Varistor 222k.6kv

Varistor 222k.6kv

Uploaded by

Jess AJCopyright:

Available Formats

Varistor 222k.6kv

Varistor 222k.6kv

Uploaded by

Jess AJOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Varistor 222k.6kv

Varistor 222k.6kv

Uploaded by

Jess AJCopyright:

Available Formats

catalog is downloaded from the website (for of Murata Manufacturing co., ltd.

Therefore, its specifications are to change or our products in it may be discontinued without advance notice. Please check with our Please read rating and ! CAUTION storage, operating, rating, soldering, mounting and handling) insubject this catalog to prevent smoking and/or burning, etc. !Note This !PDF Note

sales representatives or product engineers before ordering. This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C85E.pdf 06.6.1

Safety Recognized/High Voltage Ceramic Capacitors

DEC Series (Class 1, 2/DC6.3kV)

Features

1. Coated with flame-retardant epoxy resin (equivalent to UL94V-0 standard). 2. Available product for RoHS Restriction (EU Directive 2002/95/EC).

e 25.0 min. d D max. T max.

Applications

1. Ideal for use as the ballast in back lighting inverters for liquid crystal displays (SL Char.). 2. Ideal for use on high voltage circuits such as Cockcroft circuits (B Char.).

[Bulk] Straight Long (C4)

F1.0

(in mm)

Lead Code C4

Coating Extension e 3.0 max.

d 0.60.05

Marking

Temp. Char. Nominal Body Diameter SL B E

7mm

5D 6KV

8-9mm

47J 6KV 66

331K 6KV 66

10-15mm

151J 6KV 66

B 102K 6KV 66

222Z 6KV 66

Temperature Characteristics Nominal Capacitance Capacitance Tolerance Rated Voltage Manufacturer's Identification Manufactured Date Code

Marked with code for char. B (omitted for nominal body diameter 9mm and under) Under 100pF: Actual value, 100pF and over: Marked with 3 figures Marked with code Marked with code (In case of DC6.3kV, marked with 6KV) Marked with (omitted for nominal body diameter 9mm and under) Abbreviation (omitted for nominal body diameter 7mm)

SL Characteristics

Part Number DEC1X3J050DC4BMS1 DEC1X3J100JC4BMS1 DEC1X3J120JC4B DEC1X3J150JC4B DEC1X3J180JC4B DEC1X3J220JC4B DEC1X3J270JC4B DEC1X3J330JC4B DEC1X3J390JC4B DEC1X3J470JC4B DEC1X3J560JC4B DEC1X3J680JC4B DEC1X3J820JC4B DEC1X3J101JC4B DEC1X3J121JC4B DEC1X3J151JC4B DC Rated Voltage (Vdc) 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 6300 Capacitance (pF) 5 0.5pF 10 5% 12 5% 15 5% 18 5% 22 5% 27 5% 33 5% 39 5% 47 5% 56 5% 68 5% 82 5% 100 5% 120 5% 150 5% Body Dia. D (mm) 7 7 8 8 9 9 9 9 9 9 10 12 12 13 14 15 Lead Spacing F (mm) 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0 Body Thickness T (mm) 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0 7.0

10

49

catalog is downloaded from the website (for of Murata Manufacturing co., ltd. Therefore, its specifications are to change or our products in it may be discontinued without advance notice. Please check with our Please read rating and ! CAUTION storage, operating, rating, soldering, mounting and handling) insubject this catalog to prevent smoking and/or burning, etc. !Note This !PDF Note

sales representatives or product engineers before ordering. This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C85E.pdf 06.6.1

B Characteristics

Part Number DECB33J101KC4B DECB33J151KC4B DECB33J221KC4B DECB33J331KC4B DECB33J471KC4B DECB33J681KC4B DECB33J102KC4B DC Rated Voltage (Vdc) 6300 6300 6300 6300 6300 6300 6300 Capacitance (pF) 100 10% 150 10% 220 10% 330 10% 470 10% 680 10% 1000 10% Body Dia. D (mm) 9 9 9 9 10 11 13 Lead Spacing F (mm) 10.0 10.0 10.0 10.0 10.0 10.0 10.0 Body Thickness T (mm) 7.0 7.0 7.0 7.0 7.0 7.0 7.0

E Characteristics

Part Number DECE33J102ZC4B DECE33J222ZC4B DC Rated Voltage (Vdc) 6300 6300 Capacitance (pF) 1000 +80/-20% 2200 +80/-20% Body Dia. D (mm) 11 15 Lead Spacing F (mm) 10.0 10.0 Body Thickness T (mm) 7.0 7.0

10

50

catalog is downloaded from the website (for of Murata Manufacturing co., ltd. Therefore, its specifications are to change or our products in it may be discontinued without advance notice. Please check with our Please read rating and ! CAUTION storage, operating, rating, soldering, mounting and handling) insubject this catalog to prevent smoking and/or burning, etc. !Note This !PDF Note

sales representatives or product engineers before ordering. This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C85E.pdf 06.6.1

DEC Series Specifications and Test Methods

No. 1 2 3 Item Operating Temperature Range Appearance and Dimensions Marking Between Lead Wires -25 to +85C No marked defect on appearance form and dimensions are within specified range. To be easily legible No failure The capacitor should be visually inspected for evidence of defect. Dimensions should be measured with slide calipers. The capacitor should be visually inspected. The capacitor should not be damaged when DC voltage of 200% of the rated voltage is applied between the lead wires for 1 to 5 sec. (Charge/Discharge currentV50mA) The capacitor is placed in the container with metal balls of diameter 1mm so that each lead wire, short circuited, is kept about 2mm off the metal balls as shown in the figure at right, and DC voltage of 1.3kV is applied for 1 to 5 sec. between capacitor lead wires and metal balls. (Charge/Discharge currentV50mA) The insulation resistance should be measured with DC50050V within 605 sec. of charging. The capacitance should be measured at 20C with 10.2kHz (Char. SL: 10.2MHz) and AC5V(r.m.s.) max. The dissipation factor and Q should be measured at 20C with 10.2kHz (Char. SL: 10.2MHz) and AC5V(r.m.s.) max. The capacitance measurement should be made at each step specified in Table. Specifications Testing Method

Dielectric Strength Body Insulation No failure

About 2mm Metal balls

5 6

Insulation Resistance (I.R.) Capacitance Q

Between Lead Wires

10000M min. Within specified tolerance Char. SL: 400+20C*2min. (30pF under) 1000 min. (30pF min.) Char. B, E: 2.5% max. Char. SL: +350 to -1000ppm/C (Temp. range: +20 to +85C) Char. B: Within 10% Char. E: Within +20/-55%

7 Dissipation Factor (D.F.)

Temperature Characteristics Pre-treatment : Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before measurements. (Char. B, E) 1 2 3 4 5 Step 202 -253 202 852 202 Temp. (C) As shown in the figure at right, fix the body of the capacitor and apply a tensile weight gradually to each lead wire in the radial direction of the capacitor up to 10N and keep it for 101 sec.

Pull 9 Strength of Lead Lead wire should not be cut off. Capacitor should not be broken.

Bending

Each lead wire should be subjected to 5N of weight and bent 90 at the point of egress, in one direction, then returned to its original position and bent 90 in the opposite direction at the rate of one bend in 2 to 3 sec. No marked defect Within specified tolerance Char. SL: 400+20C*2min. (30pF under) 1000 min. (30pF min.) Char. B, E: 2.5% max. The capacitor should be firmly soldered to the supporting lead wire and vibrated at a frequency range of 10 to 55Hz, 1.5mm in total amplitude, with about a 1 minute rate of vibration change from 10Hz to 55Hz and back to 10Hz. Apply for a total of 6 hrs., 2 hrs. each in 3 mutually perpendicular directions. The lead wire of a capacitor should be dipped into a ethanol solution of 25wt% rosin and then into molten solder for 20.5 sec. In both cases the depth of dipping is up to about 1.5 to 2mm from the root of lead wires. Temp. of solder: Lead Free Solder (Sn-3Ag-0.5Cu) 2455C H63 Eutectic Solder 2355C The lead wire should be immersed into the melted solder of 35010C up to about 1.5 to 2mm from the main body for 3.50.5 sec. Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 1 to 2 hrs. at *1room condition. (Char. SL) Post-treatment: Capacitor should be stored for 4 to 24 hrs. at *1room condition. (Char. B, E)

Appearance Capacitance 10 Vibration Resistance Q D.F.

11

Solderability of Leads

Lead wire should be soldered with uniform coating on the axial direction over 3/4 of the circumferential direction.

Appearance Capacitance Change 12 Soldering Effect (Non-Preheat) Dielectric Strength (Between Lead Wires)

No marked defect Char. SL: Within 2.5% Char. B: Within 5% Char. E: Within 15%

Per item 4.

*1 "room condition" Temperature: 15 to 35C, Relative humidity: 45 to 75%, Atmospheric pressure: 86 to 106kPa *2 "C" expresses nominal capacitance value (pF)

Continued on the following page.

10

51

catalog is downloaded from the website (for of Murata Manufacturing co., ltd. Therefore, its specifications are to change or our products in it may be discontinued without advance notice. Please check with our Please read rating and ! CAUTION storage, operating, rating, soldering, mounting and handling) insubject this catalog to prevent smoking and/or burning, etc. !Note This !PDF Note

sales representatives or product engineers before ordering. This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C85E.pdf 06.6.1

DEC Series Specifications and Test Methods

Continued from the preceding page.

No.

Item Appearance Capacitance Change

Specifications No marked defect Char. SL: Within 2.5% Char. B: Within 5% Char. E: Within 15%

Testing Method First the capacitor should be , Capacitor Thermal stored at 120+0/-5C for Screen, , 60+0/-5 sec. , , 1.5 ,,,,,, ,,,,,,,,,, , Then, as in figure, the lead wires ,,,,,,,,,, ,,,, , to 2.0mm , , Molten should be immersed solder of ,,, 260+0/-5C up to 1.5 to 2.0mm Solder from the root of terminal for 7.5+0/-1 sec. Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 1 to 2 hrs. at *1room condition. (Char. SL) Post-treatment: Capacitor should be stored for 4 to 24 hrs. at *1room condition. (Char. B, E) The capacitor should be subjected to 5 temperature cycles, then consecutively to 2 immersion cycles. <Temperature cycle> Step 1 2 3 4 Temperature (C) Time (min) -253 30 Room Temp. 3 853 30 Room Temp. 3 Cycle time: 5 cycle

13

Soldering Effect (On-Preheat) Dielectric Strength (Between Lead Wires) Per item 4.

Appearance Capacitance Change Q D.F. 14 Temperature and Immersion Cycle I.R.

No marked defect Char. SL: Within 3% Char. B: Within 10% Char. E: Within 20% Char. SL: 275+5/2C* min. (30pF under) 350 min. (30pF min.) Char. B, E: 4.0% max. 2000M min.

2

Dielectric Strength (Between Lead Wires)

<Immersion cycle> Step Temperature (C) Time (min) Immersion water 1 65 +5/-0 15 Clean water 2 0 3 15 Salt water Cycle time: 2 cycle Per item 4. Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 4 to 24 hrs. at *1room condition. No marked defect Char. SL: Within 5% Char. B: Within 10% Char. E: Within 20% Char. SL: 275+5/2C*2min. (30pF under) 350 min. (30pF min.) Char. B, E: 5.0% max. 1000M min. No marked defect Char. SL: Within 7.5% Char. B: Within 10% Char. E: Within 20% Char. SL: 100+10/3C*2min. (30pF under) 200 min. (30pF min.) Char. B, E: 5.0% max. 500M min. No marked defect Char. SL: Within 3% Char. B: Within 10% Char. E: Within 20% Char. SL: 275+5/2C*2min. (30pF under) 350 min. (30pF min.) Char. B, E: 4.0% max. 2000M min. Apply the rated voltage for 500 +24/-0 hrs. at 402C in 90 to 95% relative humidity. (Charge/Discharge currentV50mA.) Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 1 to 2 hrs. at *1room condition. (Char. SL) Post-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. (Char. B, E) Apply a DC voltage of 150% of the rated voltage for 1000 +48/-0 hrs. at 852C with a relative humidity of 50% max. (Charge/Discharge currentV50mA.) Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 1 to 2 hrs. at *1room condition. (Char. SL) Post-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. (Char. B, E) Set the capacitor for 500 +24/-0 hrs. at 402C in 90 to 95% relative humidity. Pre-treatment: Capacitor should be stored at 852C for 1 hr., then placed at *1room condition for 242 hrs. before initial measurements. (Char. B, E) Post-treatment: Capacitor should be stored for 1 to 2 hrs. at *1room condition.

Appearance Capacitance Change 15 Humidity (Under Steady State) Q D.F. I.R. Appearance Capacitance Change 16 Humidity Loading

Q D.F. I.R. Appearance Capacitance Change

17

Life

Q D.F. I.R.

* "room condition" Temperature: 15 to 35C, Relative humidity: 45 to 75%, Atmospheric pressure: 86 to 106kPa *2 "C" expresses nominal capacitance value (pF)

10

52

catalog is downloaded from the website (for of Murata Manufacturing co., ltd. Therefore, its specifications are to change or our products in it may be discontinued without advance notice. Please check with our Please read rating and ! CAUTION storage, operating, rating, soldering, mounting and handling) insubject this catalog to prevent smoking and/or burning, etc. !Note This !PDF Note

sales representatives or product engineers before ordering. This catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering. This PDF catalog has only typical specifications because there is no space for detailed specifications. Therefore, please approve our product specifications or transact the approval sheet for product specifications before ordering.

C85E.pdf 06.6.1

High Voltage Ceramic Capacitors Characteristics Data (Typical Example)

Capacitance-Temperature Characteristics

B, E, F, SL char.

60 20

C, D, R char.

40 10 Cap. Change (%) Cap. Change (%) 20 SL B

C R

B SL

-20 E -40 E -60

-10

-20

R C D 120 140

F -80 -40 -20 0 20 40 60 Temperature (C) 80

F 100 120

-30 -40

-20

20

40 60 Temperature (C)

80

100

Capacitance-DC Bias Characteristics

20 DESD33A471KA2B DEA1X3D221JA2B 0 DEHR33D102KA3B Cap. Change (%) -20

-40 DEBB33D102KA2B -60 DEBE33D222ZA2B -80

-100 0 500 1000 DC Bias (V) 1500 2000

10

53

You might also like

- Nec Tokin Oe128 DatasheetDocument2 pagesNec Tokin Oe128 DatasheetAfwan Al Fauzan Assalafy100% (3)

- Operating Instruction ZETADYN 2CF2SY PDFDocument121 pagesOperating Instruction ZETADYN 2CF2SY PDForioldelgado100% (4)

- Logic Gate Question and AnswersDocument5 pagesLogic Gate Question and AnswersMijanur Rahman100% (3)

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Manual JT7700Document60 pagesManual JT7700Alecsandru NitaNo ratings yet

- Murata Polymer Aluminum Electrolytic CapacitorsDocument8 pagesMurata Polymer Aluminum Electrolytic Capacitorskn65238859No ratings yet

- 104 K5C CapacitorDocument54 pages104 K5C CapacitorsotaquitoNo ratings yet

- AEA5000CE4Document6 pagesAEA5000CE4Marsiano QendroNo ratings yet

- Polymer Aluminum Electrolytic CapacitorsDocument8 pagesPolymer Aluminum Electrolytic CapacitorsRanaJafaryNo ratings yet

- Relay 5vDocument2 pagesRelay 5vNgoc Loi Nguyen HoNo ratings yet

- Radial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21Document54 pagesRadial Lead Type Monolithic Ceramic Capacitors: Cat - No.C49E-21davidninrioNo ratings yet

- Surface Mount Multilayer Ceramic Chip Capacitors: Commerical GradeDocument19 pagesSurface Mount Multilayer Ceramic Chip Capacitors: Commerical Gradedovesnest_inNo ratings yet

- HF43F DatasheetDocument3 pagesHF43F Datasheetdff1967dffNo ratings yet

- Id Almiec CPH Tech eDocument60 pagesId Almiec CPH Tech ealltheloveintheworldNo ratings yet

- C0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)Document18 pagesC0G Dielectric, 10Vdc-200Vdc (Automotive Grade) : Surface Mount Multilayer Ceramic Chip Capacitors (SMD MLCCS)dovesnest_inNo ratings yet

- Murata High Performance Electrical Double Layer CapacitorDocument8 pagesMurata High Performance Electrical Double Layer Capacitorkn65238859No ratings yet

- Multilayer Ceramic CapacitorsDocument12 pagesMultilayer Ceramic CapacitorscostpopNo ratings yet

- Murata Ceramic Capacitor Data BookDocument83 pagesMurata Ceramic Capacitor Data Bookvemuri_sriNo ratings yet

- K48-50 Carbon Film ResistorsDocument3 pagesK48-50 Carbon Film ResistorseminuscloudNo ratings yet

- HTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)crplzNo ratings yet

- Resistor FusibleDocument4 pagesResistor Fusibleassault51No ratings yet

- NHG A: Aluminum Electrolytic Capacitors/ NHG Radial Lead TypeDocument5 pagesNHG A: Aluminum Electrolytic Capacitors/ NHG Radial Lead TypeChaitanya VaidyaNo ratings yet

- Vishay Bccomponents: FeaturesDocument16 pagesVishay Bccomponents: FeaturesPetrutStefanVartolomeiNo ratings yet

- Kem A4003 ExvDocument16 pagesKem A4003 ExvAndrzej GomulaNo ratings yet

- Specification LR770D: SSC CustomerDocument12 pagesSpecification LR770D: SSC CustomerMangesh GaikwadNo ratings yet

- X7R Tip & RingDocument16 pagesX7R Tip & Ringdovesnest_inNo ratings yet

- LG 32LD650 - 32LD651 - 32LD680 - 32LD690 LCD TV SM PDFDocument40 pagesLG 32LD650 - 32LD651 - 32LD680 - 32LD690 LCD TV SM PDFQDownload4575No ratings yet

- High Voltage MLC Chips: For 600V To 5000V ApplicationsDocument2 pagesHigh Voltage MLC Chips: For 600V To 5000V ApplicationsJoseph Abou El OulaNo ratings yet

- NEC TOKIN 0E128 OE128 Proadlizer CapacitorsDocument2 pagesNEC TOKIN 0E128 OE128 Proadlizer CapacitorsJana JrabNo ratings yet

- Codificare Rezistente SMD 60A Are 412 Ohmi CF TabelDocument6 pagesCodificare Rezistente SMD 60A Are 412 Ohmi CF Tabelromeo1966No ratings yet

- Service Manual: Digital Video Camera RecorderDocument174 pagesService Manual: Digital Video Camera RecorderBogdan BancilaNo ratings yet

- SMD FusesDocument5 pagesSMD FusesatentinNo ratings yet

- Semikron SKB - 25 - 07238680Document3 pagesSemikron SKB - 25 - 07238680shamkhairnarNo ratings yet

- Surface Mount Multilayer Ceramic Chip Capacitors: Automotive GradeDocument17 pagesSurface Mount Multilayer Ceramic Chip Capacitors: Automotive Gradedovesnest_inNo ratings yet

- Datasheet PDFDocument5 pagesDatasheet PDFgbaetaNo ratings yet

- DSA00116625Document7 pagesDSA00116625Ricardo Campos LandaetaNo ratings yet

- Murata PTC-NTC For Surface Mounting ApplicationDocument12 pagesMurata PTC-NTC For Surface Mounting Applicationkn65238859100% (1)

- Ceramic Capacitor: TC / Hik High Voltage Ceramic CapacitorsDocument4 pagesCeramic Capacitor: TC / Hik High Voltage Ceramic CapacitorsIdajet ProjkoNo ratings yet

- Do3316p 270670Document3 pagesDo3316p 270670salmanNo ratings yet

- Murata High Voltage CeramicDocument38 pagesMurata High Voltage CeramictycristinaNo ratings yet

- C85e AshxDocument84 pagesC85e AshxRanaJafaryNo ratings yet

- SCR 2Document237 pagesSCR 2euqehtbNo ratings yet

- MCD288 DVD Micro Theatre: /all VersionsDocument39 pagesMCD288 DVD Micro Theatre: /all VersionsLeonelHernandezNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayelecompinnNo ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bwilburroberts20034852No ratings yet

- Especificacion Tecnica LEDDocument10 pagesEspecificacion Tecnica LEDJorge Herrero GarcíaNo ratings yet

- Loc 110Document6 pagesLoc 110Freezer Aurelio Pinto ParedesNo ratings yet

- D/CRCW E3: VishayDocument8 pagesD/CRCW E3: VishayFilipe BrendlerNo ratings yet

- MCH 18Document15 pagesMCH 18Tim SmithNo ratings yet

- Ceramic CapDocument155 pagesCeramic Capcamiloc320No ratings yet

- Aluminium CappacitorDocument5 pagesAluminium CappacitorHieuhl LeNo ratings yet

- X7R Open Mode PDFDocument16 pagesX7R Open Mode PDFdovesnest_inNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Advances in Solid Oxide Fuel Cells XFrom EverandAdvances in Solid Oxide Fuel Cells XMihails KusnezoffNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Static-Inverter 1.0: A Complete Design Process to Convert D.C. to A.C. Electricity Using the Astable-MultivibratorFrom EverandStatic-Inverter 1.0: A Complete Design Process to Convert D.C. to A.C. Electricity Using the Astable-MultivibratorNo ratings yet

- Symetrix Solutions: Tech Tip: Transient Suppressor DSP ModuleDocument1 pageSymetrix Solutions: Tech Tip: Transient Suppressor DSP ModuleJess AJNo ratings yet

- Shopjimmy T Con Board Samsung Bn96 42319aDocument1 pageShopjimmy T Con Board Samsung Bn96 42319aJess AJNo ratings yet

- TT2000 Ticket Eater MANUAL WITH BJ 100 LOGIC PCB PDFDocument31 pagesTT2000 Ticket Eater MANUAL WITH BJ 100 LOGIC PCB PDFJess AJNo ratings yet

- Bottom Freezer Refrigerator: Refrigerador Con Congelador InferiorDocument92 pagesBottom Freezer Refrigerator: Refrigerador Con Congelador InferiorJess AJNo ratings yet

- Hamilton Beach 22810 ToasterDocument24 pagesHamilton Beach 22810 ToasterJess AJNo ratings yet

- VP 100 Users Manual PDFDocument8 pagesVP 100 Users Manual PDFJess AJNo ratings yet

- T3 PINBALL sb145 PDFDocument1 pageT3 PINBALL sb145 PDFJess AJNo ratings yet

- P6NA60FP DatasheetDocument5 pagesP6NA60FP DatasheetJess AJNo ratings yet

- 01international Lodges1 enDocument6 pages01international Lodges1 enJess AJNo ratings yet

- T3 PINBALL sb143 PDFDocument1 pageT3 PINBALL sb143 PDFJess AJNo ratings yet

- SCR 400 A 600 Volts 10 AmperesDocument2 pagesSCR 400 A 600 Volts 10 AmperesJess AJNo ratings yet

- Tl084 Amplificador Operacional para Etapa Pre Amp Amplificador Bunker Mx2400 1Document44 pagesTl084 Amplificador Operacional para Etapa Pre Amp Amplificador Bunker Mx2400 1Jess AJNo ratings yet

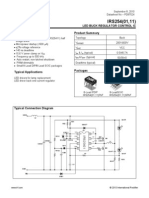

- Features Product Summary: Led Buck Regulator Control IcDocument20 pagesFeatures Product Summary: Led Buck Regulator Control IcJess AJNo ratings yet

- Inter M Ca-6215Document13 pagesInter M Ca-6215mirescualinNo ratings yet

- Project Report Electronic Number LockDocument13 pagesProject Report Electronic Number Locksushmadasari1067% (3)

- Repair of An Atari 130xe ComputerDocument3 pagesRepair of An Atari 130xe ComputergamerhobbistaNo ratings yet

- We en Web in Ar Sic Mosfet 1638931895460Document29 pagesWe en Web in Ar Sic Mosfet 1638931895460AlexxisNo ratings yet

- RCS-985A Generator Protection Instruction Manual SupplementDocument87 pagesRCS-985A Generator Protection Instruction Manual SupplementDipak Kumar PatelNo ratings yet

- 876-0255-000 - b1 (Install Procedure, Bantam)Document16 pages876-0255-000 - b1 (Install Procedure, Bantam)mglemNo ratings yet

- Applied Electronics IDocument4 pagesApplied Electronics IGebru GurmessaNo ratings yet

- Input Displacement Factor Correction For Three-Phase Three-Level AC To DC PWM-based Boost RectifierDocument9 pagesInput Displacement Factor Correction For Three-Phase Three-Level AC To DC PWM-based Boost Rectifiertamann2004No ratings yet

- Answer ALL Questions. Missing Data May Be Suitably Assumed.: Page 1 of 3Document3 pagesAnswer ALL Questions. Missing Data May Be Suitably Assumed.: Page 1 of 3DevenderNo ratings yet

- SB220, SB230, SB240, SB250, SB260: Vishay General SemiconductorDocument4 pagesSB220, SB230, SB240, SB250, SB260: Vishay General SemiconductorLuis KissNo ratings yet

- ReportCorrosion-Resistant Cast IronDocument9 pagesReportCorrosion-Resistant Cast IronMohammed J AlobaidiNo ratings yet

- Mcrf250: 125 KHZ Microid Passive Rfid Device With Anti-CollisionDocument24 pagesMcrf250: 125 KHZ Microid Passive Rfid Device With Anti-CollisionPanagiotis PanagosNo ratings yet

- Basic Electronic SurveillanceDocument43 pagesBasic Electronic SurveillanceMike BaillieNo ratings yet

- Gateforum Ece Question Paper-25Document16 pagesGateforum Ece Question Paper-25Anjaneyulu Bodhanapu100% (1)

- HBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris PavlidisDocument4 pagesHBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris Pavlidissagacious.ali2219No ratings yet

- APhO 2016 E2 QuestionDocument10 pagesAPhO 2016 E2 QuestionSiddharth AcharyaNo ratings yet

- RFUH20TF6S RohmDocument5 pagesRFUH20TF6S Rohmvictory_1410No ratings yet

- Sick 48ue 2osDocument4 pagesSick 48ue 2oschnanduNo ratings yet

- PCA9541ADocument45 pagesPCA9541AkapakdoonNo ratings yet

- 3rw SchematicDocument23 pages3rw Schematicrajinipre-1No ratings yet

- ACP - The Truth About Power Consumption Starts HereDocument4 pagesACP - The Truth About Power Consumption Starts Hereblackblue_wahyu07No ratings yet

- Nota Kimia Ting.4 Bab4Document9 pagesNota Kimia Ting.4 Bab4fauzan_evandraNo ratings yet

- Electronics WorksheetDocument5 pagesElectronics WorksheetrajaNo ratings yet

- AerfaerfDocument4 pagesAerfaerfTiongJingYinNo ratings yet

- Analysis and Design of Analog Integrated Circuits: Unit 1 Single Stage AmplifiersDocument58 pagesAnalysis and Design of Analog Integrated Circuits: Unit 1 Single Stage AmplifiersjeevithaNo ratings yet

- Ws Perfect Harmony Wasser enDocument8 pagesWs Perfect Harmony Wasser enAle LoveraNo ratings yet

- Capacitor ElcoDocument5 pagesCapacitor ElcoRazi QurrahmanNo ratings yet

- Question Bank Mw-IDocument3 pagesQuestion Bank Mw-IgovindcoolNo ratings yet