Turbulence and Inertia Effects in Bearings

Turbulence and Inertia Effects in Bearings

Uploaded by

Mourad TargaouiCopyright:

Available Formats

Turbulence and Inertia Effects in Bearings

Turbulence and Inertia Effects in Bearings

Uploaded by

Mourad TargaouiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Turbulence and Inertia Effects in Bearings

Turbulence and Inertia Effects in Bearings

Uploaded by

Mourad TargaouiCopyright:

Available Formats

Turbul ence and inertia effects

in bearings

N. A. Macken* and E. A. Saibel t

Thi s arti cl e surveys t urbul ence and i nerti a effects in bearings. The effects occur f or t wo main

reasons - high-speed operati on and t he use of unconvent i onal lubricants. Experi ment al and

theoreti cal studies are considered and recommendati ons are given f or f ut ur e investigation.

N o t a t i o n

C

f

K

L

N

P

R

Re

Re*

T

U

Uo

U

U~

U t

t t r 2 t t

U , I ~ , I ~ , I ) W

V

t

V

X

Y

y+

8~+

e

Cc

EI

0

/a

p

7" W

7" o

0

Clearance

Friction factor = 2r w/ pU 2

Mixing length constant

Mixing length

Bearing length

Angular velocity

Pressure

Mean radius

Reynolds number, UC/v

Reduced Reynolds number, (UC/v) (C/L)

Torque

Tangential velocity of bearing

Core reference velocity used by Reynolds 2s

Mean velocity in tangential direction

Mainstream velocity (from boundary layer

t heory)

Fluctuating component of velocity in

tangential direction

Average fluctuating components

Axial velocity

Mean velocity normal to tangential velocity

Fluctuating component of velocity in

normal direction

Tangential. direction

Direction normal to tangential

Dimensionless distance y/OV~w/P

Constant in Reichardt' s law of the wall

Eccentricity ratio = eccentricity/clearance

Core eddy viscosity

Eddy viscosity

Angle

Absolute viscosity

Density

Bearing shear stress

Scale shear stress used by Reynolds 2s

Kinematic viscosity

* As s i s t a nt Pr of e s s or o f Mechani cal Engi neer i ng, ~" Pr of es s or o f

Appl i ed Me c ha ni c s , Car negi e- Mel l on Uni ver s i t y, Pi t t s bur gh,

Pe nns yl va ni a 15213, USA

In recent years there has been a great deal of interest in

turbulence in bearings. Previous to this, flows that occurred

in lubricant films were laminar in nature. This was borne out

by experiment and also by the agreement between laminar

theory and experiment.

Non-laminar flow occurs in bearings for two main reasons.

The first is high-speed operation. The second is the use of

unconventional lubricants such as water or liquid metals.

These materials are frequently used as process fluids. The

need to simplify equipment design or the difficulty of over-

coming shaft sealing problems lead t o their use as lubricant

as well. A high velocity combined with a low kinematic

viscosity leads t o high Reynolds numbers and departure

from laminar flow.

For the case of journal type bearings, which are the ones

most attention has been given t o, above the laminar range

there is almost always a flow regime in which a vortex

structure exists. As the Reynolds number increases, de-

parture from laminar flow is first recognized by the forma-

tion of Tayl or vortices, named after G. I. Taylor who first

observed this phenomenon. With a furt her increase,

turbulence appears t o occur but some vortex structure

almost always exists, even with higher Reynolds numbers.

Thus the flow is inherently different from the turbulent

flow in pipes, boundary layers, or jets.

Unfortunately, the experimental work that has taken

place has mostly concerned itself with gross measurements

such as torque and load capacity. Not much has been done

to measure quantities such as fluctuating flow components.

Theoretical descriptions of turbulent flow in bearings

have drawn upon mixing length t heory and laws developed

for fully developed flow in pipes. It is obvious from this

brief discussion that such models cannot adequately des-

cribe the flow field. Also, the convective inertia terms have

almost always been neglected in the equations of motion.

These terms are important in high speed flow and it is

thought that some effects attributed to turbulence may be

caused by inertia. Suprisingly enough, these theoretical

analyses have been reasonably successful in predicting

characteristics of bearings operating in this regime. Perhaps

this is because t hey contain adjustable constants that can

be made to fit existing experimental data.

154 TRIBOLOGY August 1972

E x p e r i m e n t a l i n v e s t i g a t i o n s

The earliest work connect ed with bearings outside the

laminar regime was experimental in nature. Many investi-

gations, particularly the early ones, have been visual in

nature. Gross measurements of such quantities as torque

have been used t o indicate non-laminar behavior. A few

studies have used anemomet ry. Limited in-depth studies

have been made of t urbul ent quantities.

The types of bearings studied have mainly been plain

journal bearings. This type of film is most likely to go

beyond the laminar regime. However, interesting variations

of the plain journal such as step journal, helical-grooved

journal bearings or viscoseals have received some attention.

The earliest experiments involved long concentric cylinders.

Later refinements included end effects and eccentricity.

Some recent work has also included blockage and tilted-pad

effects.

Non-laminar flow in bearings has several characteristic

features. Some of these are unique to bearings and some are

found in ot her areas of fluid mechanics. These features

include:

1 A development of secondary vortex flow when the

flow becomes non-laminar. Possible exceptions to this

are flows where ~

C/R < 1/2500

Generally, for bearings this value is around 0.001.

Anot her exception is possibly in the largest clearance

of an eccentric bearing 2 .

2 Secondary flows which are oft en laminar for a large

range of parameters despite their compl ex nature.

Since t hey also are originally stable, there is no reason

that t hey would disappear from the flow field

completely by the presence of turbulence. Some modi-

fication, however, is apparently evident 3 .

3 A three-dimensional flow field which, due t o end leak-

age, is composed of an axial flow in addition to the

tangential flow. As pointed out by Burton 4 , the cir-

cumferential type flow is a Couette type flow whereas

the longitudinal flow is a pressure type flow. The two

types cannot be separated since the flow field is really

a combination of both.

4 Geometric factors such as existence of steps, length of

bearings and the way the lubricant enters the bearing

which all have strong influence.

The term turbulent flow is frequent l y applied in bearing

literature to any flow which is non-laminar. From the above

statements, this is perhaps a misnomer.

The following paragraphs will discuss significant exper-

imental developments in more detail. Table 1 also summarizes

work that has been done.

Concentric cylinders

G. I. Tayl or s was the first t o discover the non-laminar nature

of flow between concentric cylinders. Long concentric

cylinders, with the inner cylinder rotating and the outer

cylinder stationary model full journal bearings with two im-

portant exceptions. They do not show end effects and the

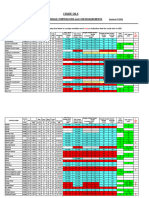

Tabl e 1

Author

Exper i ment al studies o f turbulence and inertia effects in bearings

Type of bearings Measurements made Results

Vohr 2 Eccentric cylinders

Taylor s Concentric

cylinders

Taylor 6 Concentric

cylinders

Schultz-Grunow Concentric

and Hein 7 cylinders

Wilcock 9 Journal bearing

Abramovitz 1 Tilting-pad thrust

bearing

Smith and

Fuller H

Kaye and Elgar 12

Yamada~3,14

Yamada ts

Burton and

Carper 16

Journal bearing

Concentric

cylinders

Rotating coaxial

cylinders

Rotating coaxial

cylinders with

grooves

Concentric

cylinders tilted

pads, short journal,

step pads

Torque against speed, critical speed

e, friction factor against Re, visual

observation

Visual observation I

i

Torque against speed

Visual observation

Power loss against speed, bearing

temperature against speed, oil flow

against speed, eccentricity ratio

against speed, friction coefficient

against speed

Friction coefficient against speed

Friction coefficient against Re,

pressure against 0, eccentricity

against load

Flow fluctuations by hot wire

Torque and pressure

Torque and pressure

Velocity profiles, turbulent

intensities, pressure distribution

Determination of critical speed by the

measurements made

Mathematical description of stability and

confirmation by visual observations

Further confirmation of t he stability

criterion

Examination of the flow stability before

and after the critical speed

Confirmation of the stability criterion by

the distinguished happenings at critical

speed

Friction torque increased abnormally when

speed exceeded what appeared to be a

critical value

Comparisons between laminar flow and the

flow with a speed of five times that of

critical speed.

Division of flow patterns with axial flow

Showed effect of axial flow, agreement

with Ref 12

Extend results in Refs 13, 14 to groove

geometry

Discussed intensity results, comput at i on

of wall shear, pressure jumps at dis-

continuities not ed

TRI BOLOGY August 1972 155

effects of eccentricity. Tayl or analysed mat hemat i cal l y the

stability of incompressible viscous flow in a narrow annulus

between rot at i ng concentric cylinders of infinite length. His

analysis predicted the initial instability for the case of

rotating inner cylinder and fixed out er cylinder t o be in the

form of uni form symmet ri cal vortices or eddies. He also

confirmed bot h the value of the critical speed and the

existence of the pairs of votices by means of fl ow visualiza-

tion, using the flow of water bet ween vertical cylinders with

zero axial velocity. Later on, Tayl or 6 was able t o verify his

stability criterion by a number of torque measurement

experiments. Fig 1 is one of his results showing the relation-

ship bet ween log T/pN 2 and log Np/#. Laminar flow would

be indicated from the solid line. Deviations f r om this indi-

cate the onset of vort ex flow.

Schultz-Grunow and Hein 7 among others have also made

visual observations of the format i on of Tayl or vortices in

concentric cylinders. The vort ex nature of the flow is still

evident, even at a Reynolds number of 2.13 X 10 4 . Pai s

also studied the vortices bet ween concentric cylinders using

hot wire anemomet r y and found t hat the vortices existed at

several hundred times the critical speed.

Eccentric bearings

Wilcock 9 and Abramovi t z t were among the first t o 9bserve.

non-laminar characteristics in real j ournal beatings. Wilcock

performed some experi ment s with non-concentric journal

bearings under loads operating above and below the

Tayl or transition. He also checked the critical,~peed by the

torque measurement technique which Tayl or 6 empl oyed

earlier.

Smith and Fuller l~ investigated an unloaded full journal

bearing and again verified t hat Tayl or' s critical Reynolds

number was actually very close t o the poi nt of departure

f r om laminar behavior (see Fig 2). They were operating in

the vort ex region with probabl y little superimposed

turbulence.

The effect of eccentricity was discussed most compl et el y

by Vohr 2 . He demonst rat ed t hat the transition speed for

onset of vortices increases significantly with eccentricity

ratio and t hat eccentricity has marked effect on friction

factor. Visual results also showed a breakdown i nt o large,

apparent l y irregular eddies in the wide clearance region.

The vort ex structure is i nt act in the narrow region. The

eddies eventually become finer and a vort ex structure

appeared again and persisted up t o the highest Reynolds

number studied.

O .

. J

4 . 5 N + . h . - Inner cylinder rotati ng

C r i t J c a J v a J ! ~ " . O ~ " o

3. 5 ~ d o-a---<~q~L~-~--

i l i l ~ i = i I

2<) 3"0 4 . 0

Log Np /1~

Fig 1 Vari at i on of t orque wi t h speed (from Ref 6)

- 2 . 0

- 2 . 4 f = 0. 078/ ReO' 43f = 2/Re I

- 2 . 8 " %

%

%.

Cri ti cal Re

!

!

I I I i I I I I I

2.6 3"2 3"8

Log Re

Fi g 2 Frictional characteristics of a journal bearing (from

Ref 10

~-- ~ ~r- Turbulent flow

x~ IOOO I r ~ P lus vr t k Laminar" plus vortices

o~ flow

I

2 0 0 4 0 0 6OO

NR 112 C312/v

Fig 3 Flow regime in a bearing wi t h end leakage, C/R =

0.307 ( f r om Ref 11)

a .

Effects o f bearing length

Kaye and Elgar 12 used photographi c and hot wi re tech-

niques t o investigate the effects of end leakage on con-

centri c cyl i nders. Thei r results are shown on Fi g 3. The

vel oci t y V used i n the Reynol ds number on the ordinate

curves is the axi al vel oci t y. Purel y t ur bul ent f l ow onl y

occurs f or axi al f l ow wi t h reasonably hi gh Reynol ds

number, > 1000, an ext remel y hi gh leakage rate f or bearings.

For no leakage no turbul ence was observed.

Yamada13,14,is di d considerable wor k i n thi s area. He

t ook t orque measurements of concentri c cyl i nders wi t h

axi al f l ow. The effect of rectangular grooves was also

studied Is ,

Since most journal bearings have some side leakage, a

combi nat i on of t urbul ent and vortex flow is indicated

for high rotational speeds.

Measurement o f t ur bul ent intensities

Quant i t at i ve measurements of turbul ence have been

measured by Bur t on and Carper 16 . Experi ments were

carried out using a hot wire anemomet er on a large scale

model of a journal bearing. Velocity profiles showed the flow

to be t urbul ent in nature. Measurement of the fluctuating

component u' indicated agreement with pipe flow near the

wall. Away from the wall there was disagreement, possibly

due to the presence of midstream shear stress, which is

absent in pipe flow.

Traugot t ~7 has performed experiments in induced swirling

156 TRI BOLOGY August 1972

flows with bot h tangential and axial flow fields. Measurements

of fluctuating velocity components and turbulent stresses

were taken.

T h e o r e t i c a l i n v e s t i g a t i o n s

Theoretically speaking, there are several problems associated

with non-laminar flow in bearings.

First there is the problem of mathematically determining

the viscous terms that appear in the Navier-Stokes equations.

These mathematical descriptions are basically of t wo types

as described below. Both types have theoretical bases in

fully developed turbulent flow. One met hod is derived from

mixing length theories, and the other is derived from

logarithmic profiles of fully developed t urbul ent pipe flow.

As pointed out earlier, the flow in bearings is much different

than in pipes or boundary layers, where these theories may

be valid.

In conventional lubrication, the inertia terms in the

equations are negligible to the viscous terms. As discussed

below, at high speeds, bot h inertia and turbulence effects

play a role and it is difficult to distinguish between the two.

A third difficulty with the theories is that many of them

are two dimensional. From the experimental discussion, it

should be clear that a three-dimensional model is called for.

Turbulence models and inertia are discussed in more

detail in the following paragraphs. Table 2 summarizes im-

port ant developments.

Table 2 Theoretical studies of turbulence and inertia effects in bearings

Author Turbulence model Type of Bearing Results

Tao ~s

Ta o 19

Chow and Saibel 2

Constantinescu 2t

Constantinescu 22

Arwas, Sternlicht

and Wernick 2a

Reynolds 2s

Ng ~s

Ng and pan27

Elrod and Ng 2s

Chow and Vohr 29

Vohr and Chow a

Kettleborough a9

Constantinescu as

1/7 velocity power law. Blasius law of

friction

Blasius law of friction

Mixing length:

~2 = K 2 y ( C_ y)

Mixing length:

= Ky O<y <C/ 2

= K( C- - y ) C/ 2<y <C

with K = 0.4

Same as Ref 21 except K = 0.2 to

0,4

Same as Ref 20

Law of wall

I

U = ro i 1/0.41

r o s y

~n + 2.4

o

Core velocity

1

U =: Uo - ro ~ f O' / c)

= y * - - 10.7 tanh

0

Same as Ref 26, except applied to

three dimensional flows, assuming

i sot ropy

Same as Ref 26, except also used

core viscosity

ec = 1/56f* l u =- - u l d y

0

Same as Ref 27

Same as Ref 28

Same as Ref 20

Mixing length 22 or eddy viscosity

model 27 can be used

Short journal

bearing

Slider bearing

Slider bearing

Journal bearing

Journal bearing

Journal bearing

and 180 arc

journal bearing

Slider bearing

Couette and

Poiseuille

flow

Full journal

bearing

Full journal

bearing

Helical-grooved

journal bearing

Spiral-grooved

screw seal

Slider bearing

Slider, step

beating

Closed form expressions for pressure

distribution, load capacity and attitude

angle

Expressions for load capacity, friction

force, and power loss

Expressions for pressure distribution, load

capacity friction force and power loss

Velocity profiles, pressure distribution,

and attitude angle

Load capacity and attitude angle. Good

agreement with Smith and Fuller H

Load capacity, attitude angle, and pressure

distribution. Good agreement with Smith

and Fuller n

Pressure distribution and friction stress

distribution in bearing films

Friction characteristics, velocity profile,

and pressure distribution. Not very

favourable agreement

Linearized equations, pressure distribu-

tion, load capacity, attitude angle, and

load against eccentricity ratio. Results

fall between Constantinescu and Smith

and Fuller 11

Developed working formulas using Ng's 26

t heory and incorporated core viscosity

Used linearized t heory. Load against

eccentricity ratio

Sealing coefficient against Reynolds num-

ber. Favourable agreement with 3t and 32.

Included inertia. Load capacity and

friction characteristics: i f onl y inertia is

considered, the results are in qualitative

agreement with Abramovitz t and

Smith and Fuller It

Included inertia. Used integral equation.

Results for slider and step. Also presented

equations for three-dimensional flow

TRI BOLOGY August 1972 157

Tur bul ence model s based on m i x i n g l engt h

Perhaps the simplest way to deal with the t urbul ent model

is to make use of mixing length theory. Assuming no side

leakage and dropping inertia terms, the equat i on of interest

reduces to:

OZu ~ ,

dig = la + (-- p u'v')

The turbulent stress t erm can be written as:

- p u' v' = p~ au gu

ay ay

where ~ is the mixing length Prandtl used for pipe flow, i.e.

= Ky

with K = 0.4. An alternate approach, presented by Tao is'a9

deals with turbulence in an approxi mat e fashion for the case

of short journal bearings and slider bearings. A short journal

bearing is one in which the axial length is small, and the

pressure t erm in the x direction can be neglected. Ta o

comput ed the average flows by using the Blasius law of

friction and the 1]7 velocity profile.

Chow and Saibel 2e solved equations for a slider bearing.

They neglected the laminar friction t erm and also

modified the mixing length model. Constantinescu 21 in an

early work empl oyed a similar mixing length model where:

= Ky O < y < C / 2

= K ( C - y ) C/2 ~ y <~ C

Results were comput ed with constant and variable

viscosity for a journal bearing wi t hout leakage. A comparison

with Smith and FuUer' s experimental results showed poor

agreement, as shown in Fig 4. The aut hor suggested t hat per-

haps a smaller value of K, i.e. K = 0.2 to 0.4 might be more

appropriate because of the small film thickness. In a later

paper, Constantinescu n considers the possibility of side

leakage. This leads t o an additional equation and an

additional turbulence term. The value of the mixing length

is taken to be the same as in his earlier work, 21 . In this

paper, he also recomput es his results for K = 0.3 and shows

bet t er agreement with Smi t h and Fuller. This is surprising

in light of the previous discussion t hat indicated t hat fully

t urbul ent flow was probabl y never reached by the exper-

iments.

Arwas, Sterlicht, and Wernick ~-3 used the same mixing

length approach as Constantinescu 2a in application to a full

journal bearing and a 180 arc journal bearing. Side leakage

was neglected and K = 0.4. Agreement appears as good as

t hat of Constantinescu 2~ .

Tur bul ence model s based on e d d y vi scosi t y

In dealing wi t h fully developed pipe flow, it is well

established 24 t hat the simple mixing length theories given

above do not adequately describe the phenomenon of tur-

bulence. Logarithmic ' laws of the wall' suggested by

Boussinesq, Reichardt and others are used. These laws were

arrived at by fitting fully developed pipe flow data. The

flow field is found to be composed of several regions, each

with a different logarithmic law.

Reynolds zs was one of the first to use this approach in

dealing with bearings. His turbulence model included a wall-

law region and a core flow. His met hod, applied t o a slider

bearing, showed pressures produced in the t urbul ent film

were ten times greater than those in a laminar flow.

04

E

12

u

Q.

- - - T . r , . q = 0

-----Laminar, q - O o / / o~, ~

81 o Experimental, Smith / / ',]

and Fuller o / / i

Re =3310 ~ "" / tl

/ / 0 1

.,."10 / | ,

4 / 1 0

~ J 0

" ' ~ ' ~ ' ~ " ~ 1 I I I I I I

4 0 8 0 120 160

e[o]

F i g 4 Pressure di st r i but i on f o r a journal bearing wi t h o u t

leakage ( f r om Ref 20)

8O0

6 0 0

4OO

2OO

!

I

Cl R 2.93 x I O - 3 i

I

x Smi t h end Fuller I

I

Present theory I

. . . . Constantinescu's analysti~t 7

7 4 5 0 r e v / m l ~ / / /

/ / / / x

. " I aooo .~

, ,

0. 2 0. 4 0 . 6

D

0"8

E c c e n t r i c i t y r a t i o ,

F i g 5 Load against eccent ri ci t y rat i o ( f r om Ref 26)

300O

2 0 0 0

IOOO

z

A widely used t heory for bearings at present is t hat

developed originally by Ng 26 . The viscous t erm in the

Reynolds equation is rewritten in terms of eddy viscosity.

For eddy viscosity, Reichardt' s formula gives

e~ _ K[ . V. _ 6 + ~ t a n h ( ~ + ) ]

Ng found t hat with a value of K 0.4 and 5~ = 10.7 the

above formula reasonably fits all regions of pipe flow data.

This idea has been furt her expanded by Ng and Pan 27 .

They comput ed results for a three-dimensional journal

bearing. To simplify comput at i on, a linearized form of the

equations was used. Results showed much bet t er agreement

with Smith and Fuller' s experi ment t han did Constantinescu' s

analysis as shown in Fig 5.

Elrod and Ng 28 have modified the above t heory by using

a const ant eddy viscosity in the core region, as suggested by

158 T RI BOL OGY August 1972

Clauser. Their comput at i ons also di d not use t he linearized

equat i ons. Results are compar ed t o t he linearized case.

Chow and Vohr 29'3 have applied t he linearized and non-

linearized analyses descri bed above t o hel i cal -grooved and

spiral-grooved bearings. Reasonabl e agreemerit was s hown wi t h

results o f Pape and Vr akki ng 31, as well as Ket ol a and

McGrew 32 . The bearings st udi ed have st ep confi gurat i ons,

and t he results are surprising in t erms of what is ment i oned

bel ow about inertia effects.

Inertia effects

I n t he earl y experi ment al wor k wi t h non-l ami nar fl ow i n

bear i ngs t here appeared i n t he literature muc h discussion as

t o why a depar t ur e f r om l ami nar fl ow occur ed 9 . I t was

suggested t hat t he presence o f t he Tayl or vort i ces i ndi cat ed

an increase in inertia forces in t he fluids. As i ndi cat ed, t he

analytical investigations have by and large i gnored this fact

and have consi dered onl y t urbul ence.

Ar gument s have been made t hat t he inertia forces are still

insignificant compar ed t o t he viscous forces is . Kulinski and

j our nal bearings, st ep j our nal bearings, helical-grooved

beatings and spiral-grooved bearings. The experi ment s

shoul d also st udy t hree-di mensi onal effect s of side leakage,

and di fferent met hods f or i nt r oduci ng t he l ubri cant i nt o t he

bearings.

On t he t heoret i cal side, it seems t hat inertia effects must

be mor e careful l y dealt wi t h and i ncl uded in t he analyses.

There seems little need t o cont i nue t o solve probl ems o f

mor e and more compl exi t y while still neglecting these

terms. Also, t he t urbul ence model s do not adequat el y des-

cribe t he phenomenon t hat is occuri ng in t he non-l ami nar

range o f most bearings. A new model whi ch takes i nt o

account t he vor t ex nat ur e of the fl ow and t hree-di mensi onal

effect s is needed. The measur ement s suggested above can

be used t o devel op these new theories.

Acknowledgements

The survey above was part i al l y suppor t ed by NSF grant

GK-27831. This suppor t is gr at ef ul l yacknowl edged.

Ost rach 39 have per f or med a careful order o f magni t ude

analysis. The y have shown t hat i f t he r educed Reynol ds number Ref erences

Re* = UC/ o( C/ L) ~ 0(1)

t hen t he i nert i a t erms shoul d be ret ai ned in t he equat i ons.

Onl y when Re *<< 1 can t he inertia t erms be omi t t ed f r om

t he equat i ons. Zuk et a134 also discussed inertia effect s and

came t o t he same concl usi ons. I n addi t i on, t hey c omput e d

t he modi f i ed Reynol ds number f or onset of t ur bul ence f or

various experi ment s. The values were of or der one whi ch

suggests t hat inertia effect s may be pl ayi ng a significant role.

It woul d appear t her ef or e, t hat any t heoret i cal st udy o f

t urbul ence woul d have t o i ncl ude inertia as well.

I n addi t i on, Zuk et al a4 , as well as Bur t on (see discussion

in Ref 35) have poi nt ed out t hat near steps or ot her dis-

cont i nui t i es significant inertia effect s are felt. Bur t on 3s also

i ndi cat es t hat i nert i a may be i mpor t ant in shor t bearings as

well.

Pi nkus and St ernl i cht 36 have discussed t he t wo classical

approaches t o t he pr obl em o f how t o deal wi t h inertia. The

averaging me t hod was first f or mul at ed by Osterle and

Saibe137 . The i t erat i on met hod was suggested by Kahl ert 3s ,

The dr awback t o these above approaches is t hat t hey are

bot h appr oxi mat e i n t echni que. Tur bul ence is also not

i ncl uded. Ket t l ebor ough 39 consi dered bot h inertia and

t urbul ence i n his discussion o f a slider bearing. He used

Chow and Saibel' s 2 defi ni t i on o f mi xi ng l engt h. His results

showed t hat t he i ncl usi on of t urbul ence had a compar at i vel y

small effect and caused a slight decrease in l oad capaci t y, in

cont r adi ct i on t o ot her t heoret i cal analyses. The increase in

l oad-carryi ng capaci t y was shown t o be due t o inertia and

not t o t ur bul ence effect s. Wi t h inertia, not t ur bul ence,

i ncl uded i n t he analysis, qualitative agr eement was shown

wi t h the results of Abr amovi t z 1 .

Const ant i nescu in a recent paper 3s has discussed a new

appr oach t o t urbul ence and inertia effects. The integral

equat i ons are used rat her t han t he differential equat i ons of

mot i on. Appr oxi mat e const ant s are used in t he vel oci t y

profiles. The skin fri ct i on vari at i on can be arrived at f r om

mi xi ng l engt h or El rod and Ng' s 2s t heor y. The met hod is

applied t o a slider and st ep bearing. Equat i ons are present ed

f or t hree-di mensi onal flows as well.

Conclusions

Experi ment al i nf or mat i on is sorel y needed t o bet t er des-

cribe t he nat ure of t ur bul ent fl ow in bearings. Such exper-

i ment s shoul d measure mean and f l uct uat i ng component s

1 DiPrima, R. C. ' A note on the stability of flow in loaded

journal bearings', TransAm Soc Lubric Engrs, Vol 6, No 3

(1963) pp 249-253

2 Vohr, J. H. ' An experimental study of Taylor vortices and

turbulence in flow between eccentric rotating cylinders',

Trans Am Soc mech Engrs, J Lubric Technol, Ser F, Vol 90,

No 1 (Jan 1968) pp 285-296

3 Coles, D. 'Transition in circular Couette flow', J Fluid Mech,

V.ol 21, Pt 3 (1965) pp 385-425

4 Burton, R. A. ~rurbulent film bearings under small dis-

placements', Trans Am Soc L ubrqc Engrs, Vol 7, No 4 (1964)

pp 322-332

5 Taylor, G. I. 'Stability of a viscous liquid contained between

two rotating cylinder', Trans R Soc, London, Ser A, Voi 223

(1923) p 289

6 Taylor, G. I. 'Fluid friction between rotating cylinder',

Proc R Soc, London, Set A, Vol 157 (1936) pp 546-564

7 Schultz-Grunow and Hein, H. 'Beitrag zur Couettestromung'

Z/w" Flugwiss, Vol 4 (1956) p 28

8 Pal, S. I. 'Turbulent flow between rotating cylinders',

NACA TN 892 (1943)

9 Wilcock, D. F. 'Turbulence in high speed journal bearings',

TransAm Soc mech Engrs, Vol 72 (1950) pp 825-833

10 Abramovitz, S. 'Turbulence in a tilting pad thrust bearing',

TransAm Soc mech Engrs, Vol 78 (1956) pp 7-11

11 Smith, M. I. and Fuller, D. D. 'Journal bearing operation at

super laminar speeds', TransAm Soc mech Engrs, Vol 73,

(1956) p469

12 Kaye, J. and Elgar, E. C. 'Modes of adiabatic and diabatic

fluid flow in an annulus with an inner rotating cylinder',

TransAm Soc mech Engrs, Vol 80 (1958) pp 753-765

13 Yamada, Y. 'Resi~ance of flow through an annulus with an

inner rotating cylinder', Bull Jap Soc mech Engrs, Vol 5,

No 18 (1962) pp 302-310

14 Yamada, Y. 'Torque resistance of flow between rotating co-

axial cylinders having axial flow', Bull .lap Soc mech Engrs,

Vol 5, No 20 (1962) pp 6344541

15 Yamada, Y. ' On pressure loss of flow between rotating co-

axial cylinders with rectangular grooves', Bull Jap Soc mech

Engrs, Vol 5, No 20 (1962) pp 6424551

16 Burton, R. A. and Carper, H. J. ' An experimental study of

annular flows with applications in turbulent film lubrication',

Trans Am Soc mech Engrs, J Lubric Technol, Vol 89, Set F,

No 3 (Jul 1967) pp 381-391

17 Traugott, S. C. ' Influence on solid-body rotation of screen-

produced turbulence' , NACA Tech Not e, No 4135 (1958)

TRIBOLOGY August 1972 159

18 Tao, L. N. ' A t heory of lubrication in short j ournal bearings

wi t h turbulent fl ow' , Trans A m Soc mech Engrs, Vol 78

(1958) pp 1734-1740

19 Tao, L. N. ' A t heory of lubrication with turbulent flow and

its application to slider bearings' , Tr ans Am Soc mech Engrs,

JappMech, Vol 27, Set E, No 1 (Mar 1960) pp 1-15

20 Chow, V. T. and Saibel, E. ' The effect of turbulence on slider

bearing lubrication' , Trans A m Soc mech Engrs, J appl Mech,

Vol 26, Set E, No 1 (Mar 1959) pp 122-126

21 Constantinescu, V. N. ' On turbulent lubrication' , Proc l nst

mech Engrs, Vol 173, No 38 (1959) pp 881-900

22 Constantinescu, V. N. ' Analysis of bearings operating in

turbulent regime' , Trans A m Soc mech Engrs, J bas Engng,

Vol 84, Ser D, No 1 (Mar 1962) pp 139-151

23 Arwas, E. B., Sternlicht, G. and Wernick, R. J. ' Analysis of

plain cylindrical j ournal bearings in turbulent regime' , Trans

A m Soc mech Engrs, J bas Engng, Vo186, Ser D, No 2

(Jun 1964) pp 387-395

24 Schlichting, H. Boundary layer theory, McGraw Hill, 4th

Edition (1960)

25 Reynolds, A. J. ' Analysis of turbulent bearing films' , J mech

EngngSci, Vol 5, No 3 (1963) pp 258-272

26 Ng, C. W. ' Fl ui d dynamic foundat i on of turbulent lubrication

t heory' , Trans A m Soc L ubric Engrs, Vol 7, No 4 (1964)

pp 311-321

27 Ng, C. W., and Pan, C. H. T. ' A linearized turbulent lubrication

t heory' , Trans A m Soc mech Engrs, J bas Engng, Vol 87,

Ser D, No 3 (1965) pp 675-688

28 Ekod, H. G. Jr and Ng, C. W. ' A t heory of turbulent fluid

films and its application to bearings' , TransAm Soc mech

Engrs, JLubr i c Technol, Vol 89, Ser F, No 3 (Jul (1967)

pp 346-362

29 Chow, C. Y. and Vohr, J. H. ' Hefical grooved j ournal bearing

operated in turbulent regime' , Trans Am Soc mech Engrs, J

Lubric Technol, Vol 92, Set F, No 2 (Apr 1970) pp 346-358

30 Vohr, J. H. and Chow, C. Y. ' Theoretical analysis of spiral-

grooved screw seal for turbulent operation' , Trans A m Soe

mech Engrs, JLubr i c Technol, Vol 91, Ser F, No 4 (Oct 1969)

pp 675-686

31 Pape, J. G. and Vrakking, W. J. 'Viscoseal-pressure generation

and friction loss under turbulent conditions' , Trans A m Soc

Lubric Engrs, Vol 11, No 4 (1968) pp 310-320

32 Ketoia, H. N. and McGrew, J. M. ' Turbulent operation of the

viscoseal', Trans Am Soc Lubric Engrs, Vol 10, No 3 (1967)

pp 256-272

33 Kulinski, E. S. and Ostrach, S. ' A critical evaluation of the

status and trends in high speed fluid film lubrication' ,

NASA Cr 1058 (1968)

34 Zuk, J. et al. ' Convective inertia and gas ingestion effects on

flow regimes of the viscoseal t heory and experiment' , Trans

A m Soc Lubric Engrs, Vol 10, No 3 (1967) pp 273-293

35 Constantinescu, V. N. ' On the influence on inertia forces in

turbulent and laminar self-acting films' , Trans A m Soc mech

Engrs, JLubr i c Technol, Vol 92, Ser F, No 3 (Jul 1970)

pp 473-481

36 Pinkus, O. P. and Sternficht, B. Theory o f hydrodynamic

lubrication, McGraw Hill ( 1961)

37 Ostede, F. and Saibel, E. ' On the effect of lubricant inertia

in hydrodynami c lubrication' , ZAMP, Vol 6 (1955) p 334

38 Kahlert, W. ' Der einflurs der tragheitskrafte bei der hydro-

dynamischen schmiermiteltheorie' , Ing-Arch, Vol 16 (1947)

p 321

39 Kettleborough, C. F. ' Turbul ent and inertia flow in slider

bearings' , Tr ans Am Soc Lubric Engrs, Vol 8, No 3 (1965)

pp 286-295

cr ieal

r e v i e ws i n

t " rlb ogy

1970

The f i r st issue of a new annual publ i cat i on

cri t i cal reviews in t r i b o l o g y

is now available.

The Leeds Industri al Uni t of Tr i bol ogy have scanned all the worl d' s l i terature in t r i bol ogy

f or 1970 and classified i t i nt o si x categories: devel opments - cont act , f r i ct i on and wear

- l ubri cat i on and l ubri cants - materials - mechanisms - i ndustri al appl i cati ons. Thi s

l i terature has been cr i t i cal l y reviewed by leading aut hori t i es in the f i el d, under the

General Edi t orshi p of Professor D. Dowson. In addi t i on t o the reviews, the publ i cat i on

contai ns a compl ete bi bl i ography, and a subject i ndex. 100 pages A4 size.

cri t i cal reviews in t r i b o l o g y 1 9 7 0 c o s t s 6 a copy, or 4 f or subscribers t o TRI BOLOGY.

Ai r mail postage 1. 50 extra. Order your copy now from"

Sales Manager, IPC Science and Technol ogy Press Lt d,

32 Hi gh Street, Gui l df or d, Surrey, England

160 TRIBOLOGY August 1972

You might also like

- Flow Over A Circular CylinderDocument6 pagesFlow Over A Circular CylinderMOFEEZALAMNo ratings yet

- Grashof NumberDocument6 pagesGrashof NumberNasser93No ratings yet

- Speed Chart Mabre PumpDocument2 pagesSpeed Chart Mabre PumpIsrael Gibran Cañas RodriguezNo ratings yet

- Annular Pressure Seals and Hydrostatic Bearings: Luis San AndrésDocument36 pagesAnnular Pressure Seals and Hydrostatic Bearings: Luis San AndrésisidropeNo ratings yet

- Ramberg 1983Document27 pagesRamberg 1983Pavan YadavNo ratings yet

- Review: Turbine and Related Flowmeters: !. Industrial PracticeDocument15 pagesReview: Turbine and Related Flowmeters: !. Industrial PracticemohmehrNo ratings yet

- SPE-167950-PA YPL Rot Ecc BuckledDocument15 pagesSPE-167950-PA YPL Rot Ecc BuckledAdam LyleNo ratings yet

- Articulo Taylor - CouetteDocument38 pagesArticulo Taylor - CouetteAlvaro HerreraNo ratings yet

- Drag Reduction Characteristics in Straig PDFDocument10 pagesDrag Reduction Characteristics in Straig PDFoswaldo58No ratings yet

- Vu2016 Article NumericalInvestigationOfFlowAr1Document10 pagesVu2016 Article NumericalInvestigationOfFlowAr1VU Huy CongNo ratings yet

- Bentley 1986Document43 pagesBentley 1986brouuorbNo ratings yet

- Proc Appl Math and Mech - 2009 - Scurtu - Numerical and Experimental Study of The Flow in An Eccentric Couette TaylorDocument2 pagesProc Appl Math and Mech - 2009 - Scurtu - Numerical and Experimental Study of The Flow in An Eccentric Couette TaylorAmn Elec EsiNo ratings yet

- Experimental Analysis of Pressure Drop in CTUDocument39 pagesExperimental Analysis of Pressure Drop in CTUVirginia SitompulNo ratings yet

- Chapter VI - Flow in Pipes - Part 1 2Document37 pagesChapter VI - Flow in Pipes - Part 1 2Omar Ashraf 3amerNo ratings yet

- Flow Past A Rotating CylinderDocument33 pagesFlow Past A Rotating CylinderBình Lê ĐứcNo ratings yet

- Review of Tilting Pad Lubrication TheoryDocument24 pagesReview of Tilting Pad Lubrication Theoryhimadri.banerji60No ratings yet

- European Journal of Mechanics B/Fluids: Roland Kádár, Corneliu BalanDocument10 pagesEuropean Journal of Mechanics B/Fluids: Roland Kádár, Corneliu BalanlubangjarumNo ratings yet

- Nagaraj AbstractDocument3 pagesNagaraj AbstractHistoria De VidaNo ratings yet

- Journal Euro MechDocument34 pagesJournal Euro MechShyam nathNo ratings yet

- Vu2016 Article NumericalSimulationOfFlowPastT-1Document11 pagesVu2016 Article NumericalSimulationOfFlowPastT-1VU Huy CongNo ratings yet

- Gate ValveDocument5 pagesGate ValveMohit VermaNo ratings yet

- Lecture 7Document87 pagesLecture 7Christian Rogel De TorresNo ratings yet

- A Review of Tilting Pad Bearing TheoryDocument31 pagesA Review of Tilting Pad Bearing TheoryJose Luis RattiaNo ratings yet

- Badalamenti 2008Document17 pagesBadalamenti 2008dichauvinNo ratings yet

- Numerical Study On The Effect of Shape Modi Fication To The Flow Around Circular CylinderDocument27 pagesNumerical Study On The Effect of Shape Modi Fication To The Flow Around Circular CylinderKai ZhangNo ratings yet

- Fluid Kinetic Energy As A Selection Criteria For Control ValvesDocument13 pagesFluid Kinetic Energy As A Selection Criteria For Control ValvesBruno ManzettiNo ratings yet

- Studies of The Rotating-Disk Boundary-Layer FlowDocument70 pagesStudies of The Rotating-Disk Boundary-Layer FlowKaram AlmasriNo ratings yet

- Mechanism of Stall and Surge in A Centrifugal Compressor With A Variable Vaned DiffuserDocument10 pagesMechanism of Stall and Surge in A Centrifugal Compressor With A Variable Vaned DiffuserIsmail SakrNo ratings yet

- 2013 AlamDocument11 pages2013 AlamPavan YadavNo ratings yet

- Seo 2011Document23 pagesSeo 2011BS GOURISARANNo ratings yet

- GATE 1991-2013 Topic Wise Solution PDFDocument89 pagesGATE 1991-2013 Topic Wise Solution PDFGanesh VishwanadhNo ratings yet

- IJATES Paper Anil LorDocument8 pagesIJATES Paper Anil LorNirmal SinghNo ratings yet

- Lecture EM08Document22 pagesLecture EM08sbarzani902No ratings yet

- Performance Analysis of Centrifugal Pump's Impeller of Low Specific Speed For Various Designs and Validation of Result by CFDDocument7 pagesPerformance Analysis of Centrifugal Pump's Impeller of Low Specific Speed For Various Designs and Validation of Result by CFDIDESNo ratings yet

- Cipc 2009-042Document7 pagesCipc 2009-042Ralf JonesNo ratings yet

- Flow Analysis Experiment Around A Circular Cylinder With Splitter PlateDocument12 pagesFlow Analysis Experiment Around A Circular Cylinder With Splitter PlateTJPRC PublicationsNo ratings yet

- File 1Document10 pagesFile 1lubangjarumNo ratings yet

- Jeas 0315 1746Document7 pagesJeas 0315 1746Subhram GhoshNo ratings yet

- 2010 - Laminar Flow Past An Oscillating Circular Cylinder in Cross FlowDocument8 pages2010 - Laminar Flow Past An Oscillating Circular Cylinder in Cross FlowheloverNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document7 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- SQ 24Document11 pagesSQ 24Vikram C KNo ratings yet

- E0f9 PDFDocument6 pagesE0f9 PDFnikhil tiwariNo ratings yet

- A Bi - Directional Gas Thrust BearingDocument9 pagesA Bi - Directional Gas Thrust Bearingshahir93No ratings yet

- Flowmeter Installation EffectsDocument12 pagesFlowmeter Installation EffectsgykataiNo ratings yet

- Hydrodynamics Characterization of Rotor-Stator Mixer With Viscous FluidsDocument10 pagesHydrodynamics Characterization of Rotor-Stator Mixer With Viscous FluidsRaul DionicioNo ratings yet

- Unit 4Document236 pagesUnit 4karthikNo ratings yet

- Numerical Study of Mass Transfer Enhancement in Coiled Flow InverterDocument35 pagesNumerical Study of Mass Transfer Enhancement in Coiled Flow InverternitinsethiyaNo ratings yet

- Applied Mathematical Modelling: S.J. Karabelas, B.C. Koumroglou, C.D. Argyropoulos, N.C. MarkatosDocument20 pagesApplied Mathematical Modelling: S.J. Karabelas, B.C. Koumroglou, C.D. Argyropoulos, N.C. MarkatosNMarkatosNo ratings yet

- Draft Tube SurgesDocument33 pagesDraft Tube SurgesvesselNo ratings yet

- 1 s2.0 S0889974617300701 MainDocument17 pages1 s2.0 S0889974617300701 MainJairo Javier Díaz MontenegroNo ratings yet

- Mixing VarietiesDocument64 pagesMixing VarietiesManojkumarNo ratings yet

- Control ValveDocument13 pagesControl ValveRatnakar PatilNo ratings yet

- Hydrodynamic Simulation of Cyclone SeparatorsDocument25 pagesHydrodynamic Simulation of Cyclone SeparatorsgamadaNo ratings yet

- Analysis by CFD For Flow Past Circular and Square CylinderDocument5 pagesAnalysis by CFD For Flow Past Circular and Square CylinderKhaled ChaibNo ratings yet

- Hydrodynamic Performance of A Surfboard FinDocument4 pagesHydrodynamic Performance of A Surfboard FinWesley FernandesNo ratings yet

- 2008 Liquid Loading in A Gas Well 2008Document9 pages2008 Liquid Loading in A Gas Well 2008Jamshed SoomroNo ratings yet

- Rensheng Deng, Mak Yechyn, Chi-Hwa Wang and Kenneth A. Smith September, 2005 UnpublishedDocument10 pagesRensheng Deng, Mak Yechyn, Chi-Hwa Wang and Kenneth A. Smith September, 2005 UnpublishedlubangjarumNo ratings yet

- Nagaraj PaperDocument7 pagesNagaraj Paperknightfelix12No ratings yet

- Types of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyFrom EverandTypes of Valves in Piping: Types of Valves - Tables to estimate man hours of assemblyNo ratings yet

- Confort Thermique PDFDocument25 pagesConfort Thermique PDFMourad TargaouiNo ratings yet

- Ingénierie Thermique Illustration PDFDocument16 pagesIngénierie Thermique Illustration PDFMourad TargaouiNo ratings yet

- Irrigation - IllustrationDocument10 pagesIrrigation - IllustrationMourad TargaouiNo ratings yet

- Tous Actualités Maps Vidéos Plus Paramètres Outils: ImagesDocument3 pagesTous Actualités Maps Vidéos Plus Paramètres Outils: ImagesMourad TargaouiNo ratings yet

- A Thermohydrodynamic Method ofDocument9 pagesA Thermohydrodynamic Method ofMourad TargaouiNo ratings yet

- An Exact Analytical Solution of The Reynolds Equation For The Finite JournalDocument13 pagesAn Exact Analytical Solution of The Reynolds Equation For The Finite JournalMourad TargaouiNo ratings yet

- Boon Traduction NasaDocument114 pagesBoon Traduction NasaMourad TargaouiNo ratings yet

- Cavitation Along: SlainDocument5 pagesCavitation Along: SlainMourad TargaouiNo ratings yet

- Tribology International: Shih-Kang Chen, Hsien-Chin Chou, Yuan KangDocument14 pagesTribology International: Shih-Kang Chen, Hsien-Chin Chou, Yuan KangMourad TargaouiNo ratings yet

- Wear, 44 (1977) 329: 343 0 Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsDocument15 pagesWear, 44 (1977) 329: 343 0 Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsMourad TargaouiNo ratings yet

- Génie Mécanique: Institute of Mechanical EngineeringDocument1 pageGénie Mécanique: Institute of Mechanical EngineeringMourad TargaouiNo ratings yet

- Products and Services: Rockwin's Certifications IncludeDocument4 pagesProducts and Services: Rockwin's Certifications IncludeGIL ENGINEERNo ratings yet

- Coriolis Flowmeter Calculation Summary: Condensate Tank - CMFS040M - FCSDocument1 pageCoriolis Flowmeter Calculation Summary: Condensate Tank - CMFS040M - FCSHashemAliHashemNo ratings yet

- Applications OfViscosityDocument16 pagesApplications OfViscosityJAWAD AHMAD BURTNo ratings yet

- Belinda AbekahDocument104 pagesBelinda AbekahManuel ChNo ratings yet

- معلومات الزيوت للرفاعاتDocument9 pagesمعلومات الزيوت للرفاعاتApo ghasan Al shargapiNo ratings yet

- FLUID POWER SYSTEMS Theory and PracticeDocument31 pagesFLUID POWER SYSTEMS Theory and PracticeRAMAR MNo ratings yet

- 07 June 2017 Dr.C.Senthil KumarDocument9 pages07 June 2017 Dr.C.Senthil Kumarmaran2326No ratings yet

- Crude OilsDocument21 pagesCrude Oilsiskatelsea18No ratings yet

- Prac 2 Without AnswersDocument6 pagesPrac 2 Without AnswersTitsarosal ThomasNo ratings yet

- Heat and Mass Transfer Guia ARTICULOSDocument240 pagesHeat and Mass Transfer Guia ARTICULOSCarlos MartínezNo ratings yet

- Mod 3.1 Design and Performance Analysis of Centrifugal CompressorsDocument31 pagesMod 3.1 Design and Performance Analysis of Centrifugal Compressorsinamul hasanNo ratings yet

- Chapter 9.3 ASTM D6822Document3 pagesChapter 9.3 ASTM D6822Munia AkterNo ratings yet

- Eastern Refinery Limited: Furnace Fuel To F1101Document2 pagesEastern Refinery Limited: Furnace Fuel To F1101Kaisar JamilNo ratings yet

- Performance Evaluation of A Water Treatment Plant (Case Study)Document4 pagesPerformance Evaluation of A Water Treatment Plant (Case Study)Chan KianNo ratings yet

- Heat Transfer Operations: CBE 322aDocument19 pagesHeat Transfer Operations: CBE 322atsaipeterNo ratings yet

- Water DemandDocument10 pagesWater DemandKristal SepiNo ratings yet

- Fluid Mechanics - I: DR Muhammad Sajid Assistant Professor Nust, SmmeDocument26 pagesFluid Mechanics - I: DR Muhammad Sajid Assistant Professor Nust, SmmeAsaad WaqarNo ratings yet

- Trap Mechanism in Hydrocarbon MigrationDocument51 pagesTrap Mechanism in Hydrocarbon MigrationReddy Setyawan100% (3)

- Sistem Perpipaan: Darcy-Weisbach Diagram MoodyDocument32 pagesSistem Perpipaan: Darcy-Weisbach Diagram MoodyRezi OktaviandriNo ratings yet

- Belimo CCV - Databook - V8.6 - 05.2017 PDFDocument136 pagesBelimo CCV - Databook - V8.6 - 05.2017 PDFkautukNo ratings yet

- Fluid MechanicsDocument1 pageFluid MechanicsKurt MarfilNo ratings yet

- Multiphase FlowDocument15 pagesMultiphase FlowvictorvikramNo ratings yet

- Crude Tower Simulation (Aspen Plus V8.6)Document53 pagesCrude Tower Simulation (Aspen Plus V8.6)Nabeel SiddiqueNo ratings yet

- Globe Valve À Soupape À DisqueDocument6 pagesGlobe Valve À Soupape À Disqueفوزي بنصرNo ratings yet

- Boundary Layer Theory Problems Sheet - I - 2017 - 18Document1 pageBoundary Layer Theory Problems Sheet - I - 2017 - 18Abhyuday Sharma100% (1)

- Lecture 32Document45 pagesLecture 32diwali 2022No ratings yet

- Saybolt Viscosity: Standard Test Method ForDocument7 pagesSaybolt Viscosity: Standard Test Method ForLizbeth AbrilNo ratings yet

- Fluid03 ZBDocument102 pagesFluid03 ZBZain MustafaNo ratings yet