Hydram Proposal

Hydram Proposal

Uploaded by

Chandra Shekhar ChaurasiyaCopyright:

Available Formats

Hydram Proposal

Hydram Proposal

Uploaded by

Chandra Shekhar ChaurasiyaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Hydram Proposal

Hydram Proposal

Uploaded by

Chandra Shekhar ChaurasiyaCopyright:

Available Formats

Downloaded from www.binodpandey.wordpress.

com

A Proposal on

Installation of Hydraulic Ram Pump

Submitted to:

Ministry of Science and Technology

Singhadurbar, Kathmandu

Submitted by:

Industrial Engineering Department

Thapathali Campus, Kathmandu

Downloaded from www.binodpandey.wordpress.com

Introduction

A hydraulic ram (also called hydram) is a pump that uses energy from a falling quantity of water

to pump some of it to an elevation much higher than the original level at the source. No other

energy is required and as long as there is a continuous flow of falling water, the pump will work

continuously and automatically.

Provision of adequate domestic water supply for scattered rural populations is a major problem

in many villages in Nepal. Fuel and maintenance costs to operate conventional pumping systems

are not the long lasting solution. The hydraulic ram pump (hydram) is an alternative pumping

device that is relatively simple technology which uses falling water as energy, and is durable.

The hydram has only to moving parts and can be easily maintained locally.

Recognizing that the hydraulic ram pump (hydram) can be a viable and appropriate renewable

energy water pumping technology in rural areas of the country, our project team decided to

design and manufacture more efficient and durable hydram so that it could be demonstrated in a

village so that other villages will adopt the technology. By adopting this technology settlements

in the river banks can be profited.

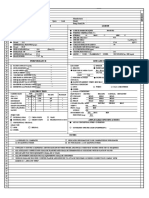

Fig 1: Components of hydraulic ram installations

Downloaded from www.binodpandey.wordpress.com

Working Principle of Hydram:

With reference to fig 1, the momentum provided by the flow (Qs), caused by the low supply

head (Hs), is used to pump a part of flow (q) to a higher elevation (hd) Qw is the wasted flow

which may be considered as the drive flow and h is the head gained by the suction of the

pump.

The hydram can be used in places where there is a steady and reliable supply of water with a fall

sufficient to operate it. Commercial hydrams which are mainly manufactured in developed

countries are known for many years. However, commercial hydrams are expensive and there is

a growing trend to develop and design smaller, lighter and low cost model which can be

fabricated in developing countries.

The hydraulic ram pump (hydram) though simple in design with only two moving parts, its

operation is not well understood. As a result, it has attracted many researchers who have tried to

derive analytical models for its operation. Because the researchers have been based in developed

countries, the developing countries did not get access to the information readily and the hydram

technology is therefore not widely used and the research has not benefited the developing

countries. This project was intended to redress this anomaly. A hamlet in a village setting can be

supplied with water using hydram as below. The system includes storage and in some cases may

include a treatment (chlorination, filtration, Solar Distillation) plant.

Fig 2: Schematic cross section of village water supply with a hydram.

As already discussed in previous section hydram is a unique device that uses the energy from a

stream of water falling from a low head as the driving power to pump part of the water to a head

much higher than the supply head. With a continuous flow of water, a hydram operates

automatically and continuously with no other external energy source.

We will see operational and constructional features if the Hydram in this section.

Downloaded from www.binodpandey.wordpress.com

A hydram is a structurally simple unit consisting of two moving parts: refer fig: the waste valve

and delivery (check) valve. The unit also consist an air chamber and an air (snifter) valve. The

operation of a hydram is intermittent due to the cyclic opening and closing of the waste and

delivery valves. The closure of the waste valve creates a high pressure rise in the drive pipe. An

air chamber is necessary to prevent these high intermittent pumped flows into a continuous

stream of flow. The air valve allows air into the hydram to replace the air absorbed by the water

due to the high pressures and mixing in the air chamber.

Project Objectives:

The overall objective of the project is to demonstrate a functional hydraulic ram in a

village in Tanahun District by the industrial engineering students so that students can learn the

manufacturing and installation of the technology and rural people can help to disseminate the

technology.

Specific objectives are:

a) To identify the potential site for hydram installations

b) To design hydram as per site and manufacture the same

Downloaded from www.binodpandey.wordpress.com

c) To construct a demonstration/testing facility consisting hydram

d) To install the hydram

e) To test the performance of hydram

Methodology:

1. Site visit and Selection

2. Site Survey

3. Design

4. Installation and operation

5. Testing and Documentation

Cost Calculation:

SN Components Amount Remarks

1. Hardware set 50,000

2. Manufacturing 20,000

3. Transportation

and Installation

20,000

4. Testing kit 10,000

Total 100,000

Total Cost: One Lakh only

Other costs will be born by the Campus

1. Travelling and daily expenditure

2. Stationary and other material

3. Contingency

Conclusion:

This project will be studied, conducted and implemented by students of Bachelor of Industrial

Engineering, Thapathali Campus, as a project work supporting their study.

You might also like

- NFPA 13-2019 Handbook 61Document1 pageNFPA 13-2019 Handbook 61sundarayya.giscoestimationNo ratings yet

- 2017standard Tender Documents For Unit Price Contracts Vol2Document797 pages2017standard Tender Documents For Unit Price Contracts Vol2Adrian FrantescuNo ratings yet

- Pedal Operated Centrifugal Water PumpDocument19 pagesPedal Operated Centrifugal Water PumpNeelmani100% (3)

- Existential HumanisticDocument76 pagesExistential HumanisticLazar NikolicNo ratings yet

- Uipl FPS Boq T1Document11 pagesUipl FPS Boq T1Sashikumar NarayanakurupNo ratings yet

- Fire Fighting UtmDocument27 pagesFire Fighting UtmNajwa Syafiqa100% (1)

- Pump Assessment PDFDocument20 pagesPump Assessment PDFJonas ArifinNo ratings yet

- Product - Catalog 2021 Page 1 To 6Document6 pagesProduct - Catalog 2021 Page 1 To 6Admin NewAgeNo ratings yet

- Katalog ZekiDocument14 pagesKatalog ZekiAnwar YanuarNo ratings yet

- Brosur - Ramus Hydrant EquipmentDocument5 pagesBrosur - Ramus Hydrant Equipmentmultipilar mandiriNo ratings yet

- Pump Curve ND 3x16978Document2 pagesPump Curve ND 3x16978g1ann1sNo ratings yet

- Suction, Fill and Vent Pipes: Top ViewDocument1 pageSuction, Fill and Vent Pipes: Top ViewNabil RamehNo ratings yet

- Format Progress Report SumbawaDocument10 pagesFormat Progress Report SumbawaFebry Christoper100% (1)

- Proposal 4034 ADocument20 pagesProposal 4034 AAbdul AlimNo ratings yet

- Catalog Citifire Golden Bright PDFDocument2 pagesCatalog Citifire Golden Bright PDFafie pio pioNo ratings yet

- Whitepaper 05 Version 02 Integration of Aisle Containment With Fire Suppression SystemsDocument32 pagesWhitepaper 05 Version 02 Integration of Aisle Containment With Fire Suppression SystemsrjendranNo ratings yet

- Technical Offer Rev.05 Tank 24x11.5 PDFDocument4 pagesTechnical Offer Rev.05 Tank 24x11.5 PDFMohamedGhanemNo ratings yet

- Fire Pumps and Pump GroupsDocument44 pagesFire Pumps and Pump GroupsDamarys A. Ulloa S.No ratings yet

- Civil Document List: No Document Number Document Title Status DataDocument12 pagesCivil Document List: No Document Number Document Title Status DataMuhammad ZaidNo ratings yet

- B.3.2.2 Pipe List - 0NE2 - MEW - 0007Document3 pagesB.3.2.2 Pipe List - 0NE2 - MEW - 0007Jaroslav KurucNo ratings yet

- Data Sheet Pompa HydrantDocument3 pagesData Sheet Pompa HydrantAnonymous 6S9tcbhNo ratings yet

- On-Off Valve DatasheetDocument80 pagesOn-Off Valve Datasheetssmith2007No ratings yet

- Precision Foam Test Kit EF10995Document1 pagePrecision Foam Test Kit EF10995o0Nesta0o0% (1)

- Fire Protection System - KimhowardDocument47 pagesFire Protection System - KimhowardFifth Avenue PlaceNo ratings yet

- Design of Automated Hammering Machine ReportDocument55 pagesDesign of Automated Hammering Machine ReportBiruk Damtew Ze MerhabeteNo ratings yet

- TC-M Series 2017.compressedDocument8 pagesTC-M Series 2017.compressedFredrik SihombingNo ratings yet

- Armstrong Pump SelectionDocument17 pagesArmstrong Pump SelectionkirmaniNo ratings yet

- SMO-DWG-DD-ME-00-FF-6301.01 P&ID Fire Sprinklers & Fire Hydrant SystemDocument1 pageSMO-DWG-DD-ME-00-FF-6301.01 P&ID Fire Sprinklers & Fire Hydrant SystemIskandar HasibuanNo ratings yet

- Fire PumpDocument20 pagesFire PumpAnonymous Ewxv1Cw6No ratings yet

- Pipelist For Ntv7Document78 pagesPipelist For Ntv7CaoQuocNo ratings yet

- Department of Mechanical Engineering-2Document16 pagesDepartment of Mechanical Engineering-2Pankaj Gaurav100% (1)

- Spec 17037-P4-P-0a1g-Sz-00006 - 5 PDFDocument50 pagesSpec 17037-P4-P-0a1g-Sz-00006 - 5 PDFiman sihotangNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- DieselDocument9 pagesDieselMahmoud MegahedNo ratings yet

- MC Check Sheet Unit - 2Document2 pagesMC Check Sheet Unit - 2SURJIT SINGHNo ratings yet

- Ipmg B SF DSH 1005 03Document5 pagesIpmg B SF DSH 1005 03sgh1355No ratings yet

- Mechanical Design of A Low Cost Parabolic Solar Dish ConcentratorDocument11 pagesMechanical Design of A Low Cost Parabolic Solar Dish ConcentratorArunsinghNo ratings yet

- Fire Fighting CatalogDocument6 pagesFire Fighting CatalogTangin YeanNo ratings yet

- Aircraft Design Report: 2007/2008 AIAA Cessna/Raytheon Design/Build/Fly CompetitionDocument60 pagesAircraft Design Report: 2007/2008 AIAA Cessna/Raytheon Design/Build/Fly Competitionthundergod88No ratings yet

- Technical Bid RIMDocument82 pagesTechnical Bid RIMpmcmbharat264No ratings yet

- Erwin Junaidi CV Project ManagerDocument11 pagesErwin Junaidi CV Project ManagerWinaelria RahmawatiNo ratings yet

- TKL Pump - Data - SheetDocument1 pageTKL Pump - Data - Sheetธนาชัย เต็งจิรธนาภาNo ratings yet

- Friction Loss.Document1 pageFriction Loss.JhonJairoMurilloVelezNo ratings yet

- CCR Component Oil Pump & GearDocument10 pagesCCR Component Oil Pump & Gearpurnomno sidiNo ratings yet

- Pipe Flow ExpertDocument7 pagesPipe Flow ExpertDesnantaGandhaNo ratings yet

- KR2XX Truck-Mounted Fire Pumps PR ENDocument24 pagesKR2XX Truck-Mounted Fire Pumps PR ENfater esmandarNo ratings yet

- 611 Pump & Fire HydrentDocument53 pages611 Pump & Fire HydrentBinay K SrivastawaNo ratings yet

- Request Form JaimonDocument306 pagesRequest Form JaimonjaimonjoyNo ratings yet

- Resume: Career ObjectiveDocument2 pagesResume: Career ObjectiveHemanth NaiduNo ratings yet

- Solar Parabolic Dish Collector For Concentrated SoDocument35 pagesSolar Parabolic Dish Collector For Concentrated Soaspmech25No ratings yet

- Tilak S - ResumeDocument5 pagesTilak S - ResumeKarthick RajaNo ratings yet

- Operating Conditions Liquid: Client: ServiceDocument1 pageOperating Conditions Liquid: Client: ServiceAde IskandarNo ratings yet

- SUMPITDocument7 pagesSUMPIThungNo ratings yet

- PumpsDocument30 pagesPumpsratankale0401No ratings yet

- HydramDocument70 pagesHydramMburu NjorogeNo ratings yet

- WCDE-00088-01 BMEIA Hydram Pump Design 100420Document5 pagesWCDE-00088-01 BMEIA Hydram Pump Design 100420Chandra Shekhar ChaurasiyaNo ratings yet

- Hydraulic RAM ApplicationDocument70 pagesHydraulic RAM ApplicationApoorv SinghNo ratings yet

- Delft: Hydraulic RamsDocument22 pagesDelft: Hydraulic RamsSameera LakmalNo ratings yet

- Estimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemDocument13 pagesEstimation of Power and Efficiency of Hydraulic Ram Pump With Re-Circulation SystemAnand M VNo ratings yet

- Hydraulic Ram PumpDocument9 pagesHydraulic Ram PumpmastermindishereNo ratings yet

- Informativeengli 020302 MBPDocument119 pagesInformativeengli 020302 MBPChandra Shekhar ChaurasiyaNo ratings yet

- English Grammer 19Document62 pagesEnglish Grammer 19Chandra Shekhar ChaurasiyaNo ratings yet

- WCDE-00088-01 BMEIA Hydram Pump Design 100420Document5 pagesWCDE-00088-01 BMEIA Hydram Pump Design 100420Chandra Shekhar ChaurasiyaNo ratings yet

- Pumps For Small-Scale Irrigation: International InstituteDocument37 pagesPumps For Small-Scale Irrigation: International InstituteChandra Shekhar ChaurasiyaNo ratings yet

- T Ched R.A. 7222: HE IS Composed Offices AS Specified UnderDocument17 pagesT Ched R.A. 7222: HE IS Composed Offices AS Specified UnderKimverlie AbastarNo ratings yet

- Powerone p110002Document13 pagesPowerone p110002Jim BeanNo ratings yet

- Rses Rosenberg Self Esteem Scale ScoringDocument2 pagesRses Rosenberg Self Esteem Scale ScoringCezara AurNo ratings yet

- Mandatory and Non-Mandatory Documents and Records For ISO 27001Document2 pagesMandatory and Non-Mandatory Documents and Records For ISO 27001Marcio RodriguesNo ratings yet

- Operativo Responder 1000Document21 pagesOperativo Responder 1000Roberto FalconeNo ratings yet

- Basilotta Et Al (2022) Teachers' Digital Competencies in Higher EducationDocument16 pagesBasilotta Et Al (2022) Teachers' Digital Competencies in Higher Educationmaria.diazvalencia.goetheNo ratings yet

- 5S ModuleDocument121 pages5S Modulekrovvidiprasadarao100% (1)

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument48 pagesDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceRohit raagNo ratings yet

- Understanding CATIA PackagingDocument3 pagesUnderstanding CATIA PackagingSorin MaleaNo ratings yet

- Ejercicios TermodinamicaDocument13 pagesEjercicios Termodinamica601195No ratings yet

- The Comprehensive PBR Guide by Allegorithmic - Vol. 2: Light and Matter: Practical Guidelines For Creating PBR TexturesDocument31 pagesThe Comprehensive PBR Guide by Allegorithmic - Vol. 2: Light and Matter: Practical Guidelines For Creating PBR TexturesAlex RamosNo ratings yet

- RA45H4452M: Mitsubishi RF Mosfet ModuleDocument9 pagesRA45H4452M: Mitsubishi RF Mosfet Modulep25digital2No ratings yet

- Unit 5 - Background ReadingsDocument20 pagesUnit 5 - Background ReadingsSoumya SinghNo ratings yet

- Module 8 TTL1 1st Sem 2022-2023Document7 pagesModule 8 TTL1 1st Sem 2022-2023Phil Amantillo AutorNo ratings yet

- Introduction - Evolutionary AlgorithmsDocument37 pagesIntroduction - Evolutionary AlgorithmsMayank furniturewalaNo ratings yet

- JVC LCD Lt-26dc1bhDocument78 pagesJVC LCD Lt-26dc1bhngoclinhdtddNo ratings yet

- My Career Plan 1Document1 pageMy Career Plan 1Mostafa Al AminNo ratings yet

- BorgwardDocument1 pageBorgwardRetíficaitatibaNo ratings yet

- ZF 5Hp19 Fla: (VW/AUDI) Code: 1060 040 XXX 5 SPEED AWD (Full Electronic Control)Document8 pagesZF 5Hp19 Fla: (VW/AUDI) Code: 1060 040 XXX 5 SPEED AWD (Full Electronic Control)Kevin Srz PlNo ratings yet

- C C C C C C C: CCCCCCCCCCCCCCCDocument7 pagesC C C C C C C: CCCCCCCCCCCCCCCMakhdoom SajjadNo ratings yet

- Chemistry - 1Document176 pagesChemistry - 1Drei SalNo ratings yet

- 03 Code of Ethics and Professional OrganizationsDocument37 pages03 Code of Ethics and Professional OrganizationsMON RYAN REYNo ratings yet

- Pressure Sensor With DisplayDocument5 pagesPressure Sensor With DisplayFranklin MendozaNo ratings yet

- A Precision, Low-Cost Vibrating Sample MagnetometerDocument11 pagesA Precision, Low-Cost Vibrating Sample Magnetometervleventv100% (1)

- Lobby PressurizationDocument1 pageLobby PressurizationQusai ShamlakhNo ratings yet

- Kenmore 158.1340 Sewing Machine Instruction ManualDocument50 pagesKenmore 158.1340 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- WLPweek 27Document2 pagesWLPweek 27Glide ParkNo ratings yet

- (Reaffirmed!2013) !Document53 pages(Reaffirmed!2013) !Ashish DubeyNo ratings yet

- Ejercicios Verb Ser BEGINDocument3 pagesEjercicios Verb Ser BEGINKarmele MatelanNo ratings yet