Professional Documents

Culture Documents

Online Monitoring Devices

Online Monitoring Devices

Uploaded by

yogi_swarnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Online Monitoring Devices

Online Monitoring Devices

Uploaded by

yogi_swarnCopyright:

Available Formats

ONLINEMONITORINGDEVICES

Constructional Features

Most hydro generators in service today are of the vertical type wit the turbine or

waterwheel at the bottom of the assembly and the generator on top. There are

exceptions to this statement with bulb units being the most common. A bulb unit

places the generator in a submerged chamber, and the orientation of bulb units is

usually horizontal .

Unit ratings can vary from the kW range to over 800MW. Speeds can vary from 60

to over 600 RPM and are determined by both the waterwheel type and the

hydraulic head, generally the higher the head, the higher the waterwheel speed.

The highest head and therefore highest speed water wheels are of the Pelton or

impulse type. Intermediate head machines usually employ Francis or reaction

turbines while the low head machines are typically Kaplan or propeller type

turbines.

Conventional Hydro Generator.

Vertical hydro generators are generally manufactured in one of two types,

conventional or umbrella type. Figure above is a conventional hydro generator

with its distinguishing feature being a combined guide and thrust beating above

the generator that is supported by a massive thrust girder. Conventional hydro

generators are usually three bearing machines as show in figure above .

The umbrella type hydro generator is most commonly applied on new machines

he umbrella hydro generator, which is depicted on the cover of this best practices

document is usually a two bearing machine with a turbine guide bearing and a

combined guide the thrust bearing mounted below the generator rotor. The

umbrella design is more economical to manufacture and easier to maintain

because of the lack of the thrust girders above the generator.

Hydro Generator Cross Section.

Hydro Generator Rotor

Large hydro generator rotors are manufactured at the plant site because it is

impossible to ship an assembly that can be over 50 feet in diameter and can

weigh one thousand tons. From the inside out, the hydro generator rotor consists

of hallow rolled steel shaft sections that are bolted to the top and bottom of a

frame member called a spider. The rotor spider usually consists of eight to 16

spider arms. The spider is a welded steel assembly at least partially built offer site

and shipped to the site. On large machines, the spider is built in sections

assembled on site.

Installed around the outside of the spider is a laminated assembly called the rotor

rim. The rim is built up into a steel cylinder at the plant site from steel plates

approximately 0.2 inch 95mm) thick and installed onto the spider by one of

several means. There are two basic type of rim-spider interfaces, shrink fit and

floating rim. With the shrink fit rim, the rim is heated and then shrunk on to the

rotor spider. The amount of shrink fit is designed to be sufficient to maintain a

tight fit at greater than full over speed conditions (which can reach over 200% of

normal operating speed). The floating rim design usually utilizes some type of

driven key to secure the rim to the spider circumferentially while allowing for radial

expansion with speed and temperature. The shrink fit rim is the most commonly

used method on new hydro generators. The rotors salient poles are keyed to the

outside diameter of the rotor rim.

Rotor Rim Joint

With all those bolted, welded, shrunk, and keyed joints, a properly designed,

manufactured, assembled, and operated hydro generator rotor can remain in

service for well over 50 years. Problems that lead to an out-of round condition or

off center operation can lead to a major failure. Because of the immense weight of

hydro generator rotor assemblies and their slow operating speeds, out of round or

off center rotor rim condition do not always show up as a measurable vibration.

Hydro Generator Stator

Hydro generator stators can either be manufactured in sections in the factory or

they can be manufactured in one piece at the plant. Both methods of

manufacture have advantages and disadvantages. Factory manufacturing usually

entails clean-room condition that can be difficult to obtain in the field, and it may

be difficult to duplicate the quality controls inherent in the factory under field

conditions. Manufacturing in the field requires significant floor space for the stator

with an outside diameter that could exceed 70 feet (20 meters) .

Field manufacturing involves a continuous stack or pile of the stator core

laminations with the entire circle of laminations interwoven and a continuous stator

frame. Factory manufacturing allows for the laminations to be interwoven only in

each section (upto six sections per stator core). And the core/frame sections must

be connected in the field. The joint between core sections must be carefully

designed and assembled to assure mechanical, thermal, and magnetic integrity.

Mechanical integrity of the factory manufactured and field assembled stator is a

concern, as a stator assembled from per-manufactured sections simply cannot

have the hoop strength of a single piece field manufactured stator.

Both methods of manufacturing are in use today. The ultimate decision on which

type of manufacturing is utilized usually depends on schedules, available floor

space, and certainly pricing.

Figures below are pictures of a hydro generator stator during construction.

PLACEMENT OF th STATOR SEGMENT JOINING OF STATOR SEGMENTS

CORE RELAMINATION AT JOINTS

HYDRAULIC PRESSING OF STATOR CORE

ASSEMBLED STATOR BEING LOWERED STATOR CONCRETE BARREL ON SOLE PLATES

INTO GENERATOR BARREL

Once the stator core is staked, stator coils will be installed in the vertical slots in

the stator core. The completed stator is set on a sole plant, which for large

machines provides a slip plane to allow for radial movement of the stator due to

thermal expansion. Large stators are known to expand over 0.5 inches (1.25cm)

on the diameter from ambient conditions to full temperature operation. Great care

is taken to assure that the expansion and contraction of the stator is uniform over

the entire stator to assure the stator remains round and concentric with the rotor.

After going through constructional details of Hydro Generator, which is mainly

required to be monitored online, we will discuss reasons for online monitoring and

various devices used for online monitoring.

Why Condition Monitoring on Hydro Units?

Historically, Hydro units have been reliable and robust, and have been used for

base load with only limited outages for scheduled maintenance. Utility

deregulation, environmental and water concerns have resulted in a change of

duty from base loading to peaking only. This change has resulted in multiple

starts and stops each day for units which were never designed to do so, causing

premature ageing, un-foreseen mechanical and electrical stress, resulting in

degraded reliability and performance. Financial pressures on operators have also

resulted in reduced routine maintenance. This is particularly the case with

pumped storage units.

Why do Thrust Monitoring?

Large Hydro units can weigh over 1000 tons, with the entire weight carried by the

thrust bearing. It is therefore critical that the oil film is present between the bearing

shoes and the rotor before the valves are opened and the high pressure water is

allowed to enter the turbine.

Monitoring of the thrust position is able to provide a permissive to operate,

indicating the presence of the oil film by measuring the lift of the rotor.

Why do Vibration Monitoring?

Measuring vibration on Hydro Rotors provides the same benefits as in monitoring

conventional units. Parameters such as rough zone operation, cavitation,

unbalance, bearing problems and wicket gate problems can be diagnosed from

vibration signatures during day-to-day operation. Developing Faults can be

diagnosed and repairs scheduled long before they become critical or catastrophic

failure occurs.

Why do Air Gap monitoring?

Monitoring Air Gap has been proven itself to be an efficient tool to detect and

diagnose structural problems related to :

loose rotor rim

weak rotor structure

uneven thermal and magnetic forces causing expansion of the

rotor and stator

structural change of stator foundation (concrete

deformation).

Monitoring generator problems enables plant owners avoid costly forced outages

for breakdowns or rotor-stator repairs, caused by

Overheating

rotor-to-stator rubs

structural issues

Air Gap monitoring can help to extend safe generator usage up to the next major

refurbishment. Uneven air gap also diminishes efficiency performance.

What is Air Gap?

The air gap is the distance measured between stator and rotor of a generator.

Large hydroelectric turbines are subjected to constantly varying centrifugal,

thermal and magnetic forces that are capable of distorting the stator and rotor of

the turbine, thereby causing this air gap to vary. Monitoring of air-gap is essential

part of online condition monitoring as it can provide early warning of impending

problems and facilitated timely maintenance procedures.

Air Gap Monitoring

Air gap is a measure of the distance between rotor and stator in the hydro

generator. Monitoring of air gap is critically important because unlike high speed

generators. Both the stator and the rotor on large hydro machines can be quite

flexible the bore diameter on the largest hydro machine can be over 50 feet(>15

meters) and the height of the stator can be over 12 fee (>3 Meters). Nominal air

gaps on large hydro machines vary from approximately 0.3 inches to 1.6 inches

(0.7 to 4cm.) with operating speeds ranging from 60 to over 600 RPM. Peak

operating efficiency is achieved when both rotor and stator are rotor and

concentric. Air gap monitoring provides the operator with early warning of

impending problems with shape and concentricity.

Out of round or off center conditions of the rotor and/or the stator can cause

problems. Any decrease in nominal air gap is a concern because of the magnetic

attraction between rotor and stator. Under normal conditions, the magnetic

attraction between rotor and stator increases approximately with the inverse

square of the air gap. So any anomaly that leads to a decreased air gap tends to

worsen with time as the increased magnetic attraction further decreases the gap.

The increased magnetic field at the location of a small air gap also increases the

magnetic heating in the stator, thus increasing the thermal aging of the stator

winding and core.

In service air gap measurements are made with Stator Mounted air Gap (SMAG)

probes. Measurements are made from the inner surface of the stator core to the

rotor poles. These measurements provide a direct measure of rotor shape. Stator

shape is calculated utilizing multiple SMAG probes. The table below lists standard

tolerances for air gap, rotor and stator roundness and rotor and stator

concentricity as defined in the Guide for erection Tolerances and Shaft alignment

published by CEA (Canadian Electrical Association). These numbers are provided

for reference purposes.

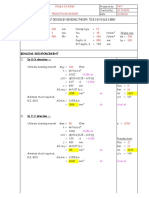

Parameter Definition Erection

Deviation

1

Acceptable

Deviation

Critical

Deviation

Air Gap Maximum difference

between air gap measured at

any point on a single plane

and nominal air gap

13% 20% 30%

Stator

Roundness

Difference between

maximum inside radius and

minimum inside radius

measured from the rotor

rotation axis.

7% 20% 12%

Stator

Concentricity

Difference between rotor

rotation axis and the best

stator centre measure on the

same plane and calculated

from the for reference pole

5% 7.5% 10%

Rotor

Roundness

Difference between

maximum outside radius

and minimum outside radius

on the same plane.

6% 8% 10%

Rotor

concentricity

Difference between the rotor

rotation axis and the best

rotor centre calculated from

the outside radius of each

pole on he same plane

1.2% 2.55 4%

1

Deviations expressed in percentage of nominal air gap.

A minimum of four SMAG probes per plane are recommended for stator bore

diameters upto 25 feet (7.5 meters) with a minimum of eight SMAG probes

recommended for larger machines. More SMAG probes will provide a better

approximation of stator shape. Single plane measurements should always be

made at the top of the stator, as the top of the machine is more flexible because

the bottom rests on sole plates. Measuring air gap in both top and bottom planes

will provide more protection for the user.

Location of sensors for Air gap

Air gap Sensors

Bearing Vibrations

Hydroelectric turbines are subject to unique forces and operating conditions,

typically operate at low operating speeds (60-600 rpm), and generally incorporate

vertical shaft arrangements. For these reasons, they exhibit unique vibration

characteristics and require specialised filtering for monitoring the various relevant

machinery condition parameters.

TGB Vibration Sensors

Some of vibration behaviours typical of hydroelectric turbines are caused by

rough load conditions (NOT 1X), shear pin failure (nX), faults with or debris in

wicket gates (nX), stator faults, and various sources of unbalance(1X).The system

provides alarm indications for these and other vibration conditions with low

frequency sensitivity necessary to effectively monitor hydroelectric turbines.

Inherent with these low speed turbines are longer response times and larger

vibration levels; therefore, the design of the system is such that it covers this

unique behavior of hydro turbines. Bearing vibration can indicate problems related

to fluid filmed bearings, including overload, misalignment, rough load zone (NOT

1X), shear pin failure (nX), faults with or debris in wicket gates (nX), stator faults,

and various sources of unbalance (1X). Bearings can be drilled and tapped to

accept probe mounting hardware and cable tie-downs during the manufacturing

process. For retrofit installations, the bearings can always be removed and drilled

to accept the probes mounting hardware and cable tie downs.

Stator Core and Frame Vibration Monitoring

Vibration between the stator core and frame and between the stator frame and

sole plate is monitored as a predictive measure for various problem scenarios.

Loose stator core laminations will cause a vibration twice the electrical frequency

either 100 or 120 Hz. A seismic transducer, such as the Velomitor CT, is the

recommended probe for this measurement.

Uneven air gap forces will cause stator core and frame vibrations twice the

operating speed of the generator. Since the vibration caused by uneven air gap

forces can be as low as one or 2Hz., the 3300XL is the recommended probe for

measurement of this low frequency vibration.

The table lists standard tolerances for stator core and frame vibrations as defined

in the Guide for erection tolerances and Shaft alignment published by CEA

(Canadian Electrical Association). These numbers are provided for reference

purposes.

Parameter Definition Erection

Deviation

1

Acceptable

Deviation

Critical

Deviation

Stator Core

vibration

Measured

between the

core and

frame

1.0 1.4 2.0

Frame

vibration

Measured

between the

frame and the

sole plate

1.0 2.5 5.0

1

Vibration expressed in mils peak to peak.

Thrust Bearing Oil Film Thickness:

Unlike horizontal, high speed generators, hydroelectric generators have a great

amount of freedom in the axial direction. During full load reject, some rotors move

over an inch (2.54cm) in the axial direction. For this reason axial position

measurement (rotor position relative to the machine case) are not recommended.

Most large hydroelectric generators are vertical machines. The thrust pads have

to carry the static weight of the machine and any load generated by the water flow

through turbine. An absence or reduction in oil film thickness at the thrust pads

results in rapid breakdown of the bearing Babbitt and can result in rotor/bearing

damage if not caught. Thrust pad oil film thickness can indicate problems related

to fluid-filmed bearings, including overload, bearing fatigue or insufficient

lubrication.

Thrust pads can be drilled and tapped to accept probe mounting hardware and

cable tie-downs during the manufacturing process. For retrofit installations, the

pads can always be removed and drilled to accept the probes mounting hardware

and cable tie downs. For most cases, two pads, separated by approx.. 90 degree,

are instrumented. If the machine is large (more than 100MW) it may be advisable

to place two probes at opposite corners of the each thrust pad because pads on

large machines can saddle under load.

Generator Temperature Monitoring

Generator temperatures are commonly measured with RTDs and thermocouples.

Virtually all generators have RTDs installed between coils in the stator slots.

Unless specified otherwise by the user, 12 slot RTDs are installed in most

generators. Note that hydro generator can have over 500 slots, so monitoring

coverage of stator temperature is minimal.

Cooling air is generally measured with RTDs or thermocouples monitoring cool

inlet air and hot outlet air. Units with air to water coolers will measured hot and

cold (inlet and outlet) air on each cooler alongwith cooling water inlet and outlet

temperatures.

Some very large hydro generators are equipped with water inner-cooled windings

where deionized water passes through each stator coil. In these cases, each

stator coil will be equipped with a water inlet and/or outlet thermocouple.

Generator air designed to operate at full load within a specified temperature rise

over ambient temperature. A 40C ambient is generally specified. The rated

temperature rise will be stated such that at full load, stator temperature measured

by the embedded RTDs will not exceed the maximum allowable hot spot

temperature for the stator winding insulations system. The most common

insulation classes in modern machines and their maximum temperature limits are

listed in the table below:-

Insulation Class Maximum allowable

temperature

B 130C

F 155C

H 180C

Most operators will limit operation to some level under the maximum allowable

temperature as with only 12 RTDs covering over 500 coils, you can be virtually

assured that the actual hot spot is not measured. A conservative method of

specifying a new machine that is commonly used is to require class F insulation,

but specify a class B temperature rise of 90C over a 40C ambient. In this way, a

machine with Class F insulation will operate at a maximum temperature of 130C

at full load.

Partial discharge Analysis

Partial discharge (PD) is a radio frequency noise measured in the MHz range

that is generated by low level arcing and sparking in generator stator insulation.

There are three basic types of PD of concern in medium voltage generators ( 5-

20kV range)

Internal void discharges occur where the insulation on high voltage coils has

internal voids across which a charge builds up. Generator coil insulation is made

up of many overlapped layers of insulating tape all glued together with a resin,

polyester or epoxy on modern machines. If done correctly, the system should be

void free. Where voids exist, a sufficient charge will build up and arc across the

void and create some measurable radio frequency noise. Void discharges occur

only at the high voltage end of the winding, usually on coils operating at 4,000

Volts to ground or higher. In air cooled generators (Virtually all hydro generators

are air-cooled) and motors, internal void PD can be quite damaging as the arc

produces ozone which erodes the surrounding insulation. This is the reason PD is

not a big concern in hydrogen cooled generators like large high speed units, no

oxygen, so no ozone.

Slot discharge occurs where the stator coil is loose and vibrating in the stator slot.

Stator coils have a semi conducting coating on the outer surface to ground the slot

portion. If the coil vibrates, making and breaking the connection between the semi

conductor surface and the grounded core will create arcing. Slot discharge is not a

function of coil voltage, and can occur anywhere in the winding from high voltage

to neutral side. Like the void discharges, slot discharges are damaging in air

cooled winding because the ozone produced attacks the outer surface of the coil,

first destroying the semi conductor costing, and then eating away at the coil

insulation .

End winding pollution discharge occurs when sufficient conductive dirt build up

occurs on the stator end windings, usually bridging between coils with significant

voltage differences. In most cases, end winding discharges are not damaging, just

an indication that the winding needs cleaning.

The hydro Trac instrument takes PD measurement automatically and stores the

data for analysis and tending. Presence of each of the three types of PD

described above can be determined by analysis of the data, particularly where on

the voltage waveform the PD is detected. Trending of the PD data over time is

used to predict long term insulation degradation. Unlike temperature or vibration

measurements, there is no established good or bad level of PD. New machines

by the same manufacturer can have significantly different PD levels and still be

acceptable for operation. Increasing levels of PD with time is the primary indicator

of degrading insulation.

*****

References:-

1. Bentley Navada Paper on online monitoring

2. R, M & U of Bhakra Right Power House, Er. Surinder Singh

You might also like

- Conveyor Belt TroubleshootingDocument4 pagesConveyor Belt TroubleshootingchandankrdumkaNo ratings yet

- ICML 2017 Conference BookDocument69 pagesICML 2017 Conference BookCHRISTHIAN9144390% (1)

- Calculation Cathodic Protection DesignDocument14 pagesCalculation Cathodic Protection DesignVIETLH100% (1)

- Astronomy SolutionsDocument15 pagesAstronomy SolutionsGowrisankar RaoNo ratings yet

- AV51DOT1Document25 pagesAV51DOT1AnthonyNo ratings yet

- User'S Manual: Dynamic Signal Analyzers For Vibration Analysis and MonitoringDocument41 pagesUser'S Manual: Dynamic Signal Analyzers For Vibration Analysis and MonitoringJolito RamosNo ratings yet

- GensetDocument29 pagesGensetjason Cheng100% (1)

- Bently Hydrobrochure r3 LR Ok For Website 11.2.18Document12 pagesBently Hydrobrochure r3 LR Ok For Website 11.2.18Deepen SharmaNo ratings yet

- Bearings: Sliding Bearings Rolling Bearings Journal ThrustDocument3 pagesBearings: Sliding Bearings Rolling Bearings Journal ThrustShirishaVijayapuramNo ratings yet

- Gulf Synthetic Gear Oil - PAGDocument1 pageGulf Synthetic Gear Oil - PAGatripathi2009No ratings yet

- User Manual: Programmable Automation Controller AMC 300Document38 pagesUser Manual: Programmable Automation Controller AMC 300FrijoNo ratings yet

- RONDS Intelligent Wireless Condition Monitoring System: Anhui Rong Zhi Ri Xin Information Technology Co., LTDDocument12 pagesRONDS Intelligent Wireless Condition Monitoring System: Anhui Rong Zhi Ri Xin Information Technology Co., LTDMounicaRasagyaPallaNo ratings yet

- Hydraulic Troubleshooting GuideDocument9 pagesHydraulic Troubleshooting Guideusamaperwez100% (2)

- PLC & HMI Interfacing For AC Servo Drive: Naveen Kumar E T.V.Snehaprabha Senthil KumarDocument5 pagesPLC & HMI Interfacing For AC Servo Drive: Naveen Kumar E T.V.Snehaprabha Senthil KumarNay Ba LaNo ratings yet

- German Mission in British IndiaDocument133 pagesGerman Mission in British IndiaNilia PustakaNo ratings yet

- WindCon BrochureDocument8 pagesWindCon BrochureErik RSNo ratings yet

- CBSE Board Class 8 Maths Syllabus PDFDocument5 pagesCBSE Board Class 8 Maths Syllabus PDFrs149No ratings yet

- GulfSea Synth Gear Oil PG 220 PDFDocument2 pagesGulfSea Synth Gear Oil PG 220 PDFObydur RahmanNo ratings yet

- 9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Document3 pages9.2 Oils For Machine Lubrication - List of Suppliers: DIN 51517 Teil 3. (Viscosity at 40° C)Urke VukNo ratings yet

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009No ratings yet

- Compressor Cond MonDocument33 pagesCompressor Cond MonJai GaizinNo ratings yet

- Servo Motors Types and ApplicationsDocument22 pagesServo Motors Types and ApplicationsJavierNo ratings yet

- 1106-E66TAG Sales PresentationDocument13 pages1106-E66TAG Sales Presentationakheel201No ratings yet

- AP POLYCET - CEEP Syllabus and Exam PatternDocument2 pagesAP POLYCET - CEEP Syllabus and Exam PatterngayathriNo ratings yet

- Role of WaqfDocument13 pagesRole of Waqfdkhana243No ratings yet

- Caterpillar Oil and Gas Solutions BrochureDocument10 pagesCaterpillar Oil and Gas Solutions BrochuremaggioraNo ratings yet

- Natural Frequencies For Common SystemsDocument6 pagesNatural Frequencies For Common SystemsChristophe DormenvalNo ratings yet

- Ac 31 GrafsoftDocument461 pagesAc 31 GrafsoftantonyamnrNo ratings yet

- Control Engineering 2018-02Document54 pagesControl Engineering 2018-02Zigor Larrabe UribeNo ratings yet

- PLC GeneralDocument46 pagesPLC GeneralastranegroNo ratings yet

- Hot Isotactic Processing (Hip) : Mehmet Can HATİBOĞLUDocument18 pagesHot Isotactic Processing (Hip) : Mehmet Can HATİBOĞLUthesecretgardenscatNo ratings yet

- G3600 PKG Tips - Cooling SystemsDocument57 pagesG3600 PKG Tips - Cooling SystemsshivNo ratings yet

- NuggetsDocument202 pagesNuggetsfazzlieNo ratings yet

- What Are The Main Parts of An Automobile Engine?Document11 pagesWhat Are The Main Parts of An Automobile Engine?PremnathRajasekaranNo ratings yet

- Instrumentation in The Oil SectorDocument16 pagesInstrumentation in The Oil SectorChibuzo NnonyeluNo ratings yet

- Aluminum Cold Mill Rolling Oil DistillationDocument3 pagesAluminum Cold Mill Rolling Oil DistillationbwelzNo ratings yet

- Chapter 1 Pneumatic SystemDocument95 pagesChapter 1 Pneumatic SystemNazer Mangirapin BarisNo ratings yet

- Bevel Gear ManualDocument8 pagesBevel Gear ManualPiort ZelaskiNo ratings yet

- Petrol Injection SystemDocument15 pagesPetrol Injection Systemmeghraj7134No ratings yet

- Motor Saver PDFDocument88 pagesMotor Saver PDFManuelVargasRamirezNo ratings yet

- Air Polution Control - Project (Rockwell)Document16 pagesAir Polution Control - Project (Rockwell)Chandan MandalNo ratings yet

- FG Wilson Generator Set Operator & Maintenance Instruction ManualDocument72 pagesFG Wilson Generator Set Operator & Maintenance Instruction ManualWahyu DiyonoNo ratings yet

- Dalits and Memories of 1857 PDFDocument35 pagesDalits and Memories of 1857 PDFDev OshanNo ratings yet

- A EG3200 Section 8 Controller (NXPowerLite)Document32 pagesA EG3200 Section 8 Controller (NXPowerLite)Halit YalçınkayaNo ratings yet

- Ehvs PDFDocument24 pagesEhvs PDFantoniomecptNo ratings yet

- Ballmillinspection PDFDocument4 pagesBallmillinspection PDFrodrigoalcainoNo ratings yet

- Roller Chain MaintenanceDocument8 pagesRoller Chain MaintenanceRodrigo SenedezeNo ratings yet

- Systematic Approach To Solving Vibration ProblemsDocument24 pagesSystematic Approach To Solving Vibration Problemsantok09No ratings yet

- Presion de Gas de Etntrada MotorDocument24 pagesPresion de Gas de Etntrada MotorSERTECC SASNo ratings yet

- Cat C175-16 - Jul 2010Document6 pagesCat C175-16 - Jul 2010Lei YinNo ratings yet

- Gulf Oil Marine - Product Data SheetDocument10 pagesGulf Oil Marine - Product Data SheetObydur RahmanNo ratings yet

- EmitDocument20 pagesEmitecavalinNo ratings yet

- Euchner - Siemens PDFDocument22 pagesEuchner - Siemens PDFTalicni TomNo ratings yet

- Engine Maintenance Ankit AmityDocument19 pagesEngine Maintenance Ankit AmityAnonymous x07rAkLDONo ratings yet

- CAT - 3516H Coolant Pressure Is HighDocument3 pagesCAT - 3516H Coolant Pressure Is Highwagner_guimarães_1No ratings yet

- Catalogo de Motores H Compact-HCompact PlusDocument364 pagesCatalogo de Motores H Compact-HCompact PlusSrinivas GopalNo ratings yet

- KATO GeneratorDocument20 pagesKATO GeneratormotiondrillNo ratings yet

- Generador KatoDocument20 pagesGenerador KatoVelasquez DavisNo ratings yet

- Manufacturing of Turbo GeneratorsDocument19 pagesManufacturing of Turbo GeneratorsKeerthana Kola100% (2)

- CH 5 HydroDocument29 pagesCH 5 Hydroazizamuhammed21No ratings yet

- GE Large Induction MotorsDocument8 pagesGE Large Induction MotorsidontlikeebooksNo ratings yet

- Coulombic Efficiency, Energy Efficiency and Effective CapacitanceDocument4 pagesCoulombic Efficiency, Energy Efficiency and Effective CapacitanceHoàng TrươngNo ratings yet

- MME-Electrical-Session-2 Network Theorems PDFDocument74 pagesMME-Electrical-Session-2 Network Theorems PDFgpuonlineNo ratings yet

- Electrical Safety - Construction: OSHA Office of Training & Education 1Document41 pagesElectrical Safety - Construction: OSHA Office of Training & Education 1AmiibahNo ratings yet

- Work 2 Electrical-MachineryDocument1 pageWork 2 Electrical-MachineryOmar AlvaradoNo ratings yet

- Tutorial Ch1 ProblemDocument5 pagesTutorial Ch1 ProblemKiat HauNo ratings yet

- Single Shield Vs Double ShieldDocument1 pageSingle Shield Vs Double ShieldMuthuraj74No ratings yet

- Es Catalogue enDocument16 pagesEs Catalogue enLiêm HiếuNo ratings yet

- D Alembert PrincipleDocument11 pagesD Alembert PrincipleManu Mathew Cherian100% (2)

- Question Bank EMFTDocument14 pagesQuestion Bank EMFTAvishekNo ratings yet

- A Design of The DC Motor Control CircuitDocument9 pagesA Design of The DC Motor Control Circuitnyskyscraper051127No ratings yet

- Assignment: Motion: Very Short Answer Type Questions (1 Mark Each)Document16 pagesAssignment: Motion: Very Short Answer Type Questions (1 Mark Each)VCC100% (1)

- Synchronous Condenser Packages Brochure 9AKK108197 RevA EN A3Document6 pagesSynchronous Condenser Packages Brochure 9AKK108197 RevA EN A3Cesarin NavarroNo ratings yet

- Grade Level: Grade 3 Subject: Science Quarter Content Standard Performance Standard Most Essential Learning Competencies Duration Kto12 CG CodeDocument47 pagesGrade Level: Grade 3 Subject: Science Quarter Content Standard Performance Standard Most Essential Learning Competencies Duration Kto12 CG CodeDebz CayNo ratings yet

- Capacitor WizardDocument4 pagesCapacitor WizardMadumathi BulumullaNo ratings yet

- Guidelines and Fundamental Considerations For Axle BalancingDocument40 pagesGuidelines and Fundamental Considerations For Axle BalancingAnonymous PVXBGg9TNo ratings yet

- N2XBYDocument5 pagesN2XBYcyuenkNo ratings yet

- Banking of RoadsDocument4 pagesBanking of RoadsSantSarovarNo ratings yet

- 05 EMC Power AskLorandtDocument150 pages05 EMC Power AskLorandtPradeep PolavarpuNo ratings yet

- Finite Control Volume AnalysisDocument30 pagesFinite Control Volume Analysishari tubagusNo ratings yet

- Over Current Relay Working Principle Types - Electrical4uDocument3 pagesOver Current Relay Working Principle Types - Electrical4uEimi EimiteNo ratings yet

- Addendum-1 Anwar IspatDocument8 pagesAddendum-1 Anwar IspatPranoy BaruaNo ratings yet

- EC8451 Electromagnetic FieldsDocument13 pagesEC8451 Electromagnetic Fieldsallanjwilson100% (1)

- Slide CLTDocument28 pagesSlide CLTleoNo ratings yet

- 00IB ClassNotes PDFDocument158 pages00IB ClassNotes PDFaftab100% (1)

- Physics I Problems PDFDocument1 pagePhysics I Problems PDFBOSS BOSSNo ratings yet

- Physics Class Xi Test Papers 2016 PDFDocument82 pagesPhysics Class Xi Test Papers 2016 PDFRohit100% (1)

- Pilecap Design by Bending Theory To B.S 8110 & B.S 8004Document59 pagesPilecap Design by Bending Theory To B.S 8110 & B.S 8004azwanNo ratings yet

- Induced EmfDocument5 pagesInduced Emftajju_121No ratings yet