CuSn6 Bronze - Hard Material

CuSn6 Bronze - Hard Material

Uploaded by

vinodmysoreCopyright:

Available Formats

CuSn6 Bronze - Hard Material

CuSn6 Bronze - Hard Material

Uploaded by

vinodmysoreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CuSn6 Bronze - Hard Material

CuSn6 Bronze - Hard Material

Uploaded by

vinodmysoreCopyright:

Available Formats

Wieland-B06/BV9 Phosphor bronze

Extruded/drawn products

Chemical composition* Sn P Cu 6.3% 0.04% 0,2% balance Material designation EN UNS DIN* BS* NF* CuSn6, CW452K C51900 CuSn6-2.1020 not standardized CuSn6P

Wieland-B06/BV9 is a phosphor bronze containing 6 % tin making it possible to achieve high mechanical strength and good spring properties. It also exhibits good resistance to wear and corrosion. Phosphor bronze has good cold working properties and can be machined satisfactorily with suitable tool parameters.

for B06 for BV9

* Reference values in % by weight

* Former national standards

Physical properties* Electrical conductivity MS/m % IACS Thermal conductivity W/(m*K) 9 15 75

Fabrication properties Forming Machinability (CuZn39Pb3 = 100 %) Capacity for being cold worked Capacity for being hot worked Joining Resistance welding Inert gas shielded arc welding Hard soldering Soft soldering

Corrosion resistance* In general excellent resistance to corrosion in seawater, industrial atmosphere and to stress corrosion cracking.

20%

excellent poor good good good excellent

Thermal expansion (0-300 C) 10 -6/K coefficient Density Modulus of elasticity g/cm

18.5 8.8

GPa

118

* Reference values at room temperature 1 GPa = 1 kN/mm 1 MS/m = 1 m/ mm

Surface treatment Polishing Electroplating Heat treatment Melting range Hot working Soft annealing Thermal stress-relieving mechanical electrolytic good good good

Product standards Rod Wire Section Tube EN 12163 EN 12166 EN 12167 EN 12449

910-1040 C 750-850 C 500-700 C, 1-3 h 200-300 C, 1-3 h

Mechanical properties (values can be achieved and are a function of size and form) Reference values Rm [MPa] Rp0,2 A5 HB [MPa] [%] from (soft/extruded) 350 170 65 85 to (hard) 1160 840 3 (Values achievable with wire)

Forms and sizes available

Material EN designation Wieland Brief designation Number B06/BV9 CuSn6 CW452K Round tubes Drawn sections Extruded sections Sectional tubes Round and polygonal rods Round wires Polygonal wires All values in mm Outside diameter from to 6 90 Wall thickness from to 0.1 9 Circumscribing diameter from* to 2.5 100 100 70 2 0.3 2 100

Diameter / width across flats

from

to

* Depending on the form, cross-sections in the lower size range are also available as wire.

Wieland-Werke AG 89070 Ulm Germany Telephone: Telefax: info@wieland.de www.wieland.de

+49 (0) 731 944 - 0 +49 (0) 731 944 - 28 79

This leaflet is for your general information only and is not subject to revision. No claims can be derived from it unless there is evidence of intent or gross negligence. The data given are no warranty that the product is of a specified quality and they cannot replace expert advice or the customer's own tests.

0310 ZMT/Er

Wieland - B06/BV9

You might also like

- Portable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberDocument3 pagesPortable Appliance Testing (Pat) Report/Certificate: Copy Certificate Certificate Reference NumberPete KomorNo ratings yet

- 33cpa S 25w 45w 70w PDFDocument6 pages33cpa S 25w 45w 70w PDFdanielstancu883296No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Copper Alloy Spec SheetsDocument1 pageCopper Alloy Spec SheetsvinodmysoreNo ratings yet

- Surface Finish StandardDocument3 pagesSurface Finish StandardvinodmysoreNo ratings yet

- Flex Gabion Standard ASTM A975-97Document7 pagesFlex Gabion Standard ASTM A975-97Moh Ragil SodikinNo ratings yet

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- Hot RolledDocument16 pagesHot Rolledlbo33No ratings yet

- Diehl Metall Strips MB30 V2 M-SM PDFDocument2 pagesDiehl Metall Strips MB30 V2 M-SM PDFVinoth KumarNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- Pipe Steel Pipe CatalogueDocument16 pagesPipe Steel Pipe Cataloguezishanf_1No ratings yet

- Bollards PDFDocument10 pagesBollards PDFsiladharmaNo ratings yet

- Welding Consumables For The Offshore IndustryDocument24 pagesWelding Consumables For The Offshore IndustryLuis DuarteNo ratings yet

- FPD190 - Differential Pressure - Restriction Orifice PlatesDocument12 pagesFPD190 - Differential Pressure - Restriction Orifice PlatesPeter MarkwellNo ratings yet

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungNo ratings yet

- Head Cones E 16012009Document28 pagesHead Cones E 16012009Zoran DanilovNo ratings yet

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvNo ratings yet

- Boiler PlateDocument2 pagesBoiler PlateshazanNo ratings yet

- AAP S6 High Pressure Fittings E2 SDocument23 pagesAAP S6 High Pressure Fittings E2 SJusthyTaquiri0% (1)

- All Types of MaterialsDocument8 pagesAll Types of MaterialsAniket KabadeNo ratings yet

- TrelleborgDocument10 pagesTrelleborgrofiqq4No ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- CW CAT TABEL25!08!09 BewerkversieDocument46 pagesCW CAT TABEL25!08!09 BewerkversieAdeKusumahNo ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Copper Alloy ProductDocument7 pagesCopper Alloy ProductFernando Fernandes Da SilvaNo ratings yet

- 107 Weldox 700 Uk Data SheetDocument2 pages107 Weldox 700 Uk Data SheetAnurag JainNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- AISI 1015: Digest DDocument2 pagesAISI 1015: Digest DGovinda RajNo ratings yet

- Industrial Rolled Copper and Copper Alloy Products 2018 enDocument22 pagesIndustrial Rolled Copper and Copper Alloy Products 2018 enmoktar albhlolyNo ratings yet

- BOEHLER SC127E Open Die ForgeDocument28 pagesBOEHLER SC127E Open Die Forgegacm98No ratings yet

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Bahra BusbarDocument4 pagesBahra BusbarSalmanNo ratings yet

- Yieh Carbon Steel ProductsDocument5 pagesYieh Carbon Steel ProductsBrion Bara IndonesiaNo ratings yet

- Alt Industrial Rolled Copper and Copper Alloy Products 2016 GBDocument22 pagesAlt Industrial Rolled Copper and Copper Alloy Products 2016 GBsrinuNo ratings yet

- Sheet Metalwork Aluminium 5251Document2 pagesSheet Metalwork Aluminium 5251Josko SpehNo ratings yet

- 1020 Bright Carbon Steel Bar 2Document3 pages1020 Bright Carbon Steel Bar 2thyskieNo ratings yet

- Cold Rolled Steel StripDocument40 pagesCold Rolled Steel StripshelarsanjayNo ratings yet

- OK Tubrod 15.14Document2 pagesOK Tubrod 15.14Luis DuarteNo ratings yet

- MIP Bohler Welding Austwqrwq2332e3eddwria 98Document1 pageMIP Bohler Welding Austwqrwq2332e3eddwria 98maxi27No ratings yet

- Overhead Line ConductorDocument30 pagesOverhead Line ConductorArif AliNo ratings yet

- #Fffi : Adwdnced Fittinas LidDocument10 pages#Fffi : Adwdnced Fittinas LidadfitindiaNo ratings yet

- Rubber-Steel GasketsDocument12 pagesRubber-Steel Gasketsgalici2002No ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- Assab 709Document3 pagesAssab 709Basir Ilyas100% (1)

- PB Alumec EnglishDocument12 pagesPB Alumec EnglishByron RodriguezNo ratings yet

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- E 2209 AcdcDocument2 pagesE 2209 AcdcLuis Alejandro Gonzalez SantanaNo ratings yet

- Steel Grades en 10028 ASTMDocument24 pagesSteel Grades en 10028 ASTMGeorge_Wabag_2014No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Bolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.From EverandBolted Flanged Joint: Flanges, Studs & Gaskets. Recommended Practices for the Assembly of a Bolted Flange Joint.No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- CuZn6 Corrosion ProperiesDocument5 pagesCuZn6 Corrosion ProperiesvinodmysoreNo ratings yet

- DIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CatalogueDocument4 pagesDIN-6912-Socket Head Screw Low Head With Pilot Recess Mfa CataloguevinodmysoreNo ratings yet

- Avdel RevetDocument104 pagesAvdel RevetvinodmysoreNo ratings yet

- General Brochure ConductorsDocument12 pagesGeneral Brochure ConductorsAhmed Bilal KhanNo ratings yet

- SL GR 3 Effects of Forces L4 All Printable ResourcesDocument23 pagesSL GR 3 Effects of Forces L4 All Printable Resourcesdchouhan72004No ratings yet

- RCCB & ElcbDocument5 pagesRCCB & ElcbRakesh Joshi100% (1)

- Sample Electrical LayoutDocument1 pageSample Electrical LayoutLaazey RueNo ratings yet

- Brosure Kabel NA2XSYDocument5 pagesBrosure Kabel NA2XSYcandra handarsenNo ratings yet

- Assignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020Document4 pagesAssignment-1 EE-2101: Name:-Hage Nobin Roll no.-B/19/EE/036 Date of Submission-30/10/2020x caliber10No ratings yet

- Total Laboratory-430 Sr. No. Lab Name Field Discipline GroupDocument258 pagesTotal Laboratory-430 Sr. No. Lab Name Field Discipline GroupGaurav KumarNo ratings yet

- PVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitDocument1 pagePVC Schedule 80 Conduit Spec Sheet Allied Tube and ConduitJhaero Esteban PerezNo ratings yet

- EP-MS-P4-S3-010 - 33kV XLPE Single Core Cables (KM Material Spec)Document7 pagesEP-MS-P4-S3-010 - 33kV XLPE Single Core Cables (KM Material Spec)Ahmed AdelNo ratings yet

- Illustrations 12.1 GENERAL: Illustrations Rev-6 October 2011 Page 1 of 44Document44 pagesIllustrations 12.1 GENERAL: Illustrations Rev-6 October 2011 Page 1 of 44Gary BernardoNo ratings yet

- 26 - 05 - 00 - 01-A - IEC (16050) Basic Electrical Materials and MethodsDocument10 pages26 - 05 - 00 - 01-A - IEC (16050) Basic Electrical Materials and MethodsNhan Huynh TrongNo ratings yet

- Specification For Filler Metal Standard Sizes, Packaging, and Physical AttributesDocument6 pagesSpecification For Filler Metal Standard Sizes, Packaging, and Physical AttributesBoopathi MechNo ratings yet

- Crane and Hoist Rigging Safety - Answer GuideDocument5 pagesCrane and Hoist Rigging Safety - Answer GuideakpankelNo ratings yet

- Ansi - Nema - MW1000-2016 Contents-And-ScopeDocument19 pagesAnsi - Nema - MW1000-2016 Contents-And-ScopeshankarNo ratings yet

- Work Progress PMCC Item No: Saudi Aramco: Company General UseDocument18 pagesWork Progress PMCC Item No: Saudi Aramco: Company General UseEswari AnandNo ratings yet

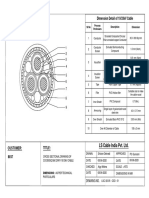

- CSD - 33KV (E) 3C X 300 SQ - MM 2xwy - BestDocument1 pageCSD - 33KV (E) 3C X 300 SQ - MM 2xwy - Bestshivam dwivediNo ratings yet

- Building GroundingDocument11 pagesBuilding Groundinggerrzen64No ratings yet

- Slings EN 12385-4 - CLASS 6X19Document1 pageSlings EN 12385-4 - CLASS 6X19Ned VasicNo ratings yet

- M. Statment Lines - OHL Instal & TestingDocument27 pagesM. Statment Lines - OHL Instal & Testingahmedshah512100% (1)

- FAA-L-824 Type C - Copper Wire Braid Screened: Airfield Lighting CableDocument1 pageFAA-L-824 Type C - Copper Wire Braid Screened: Airfield Lighting Cableantonio estradaNo ratings yet

- Wire Work Jewellery e BookDocument25 pagesWire Work Jewellery e BookGSOTOH100% (2)

- VS50 ManualDocument123 pagesVS50 ManualVENKI460231183No ratings yet

- Behringer Powerplay p1 User ManualDocument21 pagesBehringer Powerplay p1 User ManualFabio VidalNo ratings yet

- Fuses Glasses and CeramicDocument5 pagesFuses Glasses and CeramicAbhijit JanaNo ratings yet

- Guide General Installation Instructions For HV Connector - Sefcor ManufacturerDocument7 pagesGuide General Installation Instructions For HV Connector - Sefcor ManufacturerthangbinhbkNo ratings yet

- Cable Tray Manual 2011 NECDocument53 pagesCable Tray Manual 2011 NECjaymi ybanez100% (2)

- Wire Rope-Steel TechnicalDocument37 pagesWire Rope-Steel TechnicalAndreea LucaNo ratings yet

- User's Guide: Eaton Bypass Power Module (BPM)Document28 pagesUser's Guide: Eaton Bypass Power Module (BPM)Diego BalagueraNo ratings yet