0 ratings0% found this document useful (0 votes)

1K viewsMT75 Overhaul

MT75 Overhaul

Uploaded by

frodarturThis document provides instructions for overhauling the manual transmission of a 1995-2001 Scorpio vehicle. It details the disassembly process for the transmission housing, mainshaft, countershaft, and individual components. Special tools are required to remove bearings, seals, and other parts. Technicians must mark synchronized gear components and bearings as they are paired. Disassembly of the main selector shaft, synchronizer units, and double synchronizer is described.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

MT75 Overhaul

MT75 Overhaul

Uploaded by

frodartur0 ratings0% found this document useful (0 votes)

1K views31 pagesThis document provides instructions for overhauling the manual transmission of a 1995-2001 Scorpio vehicle. It details the disassembly process for the transmission housing, mainshaft, countershaft, and individual components. Special tools are required to remove bearings, seals, and other parts. Technicians must mark synchronized gear components and bearings as they are paired. Disassembly of the main selector shaft, synchronizer units, and double synchronizer is described.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides instructions for overhauling the manual transmission of a 1995-2001 Scorpio vehicle. It details the disassembly process for the transmission housing, mainshaft, countershaft, and individual components. Special tools are required to remove bearings, seals, and other parts. Technicians must mark synchronized gear components and bearings as they are paired. Disassembly of the main selector shaft, synchronizer units, and double synchronizer is described.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1K views31 pagesMT75 Overhaul

MT75 Overhaul

Uploaded by

frodarturThis document provides instructions for overhauling the manual transmission of a 1995-2001 Scorpio vehicle. It details the disassembly process for the transmission housing, mainshaft, countershaft, and individual components. Special tools are required to remove bearings, seals, and other parts. Technicians must mark synchronized gear components and bearings as they are paired. Disassembly of the main selector shaft, synchronizer units, and double synchronizer is described.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 31

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-1

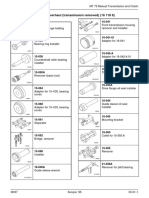

Manual Transmission Overhaul (transmission removed) (16 118 8)

Special Tools

15030A

15-030A

Universal flange-holding

wrench

15035

15-035

Bearing ring installer

15036

15-036

Countershaft roller bearing

installer

15050A

15-050A

Remover (basic tool)

15064

15-064

Adaptor for 15035, bearing

cones

15068

15-068

Adaptor for 15033, bearing

cones

15091

15-091

Separator

15092

15-092

Bridge, remover

15096

15-096

Installer

PZ16040A

16-040A

Guide sleeve wrench

16041

16-041

Front transmission housing

remover and installer

1604101

16-041-01

Adaptor for 16-041

16042A

16-042-A

Adaptor for 16-042 A-01

16042A01

16-042A-01

Threaded spindle

16043A

16-043A

Drive flange oil seal installer

16044

16-044

Guide sleeve oil seal

installer

16045

16-045

Mounting bracket

16050

16-050

Collet for 15-050 A

16056

16-056

Remover

21036A

21-036A

Remover for pilot bearing

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-2

21037B

21-037B

Pilot bearing remover

21051

21-051

Oil seal remover

21103A

21-103A

Locator

21540

21-540

Angle gauge

Workshop Equipment

Assembly stand

Materials

Cable ties

Sealer ESKM-4G242-A

High-temperature

grease

ESDM-1C220-A

Transmission fluid ESDM-2C186-A

Proprietary Tools

Two-legged puller

Internal extractor

30 mm socket wrench (double hexagon)

8 mm Allen key

14 mm Allen key

17 mm Allen key

T40 Torx wrench

9,5 mm twist drill bit

Dismantle

1. General notes.

Some synchroniser units and bearings are

identical and must be marked for reuse.

Mark the synchroniser units in the direction

of travel of the vehicle.

All the bearings are paired and must not

be mixed up.

Use soft jaws for all operations in a vice.

D1601150

2. Drain off the transmission fluid

(transmission for diesel engine shown).

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-3

D1601151

16045

1

2

3. Mount the transmission on an assembly

stand.

1 Screw the tool bolt into the threaded hole for

the oil drain plug and tighten it.

2 Secure the mounting bracket to the

transmission.

1

2

D1601011

4. Detach the pressure line and the bleed

screw.

1 Pull out the spring clip; disconnect the

quick-release coupling.

2 Remove the bleed screw.

D1601012

5. Remove the slave cylinder complete with

the release bearing.

D1601153

15030 A

6. Unscrew the drive flange nut from the

mainshaft.

S Use a 30 mm socket wrench.

S Hold with the special tool.

S Discard the nut.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-4

D1601160

15091

15092

7. Pull off the drive flange.

16040A

D1601154

8. Remove the guide sleeve.

Remove the thrust washer.

S1601148

Remove input shaft guide sleeve oil seal

9. Remove the radial oil seal.

Prise out the radial oil seal using a suitable

lever.

2

1

D1601155

10. Remove the input shaft circlip.

11. Remove the countershaft bearing

housing.

1 Remove the bearing housing locking plate.

2 Unscrew the bearing housing using a

17 mm Allen key.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-5

D1601156

1

2

12. Remove the selector interlock

mechanism.

1 Remove the plug with a 14 mm Allen key.

2 Remove the spring, pin, ball and sleeve.

D1601157

2

1

13. Remove the reversing light switch and

the locking screw.

1 Reversing light switch

2 Locking plate locking screw.

D1601158

3

2

1

14. Unscrew the transmission housing bolts.

1 Housing flange (10 bolts).

2 Only slacken the bolt of the reverse gear

idler shaft (marked in blue).

3 Unscrew the bolt of the reverse gear idler

shaft (marked in blue).

D1601163

21051

15. Prise out the radial oil seal.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-6

S1601149

16. Remove the speedometer drive pinion

and worm gear.

Remove the blanking cover.

J1601160

NOTE: Do not drive out the housing locating

dowels.

17. Separate the transmission housing

halves.

NOTE: Only apply the levers to the reinforcing

ribs.

D1601159

1604101

2

16041

1

D

CAUTION: Take care not to apply

excessive pressure to the input shaft

through the special tool as this could

damage the 4th gear synchroniser ring.

18. Pull off the front transmission housing.

NOTE: Hold the special tool with a drift.

1 Attach the puller.

2 Screw the adaptor into the threaded hole of

the guide sleeve.

S If necessary, assist with levers.

D1601161

1

2

19. Remove the 3rd/4th gear selector fork.

S Move the main selector shaft to the neutral

position.

1 Pull out the auxiliary selector shaft.

2 Remove the 3rd/4th gear selector fork.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-7

J1601168

20. Remove the second retaining bolt of the

reverse gear idler shaft (marked in blue)

and the magnetic disc.

J1601169

D

CAUTION: Move the selector shaft to the

neutral position so that the locating pin

does not break off the shift finger holder.

NOTE: Locate the puller on the housing bosses.

21. Press the mainshaft out of the bearing in

the rear transmission housing.

22. Remove the main selector shaft with the

selector fork.

23. Lift out the complete gear train.

D1601164

1

2

Dismantle main selector shaft

NOTE: Catch the two balls from the spring

carrier.

24. Dismantle main selector shaft

1 Remove the circlip.

2 Remove the spring cup, spring and spring

carrier.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-8

D1601165

3

2

1

25. Dismantle the main selector shaft

(continued).

1 Drive the roll pin out of the shift finger holder

and the main selector shaft.

2 Remove the shift finger holder.

3 Remove the 1st/2nd gear selector fork.

D1601166

3 1

2

26. Dismantle the main selector shaft

(continued).

1 Remove the locking sleeve.

2 Drive the roll pin out of the shift finger and

the main selector shaft.

3 Remove the shift finger.

J1601171

Dismantle rear transmission housing

27. Remove the countershaft rear roller

bearing.

Use a proprietary internal extractor.

D1601168

28. Remove the selector gate.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-9

D1601169

21103 A

29. Drive out the main selector shaft ball

sleeve together with the radial oil seal.

D1601167

30. Unscrew the retaining bolts of the

mainshaft ball bearing.

D1601171

31. Remove the mainshaft ball bearing.

Drive out the mainshaft ball bearing using a

suitable length of tube.

D1601172

21036 A

21037 B

Dismantle front transmission housing

NOTE: Insert a spacer (approx. 63 mm) in the

hole.

NOTE: Use remover 21-036 A with the thrust

element of 21-037 B.

32. Remove the main selector shaft ball

sleeve.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-10

D1601173

33. Remove the input shaft ball bearing.

Use a suitable length of tube or Special Tool

15-096.

S1601150

D

CAUTION: Take care not to damage the

bearing housing thread in the housing.

34. Drive out the countershaft roller bearing.

Dismantle mainshaft

35. General notes.

D

CAUTION: From build date 17.8.1994

onwards (see table on page 2, General

Specifications) the synchroniser rings for

1st, 2nd and 3rd gear have a taper angle

of 7 and are coated with molybdenum.

The synchroniser rings for 4th, 5th and

reverse gear have a taper angle of 6,5

as previously.

Vehicles manufactured from build date

17. 6.1996 are fitted with a 1st/2nd gear

double synchroniser unit.

When the shaft is dismantled, the

synchroniser rings and synchroniser units

must be marked.

When dismantling the synchroniser units,

also mark the synchroniser hubs in relation

to the shift rings.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-11

J1601179

1

3

2

36. Remove the input shaft with the 4th gear

synchroniser ring from the mainshaft.

1 Input shaft

2 4th gear synchroniser ring

3 Roller bearing

J1601180

2

1

37. Remove the 5th gear wheel with the

synchroniser ring from the mainshaft.

1 5th gear wheel

2 Needle roller bearing

J1601182

3

1

2

:

WARNING: The synchroniser units must

not be allowed to fall apart as there is a

danger of injury from springs, blocker bars

and balls.

38. Remove the 3rd/4th gear synchroniser

unit with the 3rd gear wheel.

S Clamp the mainshaft in a vice with the

output shaft pointing downwards.

S Remove the circlip.

1 3rd/4th gear synchroniser unit

2 3rd/4th gear wheel

3 Needle roller bearing

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-12

J1601183

16056

39. Pull off the 3rd gear bearing ring.

Locate the puller in the recesses in the

bearing ring.

J1601184

NOTE: Mark the parts.

40. Remove the 2nd gear wheel with the

needle roller bearing and synchroniser

ring.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-13

1

2

3

ELS1601195

Vehicles manufactured from build date

17. 6. 1996 are fitted with a 1st/2nd gear

synchroniser unit.

NOTE: Mark the shift ring for the gear

synchroniser. Components are paired.

41. Remove the 1st/2nd gear synchroniser

unit with the 1st gear wheel.

S Remove the circlip for the 1st/2nd gear

synchroniser unit.

1 1st/2nd gear synchroniser unit

2 1st gear wheel

3 Needle roller bearing

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-14

J1601188

1

2

3

NOTE: Mark the shift ring for the gear

synchroniser. The components are paired.

42. Remove the 5th/reverse gear

synchroniser unit with the reverse gear

wheel and needle roller bearing.

S Clamp the mainshaft the other way round in

the vice.

S Circlip

1 Synchroniser unit

2 Reverse gear wheel

3 Needle roller bearing

ELS1601194

4

3 1

2

1

5

:

WARNING: Take care when removing the

shift ring from the synchroniser hub. The

balls and blocker bars are spring-loaded.

43. Dismantle the synchroniser unit.

1 Synchroniser rings

2 Shift ring

3 Synchroniser hub

4 Ball and blocker bar

5 Compression spring

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-15

ELS1601193

3 2 1

4

Vehicles manufactured from built date

17. 6.1996 are fitted with a 1st/2nd gear double

synchroniser unit.

44. Double synchroniser unit components.

1 Outer synchroniser ring

2 Inner synchroniser ring

3 Synchroniser cone

4 Gear wheel

J1601190

15050 A

16050

Dismantle countershaft

NOTE: Insert the puller in the annular groove

provided in the ring.

45. Pull the inner ring off the countershaft.

J1601191

4

3 1

2

Dismantle reverse gear idler shaft

46. Dismantle the reverse gear idler shaft.

1 Drive out the roll pin.

2 Bearing housing

3 Idler

4 Needle roller bearing

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-16

J1601707

Assemble transmission

47. General notes.

S Lubricate all moving parts with transmission

fluid before or during assembly.

S Renew all the circlips, oil seals and

self-locking nuts.

S Measure the circlips so that they fit into their

grooves without free play.

48. Preparatory operations.

Clean and check all parts thoroughly and

renew if necessary.

69,0 mm 0,3 mm

D1601675

Assemble rear transmission housing

NOTE: If the rear transmission housing is

renewed, a new detent pin must be fitted.

The distance from the tip of the detent pin to the

housing mating face must be 69,0 0,3 mm.

D1601671

15068

15035

15035

15064

49. Fit the mainshaft ball bearing.

Use only the spindle of 15-035.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-17

D1601667

24 Nm

50. Secure the mainshaft ball bearing with

bolts and washers.

D1601169

21103 A

51. Drive in the main selector shaft ball

sleeve flush.

D1601670

52. Fit the main selector shaft radial oil seal.

D1601668

10 Nm

NOTE: Use new locating bolts.

53. Fit the selector gate.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-18

D1601179

15036

54. Drive in the countershaft roller bearing as

far as the stop.

2

15064

PZJ1601677

1

Assemble front transmission housing

55. Fit the input shaft ball bearing.

1 Fit the circlip in the annular groove of the

ball bearing.

2 Drive in the ball bearing from the clutch side

J1601678

15036

2,0 mm

NOTE: Do not drive the roller bearing in flush

but allow it to protrude approx. 2 mm on the

inside.

56. Fit the countershaft roller bearing.

D1601672

21103 A

57. Drive in the main selector shaft ball

sleeve flush.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-19

S1601648

16044

Install input shaft guide sleeve oil seal

NOTE: The sealing lip must face the tool on

installation.

58. Drive in the radial oil seal.

J1601706

1

2 4

3

Assemble reverse gear idler shaft

NOTE: Do not fit the bearing housing twisted.

The threaded holes must line up with one

another.

59. Assemble the reverse gear idler shaft.

1 Needle roller bearing

2 Idler

3 Bearing housing

4 Drive in the roll pin.

J1601690

Assemble countershaft

60. Fit the bearing rings.

Heat the bearing rings to approx. 100C and

slide them on.

D1601666

1 2

Assemble main selector shaft

NOTE: The shift finger must point in the

opposite direction to the actuating pin of the

reversing light switch.

61. Assemble main selector shaft

1 Slide the shift finger onto the main selector

shaft and secure it with a roll pin.

2 Slide the locking sleeve onto the selector

shaft and shift finger.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-20

D1601665

1

2

NOTE: The roll pin must be aligned centrally.

62. Assemble the selector shaft (continued).

1 Fit the 1st/2nd gear selector fork on the

selector shaft.

2 Slide the shift finger holder onto the selector

shaft and secure it with a roll pin.

D1601664

3

1

2

63. Assemble the main selector shaft

(continued).

1 Fit the spring carrier on the selector shaft

with two balls.

2 Fit the spring and spring cup.

3 Secure them with a circlip.

ELS1601194

4

3 1

2

1

5

Assemble mainshaft

64. Assemble the synchroniser unit.

1 Fit the compression springs.

2 Synchroniser hub

3 Ball and blocker bar

4 Position the shift ring correctly and slide it

on.

5 Fit the synchroniser rings.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-21

PZJ1601694

2

1

3

NOTE: Marking

65. Fit the needle roller bearing and reverse

gear wheel with the synchroniser unit.

S Clamp the mainshaft in a vice with the

output end pointing upwards.

1 Reverse gear wheel

2 Synchroniser unit

3 Select a circlip which fits without free play

and fit it.

S Available circlips:

2,03 mm

2,07 mm

2,11 mm

2,15 mm

J1601686

3

2

1

Vehicles manufactured from build date

17. 6. 1996 are fitted with a 1st/2nd gear double

synchroniser unit.

NOTE: Marking

66. Fit the 1st/2nd gear synchroniser unit.

S Clamp the mainshaft the other way round.

1 Fit the needle roller bearing.

2 Fit the 1st gear wheel.

3 Fit the 1st/2nd gear synchroniser unit.

S Select a circlip which fits without free play

and fit it.

S Available circlips:

2,03 mm

2,07 mm

2,11 mm

2,15 mm

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-22

J1601684

1

2

3

67. Fit the synchroniser ring, needle roller

bearing and 2nd gear wheel.

1 Needle roller bearing

2 Synchroniser ring

3 2nd gear wheel

J1601683

NOTE: Slide the inner bearing ring onto the

mainshaft as far as the shoulder.

68. Fit the 3rd gear wheel inner bearing ring.

Heat the inner bearing ring to approx.

100C.

J1601682

2

1

NOTE: Fit the synchroniser unit with the small

collar facing upwards.

69. Fit the 3rd/4th gear synchroniser unit.

S Fit the needle roller bearing.

1 Fit the 3rd gear wheel.

2 Fit the 3rd/4th gear synchroniser unit.

S Select a circlip which fits without free play

and fit it.

S Available circlips:

1,99 mm

2,03 mm

2,07 mm

2,11 mm

2,15 mm

2,19 mm

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-23

J1601680

1

3

2

70. Fit the 5th gear wheel.

S Clamp the mainshaft the other way round.

1 Needle roller bearing

2 5th gear synchroniser ring

3 5th gear wheel

J1601679

2

3

1

71. Fit the input shaft.

S Clamp the mainshaft the other way round.

1 Roller bearing

2 4th gear synchroniser ring

3 Input shaft

D1601677

72. Assemble the countershaft with the

mainshaft and secure the assembly with

a cable tie.

D1601676

NOTE: The 1st/2nd gear selector fork must

engage in the 1st/2nd gear synchroniser unit in

the middle.

73. Fit the main selector shaft.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-24

D1601679

74. Assemble the reverse gear idler with the

countershaft and mainshaft assembly.

S The end of the shaft with the flat points

upwards.

S Secure the assembly with a cable tie.

D1601678

75. Fit the 5th/reverse gear selector fork in

the lower synchroniser unit.

The outrigger points upwards.

D1601681

76. Fit the complete gear assembly in the

rear transmission housing.

77. Slide the speedometer worm gear onto

the mainshaft.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-25

D1601682

16042 A

16042 A01

2

1

NOTE: During installation, guide the main

selector shaft into the ball sleeve correctly.

NOTE: The distance between the countershaft

and the synchroniser ring must not be zero.

78. Draw the mainshaft into the rear

transmission housing.

1 Screw the spindle into the mainshaft.

2 Fit the adaptor.

S Guide the countershaft into the rear roller

bearing.

79. Remove the speedometer worm gear.

J1601168

80. Insert the retaining bolt for the reverse

gear idler shaft and screw it up finger

tight.

S Remove the cable ties from the gear

assembly.

S Fit the magnetic disc.

D1601661

NOTE: The chamfered end of the selector shaft

points upwards.

81. Fit the 3rd/4th gear selector fork in the

upper synchroniser unit and the auxiliary

selector shaft.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-26

J1601703

82. Fit the front transmission housing.

Position three spacers approx. 25 mm in

length between the housing sections.

D1601659

16041

2 3

1 1604101

83. Draw on the front transmission housing.

1 Attach the adaptor.

2 Attach the two clamping shells to the input

shaft.

3 Secure them with the sleeve.

D1601662

2

16041

1

NOTE: During installation, guide the

countershaft correctly into the bearing.

Tighten the flange bolts within 15 minutes.

84. Draw on the front transmission housing

(continued).

1 Slide the large sleeve over the clamping

shells and sleeve.

S Remove the spacers and apply sealer to the

mating faces of the rear transmission

housing.

S Apply sealer (ESKM-4G242-A) to the inside

of the mating faces.

2 Draw on the housing.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-27

D1601658

1

24 Nm

2

32 Nm

85. Bolt the housing halves together.

1 Insert two housing bolts on opposite sides

and draw the housing sections together.

S Fit the remaining eight bolts and tighten

them.

2 Tighten the bolts of the reverse gear idler

shaft (both bolts are marked in blue).

D1601657

1 33 Nm

2

14 Nm

86. Fit the reversing light switch and the

locking screw.

1 Reversing light switch

2 Locking plate locking screw

D1601656

1

24 Nm

2

87. Fit the selector interlock mechanism.

1 Insert the sleeve, ball, pin and spring.

2 Apply sealer (ESKM-4G242-A) and screw in

the plug (14 mm Allen key).

S1601649

88. Fit the speedometer worm gear.

89. Fit the speedometer drive pinion in the

rear transmission housing.

Apply sealer (ESKM-4G242-A) and fit the

speedometer drive pinion cap.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-28

D1601683

16043 A

90. Fit the drive flange radial oil seal.

2

D1601660

16042 A

1

16042 A01

91. Draw the drive flange onto the mainshaft.

S Fit the flange.

1 Screw the spindle into the mainshaft.

2 Screw on the adaptor.

S Hold the spindle with a drift.

D1601653

15030 A

200 Nm

92. Secure the drive flange with a new nut.

Hold the drive flange.

D1601655

93. Fit the input shaft circlip.

S Select a circlip which fits without free play

and fit it.

S Available circlips:

2,26 mm

2,30 mm

2,34 mm

2,38 mm

2,42 mm

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-29

S1601651

2

1

94. Prepare the guide sleeve for installation.

1 Fit a new O-ring.

2 Stick the thrust washer in place with grease.

16040A

S1601652

250 Nm

95. Secure the guide sleeve.

S1601653

40 Nm

96. Fit the countershaft bearing housing

using a new O-ring.

S Grease the O-ring.

S Screw in the bearing housing with a 17-mm

Allen key.

S1601654

21540

80

97. Unscrew the bearing housing 80.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-30

S1601655

NOTE: Tilt the clutch housing downwards at

least 45.

98. Drive the countershaft bearing home

against the bearing housing.

Strike two blows on each of the bosses

using a brass drift and hammer. This will

drive the bearing home against the bearing

housing.

min. 6 Nm

21540

25 Nm

S1601656

20

D

CAUTION: A minimum torque of 6 Nm

must be achieved.

99. Tighten the bearing housing 20 and

secure it with the locking plate.

If the 6 Nm are not achieved,

sub-operations 97. to 99. must be repeated.

10 Nm

D1601512

100. Fit the slave cylinder complete with the

release bearing.

1

2

D1601511

NOTE: Make sure that the quick-release

coupling is locked securely.

101. Fit the clutch pressure line and bleed

screw.

1 Connect the quick-release coupling.

2 Screw in the bleed screw.

MT 75 Manual Transmission and Clutch

09/97 Scorpio 95 00-01-31

D1601650

35 Nm

102. Detach the transmission from the

assembly stand and detach the mounting

bracket.

103. Tighten the oil drain plug.

You might also like

- 4L60E Overhaul ManualDocument185 pages4L60E Overhaul Manualanon_89043510089% (63)

- Bruno Elan Sre-3000 Stair Lift Installation Manual 05-13-2015Document78 pagesBruno Elan Sre-3000 Stair Lift Installation Manual 05-13-2015B Manual78% (36)

- General Torque Specifications N52 PDFDocument3 pagesGeneral Torque Specifications N52 PDFRoman Nava0% (1)

- ZF 6S 450PDocument2 pagesZF 6S 450PCólo Portillo75% (4)

- GMServiceManual PDFDocument48 pagesGMServiceManual PDFLuisYFer1100% (2)

- Toyota R150 R151Document4 pagesToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- Toyota U660 Transmission Exploded ViewDocument5 pagesToyota U660 Transmission Exploded ViewMarkus of Tau86% (7)

- Ib 5Document18 pagesIb 5Augusto Barragan MonsivaisNo ratings yet

- Figo 1.6 Duratech TimingDocument8 pagesFigo 1.6 Duratech TimingBerg Auto RepairsNo ratings yet

- AT2512C Eng 01 953804Document2 pagesAT2512C Eng 01 953804Victor Hugo Benitez PaezNo ratings yet

- Subaru Transmission Ratio ListDocument18 pagesSubaru Transmission Ratio ListMárius ŠupaNo ratings yet

- MT75 OverhaulDocument31 pagesMT75 Overhaulvõ đăng tiếnNo ratings yet

- Eaton Transmission Service Manual FSO-2106 / 2506Document80 pagesEaton Transmission Service Manual FSO-2106 / 2506panu suwannakoodNo ratings yet

- Engine Overhaul Manual Wl3 WLC Wec Supplement f198!10!05l19Document1 pageEngine Overhaul Manual Wl3 WLC Wec Supplement f198!10!05l19staff055No ratings yet

- 2.2 Duratorque TimingDocument9 pages2.2 Duratorque TimingJam Bab50% (2)

- Chanfa IDocument16 pagesChanfa IDouglas Antonio Paredes Marquina100% (1)

- Aw 50-40Document3 pagesAw 50-40Ramises Nery0% (1)

- Nissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aDocument64 pagesNissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aAlex Bassoco100% (1)

- CUMMINS Foton Aumark Spec SheeterDocument2 pagesCUMMINS Foton Aumark Spec SheeterJefferson Humbereto Herrera Alfonso75% (4)

- Mazda6 AJ V6 Engine OverhaulDocument65 pagesMazda6 AJ V6 Engine Overhauljerry_skarbekNo ratings yet

- Manual Skoda Octavia - Gearbox m6 02MDocument204 pagesManual Skoda Octavia - Gearbox m6 02MCornea Horatiu Sebastian100% (6)

- DCT450 Clutch Damper Repair PDFDocument1 pageDCT450 Clutch Damper Repair PDFSemen AlexandrovNo ratings yet

- R52 PDFDocument5 pagesR52 PDFcommoril100% (1)

- 303-01A-Engine - 2.4L Duratorq-Tdci (Puma) Diesel 303-01ADocument69 pages303-01A-Engine - 2.4L Duratorq-Tdci (Puma) Diesel 303-01AEnrique Arevalo Leyva50% (4)

- KiaDocument2 pagesKiaandrzej0% (1)

- 14.manual TransmissionDocument18 pages14.manual TransmissionKuba SwkNo ratings yet

- Foton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupDocument284 pagesFoton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupCINA auto partsNo ratings yet

- Montagem Motor 2.2 LDocument37 pagesMontagem Motor 2.2 LJose Luis Toco100% (2)

- FSO-4305/ 4405 EnglishDocument128 pagesFSO-4305/ 4405 EnglishCJ10aNo ratings yet

- Ford Transit Engine 2 4l DuratorqDocument9 pagesFord Transit Engine 2 4l Duratorqwendy100% (60)

- Engine MechanicalDocument17 pagesEngine MechanicalAdrian Marian GafincuNo ratings yet

- 33 - Eaton 4106 5206 Transmission Service Manual PDFDocument90 pages33 - Eaton 4106 5206 Transmission Service Manual PDFSomadbsi100% (1)

- Mitsubishi S4e Engine DataDocument1 pageMitsubishi S4e Engine DataMussard100% (1)

- Duke 200 Manual PDFDocument184 pagesDuke 200 Manual PDFMOHD ZULHELMIE ZAINAL ABIDIN100% (2)

- RT7608LL Manual de ServicioDocument108 pagesRT7608LL Manual de ServicioCesar Ego-Aguirre Calderon100% (1)

- Electrical System MF5710Document81 pagesElectrical System MF5710SudarsonoNo ratings yet

- Nissan TD 42 Manual de ServicioDocument23 pagesNissan TD 42 Manual de ServicioFerran AlfonsoNo ratings yet

- MT D2.5Document26 pagesMT D2.5Mario Acevedo100% (1)

- A 4 C F 0Document4 pagesA 4 C F 0Fabricio LimaNo ratings yet

- Mitsubishi 4M41Document6 pagesMitsubishi 4M41Sebastian Tabares Rios100% (1)

- 2013-2018 EcoSport 1.5L Duratec-16V Ti-VCT - Sigma Camshaft AlignmentDocument7 pages2013-2018 EcoSport 1.5L Duratec-16V Ti-VCT - Sigma Camshaft AlignmentRey VillafuerteNo ratings yet

- ZF5HP19FL / ZF5HP19FLA (Audi / VW) ZF5HP19FL / ZF5HP19FLA (Audi / VW)Document1 pageZF5HP19FL / ZF5HP19FLA (Audi / VW) ZF5HP19FL / ZF5HP19FLA (Audi / VW)alex310885No ratings yet

- Disassembled Views (6L50)Document20 pagesDisassembled Views (6L50)cruces.boss100% (1)

- db4429 5514Document4 pagesdb4429 5514WillianPachecoNo ratings yet

- Manual Transmission: SectionDocument48 pagesManual Transmission: SectionManuel Manrique0% (1)

- International HS 2.8L Workshop Manual ARODocument130 pagesInternational HS 2.8L Workshop Manual AROginghinacNo ratings yet

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDocument3 pagesRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNo ratings yet

- Pajero Full 2008 15Document81 pagesPajero Full 2008 15Antonio Gaspar100% (1)

- zf6hp26 26x 28 28x 6r60 6r80 2 PDFDocument10 pageszf6hp26 26x 28 28x 6r60 6r80 2 PDFPedropower PowerNo ratings yet

- X9 Meters Luxury Light VanDocument2 pagesX9 Meters Luxury Light VanNam Trần MinhNo ratings yet

- Medidas 3.2D (Duratorq - Puma)Document3 pagesMedidas 3.2D (Duratorq - Puma)Flavia CossetinNo ratings yet

- Engine Identification: Vitara 5Document35 pagesEngine Identification: Vitara 5Saulo RodriguesNo ratings yet

- JP Australia PISTON CATALOGUE2016v2Document135 pagesJP Australia PISTON CATALOGUE2016v2gume pesa100% (1)

- Cluch Truck CatalogueDocument43 pagesCluch Truck Cataloguesherzad100% (1)

- Calibração Da Caixa 6R80Document2 pagesCalibração Da Caixa 6R80automaticosbrasil100% (1)

- A 4 Lde OverhaulDocument49 pagesA 4 Lde Overhaul2791957No ratings yet

- Remo TBDocument5 pagesRemo TBTyler MacNo ratings yet

- Engine DismantlingDocument9 pagesEngine DismantlingRezha100% (1)

- Engine - Dismantle and Assemble (21 134 8) : Special Tools 15-033 21-150ADocument48 pagesEngine - Dismantle and Assemble (21 134 8) : Special Tools 15-033 21-150Anitboy_550494975No ratings yet

- D Transmission2010Document37 pagesD Transmission2010Akrae AcrNo ratings yet

- BMW DifferentialsDocument9 pagesBMW DifferentialsMohd FalahNo ratings yet

- Acoustic Optimization of An Underwater VehicleDocument83 pagesAcoustic Optimization of An Underwater VehicleJossy AbgonNo ratings yet

- Pumps-Motors-G-En 02 09 02-08 21 PDFDocument37 pagesPumps-Motors-G-En 02 09 02-08 21 PDFmc boy layNo ratings yet

- Complete Layout of Spur Gear Drive System: Top ViewDocument1 pageComplete Layout of Spur Gear Drive System: Top ViewJames VincentNo ratings yet

- BASIC TECH JSS2 3RD TERM L-NOTEDocument35 pagesBASIC TECH JSS2 3RD TERM L-NOTEanselgames2021No ratings yet

- MechanicalDocument41 pagesMechanicalrofiq100% (1)

- Machining and Machine Tool Operation PI GATE 2020 Previous Year With Ans KeyDocument21 pagesMachining and Machine Tool Operation PI GATE 2020 Previous Year With Ans Keyhyper meshNo ratings yet

- Requisition: FOR Hot Kiln Alignment & Girth Gear InspectionDocument5 pagesRequisition: FOR Hot Kiln Alignment & Girth Gear InspectionAhmad Husni RizalNo ratings yet

- Total Gear Box Specs PDFDocument80 pagesTotal Gear Box Specs PDFVinansius BudiryantoNo ratings yet

- KUMERA Drives: TG-3280H2-28-RA-E1 (18991-DRVD3101212)Document8 pagesKUMERA Drives: TG-3280H2-28-RA-E1 (18991-DRVD3101212)Anderson SouzaNo ratings yet

- Especificaciones - 2023 Indian Scout Rogue Sixty Motocicleta MXDocument3 pagesEspecificaciones - 2023 Indian Scout Rogue Sixty Motocicleta MXArmando OsoyoNo ratings yet

- UndercarriageDocument70 pagesUndercarriageRodrigo Gonzalez100% (1)

- Design and Development of Automatic Footboard Accident Prevention SystemDocument6 pagesDesign and Development of Automatic Footboard Accident Prevention Systemsageetha756No ratings yet

- Manual Despiece Yamaha FZ6 (Ingles)Document0 pagesManual Despiece Yamaha FZ6 (Ingles)felixtamaraNo ratings yet

- Cases Histories and Recent Development of The Sand Compaction PilDocument7 pagesCases Histories and Recent Development of The Sand Compaction PilVetriselvan ArumugamNo ratings yet

- IQT Workshop Manual 2008 PDFDocument210 pagesIQT Workshop Manual 2008 PDFNishanth KallingentavidaNo ratings yet

- Caterpillar Cat D6H TRACK-TYPE TRACTOR (Prefix 5HF) Service Repair Manual Instant Download (5HF00001)Document25 pagesCaterpillar Cat D6H TRACK-TYPE TRACTOR (Prefix 5HF) Service Repair Manual Instant Download (5HF00001)desodicebox22No ratings yet

- Project:: Design Calculations For 35 Ton Gantry CraneDocument5 pagesProject:: Design Calculations For 35 Ton Gantry CranedhanishlNo ratings yet

- Gear Ratio CalculationsDocument4 pagesGear Ratio CalculationsThyagu RajuNo ratings yet

- CalculationDocument50 pagesCalculationDarking1390100% (2)

- Motor Grader: Global VersionDocument20 pagesMotor Grader: Global VersionHussein SayedNo ratings yet

- Chassis System TextDocument58 pagesChassis System TextJordanChanNo ratings yet

- VoguDocument40 pagesVogufranz justin kyle syNo ratings yet

- Operating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersDocument2 pagesOperating Instructions 430-0000-DOK001 en For Helical Gear and Bevel Helical Gear ReducersMahesh Daxini ThakkerNo ratings yet

- TiraktechDocument6 pagesTiraktechRadakovicZoranNo ratings yet

- Attachment ReportDocument1 pageAttachment Reportfire benderNo ratings yet

- Planetary 789 Salvage ProcedureDocument9 pagesPlanetary 789 Salvage ProcedureAlan GonzalezNo ratings yet

- Harvester 9566755522Document2 pagesHarvester 9566755522Ram ParimalamNo ratings yet

- Chapter 15: Helical, Bevel and Worm Gears: The Main Object of Science Is The Freedom and Happiness of ManDocument32 pagesChapter 15: Helical, Bevel and Worm Gears: The Main Object of Science Is The Freedom and Happiness of ManHiresomannavar MahanteshNo ratings yet