Power ProjectAnonymous KduLd7No ratings yet

- Alstom - BoA 2&3 + WTA - 2008Document8 pagesAlstom - BoA 2&3 + WTA - 2008fransdaunNo ratings yet

- 2010 PS ActivityDocument9 pages2010 PS Activityfarhadmrt6923No ratings yet

- Proyectos PoloniaDocument21 pagesProyectos PoloniakodreteNo ratings yet

- FiT RD 661-2007Document8 pagesFiT RD 661-2007taqishah7861214No ratings yet

- Alstom GT26 TH PDFDocument4 pagesAlstom GT26 TH PDFThanapaet RittirutNo ratings yet

- Energy Transmission and Grid Integration of AC Offshore Wind FarmsDocument247 pagesEnergy Transmission and Grid Integration of AC Offshore Wind FarmsJanus Lanus100% (2)

- The European Offshore Wind Industry - Key Trends and Statistics: 1 Half 2011Document4 pagesThe European Offshore Wind Industry - Key Trends and Statistics: 1 Half 2011C LeeNo ratings yet

- Devoll Hydro Power (DHP), AlbaniaDocument122 pagesDevoll Hydro Power (DHP), AlbaniaSai SandeepNo ratings yet

- State of Nuclear Power in Europe: A ReportDocument21 pagesState of Nuclear Power in Europe: A Reportعمر نجارNo ratings yet

- Manjung 1000MWDocument27 pagesManjung 1000MWelrajilNo ratings yet

- Nuclear Power Plant Unit Olkiluoto 3Document64 pagesNuclear Power Plant Unit Olkiluoto 3Patrick LaffontNo ratings yet

- Olkiluoto 3 NumbersDocument3 pagesOlkiluoto 3 NumbersAdrien MccandlessNo ratings yet

- Nuclear Power in RussiaDocument20 pagesNuclear Power in RussiaAleksey ArtemyevNo ratings yet

- fosterwheelercfbDocument13 pagesfosterwheelercfbSachinNewaseNo ratings yet

- Validating A Thermodynamic Model of The Otahuhu B Combined Cycle Gas Turbine Power StationDocument7 pagesValidating A Thermodynamic Model of The Otahuhu B Combined Cycle Gas Turbine Power StationradanpetricaNo ratings yet

- 02-Fiche Centrale SkhiraDocument4 pages02-Fiche Centrale Skhiramed chemkhiNo ratings yet

- Poland Group ReportDocument20 pagesPoland Group ReportAlisher SamadovNo ratings yet

- Nuclear Power in The United KingdomDocument188 pagesNuclear Power in The United KingdomRita CahillNo ratings yet

- Electricity in UKDocument4 pagesElectricity in UKhugogallagherNo ratings yet

- Eskom OCGTDocument3 pagesEskom OCGTjanetNo ratings yet

- Paper Id249 Powergen2012Document21 pagesPaper Id249 Powergen2012arunNo ratings yet

- Eskom Build Programme 07Document12 pagesEskom Build Programme 07Willing ZvirevoNo ratings yet

- Techno Prom ExportDocument52 pagesTechno Prom Exportis.ekakartika11No ratings yet

- CleanPower Statkraft InstallationDocument21 pagesCleanPower Statkraft Installationpcguru.oregon5759No ratings yet

- Reference Projects Thermal Power PlantsDocument37 pagesReference Projects Thermal Power PlantsAnonymous 8iXHf2mNo ratings yet

- PDD Version 03Document47 pagesPDD Version 03KvvPrasadNo ratings yet

- The Shifting Landscape For Renewable Energy in The UKDocument4 pagesThe Shifting Landscape For Renewable Energy in The UKjohnribarNo ratings yet

- Doosan Wins French Biomass Deal From EDocument4 pagesDoosan Wins French Biomass Deal From Ejackdawn21No ratings yet

- Repowering of Ukrainian Power Plants With CFB Boilers: Babcock & Wilcox 1Document7 pagesRepowering of Ukrainian Power Plants With CFB Boilers: Babcock & Wilcox 1MKOZERDEMNo ratings yet

- JESR 2010 - 11 Final Report MEMDocument190 pagesJESR 2010 - 11 Final Report MEMHussein BoffuNo ratings yet

- Opportunities_and_threats_for_the_iDocument13 pagesOpportunities_and_threats_for_the_i24117032No ratings yet

- Challenges Facing The Electricity Sector Industry in UgandaDocument11 pagesChallenges Facing The Electricity Sector Industry in UgandaLucie Bulyaba100% (1)

- F T P R: Inal Echnical Rogress EportDocument9 pagesF T P R: Inal Echnical Rogress EportkoliaskoliaNo ratings yet

- European Nuclear Supply ChainDocument11 pagesEuropean Nuclear Supply ChainJulien VillertNo ratings yet

- Aarti Steel WHR PDDDocument34 pagesAarti Steel WHR PDDKvvPrasadNo ratings yet

- EU Hydrogen BankDocument18 pagesEU Hydrogen Bankshivani.pal.17augNo ratings yet

- Energetyka Wodna Magazine Issue 4 2022 1684656151Document42 pagesEnergetyka Wodna Magazine Issue 4 2022 1684656151MT HazrieNo ratings yet

- Corp PresDocument20 pagesCorp PresvanjadamjanovicNo ratings yet

- Pressure Reducing and Surplussing Valves For Steam and Industrial Fluids-SB-GCH-29-EnDocument18 pagesPressure Reducing and Surplussing Valves For Steam and Industrial Fluids-SB-GCH-29-EnAgus HermantoNo ratings yet

- Prandtl PDFDocument1 pagePrandtl PDFAgus HermantoNo ratings yet

- Refrigerasi: CFC-12 CFC-11 HFC-32 HCFC-22Document12 pagesRefrigerasi: CFC-12 CFC-11 HFC-32 HCFC-22Agus HermantoNo ratings yet

- Estandares AstmDocument22 pagesEstandares AstmAgus HermantoNo ratings yet

- Design SummaryDocument20 pagesDesign SummaryAgus HermantoNo ratings yet

- Ready Classroom l31Document22 pagesReady Classroom l31api-517933089No ratings yet

- 07 - Natural Experiment (Part 2) PDFDocument90 pages07 - Natural Experiment (Part 2) PDFJoe23232232No ratings yet

- Download Full Writing Ethnographic Fieldnotes 2nd Edition Robert M. Emerson PDF All ChaptersDocument61 pagesDownload Full Writing Ethnographic Fieldnotes 2nd Edition Robert M. Emerson PDF All Chapterslorionmasny100% (8)

- Checklist - MPSPGDocument2 pagesChecklist - MPSPGnazrin90No ratings yet

- Ode On A Grecian Urn: John KeatsDocument12 pagesOde On A Grecian Urn: John KeatsSharmin SultanaNo ratings yet

- Lesson 2Document4 pagesLesson 2api-297076449No ratings yet

- Solved - Chapter 2 Problem 1CP Solution - Fluid Mechanics 7th EditionDocument3 pagesSolved - Chapter 2 Problem 1CP Solution - Fluid Mechanics 7th EditionCARLOS DAVID CHASILOA QUISTANCHALANo ratings yet

- Master Thesis Aims ObjectivesDocument5 pagesMaster Thesis Aims Objectivesafkodkedr100% (1)

- Name: Shams Mashar Assignment - 05 Id: Fa18-Beee-0040Document4 pagesName: Shams Mashar Assignment - 05 Id: Fa18-Beee-0040Shams Ud DinNo ratings yet

- Kinetics of Particle Work Energy - ClassDocument46 pagesKinetics of Particle Work Energy - ClassLebogang TlhagwaneNo ratings yet

- Bibliografia EGYPTIAN MONASTICISM (2008-2012)Document17 pagesBibliografia EGYPTIAN MONASTICISM (2008-2012)PietroNo ratings yet

- Fetalink - Cheat SheetDocument2 pagesFetalink - Cheat Sheetapi-551359614No ratings yet

- Vector SpaceDocument3 pagesVector SpacemahadgaashanleNo ratings yet

- Joseph Bejogan - September 2021: 1. Introduction To AnatomyDocument2 pagesJoseph Bejogan - September 2021: 1. Introduction To AnatomyCarren SabioNo ratings yet

- Mission Statement of PTCL To Achieve Our Vision by HeavingDocument4 pagesMission Statement of PTCL To Achieve Our Vision by Heavingahscen0% (2)

- Asking and Giving Directions WorksheetDocument2 pagesAsking and Giving Directions WorksheetzawaidridloNo ratings yet

- The Influence of Vibratory Excitation On The Oil Slug Mobilization in A Capillary ModelDocument13 pagesThe Influence of Vibratory Excitation On The Oil Slug Mobilization in A Capillary ModelEmm TeddyNo ratings yet

- Books From The Troth: Idunna. We Aim To Be A Resource For All Who Would Learn More About Our WaysDocument7 pagesBooks From The Troth: Idunna. We Aim To Be A Resource For All Who Would Learn More About Our WaysAang SifNo ratings yet

- Villa B 3 BHKDocument1 pageVilla B 3 BHKVipin chandraNo ratings yet

- CBTS Hardware ManualDocument254 pagesCBTS Hardware ManualMo Ibra100% (1)

- Pengembangan Format Pengkajian OremDocument20 pagesPengembangan Format Pengkajian OremMiftakhul KhoeryNo ratings yet

- System DDocument18 pagesSystem DIoakeimTziakosNo ratings yet

- Chapter II - Preactivity Ronie R. Torres Jr.Document3 pagesChapter II - Preactivity Ronie R. Torres Jr.Ronie TorresNo ratings yet

- B.tech (Civil Engineering) Part-III (Sem V & VI) Batch 2016Document34 pagesB.tech (Civil Engineering) Part-III (Sem V & VI) Batch 2016Love preetNo ratings yet

- The Power of Doing Nothing at AllDocument9 pagesThe Power of Doing Nothing at AllPriyo DjatmikoNo ratings yet

- Computer Science A2 Level 9618 Theory NotesDocument151 pagesComputer Science A2 Level 9618 Theory Notesstacey.bobo2022No ratings yet

- Worksheet On Obstruction and AsthmaDocument14 pagesWorksheet On Obstruction and AsthmaKaye CorNo ratings yet

- Contact Center Vendor Comparison Matrix (3)Document3 pagesContact Center Vendor Comparison Matrix (3)subzzNo ratings yet

- Gossip Part VDocument3 pagesGossip Part VIven CNo ratings yet