0 ratings0% found this document useful (0 votes)

312 viewsNptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Nptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Uploaded by

globalhodmechThe course introduces the concepts and applications of design for manufacturing and assembly (DFMA) for industrial designers and manufacturing engineers. It helps analyze product design against various manufacturing processes and equipment combinations to assess cost and lead time. Through examples and case studies of real products, the course demonstrates the importance of considering manufacturing and assembly implications during design. The course contents include introduction to DFMA methodologies, material and process selection, and design for various manufacturing processes like machining, molding, and casting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Nptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Nptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Uploaded by

globalhodmech0 ratings0% found this document useful (0 votes)

312 views3 pagesThe course introduces the concepts and applications of design for manufacturing and assembly (DFMA) for industrial designers and manufacturing engineers. It helps analyze product design against various manufacturing processes and equipment combinations to assess cost and lead time. Through examples and case studies of real products, the course demonstrates the importance of considering manufacturing and assembly implications during design. The course contents include introduction to DFMA methodologies, material and process selection, and design for various manufacturing processes like machining, molding, and casting.

Original Description:

102265

Original Title

107103012

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The course introduces the concepts and applications of design for manufacturing and assembly (DFMA) for industrial designers and manufacturing engineers. It helps analyze product design against various manufacturing processes and equipment combinations to assess cost and lead time. Through examples and case studies of real products, the course demonstrates the importance of considering manufacturing and assembly implications during design. The course contents include introduction to DFMA methodologies, material and process selection, and design for various manufacturing processes like machining, molding, and casting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

312 views3 pagesNptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Nptel: Design For Manufacture and Assembly (DFMA) For Industrial Design - Web Course

Uploaded by

globalhodmechThe course introduces the concepts and applications of design for manufacturing and assembly (DFMA) for industrial designers and manufacturing engineers. It helps analyze product design against various manufacturing processes and equipment combinations to assess cost and lead time. Through examples and case studies of real products, the course demonstrates the importance of considering manufacturing and assembly implications during design. The course contents include introduction to DFMA methodologies, material and process selection, and design for various manufacturing processes like machining, molding, and casting.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

At a glance

Powered by AI

The key takeaways are that the course introduces design for manufacturing and assembly concepts and applies them to industrial design. It helps analyze product design against various manufacturing processes and equipment to assess cost and time. Case studies are used to demonstrate the importance of considering manufacturing implications during design.

The main topics covered in the course include introduction to manufacturing and assembly, design for manufacturing and assembly methodologies, selection of materials and processes, product design for different processes like machining, molding, casting, and relating CAD to DFMA.

Design methodologies discussed include design for machining, injection molding, die casting, powder metal processing, sand casting, investment casting, sheet metal working, and hot forging.

NPTEL Syllabus

Design for Manufacture and Assembly(DFMA)

for Industrial Design - Web course

COURSE OUTLINE

The course is designed to introduce the concept and application for design for

manufacturing and assembly in industrial design for practicing designers and

manufacturing engineers as well as design students (graduate and under graduate) who

are going to play a major role in design and development of various industrial products.

Furthermore, the course helps to analyze product design against various process and

equipment combinations to assess cost and manufacturing lead time. The course includes

various examples and few case studies of real product to demonstrate the importance of

manufacturing and assembly implication to design.

Contents

Introduction to manufacturing and assembly; Introduction to Design for manufacturing and

assembly concepts; Design for manufacture and assembly methodologies; Selection of

materials and process; Product design for manual assembly, Design for machining, design

for injection molding, design for sheet metal working, design for die casting, design for

powder metal processing, design for Sand casting, Design for investment casting, design

for hot forging, Design for manufacture and CAD.

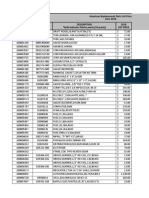

Module

No

Module Topic

No. of

Hours

1 Manufacturing- Introduction 8

2 Assembly- Introduction 7

3 Introduction to design for manufacturing and assembly 6

4 Selection of materials and process 4

5 Design for machining 4

6 Designing for Casting 5

7 Design for forming 3

8 Design for manufacture &CAD 3

Total 40

NPTEL

http://nptel.iitm.ac.in

Engineering

Design

Additional Reading:

Fundamental

manufacturing books,

Technical papers on

manufacturing and

assembly

Coordinators:

Abinash Kumar Swain

Department of DesignIIT

Guwahati

Sl.

No.

Topic

Lecture

Hour

Module I

1 Introduction to engineering materials, Materials properties 4

2 Introduction to manufacturing, Various manufacturing process 4

Module II

3

Introduction to mechanical assemblies, Various examples,

Assembly in the context of product development

4

4

Introduction to design for manufacturing and assembly, DFMA case

studies, Impact of DFMA to various Industries

3

Module III

5

General requirements for early materials and process selection,

Selection of manufacturing process, process capabilities, selection

of materials

3

6

Design with materials, design for Brittle fracture, Design for Fatigue

failure, Design for corrosion resistance, Design for wear resistance,

Designing with plastics

3

Module IV

7 Product design for manual assembly 2

8 Product design for automation 2

Module V

9

Introduction to Design for machining, Machining Using Single point

cutting tool, Machining with multi point cutting tool, Machining with

Abrasive wheels, Choice of work material, shape of work material,

machining basic component shapes, Assembly of Components,

Accuracy and Surface finish

4

Module VI

Design for injection molding, Design for die casting, design for

10 powder metal processing, Design for sand casting, design for

investment casting

5

Module VII

11 Design for sheet metal working, Design for hot forging 3

Module VIII

12

Linking CAD and DFMA, Geometric representation in CAD,

Extraction of DFMA data from CAD System

3

References:

1. J. Lesko, (1999) Industrial Design, Materials and Manufacture Guide, John Willy and

Sons, Inc

2. George E. Dieter and Linda C. Schmidt (2009), Engineering Design, Fourth edition,

McGraw-Hill companies, New York, USA

3. Geoffrey Boothroyd, Peter Dewhurst and Winston Knight (2002) Product Design for

Manufacture and Assembly, Second Edition, CRC press, Taylor & Francis, Florida,

USA

4. O. Molloy, S. Tilley and E.A. Warman (1998) Design for Manufacturing and assembly,

First Edition, Chapman &Hall, London, UK.

5. D. E. Whitney, (2004) Mechanical Assemblies: Their Design, Manufacture, and Role in

Product Development, Oxford University Press, New York

6. A.K. Chitale and R.C. Gupta, (1999) Product design and Manufacturing, Prentice Hall

of India, New Delhi.

7. James G. Bralla (1998) Design for Manufacturability Handbook, Second Edition,

McGraw-Hill companies, New York, USA

8. Geoffrey Boothroyd (2005) AssemblyAutomation and Product Design, Second

Edition, CRC press, Taylor & Francis, Florida, USA

9. G. Q. Huang (1996) Design for X, Concurrent Engineering Imperatives, First Edition,

Chapman &Hall, London, UK

A joint venture by IISc and IITs, funded by MHRD, Govt of India http://nptel.iitm.ac.in

You might also like

- BSR - NH - Circle - Jaipur - 2019 Final PDFDocument109 pagesBSR - NH - Circle - Jaipur - 2019 Final PDFRohit Bali100% (1)

- Amie Fundamentals of Design and Manufacturing DesignDocument3 pagesAmie Fundamentals of Design and Manufacturing DesignAhmed Abotoor50% (6)

- Nptel: Design For Manufacturing - Web CourseDocument3 pagesNptel: Design For Manufacturing - Web CourseChinnadurai LakshmananNo ratings yet

- M.E. Mech (Prod Des & Devp)Document41 pagesM.E. Mech (Prod Des & Devp)Peter PushpanathanNo ratings yet

- Product Design and Development SyllabusDocument7 pagesProduct Design and Development Syllabusharshottam2977No ratings yet

- Acecipe - 5. Design and Manufacturing EngineeringDocument3 pagesAcecipe - 5. Design and Manufacturing EngineeringMaryedNo ratings yet

- Mec531 IntroductionDocument14 pagesMec531 IntroductionMuhammad ZulhilmiNo ratings yet

- Manufacturing Process Lab IiiDocument5 pagesManufacturing Process Lab IiiMuhammad Bilal SahiNo ratings yet

- Course 12 Additive Manufacturing For Industry 4Document8 pagesCourse 12 Additive Manufacturing For Industry 4Ioan IonescuNo ratings yet

- DFM SyllabusDocument2 pagesDFM SyllabusSantosh SNo ratings yet

- Topics For Tool and Die Design 2Document15 pagesTopics For Tool and Die Design 2Jose Lapera Jr.No ratings yet

- 01) Theory of Material Removal Processes, Single Point Tool and Cutting Tool GeometryDocument37 pages01) Theory of Material Removal Processes, Single Point Tool and Cutting Tool GeometryAhsan NabiNo ratings yet

- AI Applications To Metal Stamping Die Design A Review PDFDocument7 pagesAI Applications To Metal Stamping Die Design A Review PDFElaine JohnsonNo ratings yet

- ManufacturingDocument9 pagesManufacturingBhairab BhowmikNo ratings yet

- General Design Principles For ManufacturabilityDocument2 pagesGeneral Design Principles For ManufacturabilityBala Mech SBNo ratings yet

- GVP College of Engineering (A) 2015Document3 pagesGVP College of Engineering (A) 2015Vasanth KumarNo ratings yet

- PROJECT REVIEW 1 FinalDocument23 pagesPROJECT REVIEW 1 FinalNani DatrikaNo ratings yet

- AI Applications To Metal Stamping Die Design - A Review: Vishal Naranje, Shailendra KumarDocument7 pagesAI Applications To Metal Stamping Die Design - A Review: Vishal Naranje, Shailendra KumarCandra WahyudiantoNo ratings yet

- A Review On Additive ManufacturingDocument10 pagesA Review On Additive ManufacturingKamlesh RanaNo ratings yet

- Integrated Process Simulation and Die-Design in Sheet Metal FormingDocument4 pagesIntegrated Process Simulation and Die-Design in Sheet Metal FormingElaine JohnsonNo ratings yet

- Design For Manufacturing and Assembly Web ReferencesDocument3 pagesDesign For Manufacturing and Assembly Web ReferencesGopinath Gangadhari0% (1)

- Computer-Aided Design of Tooling For Casting Process: August 1999Document11 pagesComputer-Aided Design of Tooling For Casting Process: August 1999didoNo ratings yet

- Project New StudentsDocument32 pagesProject New StudentsMayowaNo ratings yet

- A Generic Framework For Rapid Development of InjecDocument10 pagesA Generic Framework For Rapid Development of InjecabraNo ratings yet

- Machine Design NotesDocument349 pagesMachine Design NotesAkshay More100% (1)

- PDD PDFDocument7 pagesPDD PDFrahil_sangNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- 3D Rapid Realization of Initial Design For Plastic Injection MoldsDocument16 pages3D Rapid Realization of Initial Design For Plastic Injection MoldsDjuraTheHarpYNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- Manufacturing and AssemblingDocument6 pagesManufacturing and AssemblingMariappan ArumugamNo ratings yet

- The Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu FactusDocument8 pagesThe Word Manufacture First Appeared in English in 1567 and Is Derived From The Latin Manu Factushassan9705No ratings yet

- Syllabus DFM Latest PDFDocument1 pageSyllabus DFM Latest PDFNAVEEN KUMAR S NNo ratings yet

- Manufacturing Technology: Chapter 1: IntroductionDocument24 pagesManufacturing Technology: Chapter 1: IntroductionJaka Sembung Bawa GolokNo ratings yet

- Practical SolidWorks II - Design For ManufacturingDocument7 pagesPractical SolidWorks II - Design For ManufacturingDoran Doran DoranNo ratings yet

- Lesson Plan: Veer Surendra Sai University of TechnologyDocument2 pagesLesson Plan: Veer Surendra Sai University of Technologysanthi saranyaNo ratings yet

- IC141 Product Realization TechnologyDocument1 pageIC141 Product Realization Technologyparitoshjain01No ratings yet

- CH.1 IntroductionDocument11 pagesCH.1 IntroductionRavi SinghNo ratings yet

- Product Design and DevelopmentDocument2 pagesProduct Design and DevelopmentJoshua Cooper100% (1)

- Manufacturing Technology: Course ContentsDocument6 pagesManufacturing Technology: Course ContentsGosai RahulNo ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- A Review Paper On 3d Printing Aspects and Various Processes Used in The 3d Printing IJERTV6IS060409 PDFDocument6 pagesA Review Paper On 3d Printing Aspects and Various Processes Used in The 3d Printing IJERTV6IS060409 PDFhipovemicNo ratings yet

- 3D Printing Research Paper - Various Aspects PDFDocument6 pages3D Printing Research Paper - Various Aspects PDFhipovemicNo ratings yet

- IJERT-A Review Paper On 3D-Printing Aspects and Various Processes Used in The 3D-PrintingDocument7 pagesIJERT-A Review Paper On 3D-Printing Aspects and Various Processes Used in The 3D-PrintingGarapati MurarjiNo ratings yet

- Manufaturing ProcessDocument2 pagesManufaturing ProcessSakshi VermaNo ratings yet

- 3 D Printing and Application Second Year Syllabus 2020P c-1Document1 page3 D Printing and Application Second Year Syllabus 2020P c-1Anti PatiNo ratings yet

- Ome1902 Class NotesDocument207 pagesOme1902 Class Notes210101034No ratings yet

- Design and Analysis of Multipurpose Machine For The Productivity of Sheet Metal ProcessDocument15 pagesDesign and Analysis of Multipurpose Machine For The Productivity of Sheet Metal ProcessAshebir AyeleNo ratings yet

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- 1.-Metal 3D Printing in Construction - A Review of Methods, Research, Applications, Opportunities and ChallengesDocument17 pages1.-Metal 3D Printing in Construction - A Review of Methods, Research, Applications, Opportunities and ChallengesJosé RiquelmeNo ratings yet

- Defense University, College of Engineering Project Proposal OnDocument15 pagesDefense University, College of Engineering Project Proposal OnGODNo ratings yet

- General Introduction: Manufacturing Engineering Technology in SI Units, 6 EditionDocument54 pagesGeneral Introduction: Manufacturing Engineering Technology in SI Units, 6 Edition李尚倫No ratings yet

- Sem 2Document11 pagesSem 2jtsrinivasdownNo ratings yet

- Rapid CastingDocument23 pagesRapid CastingquarkenNo ratings yet

- Production Process by NRD SirDocument129 pagesProduction Process by NRD Sirzahidurrahmansaran279No ratings yet

- Mastering SOLIDWORKS Sheet Metal: Enhance your 3D modeling skills by learning all aspects of the SOLIDWORKS Sheet Metal moduleFrom EverandMastering SOLIDWORKS Sheet Metal: Enhance your 3D modeling skills by learning all aspects of the SOLIDWORKS Sheet Metal moduleNo ratings yet

- Model-Driven Software Development: Technology, Engineering, ManagementFrom EverandModel-Driven Software Development: Technology, Engineering, ManagementRating: 4 out of 5 stars4/5 (3)

- 301 Top Tips for Design Engineers: To Help You 'Measure Up' in the World of EngineeringFrom Everand301 Top Tips for Design Engineers: To Help You 'Measure Up' in the World of EngineeringRating: 5 out of 5 stars5/5 (1)

- High Rise Building (Part I) Group 2Document39 pagesHigh Rise Building (Part I) Group 2TAWDE KOMALNo ratings yet

- Ruidp Sor - 2013Document520 pagesRuidp Sor - 2013Manish GargNo ratings yet

- Busbar Sleeves Heat Shrink v3 RRE UAE 2023Document1 pageBusbar Sleeves Heat Shrink v3 RRE UAE 2023Shreenath MuralidharanNo ratings yet

- White Book C04 S02 Partitions GypWall CLASSICDocument51 pagesWhite Book C04 S02 Partitions GypWall CLASSICPavaloaie Marian ConstantinNo ratings yet

- American Parts List PriceDocument314 pagesAmerican Parts List Priceejatch2No ratings yet

- En 13598-2 (2009)Document23 pagesEn 13598-2 (2009)asdNo ratings yet

- Phe 1Document2 pagesPhe 1mohideenfootballNo ratings yet

- Siempelkamp Ringwalze enDocument4 pagesSiempelkamp Ringwalze enRia DevitasariNo ratings yet

- Mechanical Technology 2023 Gr10 Term 3 & 4 Fitting Machining Revision BookletDocument9 pagesMechanical Technology 2023 Gr10 Term 3 & 4 Fitting Machining Revision Bookletpopolehasa012No ratings yet

- Project Report: Summer Training at JMC Projects India Ltd. NoidaDocument57 pagesProject Report: Summer Training at JMC Projects India Ltd. NoidahjNo ratings yet

- XT66 Casement & Tilt Turn Window System: Polyester Powder CoatingsDocument35 pagesXT66 Casement & Tilt Turn Window System: Polyester Powder CoatingsBranZzZzZNo ratings yet

- Baxchem Systems Brochure 20061 PDFDocument6 pagesBaxchem Systems Brochure 20061 PDFA MahmoodNo ratings yet

- Method Statement For AAC Block WorksDocument3 pagesMethod Statement For AAC Block Worksaboodeissa97No ratings yet

- Hygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsDocument10 pagesHygrothermal Performance of Hempcrete For Ontario (Canada) BuildingsLIZETH ACNo ratings yet

- Ead 230005-00-0106Document14 pagesEad 230005-00-0106Ana Luísa EvaristoNo ratings yet

- Curved WallsDocument6 pagesCurved WallsCayddrick BallardNo ratings yet

- PeralatanDocument1 pagePeralatanAbd Muhaimin PasaenoNo ratings yet

- Method Statement - Anchor Bolt InstallationDocument2 pagesMethod Statement - Anchor Bolt Installationnoor afiqNo ratings yet

- 1 PDFDocument20 pages1 PDFRacem RebaiNo ratings yet

- TB400 Painting and Corrosion ProtectionDocument21 pagesTB400 Painting and Corrosion ProtectionAliZenatiNo ratings yet

- Cal Tube ListDocument109 pagesCal Tube Listafiqhashim89No ratings yet

- Yb22005 26-01-22 Mrs Chandra Chennai Str-03 Plinth BeamDocument1 pageYb22005 26-01-22 Mrs Chandra Chennai Str-03 Plinth BeamBoopathi YoganathanNo ratings yet

- Kaiser Aluminum Shapes Soft Alloy PDFDocument18 pagesKaiser Aluminum Shapes Soft Alloy PDFgerrzen64No ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentAshish BoraNo ratings yet

- Yellow Oxide Ya 22e PDFDocument1 pageYellow Oxide Ya 22e PDFمحمد مقلدNo ratings yet

- Basf Masterpozzolith 55 TdsDocument2 pagesBasf Masterpozzolith 55 TdsshunanlatheefNo ratings yet

- Cement Concrete BlocksDocument21 pagesCement Concrete BlocksIndika Yapa0% (2)

- Beton Terimleri TeknikDocument15 pagesBeton Terimleri Teknikaviatorfox22No ratings yet

- Comparative Study Ofbis & Aci Method of Concrete Mix Design: Pratikruti-2 18Document1 pageComparative Study Ofbis & Aci Method of Concrete Mix Design: Pratikruti-2 18Vikas Sanjay DandaleNo ratings yet