SH Cset m151 Front Chainwheel FC-M151

SH Cset m151 Front Chainwheel FC-M151

Uploaded by

Ingrid VantaCopyright:

Available Formats

SH Cset m151 Front Chainwheel FC-M151

SH Cset m151 Front Chainwheel FC-M151

Uploaded by

Ingrid VantaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SH Cset m151 Front Chainwheel FC-M151

SH Cset m151 Front Chainwheel FC-M151

Uploaded by

Ingrid VantaCopyright:

Available Formats

Front Chainwheel

FC-M151

Chain Guard Type

4 3 1

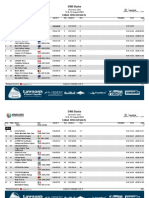

ITEM NO. * 1 * 2 * 3 4 5

SHIMANO CODE NO. Y-1JE 13000 Y-1JE 05100 Y-1JE 98010 Y-1JE 98020 Y-1BN 98010 Y-1D2 98010 Y-1JE 12000 Y-1JF 12000

DESCRIPTION Crank Arm Cap Left Hand Crank Arm 170 mm Chain Guard for 42T & Fixing Screws Chain Guard for 48T & Fixing Screws Chain Guard Fixing Screw (4 pcs.) for 42T Chain Guard Fixing Screw (4 pcs.) for 48T Chain Guard for 42T Chain Guard for 48T

INTERCHANGEABILITY

FC

Chainring teeth combinations: 42 -- 34 -- 24 T / 48 -- 38 -- 28 T

A: Same parts. B: Parts are usable, but differ in materirals, appearance, finish, size, etc. Absence of mark indicates non-interchangeability.

-M C

0708-2738A

08

General Safety Information

WARNING

Use neutral detergent to clean the chain. Do not use alkali-based or acid based detergent such as rust cleaners as it may result in damage and/or failure of the chain. Use the reinforced connecting pin only for connecting the narrow type of chain. There are two different types of reinforced connecting pins available. Be sure to check the table below before selecting which pin to use. If connecting pins other than reinforced connecting pins are used, or if a reinforced connecting pin or tool which is not suitable for the type of chain is used, sufficient connection force may not be obtained, which could cause the chain to break or fall off.

Chain 9-speed super narrow chain such as CN-7701 / CN-HG93 8- / 7- / 6-speed narrow chain such as CN-HG50 / CN-HG40 Reinforced connecting pin

Silver

6.5mm

Specifications

EZ FIRE Plus (Shifting lever)

Model number Gears ST-EF40-L SIS 3-gears

Chainstay angle

2. The level section of the chain guide outer plate should

be directly above and parallel to the largest chainring.

Cut off the excess length of inner cable and then install the inner end cap.

Chainwheel (largest chainring)

3. Secure using a 9 mm spanner (TY10) or a 5 mm Allen

key (C051, C050).

Tightening torque: 5 - 7 Nm {44 - 60 in. lbs.}

< FD-C051 / C050 >

Note: Pass the cable through as shown in the illustration.

Chain guide

Front Derailleur

Model number Front derailleur installation band diameter (Normal type) Front derailleur installation band diameter (Top route type) Chainstay angle (a) FD-C051 FD-C050 FD-TY10 S, M S, M 66- 69 FD-TZ31 FD-TZ30 FD-TZ21 FD-TZ20

S, M, L S, M, L 66- 69

S, M S, M 66- 69

S, M

Chain tool TL-CN32 / TL-CN27

Chain length

S, M 66- 69

< GS >

Add 2 links (with the chain on both the largest sprocket and the largest chainring)

Largest sprocket Largest chainring

< SS >

Smallest sprocket Largest chainring

5 mm allen key

Wire fixing bolt

Top route type

Normal type

Black

7.1mm

TL-CN32 / TL-CN27

Front chainwheel

Model number Front chainwheel tooth combination Crank arm length Pedal thread dimensions Bottom bracket cup thread dimensions Applicable front derailleur FC-M151 48T-38T-28T 170 mm BC 9/16" X 20 T.P.I. (English thread) BC 1.37" X 24 T.P.I. (68, 73 mm) FD-C051 FC-M151 42T-34T-24T 170 mm BC 9/16" X 20 T.P.I. (English thread) BC 1.37" X 24 T.P.I. (68, 73 mm) FD-C050/FD-TY10

Reinforced Connecting Pin If it is necessary to adjust the length of the chain due to a change in the number of sprocket teeth, make the cut at some other place than the place where the chain has been joined using a reinforced connecting pin or an end pin. The chain will be damaged if it is cut at a place where it has been joined with a reinforced connecting pin or an end pin. End Pin Link Pin Be careful not to let the cuffs of your clothes get caught in the chain while riding, otherwise you may fall off the bicycle. Check that the tension of the chain is correct and that the chain is not damaged. If the tension is too weak or the chain is damaged, the chain should be replaced. If this is not done, the chain may break and cause serious injury. Check that there are no cracks in the crank arms before riding the bicycle. If there are any cracks, the crank arm may break and you may fall off the bicycle. Obtain and read the service instructions carefully prior to installing the parts. Loose, worn, or damaged parts may cause injury to the rider. We strongly recommend only using genuine Shimano replacement parts. Obtain and read the service instructions carefully prior to installing the parts. If adjustments are not carried out correctly, the chain may come off and this may cause you to fall off the bicycle which could result in serious injury. Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Guide pulley Tension pulley Chain 90

Chain

While firmly pulling the cable, tighten the fixing bolt with a 9 mm spanner (TY10) or a 5 mm Allen key (C051, C050) to secure the cable.

Tightening torque: 5 - 7 Nm {44 - 60 in. lbs.}

Right angle to the ground

3. Adjustment of cable tension

Bottom Bracket

Type Triple Chain line 47.5 mm Spindle length 122.5 mm Shell width 68 mm Stamped marking D-NL Thread dimensions BC1.37 X 24 T.P.I.

Mounting the shifting lever

Use a handlebar grip with a maximum outer diameter of 32 mm.

After taking up the initial slack in the cable, re-secure to the front derailleur as shown in the illustration.

Normal type Top route type Pull

Gear shifting operation

Both lever (A) and lever (B) always return to the initial position when they are released after shifting. When operating one of the levers, always be sure to turn the crank arm at the same time. Do not operate lever (A) and lever (B) together. If you cannot shift from a large chainring to a smaller chainring, operate lever (A).

Pull

Note

The reinforced connecting pins cannot be used with the UG chain, otherwise the connections will not move properly and noise will occur. Apply grease to the thread section of the bottom bracket and to the inside thread of the adapter before installing the bottom bracket. In addition, if pedaling performance does not feel normal, check this once more. Check that there is no looseness in any joints or connections before riding the bicycle. (BB-FC, FC-PD) Do not wash the bottom bracket with high-pressure jets of water. If you feel any looseness in the bottom bracket axle, the bottom bracket should be replaced. If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts. If the amount of looseness in the links is so great that adjustment is not possible, you should replace the derailleur. You should periodically wash the chainrings in a neutral detergent and then lubricate them again. In addition, cleaning the chain with neutral detergent and lubricating it can be a effective way of extending the useful life of the chainrings and the chain. If the chain keeps coming off the chainrings during use, replace the chainrings and the chain. Use an outer casing which still has some length to spare even when the handlebars are turned all the way to both sides. Furthermore, check that the shifting lever does not touch the bicycle frame when the handlebars are turned all the way. Grease the inner cable and the inside of the outer casing before use to ensure that they slide properly. Operation of the levers related to gear shifting should be made only when the front chainwheel is turning. For smooth operation, use the specified outer casing and bottom bracket cable guide. To ensure the best performance, be sure to use only the specified type of chain. The wide type chain cannot be used. For maximum performance we highly recommend Shimano lubricants and maintenance products. Parts are not guaranteed against natural wear or deterioration resulting from normal use. For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a professional bicycle dealer.

4. Top adjustment

Set so that the clearance between the chain guide outer plate and the chain is 0 - 0.5 mm.

Chain position

5 mm Allen key Smallest sprocket Largest chainring

FD-TY10

To shift from a small chainring to a larger chainring (Lever A)

When lever (A) is pressed once, there is a shift of one step from a small chainring to a larger chainring.

To shift from a large chainring to a smaller chainring (Lever B)

When lever (B) is pressed once, there is a shift of one step from a large chainring to a smaller chainring.

Tightening torque: 6 - 8 Nm {53 - 69 in. lbs.} Tightening torque: 2.5 - 3.5 Nm {22 - 31 in. lbs.}

Top adjustment screw

Example:

from intermediate chainring to largest chainring.

Example:

from largest chainring to intermediate chainring.

Chain guide outer plate

Adjustment

Be sure to follow the sequence described below.

FD-C051 / C050

Chain

1. Low adjustment

First remove the Pro-Set alignment block. Next, set so that the clearance between the chain guide inner plate and the chain is 0 - 0.5 mm.

Pro-Set alignment block

FD-C051 / C050 FD-TY10

Low adjustment screw

5. Adjustment of the intermediate chainring

Set the chain onto the largest sprocket, and at the front, move the chain from the largest chainring to the intermediate chainring. Adjust using the cable adjusting bolt so that the clearance between the chain guide inner plate and the chain is 0 - 0.5 mm.

Lever (A) initial position

Lever (B)

Installation of the bottom bracket

Install using the special tool TL-UN74-S. First install the main body, then the adapter.

Front Chainwheel

Chain position

Largest sprocket Smallest chainring Chain guide inner plate Chain

Chain position

Largest sprocket Intermediate chainring Chain guide inner plate Chain Outer casing adjustment barrel

Tightening torque: 50 - 70 Nm {435 - 608 in. lbs.}

2. Connection and securing of cable

Adapter Bottom Bracket

Technical Service Instructions

SI-6NVFA-002

Operate lever (B) two times or more, and check on the indicator that the lever is at the lowest position. Then remove the inner hole cover and connect the inner cable.

6. Troubleshooting chart

After completion of steps 1 - 5, move the shifting lever to check the shifting. (This also applies if shifting becomes difficult during use.)

Front Drive System

In order to realize the best performance, we recommend that the following combination be used.

Series Gears Shifting lever Outer casing Front derailleur Front chainwheel Bottom bracket Chain Bottom bracket cable guide Right Left Left 7-gears 3-gears ST-EF40-L SIS FD-C051/FD-C050/FD-TY10 FC-M151 BB-UN26 CN-UG51 SM-SP18/SM-BT18 Tourney (SIS) 6-gears

Installation of the front chainwheel

Use the cotterless crank extractor (TL-FC10) to install the front chainwheel.

S

G

F C or h a i

NA n

OW y RRn l o

If the chain falls to the crank side.

Tighten the top adjustment screw clockwise (about 1/4 turn).

If shifting is difficult from the Loosen the top adjustment screw intermediate chainring to the largest counterclockwise (about 1/8 turn). chainring.

Inner hole cover Lever (B) Inner cable

Tightening torque: 35 - 50 Nm {305 - 435 in. lbs.}

If shifting is difficult from the intermediate chainring to the smallest chainring. If there is interference between the chain and the front derailleur inner plate at the largest chainring. If there is interference between the chain and the front derailleur outer plate at the largest chainring.

Loosen the low adjustment screw counterclockwise (about 1/4 turn). Tighten the top adjustment screw clockwise (about 1/8 turn). Loosen the top adjustment screw counterclockwise (about 1/8 turn). Loosen the outer casing adjustment barrel counterclockwise (1 or 2 turns).

SHI

Bottom Bracket

40

Securely tighten

Installation of the front derailleur

1. Adjust and then install the front derailleur

as shown in the illustration. Do not remove the Pro-Set alignment block at this time.

Gear teeth should come within this range

Pro-Set gauge

This service instruction explains how to use and maintain the Shimano bicycle parts which have been used on your new bicycle. For any questions regarding your bicycle or other matters which are not related to Shimano parts, please contact the place of purchase or the bicycle manufacturer.

Pro-Set alignment block

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003 Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Please note: specifications are subject to change for improvement without notice. (English) Dec. 2007 by Shimano Inc. XBC IZM Printed in Singapore.

-3

3-gears

Inserting the inner cable

Insert the inner cable into the outer casing from the end with the marking on it. Apply grease from the end with the marking in order to maintain cable operating efficiency.

Marking

SH

MA

I MA

NO

SG

NO

E

E-

SG

Cutting the outer casing

When cutting the outer casing, cut the opposite end to the end with the marking. After cutting the outer casing, make the end round so that the inside of the hole has a uniform diameter. Attach the same outer end cap to the cut end of the outer casing.

If the intermediate chainring is skipped when shifting from the largest chainring.

If there is interference between the Tighten the outer casing adjustment chain and front derailleur inner plate barrel clockwise (1 or 2 turns). when the rear sprocket is shifted to the largest sprocket when the chainwheel is at the intermediate chainring position. If shifting is difficult from the largest chainring to the intermediate chainring. If the chain falls to the bottom bracket side. Tighten the low adjustment screw clockwise (about 1/2 turn).

Outer end cap

You might also like

- Handbook For Bicycle Mechanics by Howard SutherlandDocument115 pagesHandbook For Bicycle Mechanics by Howard SutherlandCitac_1100% (2)

- W20 ScreenDocument5 pagesW20 ScreenBruno Marques100% (3)

- Shimano Ultegra 6700 Shifters Double Owners ManualDocument2 pagesShimano Ultegra 6700 Shifters Double Owners ManualTimNo ratings yet

- Shimano Tiagra 4600Document1 pageShimano Tiagra 4600Florian JurinNo ratings yet

- Installation Manual Reverse Gear 5 Speed Revision 7Document6 pagesInstallation Manual Reverse Gear 5 Speed Revision 7arieskittenNo ratings yet

- 2012 Components Technical Manual UkDocument154 pages2012 Components Technical Manual UkBrummerNo ratings yet

- 1999 Coda Expert Crank InstructionsDocument8 pages1999 Coda Expert Crank InstructionsaPaCz42No ratings yet

- Ladybird Sp2 InstructionsDocument4 pagesLadybird Sp2 Instructionsdfepj100No ratings yet

- Bike Helmets OpinionDocument2 pagesBike Helmets Opinionapi-6222275867% (3)

- KTM Phinx-2.29Document1 pageKTM Phinx-2.29dinistcomNo ratings yet

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Document1 pageAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16No ratings yet

- ShimanoDocument1 pageShimanoProto Popescu VictorNo ratings yet

- SI F920A ShimanoDocument7 pagesSI F920A ShimanoolligesNo ratings yet

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5No ratings yet

- SI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsDocument1 pageSI-0087A-001-ENG - v1 - m56577569830657743 Technical Service InstructionsIngrid VantaNo ratings yet

- Si F570CDocument1 pageSi F570CmegclayNo ratings yet

- Manuale Cambio ShimanoDocument1 pageManuale Cambio ShimanoPaola CapassoNo ratings yet

- MTB Technology: FRONT CHAINWHEEL: InstallationDocument4 pagesMTB Technology: FRONT CHAINWHEEL: InstallationRoy Chung Qi Huan100% (1)

- Shimano 105 5700 Rear Derailleur Installation ManualDocument2 pagesShimano 105 5700 Rear Derailleur Installation ManualjjjNo ratings yet

- Shimano XTR M980 Shift Lever Set ManualDocument4 pagesShimano XTR M980 Shift Lever Set ManualNick SpeisNo ratings yet

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouNo ratings yet

- Shimano Tourney Rear and Knob AdjustmentDocument1 pageShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetNo ratings yet

- SI 6PZRA 003 ENG - v1 - m56577569830677284Document1 pageSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5No ratings yet

- SI 5VV0B en v1 m56577569830604982Document1 pageSI 5VV0B en v1 m56577569830604982iodinNo ratings yet

- Disc BrakeDocument1 pageDisc BrakepahelwanNo ratings yet

- DL RD m760 2 PDFDocument1 pageDL RD m760 2 PDFtudor-72No ratings yet

- 6jr0a enDocument0 pages6jr0a enBilly GeorgiouNo ratings yet

- V-BeltDocument70 pagesV-BeltDee Trd100% (1)

- DM FD0001 00 EngDocument29 pagesDM FD0001 00 EngpietouNo ratings yet

- Conduct Hydraulic Disc Brakes - ENDocument8 pagesConduct Hydraulic Disc Brakes - ENovidiu_lung4770No ratings yet

- Inter BrakeDocument1 pageInter BrakedovlikusNo ratings yet

- CB E110 enDocument1 pageCB E110 enandNo ratings yet

- K25 8Document17 pagesK25 8mushfiq66No ratings yet

- Specifications: FC-M411 FC-M410 / FC-M410-8 FC-M361 / FC-M361-8 FC-M311 / FC-M311-8Document1 pageSpecifications: FC-M411 FC-M410 / FC-M410-8 FC-M361 / FC-M361-8 FC-M311 / FC-M311-8Lawrence A. DyNo ratings yet

- SM-BB70 / BB51 / BB50: General Safety InformationDocument1 pageSM-BB70 / BB51 / BB50: General Safety InformationaufcheNo ratings yet

- Manual Mantenimiento Mission 40Document8 pagesManual Mantenimiento Mission 40Daygor Martinez SabucoNo ratings yet

- FC-M131 / FC-M171 / FC-M171-A: General Safety InformationDocument1 pageFC-M131 / FC-M171 / FC-M171-A: General Safety InformationFelipe VSNo ratings yet

- FZR400MANUALDocument385 pagesFZR400MANUALcoccaro88No ratings yet

- Marzocchi 01 Z1 - Dropoff ManualDocument18 pagesMarzocchi 01 Z1 - Dropoff ManualHarry James BoundenNo ratings yet

- Giant Conduct SL User's ManualDocument10 pagesGiant Conduct SL User's ManualRicardo RegoNo ratings yet

- Shimano Anleitung ST5500 en-SI6BS0E-EnDocument1 pageShimano Anleitung ST5500 en-SI6BS0E-EnGA16DETNo ratings yet

- Tensioner Training PresentationDocument29 pagesTensioner Training Presentationaravindan476No ratings yet

- Steering Axle: Safety Precautions Maintenance and RepairDocument9 pagesSteering Axle: Safety Precautions Maintenance and RepairPhilip Peter HanssenNo ratings yet

- Si 1620a 001 00 EngDocument1 pageSi 1620a 001 00 EngAlejandroz GonzalezNo ratings yet

- Moulton TSR APB SuspensionDocument5 pagesMoulton TSR APB SuspensionteuapNo ratings yet

- V.en-uS.K04508359-Timing Belt AWM MotorDocument7 pagesV.en-uS.K04508359-Timing Belt AWM MotorkentNo ratings yet

- Front SuspensionDocument41 pagesFront SuspensionmanhNo ratings yet

- General Information: Torque SpecificationsDocument3 pagesGeneral Information: Torque SpecificationsLuis TepezanoNo ratings yet

- Shimano Inter-M BR-IM31-R Brakes Service InstructionsDocument1 pageShimano Inter-M BR-IM31-R Brakes Service InstructionsJon_Bramley_3524No ratings yet

- Starting SystemDocument29 pagesStarting SystemUbaldo SanchezNo ratings yet

- DiaTech Hombre Rear U-Brake InstallDocument3 pagesDiaTech Hombre Rear U-Brake InstallfgfgjlfnglkNo ratings yet

- Set Up Instructions - InvictaDocument12 pagesSet Up Instructions - InvictaRicardo XlvNo ratings yet

- Manitou 2001 Magnum Service ManualDocument12 pagesManitou 2001 Magnum Service ManualEdha AliNo ratings yet

- Shimano Bottom Bracket SM-BB6700Document1 pageShimano Bottom Bracket SM-BB6700tspinner19No ratings yet

- Steering: Service and Repair - 2006 Pontiac Truck Torrent AWD V6-3.4L VIN F Service Manual - Operation CHARMDocument13 pagesSteering: Service and Repair - 2006 Pontiac Truck Torrent AWD V6-3.4L VIN F Service Manual - Operation CHARMgilbertlys03No ratings yet

- BMW M42 44 Itb Kit InstructionsDocument9 pagesBMW M42 44 Itb Kit InstructionsmarkoNo ratings yet

- Manual Pajero 4x4 Front SuspentionDocument16 pagesManual Pajero 4x4 Front SuspentionGIAN CARLO MAMANI GILES.No ratings yet

- Front Differential AssemblyDocument8 pagesFront Differential AssemblySethu RamNo ratings yet

- DM Cn0001 00 Eng (Cadena)Document8 pagesDM Cn0001 00 Eng (Cadena)Mauricio Isaias LargaespadaNo ratings yet

- Engine Electrical SystemDocument14 pagesEngine Electrical SystemMatthew Robert QuinnNo ratings yet

- Troubleshooting LawnmoversDocument6 pagesTroubleshooting LawnmoversnamkvalNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Harley Davidson Sportster Transmission Service Manual 1959-69Document8 pagesHarley Davidson Sportster Transmission Service Manual 1959-69Mike WestonNo ratings yet

- Project405 NewDocument50 pagesProject405 Newguhan subramanianNo ratings yet

- Self Balancing Bicycle-AkshayDocument19 pagesSelf Balancing Bicycle-Akshayakshay67% (6)

- West Virginia Drivers Handbook - West Virgina Drivers ManualDocument88 pagesWest Virginia Drivers Handbook - West Virgina Drivers ManualpermittestNo ratings yet

- Mini4WD Stock Race Rules and Regulations August 2016 (Complete Set)Document11 pagesMini4WD Stock Race Rules and Regulations August 2016 (Complete Set)Ian Eldrick Dela CruzNo ratings yet

- China Horse FINAL EnglishDocument2 pagesChina Horse FINAL EnglishKhinmg SoeNo ratings yet

- Company Profile of PT. Suryaraya Rubberindo IndustriesDocument8 pagesCompany Profile of PT. Suryaraya Rubberindo IndustriesZubair KhanNo ratings yet

- Radiator FanDocument70 pagesRadiator Fanapi-3736287100% (1)

- Manufactur Documentation-1Document7 pagesManufactur Documentation-1MahirezqiNo ratings yet

- Complete Tandem Bike BuildDocument15 pagesComplete Tandem Bike Buildmarandan85No ratings yet

- Compound NounsDocument2 pagesCompound NounsCarla RochaNo ratings yet

- Radius Catalogue 2012Document20 pagesRadius Catalogue 2012Sujith AyyappanNo ratings yet

- The 1912 Royal Enfield Sidecar On The Road.Document1 pageThe 1912 Royal Enfield Sidecar On The Road.japullinNo ratings yet

- Bajaj: Pulsar 150 Pulsar 180 Engine and TransmissionDocument5 pagesBajaj: Pulsar 150 Pulsar 180 Engine and TransmissionDeepthi Madhav AnnavarapuNo ratings yet

- DVD Extra: Pre-Intermediate Unit 12Document1 pageDVD Extra: Pre-Intermediate Unit 12Daniel D'AlessandroNo ratings yet

- Analysis of Friction Clutch Plate Using FEADocument7 pagesAnalysis of Friction Clutch Plate Using FEAnileshvranaNo ratings yet

- Titanium Connecting RodsDocument2 pagesTitanium Connecting Rodscrower_scribdNo ratings yet

- EWS Burke 2022 Pro Stage ResultsDocument20 pagesEWS Burke 2022 Pro Stage ResultsMattNo ratings yet

- List of Honda FacilitiesDocument5 pagesList of Honda FacilitiesRayNo ratings yet

- SO2ndEd PI Achievement Test 3Document7 pagesSO2ndEd PI Achievement Test 3Lau RZNo ratings yet

- Adventure World Adventure World: MagazineDocument36 pagesAdventure World Adventure World: MagazineJordan BrittNo ratings yet

- Two StrokeDocument11 pagesTwo StrokeAfzal Shams100% (1)

- Cal Tri Price ListDocument2 pagesCal Tri Price Listapi-59921261No ratings yet

- HD Maintenance and LubricationDocument42 pagesHD Maintenance and LubricationCarloVanZylNo ratings yet

- Esrgw 3Document77 pagesEsrgw 3delopo desefaNo ratings yet