100%(2)100% found this document useful (2 votes)

Haier Service Manual

Haier Service Manual

Uploaded by

Nazeer1. The document provides operation instructions for various components of an air conditioner system, including infrared controllers, wired controllers, central controllers, timers, detectors, and commercial air conditioners.

2. Key functions of the remote controller are described, such as setting the temperature, selecting the operation mode, setting the fan speed, and adjusting the airflow direction.

3. Proper use of the remote controller is outlined, including starting and stopping the unit, temperature setting, and fan operation for different modes like auto, cool, heat, and dry.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

Haier Service Manual

Haier Service Manual

Uploaded by

Nazeer100%(2)100% found this document useful (2 votes)

1. The document provides operation instructions for various components of an air conditioner system, including infrared controllers, wired controllers, central controllers, timers, detectors, and commercial air conditioners.

2. Key functions of the remote controller are described, such as setting the temperature, selecting the operation mode, setting the fan speed, and adjusting the airflow direction.

3. Proper use of the remote controller is outlined, including starting and stopping the unit, temperature setting, and fan operation for different modes like auto, cool, heat, and dry.

Original Title

haier_service_manual

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

1. The document provides operation instructions for various components of an air conditioner system, including infrared controllers, wired controllers, central controllers, timers, detectors, and commercial air conditioners.

2. Key functions of the remote controller are described, such as setting the temperature, selecting the operation mode, setting the fan speed, and adjusting the airflow direction.

3. Proper use of the remote controller is outlined, including starting and stopping the unit, temperature setting, and fan operation for different modes like auto, cool, heat, and dry.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

100%(2)100% found this document useful (2 votes)

Haier Service Manual

Haier Service Manual

Uploaded by

Nazeer1. The document provides operation instructions for various components of an air conditioner system, including infrared controllers, wired controllers, central controllers, timers, detectors, and commercial air conditioners.

2. Key functions of the remote controller are described, such as setting the temperature, selecting the operation mode, setting the fan speed, and adjusting the airflow direction.

3. Proper use of the remote controller is outlined, including starting and stopping the unit, temperature setting, and fan operation for different modes like auto, cool, heat, and dry.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1/ 58

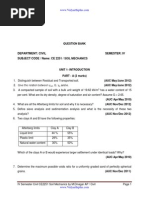

SERVICE MANUAL

-Controller and Accessory

Infrared controller:

YR-H71..........Page 1

YR-H65..........Page 12

YR-H50..........Page 13

YR-H49..........Page 13

Address set controller:

ASC-002........Page 14

Wired controller:

YR-E06..........Page 15

YR-E12..........Page 24

Central controller:

YCZ-A001......Page 29

ICR01.............Page 35

Weekly timer:

YCS-A001......Page 40

Detector:

YCJ-001.........Page 46

IGU04.............Page 57

CommerciaI Air Conditioner

14.HGH/SO Button

Used to select HGH or SOFT operation.

21

22

31

29

32

FRESH

HGH/SO TMER

SET

FLTER

B A

HEALTH

RESET

LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE

LGHT

OFF

A

U

T

O

1

2

3

4

6

7

9

10

11

15

13

5

8

16

17

30

34

35

33

23

24

25

26

27

28

20

12

14

1.TEMP Setting Button

(Used to set temperature. Setting ranges:

16 C to 30 C)

n Up/Down function, for controlling up and

down filter.

2.SWNG Button

f you press this button once, auto swing will

be activated.

f you press this button again, the louver will

fix in the present position.

3.Power ON/OFF Button

Used for unit start and stop

After power on, the LCD of remote controller

will display the previous operation state (except

for TMER,SLEEP and SWNG state).

4.Operation MODE

Used to select operation mode.

Every time you press MODE button, operation mode

changes according to following sequence:

5.HEALTH Button

Used to set health mode, if the unit has the negative ion

function and oxygen bar function.

AUTO FAN HEAT COOL DRY

6.CLOCK Button

Used to set correct time.

(Note: if time of TMER ON is the same as TMER

OFF,TMER ON/OFF cannot be set)

10.RESET Button

Press this button by using a sharp article to resume

the correct operation of the remote controller in case

of need, i.e. for example in case of malfunctions due

to electromagnetic noise.

17.SLEEP Button

(The clock must be corrected before setting sleep

function) Used to set sleep mode.

13.Up and down Button

Used to set TMER and CLOCK up or down.

8. FLTER Button

Used to set up/down function of filter.

NOTE: 1.Cooling only air conditioner does not have the displays and functions related to heating.

2.HGH/SO button

This button is activated in Cooling/Heating mode, the fan speed is in AUTO mode after

pressing it and "high functon" will be cancelled automatically after 15 minutes running.

11.LOCK Button

Used to lock operation button and LCD display

contents: by pressing this button, other buttons comes

out of function and lock state display appears; if you press

it again, lock state will be no more active and lock state

display will disappear.

7.CLOCK Button

Used to select TMER ON, TMER OFF.

9. CODE Button

Used to select code A or B, for the units except

that we recommend especially, the code is A.

18

12.LGHT Button

Used to light the control panel (only for cabinet unit)

15.SET Button

Used to confirm TMER and CLOCK settings.

16.FRESH Button

Used to set fresh mode, the unit will draw in fresh air.

19

36

1.1 Infrared controIIer YR-H71

- 2 -

Caution: YR-H71 has code A and code B, for code B, controller hasn't swing etc. functions ,and after changing

battaries ,code B will be reset to code A.

CommerciaI Air Conditioner

The distance between the remote controller and

the receiver should be max 7m and there should be

CIock Set

Displays when healthy run function is set.

22.TEMPERATURE Display

34.LOCK State Display

33.BATTERY Energy Display

Notify the user when it is time to change

the batteries.

24.HGH/SO Display

25.SGNAL SENDNG Display

26.FRESH AR Display

27.ELECTRCAL HEATNG Display

29.HEALTH Display

32.SLEEP State Display

31.Operation MODE Display

AUTO RUN COOL RUN DRY RUN HEAT RUN FAN RUN

35.FAN SPEED Display

23.AUTO SWNG Display

19.TMER OFF Display

21.FLTER Display

36.TMER ON Display

When unit is started for the first time and after replacing batteries in remote

controller, clock should be adjusted as follows:

1.Press CLOCK button, clock indication of " AM " or " PM " flashes.

2.Press or to set correct time. Each press will increase or decrease

1 min. f the button is kept pressed, time will increase or decrease quickly.

3.After time setting is confirmed, press "SET" : AM or PM stop flashing,

while clock starts working.

When operating the remote controller in an

area where electronically controlled lights are

installed or wireless handsets are used, please move

closer to the indoor unit as the function of the remote

controller might be affected by signals emitted

by the above mentioned equipments.

AUTO

LO

MD

H

AUTO

Remote ControIIer' Operation

When in use, direct signal transmission

head to the receiver placed on the indoor

unit

no obstacle between them.

Do not throw the remote controller; prevent it

from being damaged.

18.FAN Button

Used to select fan speed:LOW,MD,HGH,AUTO.

20.CLOCK Display

30.DEHUMDFCATON Display

28.Some other buttons

All these functions are not available now.

FRESH

HGH/SO TMER

SET

FLTER

HEALTH

RESET

LOCK

SLEEP MODE

CLOCK

CODE

LGHT

3

2 1

Confirmation indicator

f no indication is displayed after press ON/OFF button,

reload the batteries.

Caution:

f the remote controller does not operate as designed

after fitting new batteries of the same type, press

the Reset button (marked ) with a pointed article.

Loading the battery

Ensure that batteries are correctly placed in the com

-partment as required for positive and negative ter

-minals.

RepIacing the battery compartment Iid

The battery compartment lid is reinstalled in the

reverse sequence.

DispIay review

Press the button to see if batteries are properly fitted.

f no display appears, refit the batteries.

Battery loading

Battery loading

Batteries are fitted as follows:

Remove the battery compartment lid

Slightly press and disengage the battery compartment

lid marked with " " and then hold the remote

controller by the upper section and then remove

the battery compartment lid by pressing in the direction

of the arrow as shown in the figure above.

C

C C

C

Note:AM means morning and PM means afternoon.

- 3 -

Fan Operation

1.Unit start

Press ON/OFF button to start your air conditioner.

Previous operation status appears on LCD (except for

TMER, SLEEP, and SWNG setting).

2.Select operating mode

Press MODE button. At each press, operation mode

changes as follows:

3. Adjust fan speed

Press FAN button. At each press, fan speed changes as

follows:

Air conditioner will run at the selected fan speed.

When in AUTO mode, unit will adjust fan speed according

to room temperature automatically.

4. Unit stop

Press ON/OFF button to stop unit.

Then select FAN

About FAN mode

When the air conditioner runs in FAN mode,

it is not possible to select AUTO FAN or to

set temperature.

AUTO FAN HEAT COOL DRY

LOW MD HGH

Note:

t is recommended that the batteries be removed from the compartment if the remote controller is not

used for an extended period.

The remote controller is programmed for automatic test of operation mode after the batteries are replaced.

When the test is conducted, all icons will appear on the screen and then disappear if the batteries

are properly fitted.

A

FRESH

HGH/SO TMER

SET

FLTER

HEALTH

RESET

LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE

LGHT

A

U

T

O

4

1

3

2

AUTO, COOL , HEAT and DRY Operation

1. Unit start

Press ON/OFF button,unit starts.

Previous operation status appears on LCD (except for TMER,SLEEP and SWNG setting)

2.Select operation mode

Press MODE button. At each press, operation mode changes as follows:

AUTO FAN HEAT COOL DRY

CommerciaI Air Conditioner

- 4 -

3.Temperature setting

Then select AUTO run or select COOL operation or

select DRY operation or select HEAT operation

Press TEMP button.

Every time the button is pressed, temp. setting increases

1 C; if the button is kept pressed, temp. setting will increase

quickly.

Every time the button is pressed, temp. setting decreases

1 C, if the button is kept pressed, temp. setting will decrease

quickly.

Set proper temperature

4.Adjust FAN button

Press FAN button. At each press, fan speed changes as follows:

Air conditioner will run at the selected fan speed.

5. Unit stop

Press ON/OFF button,unit stops.

n ATUO mode, the temperature setting is not displayed on LCD. n this mode, during running air conditioner

will select COOL, HEAT or FAN mode automatically according to the room temperature.

n DRY mode, when room temperature becomes 2 C higher than temperature setting, unit will run intermittently

at LOW speed regardless of FAN setting. When room temperature is lower than temperature setting, unit will

only run FAN operation.

n HEAT mode,warm air will blow out after a short period of time due to cold-draft prevention function.

AUTO LOW MD HGH

A

U

T

O FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET

LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE

LGHT

A

U

T

O

3

5 1

3

4

2

Temp. setting +2 C

Temp.setting

On reaching temp.setting

+2 C, unit will run in mild

DRY mode.

Ultra-low air flow

COOL operation starts

when room temp.is

higher than temp.

setting.

Press SWNG button.Up and down airflow varies upwards and downwards. Left and right airflow varies

left and right sides. When the automatic swing louver moves to the proper angle, press SWNG button

can fix the airflow direction.

AUTO SWNG

Adjusting air fIow direction

Always use SWNG button on the remote controller to adjust flaps. Adjusting them by hand may result

in air conditioner's abnormally running.

CommerciaI Air Conditioner

- 5 -

Displays on the LCD disappear.

All indicators on the indoor unit go out.

Swing louver automatically close the air outlet.

After unit stops:

Please carefully set temperature when children, old or weak people use

the air conditioner.

n case of great humidity, f the vertical flaps are completely turned

towards left or right, the louver will drop water.

Never adjust the louver directly by hand, as this could make it work

abnormally.f the louver work abnormally, stop unit, restart and adjust the

louver by remote controller.

Hints:

As in COOL mode air flows downwards, adjusting airflow horizontally will

be much more helpful for a better air circulation As in HEAT mode air flows

upwards, adjusting airflow downward will be much more helpful for a better

air circulation. Be careful not to catch a cold when cold air blows downward

directly.

n COOL or DRY mode, do not leave the louver in downward position for

a long time, as the water vapor close to the grille may condense and water

may drop from the air conditioner.

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET

LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE

LGHT

A

U

T

O

SIeep Function

Before going to bed you can press down the SLEEP button and the air conditioner will run so as to

make you sleep more comfortably. Before using this function, the clock must be set.

Use of SLEEP function

After the unit's start, set running mode and then press SLEEP button once to make the air conditioner

have the previous-set sleep time (first power-on is "1h"). The sleep symbol will appear.

/ : Press time button, you can choose the time in 1~8 hours. Each time the button is pressed, the time

increases/decreases 1 hour: "xh" and "OFF" indications appear on the display.

Operation Mode

1.n COOL, DRY mode

One hour after sleeping operation start, the temperature is 1 C higher than the setting one. After another

hour, temperature rises 1 C: sleep run continuously for another 6 hours and then stops. The actual

temperature is higher than the setting one which is to prevent from being too cold to your sleep.

2.n HEAT mode

One hour after sleeping operation start, the temperature is 2 C lower than the setting one. After another

hour, temperature decreases by 2 C more. Temperature will automatically rise by 1 C after another

3 hours' continuous operation. The actual temperature is lower than the setting one which is to prevent

from being too hot to your sleep.

3.n AUTO mode.

The air conditioner will run in corresponding sleep operation according to the automatically selected

operation mode.

CommerciaI Air Conditioner

- 6 -

SLEEP RUN BEGNS SLEEP RUN STOPS

SETTNGTEMP

SHUT DOWN

about 6 hrs

1 hrs

n COOL,DRY mode

increase 1 C

increase 1 C

SLEEP RUN BEGNS

SLEEP RUN STOPS

SETTNGTEMP

SHUT DOWN

1 hrs

1 hrs

3 hrs

about 6 hrs

increase 1C

decrease 2 C

decrease 2 C

n HEAT mode

Notes:

After setting SLEEP function, it is not possible to set clock.

f set-sleep time does not reach 8 hours, unit will automatically stop operation

after set time is reached.

Set " TMER ON " or " TMER OFF "n COOL,DRY mode function first,

then set SLEEP. After set SLEEP function, the TMER function cannot be

set.

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

OFF

A

U

T

O

Timer ON/OFF Function

Set clock correctly before starting TMER operation

Every time the button is pressed, time increases 10 minuts. f the button is kept pressed, time changes

quickly.

1.Unit start

After unit start, select your desired operation mode (operation mode will be displayed on LCD)

2.TMER mode selection

Press TMER button on the remote controller to change TMER mode. Every time the button is pressed,

display of TMER mode changes as follows:

Then select TMER mode as needed (TMER ON or TMER OFF).

Now or will flash.

3.TMER setting (press time adjust buttons )

Every time the button is pressed, time decreases 10 minuts. f the button is kept pressed, time changes

quickly. t can be adjusted within 24 hours at will.

4.Confirm setting

After setting correct time, press SET button to confirm time. Now or stop flashing.

Time displayed: unit starts or stops at X hour X min (TMER ON or TMER OFF)

5.Cancel TMER mode

Just press TMER button several times until TMER mode disappears.

ON OFF

ON OFF

ON OFF ON OFF

AM12:00 PM12:00

TMER ON TMER OFF TMER ON-OFF

blank

AM12:00 PM12:00

CommerciaI Air Conditioner

- 7 -

Hints:

After replacing batteries or if a power failure occurs, TMER setting must be reset.

Remote controller has memory function. When you use TMER mode next time,

just press SET button after mode selection if timer setting is the same as the

previous one.

Note:

After setting TMER function, the remote controller displays TMER time. f you want

to see clock time, just press CLOCK button once: clock time will be displayed (if you

press the button again continuously, you can adjust clock). 5 seconds later, the

display will show TMER time again.

Timer ON-OFF Function

Set clock correctly before starting TMER operation

1.Unit start

After unit start, select your desired operation mode (operation mode will be displayed

on LCD)

2.TMER mode selection

Press TMER button on the remote controller to change TMER mode. Every time

the button is pressed, display of TMER mode changes as follows:

OFF

3.Time setting for TMER ON

4.Timer confirming for TMER ON

After setting correct time, press TMER button to confirm time. Now

5.Timer setting for TMER OFF

Press time buttons and follow the same procedures in " Time setting for TMER ON"

Press time button

ON

stops to flash, while

starts flashing. Time displayed : unit starts at X hour X min.

6.Time confirming for TMER OFF

After time setting, press SET button to confirm time.

stops to flash.

Time displayed: unit starts at X hour X min.

ON Then select TMER ON-OFF mode.

will flash.

Every time the button is pressed, time increases 10 minuts.

f the button is kept pressed, time will changes quickly.

Every time the button is pressed, time decreases 10 minuts.

f the button is kept pressed ,time will changes quickly.

t can be adjusted within 24 hours at will.

AM refers to morning and PM refers to afternoon.

OFF

ON OFF ON OFF

TMER ON TMER OFF TMER ON-OFF

blank

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

1

2

3

4

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

OFF

1

3 6

5 4

2

PM12:00 AM12:00 AM12:00 PM12:00

CommerciaI Air Conditioner

- 8 -

7.Canel TMER mode

Just press TMER button several times until TMER mode disappears. According to the time setting

sequence of TMER ON and TMER OFF, either start-stops or stops-start can be realized.

f the time setting of TMER ON is the same as TMER OFF, TMER ON-OFF function cannot be set.

After the air conditioner has operated for a certain period, dust has

accumulated on the filter, and the filter up/down function can be used to

clean it.

1.Whether unit starts or stops, continuously press FLTER button for 3 seconds,

and enter the filter up/down waiting status (when unit stops, the yellow TMER

indicator flashes, and filter and clock indication are displayed on the remote

controller. Only the FLTER button, the temperature buttons " " " " and

time buttons are active).

2.Press temperature " " button or time " " button in filter up/down

waiting status: the up/down mechanism makes the filter moving downward

and does not stop until it has reached the maximum limit.

3.Press temperature " " button or time" " button in filter up/down waiting

status: the up/down mechanism makes the filter to moving upward till near

the surface board and then automatically adjusts it to reset (when adjusting

to reset, it will not be controlled by the remote controller till the adjustment is

finished).

4.During moving downward, press temperature" "button or time " " button:

moving stops.

6.Continuously press FLTER button 3 seconds again to cancel the filter

up/down waiting mode (unit stops, the yellow timer indicator stops flashing,

the filter goes back to the original position, the remote controller goes back

to off status and only clock is displayed).

Note:

f the filter does not thoroughly go back to the original position, only needs to operate several times

repeatedly.

FiIter Up/Down

(Only for 600*600 panel of single unit)

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET

LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE

LGHT

1

5.During moving downward, press temperature" "button or time " " button:

moving stops.

" High mode " Operation

OutIine of operation in "High Mode"

This function is suitable when the set temperature must be reached in the shortest delay. The button

"HGH/SO", referred to this function, is effective in Cooling/Heating mode (not in Auto/Dry/Fan modes).

NOTCE:

When the air conditioner is operating in " High Mode " , unevenness of roomair temperature may occur due

to the intensive operation in a short time.

Anyway, operation in "High Mode", does not last for more than 15 minutes, then regular operation is

automatically restored.

CommerciaI Air Conditioner

- 9 -

Press the HIGH/SO button twice

f the button is pressed once, the indication is displayed on the

remote controller. f you press the button once again, the indication

disappears, regular operation is restored and fan speed goes back to the

mode set before "High Mode" operation.

Press the HIGH/SO button noce

The indication appears on the display of the remote controller

and operation in "High Mode" starts.

The AUTO fan speed is automatically set and the corresponding indication

is also displayed.

ON

OFF

Press the HIGH/SO button twice

NOTICE:

When the air conditioner is operating in " High Mode " , unevenness of roomair temperature may occur

due to the intensive operation in a short time.

Anyway, operation in "High Mode", does not last for more than 15 minutes, then regular operation is

automatically restored.

" Soft mode " Operation

f the button is pressed once, the indication is disappears from the

remote controller's display. f you press the button once again, regular

operation is restored and fan speed goes back to the mode set before

"Soft Mode" operation.

Press the HIGH/SO button twice

The indication appears on the display of the remote controller

and operation in "Soft Mode" starts. The AUTO fan speed is

automatically set and the corresponding indication is also displayed.

OutIine of operation in "Soft Mode"

Operation in "Soft Mode", more silent, is suitable when noises should be reduced, e.g.. for reading or

sleeping. The button "HGH/SO", referred to this operation, is effective in Cooling/Heating mode (not in

Auto/Dry/Fan modes).

ON

OFF

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

A

U

T

O

1

CommerciaI Air Conditioner

- 10 -

Auto restart function setting

Setting Method: When the remote controller is on (excluding timer mode

and fan mode),press the "Sleep" button on the remote controller 10 times

within 5seconds, and after the buzzer rings 4 times, the air conditioner will

enter the state of auto restart.

CanceI Method: Press the "Sleeping" button on the remote controller 10

times within 5seconds, and after the buzzer rings 2 timer, the auto restart

mode will be cancelled.

Notes: When a power failure suddenly occurs during the air conditioner is work

ing after the power failure compensation is set, if the air conditioner will not be

used for a long time, please cut off the power supply to prevent its operation from

being resumed after the power is supplied again, or press the "Switch On/Off"

button after the power comes again.

After the power failure compensation is set, if power failure suddenly occurs while the

air conditioner is working, it will resume the previous working state when the power

is supplied again.

If the unit has not the "sIeep" button or function, pIease reaIize the function

by pressing "swing" with the same method.

FRESH

HGH/SO TMER

SET

FLTER

A

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

A

U

T

O

Note:

This kind of remote controller can be used for all UNTARY FREE indoor units except for AP182ACBEA.

CommerciaI Air Conditioner

The right figure is a remote controller, which can be used on series remote control units and the

matching remote control receiver

1.Remote control receiver using method :

Use remote controller control the

remote control window of the remote

control receiver.

2.For Unitary Free and Free MuIti units, the controIIer CODE

pIease seIect code "A"; for H-MRV and AS**X

ABAA unit, pIease seIect code "B".

f the unit is wired type and it is without the remote receiver, you can use the remote receiver RE-01

and the remote controller YR-H71 to realize the remote function. The installation of remote receiver

and usage function are as follows:

Infrared controIIer YR-H71 and remote receiver RE-01:

FRESH

HGH/SO TMER

SET

FLTER

B A

M D

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

OFF

A

U

T

O

Remote controlller Remote receiver

- 11 -

CommerciaI Air Conditioner

Connecting wiring method of receiver :

Refer the indoor unit wiring diagram .

Safety cautions see the electrical wiring part .

1 .Emergency switch

2 .Running lamp: When the compressor working, this lamp bright.

3 .Timing lamp: When the unit been setting Timing running, this lamp bright.

4 .Power lamp: After open the unit, this lamp bright when the unite enter

health running, the lamp change from orange to blue lamp.

5 .ndoor temp. sensor: Test the room temperature.

1

3

4

5

2

nstallation of receive display

Because of the temperature sensitive device, do not install the receive display at straight sunlight place,

either in front of air outlet grill, for it is effected greatly from cool air and heat air, the receive display is

at least 20mm distance to the air outlet grill.

Since there is light sensitive device which receives wireless remote signal, so do not installed behind the

window curtain or other obstacles, in order not to obstruct the signal.

Must fix the remote control wire far from strong electricity (such as the wiring of electric light, air cond-

itioner, etc.) and weak electricity (such as the wiring of telephone, interphone, etc.).

2.Place the panel onto the fixed frame, pay attention

that the four claws must be placed into the

corresponding four poles on the frame

1.Fix the receive display with screws

on the selected place

1.2 Infrared controIIer YR-H65

ON

OFF

TEMP

HEALTH FAN

MODE

SLEEP SWING

CLOCK

TIMER

SET

LOCK LIGHT RESET

2

29

HEALTH AIRFLOW

FRESH

STERILIZE

CODE

1

3

4

5 6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

23

24

25

26

28

20

B A

27

22

30

31

o2

Except [swing][Health Aireflow][Sterilize] function, the other basic

functions are same with YR-H71, please reference YR-H71 manual.

[Swing] function description:

Put louvers at up position in cooling and down position in heating mode.

This will be helpful to keep an even room temp.

Note:

Side from side

Fixed position

Press the SWNG again to fix the

horizontal louvers at your desired position.

Swing

Press SWNG the horizontal

louvers move from up to down.

Fixed position

Press the SWNG again to fix the

vertical louvers at your desired position.

Swing

Press SWNG the vertical

louvers move from side to side.

13

- 12 -

CommerciaI Air Conditioner

n cooling or dry operation, don't put horizontal louvers at downward

position for a long time, or outlet grill might get frosted. Don't expose

your skin to cool or warm air for a long time.

Notice:

ON

OFF

TEMP

HEALTH FAN

MODE

SLEEP SWING

CLOCK

TIMER

SET

LOCK LIGHT RESET

HEAT

B A

POWER/SOFT

1.3 Infrared controIIer YR-H50

The main functions of YR-H50 are same with YR-H65, please

reference YR-H71 and YR-H65 manuals.

STERILIZE

(This Iunction is optional)

29

HEALTHAIRFLOW

Used to set healthairIlow

30

ON

OFF

TEMP

HEALTH FAN

MODE

SLEEP SWNG

CLOCK

TMER

SET

LOCK LGHT RESET

HEAT

B A

Please reference YR-H71 operation manual to use the controller.

1.4 Infrared controIIer YR-H49

- 13 -

Notice: For remote type units, remote controller doesn't display error

code, in the indoor unit ,there is a error lamp in display board, the

error lamp will flash and tell you what trouble it's happening.

CommerciaI Air Conditioner

1. nitial connection of power supply

Three seconds after the remote controller is connected to power supply,default symbol

"1" of the unit model will be displayed on the LCD and the new icon " " shall be transmitted.

2. Operationof remotecontroller

The "Read" button: Pressing of this button will result insimultaneous display of dehumidifying and

transmission icons (black water drop and pyramid as shown inthe figure)

The Lock button: Thisbutton canbe pressed after newcode transmissionis set.When the button

is pressed,the icon"Off" appears on theLCD, thenexcept the Reading button,all the buttons will be

shielded with the receiver codelocked. f the buttonis pressed again, icon"Off" disappears and the

lock-on function is inactivated for all the other buttons.

Machine number button (No.1 to No.6 unit): f the button is pressed, a machine serial button is

displayed with a flashing frequency of 1Hz.

Machine number "set" button: This button can be set when machine number flashes on the

LCD. Machine number flashing will beset and transmitted if the buttonis pressed, the machine

number stops flashing and a transmissionicon (the black pyramid shown in the figure) will

appear on the LCD.

The "Reset" button: nset a pointedtool ( 2mm) into the hole

of the Reset button. Every press of the tool will reset theexisting

setting, and three seconds later, initial operation mode will

appear on the LCD.

3. Test of remotecontroller (ie. No. 3unit)

Press Unit 3 button,the number 3 flashes with a frequency of 1Hz.

Press the machine number set button, the selected unit number

will be set and transmitted to the receiver of the unit.

Press the Read button and the selectedunit starts read the

set machine number.f machinenumber of selected indoor

unit is correctly displayed,(Flash number of the indoor unit

power indicator implies machine number) setting of machine

number is successful or vice versa.

When setting is completed, press the Lock button, (for new

number remote controller only) and the icon Lock-on appears

on the LCD, thenthe machine number of the indoor unit is locked.

Usually machine numbers do not need to be locked.

4. A slight soundmay be produced by the indoor unit when the

signal from the remote controller is received.

Note: Do not set machine numbers for more than one indoor unit

before a

lapse of 20 seconds after completionof setting of

machine number

of an indoor unit.

]Z^Z_

[\ST

SELECT

^Z_

OFF

LOCK

[\SU [\SV

[\SW [\SX [\SY

Set machine number 7,8: press button 6,and within 2seconds press button 1, then loose them simultaneously,

7 will display in the screen, which stands for selecting unit 7. And then press button"set", you can set unit

7.Then press "READ" to confirm if the unit number is right. With the same method, set unit No.8.

1.5 Address set controIIer ASC-02

The "select" button: The icon " " and " " is displayed when the button is pressed and please

choose " ".

Note:

1. Do not set machine numbers for more than one indoor unit

before a lapse of 20 seconds after completion of setting of

machine number of an indoor unit.

2. Address set control l er i s necessary for H MRV AB(Cassette

type),AC(Convertible type),AF(Console type),AS(Wall mounted type)

installation.

- 14 -

CommerciaI Air Conditioner

1.6 Wired controIIer YR-E06

Used to adjust the

time of timer and

clock

When the wire

controller appears

abnormal condition,

use a sharp-pointed

article to press this

button to make the

wire controller

resume normal

After cleaning the

air inlet, press this

button, the unit

can start to operate

24.Time Adjusting

button

23.Sleep button

Used to set Sleep

state

When there is too much dust collected on

the air inlet, the wire controller will show

this display to remind theuser to clean the

air inlet.After cleaning and installation,

just press the air filter reset button.

25.Reset button

26.Air Filter Reset button

27.Timer button

Used to set the

mode of timer

28.Lock state display

22.Setting button

Used to confirm

the time of timer

and clock

29.Health

Used to control the

generating oxygen

function and negative

ion-function

30.Remote control window

Used to receive the

remote control signal

14.Network control display

15.Working mode display

CaIibration of cIock

When turning on the unit for the first time, the clock should be calibrated. The method of calibration is:

1.Press "Clock" button, the Clock display " AM" " PM" will flash.

2.Press or to adjust time. For each press, the time will increase or decrease 1 minute. f depressing

the button, the time will increase or decrease rapidly.

3.After confirming the time, press " Set" button, " AM" or " PM" will stop flashing,the clock will begin to work.

Note: 1.This model does not have the following related display and function

2.The outdoor unit no oxygen-bar function or no negative ion unit no health function and health display. 29 10

6 6 7 9 11 12 14 16 26

SUR

1

2

3

4

6

6

7

8

9

11

12

13

14 16 16 17 18

20

21

22

23

24

26

26

27

28

AUTO

10

19

MODE FAN SWNG

TEMP

CLOCK SET

TMER

SLEEP

RESET

FLTER RESET

ON/OFF

SET

HEALTH

29

30

17.Operation mode button

21.Clock button

Used to calibrate the time of

timer and clock

16.Electric heating display

Used to set working mode:

Auto, Cooling, Dehumidifying,

Heating, Fan

18.Fan speed button

Used to set fan speed: Low

Fan, Med Fan, High Fan, Auto

20.Temperature Setting button

Used to set temperature,

temperature range: 16 C~30 C

19.Swing button

Used to set Auto Swing or

Fixed air sending direction

Working

mode

Auto

operation

Cooling

operation

DehumidiIying

operation

Heating

operation

Fan

operation

Wire

controller

12.Humidifying state display

Used to turn on/off unit

1.ON/OFF button

6.Air filter cleaning display

?

7.Super/Soft operation display

2.Temperature display

8.Fan speed display

9.Auto Swing display

11.Fresh air state display

4.Timer ON/OFF display

3.Clock display

5.Humidity display

10.Health state display

Auto

Low Fan Med Fan High Fan Auto

13.Sleep state display

- 15 -

CommerciaI Air Conditioner

Use COOL in summer.

Use HEAT in winter.

Use DRY in spring,autumn and in damp climate.

(1) Unit

(2) Select operation

(3) Select temp.

Press ON/OFF button, unit starts.

Previous operation status appears on display

(Not Timer setting). Power indicator lights up.

Press MODE button. For each press, operation

mode changes as follows:

Unit will run in operation mode displayed on

LCD.Stop display at your desired mode.

Every time the button is pressed, temp. setting

increases 1 C.

f button is kept depressed, temp.setting will

increase quickly.

Every time the button is pressed, temp. setting

decreases 1 C.

f button is kept depressed, temp. setting will

decrease quickly.

Recommendations

(4) Fan speed

Unit will start running to reach the temp. setting

on LCD.

Press TEMP button

Auto running: During the Auto running mode, air conditioning running and can auto-select the

cooling,heating, fan mode according to the room temperature.

Fan running: The AC only have air supply running no cooling and heating running at the condition,

AC can't have auto air supply running, and can't display the setting temperature value on the LCD.

During the heating running, after start the AC, in order to prevent cooled air, AC can stop for a

while before send heat air.

During the dehumification running, when the room temp. setting temp. , not setting condition

according to the air speed.

AUTO

MODE FAN

HEALTH TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

ON/OFF

1

AM

SWNG

2

3

4

5

AUTO COO DRY FAN HEAT

LOW MID HIGH

w

4

3

.

AUTO

Hint

Wire controller can memorize each operation

status.

When starting it next time, just press ON/OFF

button and unit will run in previous status.

Press FAN button. For each press,

fan speed changes as follows:

Unit runs at the speed displayed on LCD.n

HEAT mode, warm air will blow out after a

short period of time due to cold-draft prevention

function.

n DRY mode, when room temp. becomes 2 C

higher than temp. setting, unit will run intermitte-

ntly at LOW speed regardless of FAN setting.

Press ON/OFF button.

Only time and room temp remains on LCD.

All indicators go out.

Vertical flap closes automatically.

(5) Unit stop

Remote controller

LOW MID HIGH

AUTO

AUTO

Wire controller

- 16 -

CommerciaI Air Conditioner

Hints:

Set CIock correctIy before starting Timer operation.

You can let unit start or stop automatically at following time: Before

you wake up in the morning, or get back from outside or after you

fall asleep at night.

Operation mode will be displayed

on LCD.Power indicator lights up.

(2)TIMER mode seIection

Press TMER button to change

TMER mode.Every time the

button is pressed, display

changes as follows:

TMER

Wire controller possesses memory function, when use TMER mode next time, just

press SET button after mode selecting if timer setting is the same as previous one.

(1)After unit start, seIect your

desired operation mode.

blank

ON

OFF ON

OFF

Please close health function first before setting Timer, then you can do the TMER ON

operation.Please do not use the health function when in TMER ON state.

Wire remote controller or remote controller can memorize each working condition. Next

time open the unit, only need to press the ON/OFF key, the AC can work according to

last time working condition.(Timing, Sleeping and Swing mode not included.)

From Timing close to timing open, can setting sleep mode.

*

ON

MODE FAN

HEALTH TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

ON/OFF

AM AM

1

SET

3

4

2

SWNG

Select your desired TMER mode

(ON or OFF)

(3)Timer setting

Press TME button.

Every time the button is pressed, time increases 10min.f button is kept

depressed, time will change quickly.

Every time the button is pressed, time decreases 10min.f button is kept depressed,

time will change quickly.

Time will be shown on LCD. t can be adjusted within 24hours.

(4)Confirming your setting

After setting correct time, press SET button to confirm "ON" or "OFF" stops flashing.

Time displayed: Unit starts or stops at x hour x min (ON or OFF). Timer mode indicator lights up.

To cancel TMER

Just press TMER button several times until TMER mode disappears.

According to the seting timing open, close sequence, can realize first open then colse the unit

or first close then open the unit.

- 17 -

CommerciaI Air Conditioner

blank

ON

OFF ON

OFF

TMER ON-OFF

Operation mode will be displayed on LCD. Power indicator lights up.

Every time the button is pressed, display changes as follows:

Select .

(3)Time setting for TIMER ON

Press TME button.

(5)Time setting for TIMER OFF

To cancel TMER mode

Every time the button is pressed, time increases 10min.f button is kept depressed, time will change

quickly.

Every time the button is pressed, time decreases 10min.f button is kept depressed, time will change

quickly.Time will be shown on LCD.t can be adjusted within 24hours.

AM refers to morning and PM to afternoon.

Time displayed: Unit starts at Xhour X min.

After time setting, press TMER button to confirm."ON" stops blinking, While "OFF" starts blinking.

(4) Time confirming for TIMER

Follow the same procedures in "Time setting for TMER ON".

(6)Time confirming for TIMER OFF

After time setting, press SET button to confirm"OFF" stops flashing.

Time displayed: Unit stops at X hour X min.

According to the Time setting sequence of TMER ON or TMER OFF, either Start-Stop or

Stop-Start can be achieved.

(1)After unit start, seIect your desired operation mode

(2) Press TIMER button to change TIMER mode

ON

OFF

*

ON OFF

MODE FAN

HEALTH TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

ON/OFF

PM

AM

1

SET

SWNG

6

3

2

4

5

Just press TMER button several times until TMER mode disappears.

- 18 -

CommerciaI Air Conditioner

At night, before going to bed you can press

down the SLEEP button on the controller

and the air-conditioner will run by the

comfortable sleeping mode to make you sleep

more comfortable.

In cooIing, dehumidifying mode

In heating mode

Comfortable Sleep

Note: n AUTO mode, unit will run in SLEEP function according to the operation mode.

After setting SLEEP function, it is forbidden to calibrate clock.

f the set sleep-time does not reach 8 hours, the unit will stop operation automatically after set time

is complete.

Set "TMER-OFF" function first, then set SLEEP, and the sleep-set is performance; set TMER-ON

function first, the sleep function can only be set before TMER-ON; if set theSLEEP function first,

the TMER function can not be set.

Note: Before using this function, must adjust the

clock, or the sleep function will be disordered.

After setting sleep function, not allowed to adjust the clock. Can't use the remote controller operate the

AC. f so, please cancel the sleep function first.

After setting sleep function, can't set the timing function.

*

MODE FAN

HEALTH TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

ON/OFF

AM

SET

AM

SWNG

One hour after start up, the temp. decrease 2 lower than the setting one. After another hour decrease by

more 2 .

The temperature will automatically rise by 1 after another 3hrs' operation, and then automatically close

after 3hrs' continuous operation. The actral temperature is lower than the setting one which is to prevent

from being too hot to your sleep.

C

C

One hour after sleeping operation start, the temp. is 1 higher than the setting one. After another hour the

temp. rises 1 and then run continuously for another 6hrs' and then close. The actual temp. is higher than

the setting one which is to prevent from being too cool to your sleep.

C

C

C

SETTNG T

SLEEP RUN BEGNS SLEEP RUN STOPS

1 hr

1 hr

3 hrs

about 3 hrs

decrease 2

decreases 2

increase1

SHUT DOWN

Heat mode

C

C

C

about 6 hrs

1 hr

1 hr

increase 1

increase 1

SLEEP RUN STOPS SLEEP RUN BEGNS

SETTNG T

SHUT DOWN

Cooling mode

C

C

Press SLEEP button once to make the air conditioner have

the pre-set sleep time (first power-on is "1h"), the sleep symbol

will appear. Press time button , you can shoose the time

in 1~8 hours. Each press of , the time increases/reduces

1hour and "xh" appear in the humidity setting area, "OFF" appears

in "TMER OFF" display area and timer-off time; press SLEEP

button again to cancel sleep function, the sleep symbol disappears.

OFF

- 19 -

Auto restart function (to be appIied for a necessary situation) :

Setting Method: When the remote controller is on (excluding timer mode and fan mode), press

the "SLEEP" button on the remote controller 10 times within 5 seconds, and after the buzzer

rings 4 times, the air conditioner will enter the state of auto-restart function.

Cancel Method: Press the "Sleeping" button on the remote controller 10 times within 5 seconds,

and after the buzzer rings 2 timer, the power failure compensation mode will be cancelled.

Notes: When a power failure suddenly occurs during the air conditioner is working after the power

failure compensation is set, if the air conditioner will not be used for a long time, please cut off the

power supply to prevent its operation from being resumed after the power is supplied again, or

press the "Switch On/Off" button after the power comes again.f the controller no sleep key ,use

the "swing" key instead the "sleeping" on setting the auto restart function.

After the auto-restart function is set, if power failure suddenly occurs while the air conditioner

is working, it will resume the previous working state when the power is supplied again.

About the remote cnotrol operation, above only take wired remote controller and remote controller

as a example about the remote controller and remote receiver use method, it is the same remote

controller , please use refer to above method.

No sleep function when use remote and remote receiver.

User Caution

Concerning MRV Auto Restart function for H-MRV models

Haier Auto Restart function when the unit power drops down suddenly, the unit microprocessor

will store the previous working condition and when the power is on again, the unit will run as this

memory.

Auto Restart function is designed basically on the MRV whole system, but it is suitable for each

indoor unit individually.

f some of indoor units power cut down, but the outdoor unit and the other indoor units still work,

maybe problems will happen such as freezing at cooling mode and overload protection at

heating mode on those indoor units without power.

Reason

When one or some indoor units power drops down and the other indoor units are still work, the

indoor units without the power, will keep the previous working condition before the power is off.

And expansion valve keeps open at a kind of opening rate condition as the previous requirement,

so there is refrigerant flowing in the exchanger, but the indoor fan stops working. f the units work

at cooling mode, the indoor units without the power will maybe make freezing. f the unit works

at heating mode, maybe the outdoor unit compressor will stop because of the pressure or

temperature protection. This is our design basically on Auto Restart function currently.

Haier, Herewith, solemnly informs our customers, installers, distributors, etc. when making instaIIation,

pIease make sure when the power is shut down whether artificiaIIy or accidentaIIy, the whoIe

system incIuding outdoor unit and aII the indoor units must be off. If you do not make the

instaIIation as our indication, Haier wiII not be responsibIe for any probIem resuIting from this.

- 20 -

CommerciaI Air Conditioner

*

MODE FAN

HEALTH TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

ON/OFF

AM

SET

OFF

1.How to use the health function (only for units with this function)

After set the right function mode, press health button,

remote controller or wire controller displays " ",oxygen pump

or negative ion generator starts up to apply oxygen or negative

ion to indoor unit. Press the button again,the sign " " disapp-

eared and negative ion generator stops working. After all health

function of the indoor unit being fully canceled, oxygen pump

stopped. AM

On the "Health" mode, if you want to

setting timing open mode, should

close the health first: On the timing

open mode, please don't use health

function.

SWNG

About heaIth function

CAUTON:

When the temperature of the outdoor unit is lower than 4 ,

oxygen pump is automatically stopped, if press health button

just then, oxygen pump could not start up. But if the air condi-

tioner has the negative ion function simultaneous,when press

the health button, negative ion function could still be operated.

When the temperature of the outdoor unit is higher than 6 ,

oxygen pump could automatically resume to oxygen-make

function.

C

C

Left picture is a wired remote controller, which can be used on Series wired control

units ,The remote controller can be purchased extrally.

Wired remote Controller using method:

1.Use one wired remote controller. See fig (1)

2.Also can buy a remote controller extrally, realize

wired remote control + remote control dual control modes.

3.When the remote controIIer can be used on series wired remote controIIer

units ,than pIease press the botton "CODE"to choose the program of code "A"

FRESH

HGH/SO TMER

SET

FLTER

B A

M D

HEALTH

RESET LOCK

SLEEP

FAN

TEMP

ON

OFF

SWNG

MODE

CLOCK

CODE LGHT

OFF

A

U

T

O

SET

ROOM

MODE FAN

TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

HEALTH

SW NG

C

ON OFF

*

AUTO

ON/OFF

For H-MRV wired type indoor unit, the wired controller can be matched with the remote controller

YR-H71 to realize the remote control function.

SET

ROOM

MODE FAN

TEMP

CLOCK SET

TMER SLEEP

RESET

FLTER RESET

HEALTH

SWNG

C

ON OFF

*

AUTO

ON/OFF

Remote controlller Wire remote controlller

Remote controlller is an accessory, to be ordered extrally

- 21 -

CommerciaI Air Conditioner

11

6. RepIace the upper cover of wire controIIer

Note

Try as far as possible a flat surface for installation.

Don't use excessive force when tightening screws,

or lower part might got deformed.

Hint 1. Power supply switch and signal wire should be prepaired by the user.

2. Don't touch PCB with hand.

Be careful not to hold down the wiring.

1. Remove upper cover of wire controIIer

Remove upper part of wire controller by press.

Lower cover of wire

controller

Upper cover of wire

controller

2. InstaII the wired remote controIIer

Please drill two holes on the wall according to the

back cover screw hole position of the wire remote

controller, then strike the wood block to the holes

respectively, then align the 2 screw hole of the wire

controller back cover to the wood block, fasten the

wire reote controller to the wall use wood screws.

3. Switch setting

The switchs setting as follows:1.ON 2.OFF 3.ON 4.OFF

4. Connecting method as the foIIowing chart

Back cover of the wire

controller

PCB is mounted on lower part of wire

controller, be careful not to damage it.

No Symbol colour contents

1

2

3

4

A

B

C

D

White or Green

Red

Yellow

COM

Gnd

12V

Switch button

Screw hole

Use shielede wires for telecommunication

between wire controller and indoor unit;

indoor unit and outdoor unit. Ground the

shield on one side.

Otherwise misoperation because of noise

may occur.

Signal wire is self-provided by user.

Shielded wire

ground

5. Functions of dip switch

11

No ON OFF

1

2

3

4

H MRV or Fixed

frequence types

Has [free elevating

inlet grill] function

Has [swing]

function

No [swing]

function

No [free elevating

inlet grill] function

Single split

inverter

Use the ambient

sensor in indoor

unit

Use the ambient

sensor in wired

controller

-- 222 --

CommerciaI Air Conditioner

- 23-

The first site of dip switch in YR-E06 is used to distinguish diferent types, ON:H MRV or

Fixed frequence types, OFF:Single split inverter. Their diagnostic codes are different.

ON OFF

Normal state -- --

Indoor ambient temp. sensor error E1 F1

Indoor pipe temp. sensor error E2 F2

Indoor pipe is over-heat in heating mode F4 F4

Indoor pipe is in anti-freezing function in cooling F5 F5

Communication error between indoor and outdoor units E9 E3

Communication error between indoor and wired controller E8 F7

Outdoor power model error E0 E1

Outdoor current is too low F2 E2

Compressor is over-heat F6 E4

CT current is over high/one phase of power line is lost E5 E5

Outdoor ambient temp. sensor error E3 E6

Outdoor pipe temp. sensor 1 error E4 E7

The voltage is over-high or over-low E7 E10

Outdoor high or low pressure error E6 E13

Outdoor pipe temp. sensor 2 error E15 E15

The indoor pipe sensor temp. is too high E12 E12

Outdoor pipe temp. sensor 3 error E14 E14

Outdoor suction temp. sensor error E13 E11

Compressor temp. sensor error F7 E9

Indoor mid-evaporator temp. sensor error F3 F3

Indoor PCB error F8 E8

Water outlet system problem E0 F6

Power lines is in wrong connection turn or one phase is lost E10 F0

Humidity sensor error E11 F8

Error Discription

SW1-1

CommerciaI Air Conditioner

CLOCK

Used to adjust time.

TIMER

Used to set timer mode.

/-

stands for time plus/minus,

used to adjust time.

Used Ior unit start and stop.

POWER ON/OFF

MODE

Used for select indoor

operation mode.

FAN

Used for select indoor

air flow.

HEALTH

Used for setting indoor

health function.

TEMP + -

Used for changing set

temperature.

RECOVERY

used to switch over air-

exchanging mode.

SWING

Used for setting indoor

swing mode.

CHECK

Auto-diagnostic button.

Filter-cleaned button.

FILTER

RESET

Reset correct mode button.

C

HEALTH

SET RECOVERY

CHECK

F

1.7 Wired controIIer YR-E12

|MODE|

|AUTO|:Auto operation mode. |FAN ONLY|:air-throwing mode.

|COOL|:Cooling operation mode. |DRY|:DehumidiIication mode.

|HEAT|:Heating operation mode.

|TES|:In heating mode, auxiliary electric heater is running. Only when the unit with auxiliary electric heater is in

auxiliary electric heating mode, it will display.

|FAN|

|AUTO|:Auto Ian running. |HIGH|:High Ian speed.

|MED|:Medium Ian speed. |LOW|:Low Ian speed.

|FIX|: Fixed Ian speed, it will display only when Iixed Ian speed is requested to main indoor unit.

|CENTRAL|:Central control mode.

|OPERATION|:Running mode.

|STAND BY|: Waiting mode.

|PRE-HEAT|: Pre-heating mode.

|DEFROST|: DeIrosting mode.

|FILTER|: Request oI Iilter to be cleaned.

|HEALTH|:Health Iunction.

|CEN.ADD|:Central control address, the address number will display on "88".

|SYS.ADD.|:System address, the address number will display on "88".

|CHECK|:Auto-diagnostic, trouble shooting.

|DEMAND|:Compulsory operation Iunction, when it works, |CENTRAL| will Ilash.

|SWING||MANUAL|:Swing mode.

|ROOM TEMP.|:Indoor ambient temperature.

|SET TEMP.|:Set admired temperature.

|TIMER|

|ON|:Timer Iunction is on. |OFF| :Timer Iunction is oII.

|ON||OFF| :Timer Iunction ON-OFF.

|ON||OFF||DAILY|:Timer ON-OFF will switch over in turn daily

|CLOCK|:Clock display, the displaying time is the current time oI the clock.

|UP|,|DOWN|:Indicator oI Iilter elevating.

|VENTILATION|

|AUTO|:Auto ventilation mode. |RECOVERY|:Fully heat exchanging ventilation mode.

|NORMAL|:Normal ventilation mode.

- 24 -

CommerciaI Air Conditioner

2

3

1,7

4

5

6

C

HEALTH

SET RECOVERY

CHECK

2>L 3~,z1 HI>J:LBHGv

Ad[ust clock: when powered on, Ior the Iirst time to set timer Iunction, the clock will

be ad[usted.

Press "CLOCK" button, and set the current clock. Now, "CLOCK" will Ilash at the

Irequency oI 2Hz . Press the clock /- button; the current clock

can be ad[usted. Until the proper time comes, press |SET|.

3~,z1 .- HI>J:LBHGv

Press TIMER button, and keep pressing it, in the display section |TIMER| will switch

over in below sequence: |ON| |OFF| |ON||OFF|

|ON||OFF||DAILY| | |. Select |TIMER| |ON|, then |TIMER| |ON| Ilashes, press

the clock /- button to ad[ust the time oI TIMER ON, press |SET| button.

C

Note:

1. II the two times are same, the timer state which is set later will Ilash, in this case, timer can not be set.

2. When entering TIMER setting state, iI you do not input any button in continuous 10 seconds, the unit will

quit Irom the TIMER mode.

x:G<>E 3~,z1 HI>J:LBHGv

In the timer operation state, press |TIMER| button, the unit will quit Irom the current timer operation state, and

the set data will be memorized, then enter the next timer mode. When |TIMER| dose not display, the timer will be

cancelled.

8{~+3z19 ?MG<LBHG

2

3

1,4

C

HEALTH

SET RECOVERY

CHECK

{w- .-+7 ./z1w3~.-f2>> IB<LMJ> mgv

1)Start up operation: press the button oI ON/OFF, the system will

start up, and will display on LCD.

2)Select MODE: press the MODE button, then you will see in the

display section |MODE| switch over in below sequence:|FAN

ONLY| |COOL| |DRY| |HEAT| |AUTO| |FAN

ONLY|. Select |FAN ONLY|.

3)Select Ian speed: press FAN button, then you see in the display

section |FAN| switch over in below sequence: |HIGH| |MED|

|LOW| |HIGH|. Select proper Ian speed.

4)Power oII: press ON/OFF button, indoor unit will be powered

oII, there are only time and the ambient temperature in the screen.

w43. HI>J:L B HGi x..+~ -|i }zw3~ -| :G=

yz}4,~y~{~xw3~.- HI>J:LBHG f2>> /B<LMJ> ngv

1) Start up operation: press the button oI ON/OFF, the system will

start up, and will display on LCD.

2) Select MODE: press the MODE button, then you will see in the

display section |MODE| switch over in below sequence:|FAN

ONLY| |COOL| |DRY| |HEAT| |AUTO| |FAN ONLY|.

Select |COOL|.

3) Change set temperature: press TEMP or - every time, |SET|

will display, and set temperature will increase/reduce 1 C( F).

4) Select Ian speed: press FAN button, then you see in the display

section |FAN| switch over in below sequence: |AUTO| |HIGH|

|MED| |LOW| |AUTO|. Select proper Ian speed.

5) Select |SWING|: press |SWING| button, |SWING| will display,

swing Iunction is valid, press again, |SWING| will disappear,

swing Iunction is invalid.

6) Set |HEALTH|: used to set the indoor health Iunction. Press it

once, |HEALTH| will display in the display section, then indoor

health Iunction is valid. Press it again, |HEALTH| will disappear,

then the health Iunction is invalid.

This Iunction is valid only Ior the unit with health Iunction.

7) Power oII: press ON/OFF button,

indoor unit is powered oII. There are

only time and the ambient temperature

in the screen.

/B<LMJ> m

/B<LMJ> n

- 25 -

CommerciaI Air Conditioner

{~+3z1 z+z5w3~-| ?MG<LBHGv fHGEP ?HJ LA> MGBL OBLA >E>N:LBG@ ?MG<LBHGg

When the Iilter needs to be cleaned, the panel can be lowered to the admired height

by the |FILTER||UP||DOWN| Iunction. Method is below: In power oII state, press

|HEALTH| Ior 15 seconds to enter Iilter elevating set state. In this state, the sign

|FILTER| will Ilash and |UP| |DOWN| will display simultaneously, Press TEMP

||, in timer section |UP| will display, while press TEMP |-|, in timer section |DOWN|

will display. When it arrives the appropriate position, press |UP|, |UP||DOWN| will

display simultaneously, Iilter will stop going down. Press |UP| again, Iilter will go

up. Press |FILTER| button to quit the mode.

3JB:E JMGGBG@ HI>J:LBHG ?MG<LBHGv

By this Iunction, all the indoor units can be made in nominal mode. Set the operation

mode in cooling and then shut oII the unit. In the stop state, press

|ON/OFF| button Ior 5 seconds to enter cooling trial operation state. II it is in heating

mode beIore shut oII the unit, then press |ON/OFF| button Ior 5

minutes, it will enter heating trial operation state. In cooling, there will be "LL" in

the position where the set temperature displays. In heating, there

5z-3~+w3~.- FH=> fHGEP ?HJ LA> MGBL OBLA ?J>KA :BJ ?MG<LBHG HJ A>:L J><HN>JP ?MG<LBHG)

Press |RECOVERY| button, then the unit will switch over the ventilation mode:

| | |VENTILATION||AUTO| |VENTILATION||RECOVERY| |VENTALATION||NORMAL| | |, please

select appropriate ventilation mode.

0M>JP BG=HHJ F:E?MG<LBHG ABKLHJPv

In the state oI power on or power oII, press |CHECK| button, enter the malIunction-querying mode oI all indoor

units in the group. Then |CHECK| and

|UNIT NO.| will display, and the actual indoor numbers will be displayed in some sequence (unit number is in

decimals). At the same time, in the time region,

there will be the current malIunction and the latest time malIunction, the displaying Iormat is |XX:YY|, in which

XX stands Ior the current malIunction, iI normal, it will display "--"; YY stands Ior the latest time malIunction.

The Iailure code oI every unit will display Ior 3 seconds. AIter the Iailure codes oI all indoor units in the whole

group are displayed, the mode will quit automatically.

xE>:J :;GHJF:E KL:L> :G= F:E?MG<LBHG ABKLHJPv

In normal state, press |CHECK| button Ior 5 seconds to clear abnormal states, at the same time, wired controller

How to change the Iunction switches?

Y ZZZ Type

A Indoor capacity (W) Nominal cooling capacity/10, decimal

B Request oI indoor capacity(Hz) Actual value, decimal

C Temperature oI indoor ambient temp. sensor TA Actual value, decimal

d Temperature oI indoor gas pipe sensor TC1 Actual value, decimal

E Temperature oI indoor liquid pipe sensor TC2 Actual value, decimal

F Open degree oI indoor PMV Actual value, decimal

g Preset ---

H Outdoor total capacity Actual value, decimal

No. Type State oI switch Function description

J01 Changeover oI Wired Connected Central controller

controller and central controller Cut oII Wired controller

J02 Changeover oI type oI Connected Set as simple controller

wired controller Cut oII Set as standard controller

J06 Selection oI room Connected Use the sensor in the wired controller

temp. sensor Cut oII Use the sensor in the indoor unit

J07 Auto restart aIter Connected Common control

power Iailure Cut oII Auto restart aIter power Iailure

J03 Display oI room Connected Yes

temperature Cut oII No

SW01 Changeover oI master ON Set as slave controller

or slave controller OFF Set as master controller

SW01 C or F ON F

OFF C

D1 Shorten time Iunction Connected Indoor unit in shorted time Iunction

Cut oII Common control

D2 Compulsorily deIrost Connected Send compulsorily deIrost signal to indoor unit

Cut oII Common control

1

2

In check mode, press |CHECK| to quit the check mode, and go into normal running mode.

/B<LMJ> o

- 26 -

CommerciaI Air Conditioner

Note: 1. The switches in grey can be operated aIter opening the cover oI wired controller.

2. Switches or [umper wire must be ad[usted when the wired controller is powered oII. II the wired controller is

powered on, the above operations will be invalid.

3. Shorten time Iunction

In normal operation, D1 is in short circuit, it will enter shorten time mode, and the time will be shortened in the

proportion oI 60:1. In shorten time mode, LED will Ilash at the Irequency oI 0.5 second. Cut oII D1, it will quit

the shorten time mode and return to the normal operation mode.

4. Compulsorily deIrost

In heating mode, D2 is in short circuit, it will enter compulsorily deIrost mode; cut oII D2, it will quit.

5. Lock Iunction

There is no lock Iunction only in the wired controller. But when it is connected with a central controller, iI the central

controller is set to "central", the buttons in the wired controller will be invalid, or the buttons will be valid.

mk 6BJBG@ <HGG><LBHGK H? OBJ>= <HGLJHEE>Jv

1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

Indoor 16 Indoor 15 Indoor N Indoor 2 Indoor 1

Wired controller Wired controller Wired controller Wired controller Wired controller

(master unit)

A B C

Wired controller

Control wiring oI

wired controller,

polar.

1 2 3

Indoor 1

Wired controller

A B C

Wired controller

Poler wire

1 2 3

Indoor 1

Wired controller

A B C

Wired controller

Poler wire

A B C

Wired controller

Poler wire

A

B C

There are three methods to connection wired controller and the indoor units:

A.One wired controller can control max. up to 16 sets oI indoor units, and 3 pieces oI polar wire must connect the

wired controller and the master unit (the indoor unit connected with wired controller directly), the others connect

with the master unit through 2 pieces oI polar wire.

B. One wired controller controls one indoor unit, and the indoor unit connects with the wired controller through 3

pieces oI polar wire.

C. Two wired controllers control one indoor unit. The wired controller connected with indoor unit is called master

one, the other is called slave one. Master wired controller and indoor unit; master and slave wired controllers are

all connected through 3 pieces oI polar wire.

nk xHFFMGB<:LBHG OBJBG@v

The wired controller is equipped with special communication wiring in the accessories. 3-core terminal (1-white

2-yellow 3-red) is connected with the terminal A, B, C oI wired controller respectively.

The communication wiring is 4 meter long; iI the actual length is more than it, please distribute wiring according

to below table:

Communication wiring length(m) Dimensions oI wiring

100 0.3mm

2

x3-core shielded wire

100 and 200 0.5mm

2

x3-core shielded wire

200 and 300 0.75mm

2

x3-core shielded wire

00 and 400 1.25mm

2

x3-core shielded wire

400 and 600 2mm

2

x3-core shielded wire

*One side oI the shielded sheet oI communication wire must be earthed.

Contrastive items Master wired controller Slave wired controller

Function All oI Iunctions Only with below Iunctions: ON/OFF, MODE,

FAN SPEED, SET TEMP., SWING

7. Function diIIerence between simple wired controller and the standard one:

Contrastive item Standard wired controller Simple wired controller

Function With all Iunctions Only can control ON/OFF, MODE,

FAN, TEMP.,SWING.

Master/Slave Can be either oI Master Only can be Master controller

selection and Slave controller

- 27 -

CommerciaI Air Conditioner

Note:

The wired controller must be used with cooperation with indoor unit. When wired control type is selected, the

Iunction oI indoor unit must be ad[usted (aIter power cut oII).

The indoor PCB(0010451167) is matched with this wired controller (0010451521)which can be set according to

below table:

When the wired controller controls several indoor units, there is only one Master unit, and other can be set as Slave

unit.

ok2>LLBG@ :==J>KK F>LAH=v

The address setting can be realized by setting indoor PCB.

II you use the group control Iunction, there should be a master unit and 15 sets oI slave units. For the master

unit, the SW5-3 should be at "ON". For the slave units, the SW5-3 should be at "OFF"

Please reIer the below table,

Connected Cut oII

J1 Remote control Wired control

J2 In heating mode, with temperature compensation Without temperature compensation

J4 Heat pump Cooly only

J7 Sychronous motor swing Stepping motor swing

J9 Master unit Slave unit

Indoor unit address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SW1-4

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

SW1-3

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

SW1-2

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

SW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

- 28 -

Failure description

Room temp. sensor abnormal

Indoor coil temp. sensor abnormal

Outdoor coil temp. sensor abnormal

Over-current malfunction

Communication malfunction between indoor and wired controller

Communication malfunction between indoor and outdoor abnormal

Coil gas pipe temp. Sensor abnormal

Code on wired controller

01

02

4A

49

48

53

07

06

03

Outdoor temp. sensor abnormal

High / Low pressure abnormal

Temperature protection malfunction

0D

Drainage system malfunction 08

Indoor EEPROM abnormal

N/A 0B

05

4. Diagnostic code display

CommerciaI Air Conditioner

.0/+4|2 3|4 5/+4

A540

4|.1

200.

4|.1

0|/42A-2|.04|

4+.|2 0/

|6|27 0A7

3|-|04

0/

0**

.00| *A/

4|.1.

4+.|

4+.| 4+.|2