0 ratings0% found this document useful (0 votes)

149 viewsThis Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

Uploaded by

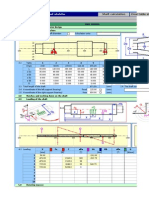

pablo_stzThis document provides information on the calculation of a bevel gear pair using the KISSsoft software. It contains 3 warnings regarding the material properties used in the calculation not matching standard recommendations. The document then details the geometry, materials, and loads used to model Gears 1 and 2, which are case-hardened steel bevel gears with 36 and 8 teeth respectively. Tables provide dimensions and values for factors influencing the root bending stress calculation for each gear. The root bending stresses calculated are 32464 psi for Gear 1 and 21723 psi for Gear 2.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

Uploaded by

pablo_stz0 ratings0% found this document useful (0 votes)

149 views7 pagesThis document provides information on the calculation of a bevel gear pair using the KISSsoft software. It contains 3 warnings regarding the material properties used in the calculation not matching standard recommendations. The document then details the geometry, materials, and loads used to model Gears 1 and 2, which are case-hardened steel bevel gears with 36 and 8 teeth respectively. Tables provide dimensions and values for factors influencing the root bending stress calculation for each gear. The root bending stresses calculated are 32464 psi for Gear 1 and 21723 psi for Gear 2.

Original Title

KISS Casa

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information on the calculation of a bevel gear pair using the KISSsoft software. It contains 3 warnings regarding the material properties used in the calculation not matching standard recommendations. The document then details the geometry, materials, and loads used to model Gears 1 and 2, which are case-hardened steel bevel gears with 36 and 8 teeth respectively. Tables provide dimensions and values for factors influencing the root bending stress calculation for each gear. The root bending stresses calculated are 32464 psi for Gear 1 and 21723 psi for Gear 2.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

149 views7 pagesThis Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

This Kisssoft Demoversion May Not Be Used For Professional Application ! Important Hint: at Least One Warning Has Occurred During The Calculation

Uploaded by

pablo_stzThis document provides information on the calculation of a bevel gear pair using the KISSsoft software. It contains 3 warnings regarding the material properties used in the calculation not matching standard recommendations. The document then details the geometry, materials, and loads used to model Gears 1 and 2, which are case-hardened steel bevel gears with 36 and 8 teeth respectively. Tables provide dimensions and values for factors influencing the root bending stress calculation for each gear. The root bending stresses calculated are 32464 psi for Gear 1 and 21723 psi for Gear 2.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 7

1/7

KISSsoft Release 03/2013

KISSsoft-Demo-Version KISSsoft AG CH-8634 Hombrechtikon

File

Name : BevelGear 5 (Gleason)

Description: KISSsoft example

Changed by: JPM am: 13.10.2013 um: 09:18:12

This KISSsoft demoversion may not be used

for professional application !

Important hint: At least one warning has occurred during the calculation:

1-> Gear 1:

The sat and sac material data may not match the values stated in AGMA 2001 or 2101.

2-> Gear 2:

The sat and sac material data may not match the values stated in AGMA 2001 or 2101.

3-> Materials in KISSsoft database are according to the recommendations of AGMA2001 (cylindrical gears).

Indications for sat and sac acc. AGMA2003 (bevel gears) differ partly.

You can modify the values by adjusting the material data using 'Own input'.

BEVEL-GEAR-CALCULATION (BEVEL-GEAR-PAIR)

Drawing or article number:

Gear 1: 0.000.0

Gear 2: 0.000.0

Calculation method Bevel gear AGMA 2003-C10

Geometry calculation according ISO 23509:2006, method 1

Constant slot width, fig 2 (Gleason)

Manufacture process: lapped

Spiral toothing

Face milling (single indexing method)

Cutter radius (in) [rc0] 7.50

------- GEAR 1 -------- GEAR 2 -------

Power (hp) [P] 292.02

Speed (1/min) [n] 1000.0 222.2

Rotation direction, wheel 1, viewed on cone tip: left

Torque (ft*lbf) [T] 1533.7 6901.6

Gear driving (+) / driven (-) + -

Overload factor [Ko] 1.00

Required service life [H] 1000.00

1. TOOTH GEOMETRY AND MATERIAL

------- GEAR 1 -------- GEAR 2 -------

Hypoid offset (in) [a] 0.000

Shaft angle () [Sigma] 90.000

Mean normal module (in) [mmn] 0.3150

Pressure angle at normal section () [alfn] 20.000

Mean spiral angle () [betm] 35.0000

Hand of gear left right

2/7

Number of teeth [z] 8 36

Facewidth (in) [b] 2.76 2.76

Assumed and measured contact pattern width (in) [be] 2.76 2.76

Accuracy grade [Q-ISO17485] 7 7

Internal diameter gearbody (in) [di] 0.000 0.000

Pitch apex to front of gear blank (in) [yi] 5.681 1.805

Pitch apex to back of gear blank (in) [yo] 8.440 2.798

H misalignment (P misalignment) (mil) [DeltaH] 0.000

G misalignment (mil) [DeltaG] 0.000

V misalignment (E misalignment) (mil) [DeltaV] 0.000

Material

Gear 1: 17NiCrMo6-4, Case-carburized steel, case-hardened

ISO 6336-5 Figure 9/10 (MQ), core strength >=25HRC Jominy J=12mm<HRC28

Gear 2: 17NiCrMo6-4, Case-carburized steel, case-hardened

ISO 6336-5 Figure 9/10 (MQ), core strength >=25HRC Jominy J=12mm<HRC28

Surface hardness HRC 60 HRC 60

(lb/in), (N/mm) (lb/in), (N/mm)

Allowable bending stress number [sat] 62366, 430.00 62366, 430.00

Allowable contact stress number [sac] 217557, 1500.00 217557, 1500.00

Tensile strength (lbf/in) [Rm] 174046.02 174046.02

Yield point (lbf/in) [Rp] 123282.60 123282.60

Young's modulus (lbf/in) [E] 29877900 29877900

Poisson's ratio [ny] 0.300 0.300

Mean roughness, Ra, tooth flank (mil) [RAH] 0.02 0.02

Mean roughness height, Rz, flank (mil) [RZH] 0.19 0.19

Mean roughness height, Rz, root (mil) [RZF] 0.79 0.79

Tool or reference profile of gear 1 :

Reference profile (Own input) Eigene Eingabe

Dedendum coefficient [hfP*] 1.181

Root radius factor [rhofP*] 0.211

Addendum coefficient [haP*] 0.960

Tip radius factor [rhoaP*] 0.000

Tip form height coefficient [hFaP*] 0.000

Protuberance height factor [hprP*] 0.000

Protuberance angle [alfprP] 0.000

Ramp angle [alfKP] 0.000

not topping

Tool or reference profile of gear 2 :

Reference profile (Own input) Eigene Eingabe

Dedendum coefficient [hfP*] 1.181

Root radius factor [rhofP*] 0.211

Addendum coefficient [haP*] 0.960

Tip radius factor [rhoaP*] 0.000

Tip form height coefficient [hFaP*] 0.000

Protuberance height factor [hprP*] 0.000

Protuberance angle [alfprP] 0.000

Ramp angle [alfKP] 0.000

not topping

Summary of reference profile gears:

Dedendum reference profile (in module) [hfP*] 1.181 1.181

Root radius reference profile (in module) [rofP*] 0.211 0.211

3/7

Addendum reference profile (in module) [haP*] 0.960 0.960

Protuberance height coefficient (in module) [hprP*] 0.000 0.000

Protuberance angle () [alfprP] 0.000 0.000

Tip form height coefficient (in module) [hFaP*] 0.000 0.000

Ramp angle () [alfKP] 0.000 0.000

Type of profile modification:

none (only running-in)

Tip relief (mil) [Ca] 0.1 0.1

No modification at tip circle

Lubrication type oil bath lubrication

Type of oil Oil: ISO-VG 150

Lubricant base Mineral-oil base

Kinem. viscosity oil at 40 C (cSt) [nu40] 150.00

Kinem. viscosity oil at 100 C (cSt) [nu100] 13.00

FZG test A/8.3/90 ( ISO 14635-1:2006) [FZGtestA] 12

Specific density at 15 C (lb/ft) [roOil] 55.686

Oil temperature (F) [TS] 212.000

------- GEAR 1 -------- GEAR 2 -------

Overall transmission ratio [itot] -4.500

Gear ratio [u] 4.500

Outer spiral angle () [bete] 40.469 40.469

Mean spiral angle () [betm] 35.000 35.000

Inner spiral angle () [beti] 30.400 30.400

Pinion offset angle in axial plane () [zetm] 0.000

Pinion offset angle in pitch plane () [zetmp] 0.000

Offset in pitch plane (in) [ap] 0.000

Outer normal module (in) [men] 0.3494

Outer transverse module (in) [met] 0.4593 0.4593

Mean normal module (in) [mmn] 0.3150

Mean transverse module (in) [mmt] 0.3846 0.3846

Inner normal module (in) [min] 0.2673

Inner transverse module (in) [mit] 0.3099 0.3099

Sum of profile shift coefficients [xhm1+xhm2] 0.0000

Profile shift coefficient [xhm] 0.2307 -0.2307

Undercut boundary [xhmmin] 0.2307 -15.6455

Tooth thickness modification coefficient [xsmn] 0.0000 -0.0000

Outer pitch diameter (in) [de] 3.675 16.535

Outer tip diameter (in) [dae] 4.625 16.665

Outer root diameter (in) [dfe] 2.956 16.294

Mean pitch diameter (in) [dm] 3.077 13.845

Mean tip diameter (in) [dam] 3.809 13.945

Mean root diameter (in) [dfm] 2.492 13.652

Inner pitch diameter (in) [di] 2.479 11.155

Inner tip diameter (in) [dai] 2.992 11.225

Inner root diameter (in) [dfi] 2.028 11.011

Addendum (in) [hae] 0.487 0.298

(in) [ham] 0.375 0.230

(in) [hai] 0.263 0.161

Dedendum (in) [hfe] 0.368 0.557

(in) [hfm] 0.299 0.445

4/7

(in) [hfi] 0.231 0.333

Tooth height (in) [he] 0.855 0.855

(in) [hm] 0.674 0.674

(in) [hi] 0.494 0.494

Working depth (in) [whe] 0.785

(in) [whm] 0.605

(in) [whi] 0.424

Tip clearance (in) [ce] 0.070 0.070

(in) [cm] 0.070 0.070

(in) [ci] 0.070 0.070

Outer cone distance (in) [Re] 8.469 8.469

Mean cone distance (in) [Rm] 7.091 7.091

Inner cone distance (in) [Ri] 5.713 5.713

Pitch angle () [delta] 12.529 77.471

Face angle () [dela] 17.176 80.317

Addendum angle () [thea=dela-delta] 4.647 2.845

Root angle () [delf] 9.683 72.824

Dedendum angle () [thef=delta-delf] 2.845 4.647

Distance along axis to crossing point (in) [txo] 8.162 1.546

(in) [txi] 5.520 1.082

Distance apex to crossing point (in) [tz] 0.000 0.000

(in) [tzF] -0.680 -0.124

(in) [tzR] 0.315 0.137

Distance in axial direction to the cone tip (in) [ye] 8.268 1.837

(in) [yae] 8.162 1.546

(in) [yai] 5.520 1.082

Theoretical tip clearance (in) [c] 0.070 0.070

Effective tip clearance (in) [c.e/i] 0.070 / 0.070 0.070 / 0.070

Characteristic values for sizing [Re2/b2] 3.073

[b2/mmn] 8.748

2. FACTORS OF GENERAL INFLUENCE

Effective facewidth (in) [F,b] 2.76

Nominal transverse load at operating pitch circle (lbf) [Ftw] 11963.7

Nominal circum. force at pitch circle (lbf) [Ft] 11963.7

Axial force (lbf) [Fa] 9330.7 3371.9

Radial force (lbf) [Fr] 3371.9 9330.7

Normal force (lbf) [Fnorm] 15542.3

Circumferential speed at dm (m/sec) [vm] 4.09

Circumferential speed at de (m/sec) [ve] 4.89

Load distribution modifier [Kmb] 1.000

Load distribution factor [Km,KHb] 1.027

Transmission accuracy grade number [Qv] 10

Dynamic factor [Kv] 1.133

Number of load cycles (in mio.) [NL] 60.000 13.333

3. TOOTH ROOT STRENGTH

------- GEAR 1 -------- GEAR 2 -------

Size factor [KS, Yx] 0.5847 0.5847

(in) , (mm) (in) , (mm)

Bending lever arm (in) [hN] 0.012, 0.30 0.009, 0.23

Tooth thickness at critical section [2*sN] 0.601, 15.27 0.732, 18.61

5/7

Radius at curvature of fillet curve [rfm] 0.087, 2.22 0.069, 1.76

Load angle () [alfh] 21.35 19.38

Tooth form factor Y [Y] 0.503 1.018

Stress correction factor [Kf] 2.006 2.559

Cutter radius (in) [rc0] 7.500

Tooth lengthwise correction factor [Kx,Ybet] 1.000

Bending strength geometry factor J [J] 0.166 0.248

(lb/in), (N/mm) (lb/in), (N/mm)

Bending stress number [st] 32464, 223.83 21723, 149.77

Stress cycle factor [KL,YNT] 0.986 1.012

(for general applications)

(lb/in), (N/mm) (lb/in), (N/mm)

Allowable bending stress number [sat] 62366, 430.00 62366, 430.00

Temperature factor [KT] 1.00 1.00

Reliability factor [KR,YZ] 1.00

Reverse loading factor [-] 1.000 1.000

Effective allow. b.s.n. [sateff] 61474, 423.85 63142, 435.35

Bending strength power rating (hp) [Pat] 552.96( 412.34 kW) 848.81( 632.95 kW)

Note: Pat calculated with Ko=1, KR=1, SFmin=1

Safety factor (foot) [sateff/st] 1.89 2.91

Required safety factor [SFmin] 1.00 1.00

Transmittable power [Pat/SFmin] 552.96( 412.34 kW) 848.81( 632.95 kW)

AGMA2003, Annex C(M):

hfe1 = 0.368 in hfe2 = 0.557 in rhoao1= 0.066 in rhoao2= 0.066 in

s1 = 0.539 in s2 = 0.435 in thef1= 2.85 thef2= 4.65

Y1 = 0.50 Yf1 = 2.01 YK1 = 0.25 epsNJ= 1.00 Yi = 1.02

rmyo1= 1.656 in rmpt1= 1.576 in b1' = 2.115 in b1 = 2.756 in

Y2 = 1.02 Yf2 = 2.56 YK2 = 0.40 epsNJ= 1.00 Yi = 1.02

rmyo2= 33.218 in rmpt2= 31.911 in b2' = 2.012 in b2 = 2.756 in

4. SAFETY AGAINST PITTING (TOOTH FLANK)

------- GEAR 1 -------- GEAR 2 -------

(lb^.5/in), (N^.5/mm)

Elastic coefficient [Cp,ZE] 2285.3, 189.81

Size factor [Cs,Zx] 0.782 0.782

Crowning factor [Cxx,Zxx] 1.500

Geometry factor I [I] 0.1131

(lb/in), (N/mm)

Contact stress number [sc,sigH] 249769, 1722.10

Stress cycle factor [CL,ZNT] 1.185 1.297

(for general applications)

Hardness ratio factor [CH,ZW] 1.00 1.00

Temperature factor [KT] 1.00 1.00

Reliability factor [CR,ZZ] 1.00

(lb/in), (N/mm) (lb/in), (N/mm)

Allowable contact stress number [sac] 217557, 1500.00 217557, 1500.00

Effective allow. c.s.n. (lb/in) [saceff] 257740, 1777.05 282166, 1945.47

Pitting resistance power rating (hp) [Pac] 310.95( 231.87 kW) 372.68( 277.91 kW)

Note: Pac calculated with Ko=1, KR=1, SHmin=1

Safety factor (flanc) [saceff/sc] 1.03 1.13

Required safety factor [SHmin] 1.00 1.00

Transmittable power [Pac/SHmin^2] 310.95( 231.87 kW) 372.68( 277.91 kW)

6/7

AGMA2003, Annex C(M):

Re = 8.469 in hae1 = 0.487 in hae2 = 0.298 in de1 = 3.675 in de2 = 16.535 in

del1 = 12.53 del2 = 77.47 dela1= 17.18 dela2= 80.32

p2 = 1.311 in gan1 = 0.793 in gan2 = 0.660 in gc = 1.452 in

rhoy0= 0.966 in mmt = 0.385 in met = 0.459 in

Zi = 0.040 in epsNI= 0.99

SERVICE FACTORS:

Service factor for tooth root [KSF] 1.89 2.91

Service factor for pitting [CSF] 1.06 1.28

Service factor for gear set [SF] 1.06

Note: Service factors are calculated with Ko=1, KR=1

Transmittable power including required service factors KSFmin, CSFmin (hp) 310.95( 231.87 kW)

KSFmin = 1.00, CSFmin = 1.00

4c. Safety of the hardened layer (EHT) according to DNV41.2:2012

Required hardening depth EHT (in) [t550] 0.03/ 0.03 0.03/ 0.03

Required hardness at t550 (HV) [HV.t] 550 550

Condition for hardness on the surface (HV) [HV.0] > 676 (HRC 60) > 676 (HRC 60)

Safety of the hardened layer [SEHT] 0.78 0.78

Required safety [SHssmin] 1.00 1.00

Result 3 3

(-1:Not checked 0:EHT too small 1:EHT too great or HV.0 too low 2:EHT too great (> 0.25*mn) 3,4:Proved)

6. ALLOWANCES FOR TOOTH THICKNESS

------- GEAR 1 -------- GEAR 2 -------

Tooth thickness deviation Own Input Own Input

Tooth thickness allowance (normal section) (in) [As.e/i] -0.006 / -0.009 -0.006 / -0.009

The following data apply on the middle of the facewidth:

Tooth thickness (chordal) in pitch diameter (in) [smnc] 0.546 0.442

(in) [smnc.e/i] 0.540 / 0.538 0.436 / 0.433

Reference chordal height from dam (in) [hamc] 0.391 0.230

Circumferential backlash (in) [jmt] 0.020 / 0.015

(in) [jet] 0.024 / 0.018

Normal backlash (in) [jmn] 0.016 / 0.012

(in) [jen] 0.018 / 0.013

7. GEAR ACCURACY

------- GEAR 1 -------- GEAR 2 --

According to ISO 17485:2006:

Accuracy grade [Q-ISO17485] 7 7

(Diameter (in) [dT] 3.39 13.78)

Single pitch deviation (mil) [fpT] 0.87 0.94

Total cumulative pitch deviation (mil) [FpT] 2.64 3.35

Concentricity deviation (mil) [FrT] 2.09 2.68

7/7

Tangential tooth-to-tooth composite deviation (mil)

[fisTmax/fisTmin] 1.57/ 0.00 1.57/ 0.00

(fisTmax, fisTmin: ISO 17485:2006, Table B1, q=2)

Total tangential composite deviation (mil) [FisT] 4.21 4.92

9. DETERMINATION OF TOOTHFORM

Data for the tooth form calculation :

Data not available.

10. ADDITIONAL DATA

Input data for calculating the gear measurements according to ISO 23509:2006

Data of type 1 (according to table 3, ISO 23509:2006):

xhm1= 0.2307 khap= 0.9595 khfp= 1.1809 xsmn= 0.0000

Data of type 2 (according to table 3, ISO 23509:2006):

cham= 0.3798 kd= 1.9190 kc= 0.1154 kt= 0.0000

Calculation according to

Niemann

Mean coeff. of friction (acc. Niemann) [mum] 0.078

Wear sliding coef. by Niemann [zetw] 0.770

Power loss from gear load (hp) [PVZ] 4.754

Meshing efficiency (%) [etaz] 98.372

Weight - calculated with da (lb) [Mass] 8.804 26.156

End of Report lines: 357

You might also like

- Bf40D - Bf50D Remote Control Type Wiring DiagramDocument1 pageBf40D - Bf50D Remote Control Type Wiring DiagramJoe75% (4)

- Acroba SerManual FA15-30Document190 pagesAcroba SerManual FA15-30Vasile Vrabie100% (4)

- Essentials of Business Communication 10th Edition Guffey Test Bank 1Document36 pagesEssentials of Business Communication 10th Edition Guffey Test Bank 1brittneybyrdocsxdfgkyq100% (45)

- Worm DriveDocument6 pagesWorm DriveRavi Kiran MeesalaNo ratings yet

- SPLINEDocument6 pagesSPLINEDaggupati PraveenNo ratings yet

- CX1Document7 pagesCX1acceleron8No ratings yet

- KissoftDocument7 pagesKissoftGopi Krishnan VNo ratings yet

- Program PT AngrenajeDocument7 pagesProgram PT AngrenajeBalla AttilaNo ratings yet

- Sugar Beet Conveyor Belt Gear Box-Pinion-11kwDocument4 pagesSugar Beet Conveyor Belt Gear Box-Pinion-11kwShabanali OmraniNo ratings yet

- Calculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDocument10 pagesCalculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationM036No ratings yet

- Calculation of A Helical Gear: 1. Tooth Geometry and MaterialDocument4 pagesCalculation of A Helical Gear: 1. Tooth Geometry and MaterialChetan PrajapatiNo ratings yet

- Gear Pair 1 GearDocument2 pagesGear Pair 1 GearYunji GuNo ratings yet

- M1 5xZ59xX-0 3225x25L-RA-1 5VSWK de enDocument2 pagesM1 5xZ59xX-0 3225x25L-RA-1 5VSWK de enYunji GuNo ratings yet

- Bevel-Gear-Calculation (Bevel-Gear-Pair) : 1. Tooth Geometry and MaterialDocument1 pageBevel-Gear-Calculation (Bevel-Gear-Pair) : 1. Tooth Geometry and MaterialPIRATASANTANANo ratings yet

- O.GB - gp1.gp1: Calculation of A Helical Gear PairDocument102 pagesO.GB - gp1.gp1: Calculation of A Helical Gear PairS.DasguptaNo ratings yet

- Helical Gear Calculation Using SoftwareDocument10 pagesHelical Gear Calculation Using SoftwareM036No ratings yet

- KS Worm Gear-Sample ReportDocument3 pagesKS Worm Gear-Sample ReportMarco ViniciusNo ratings yet

- Calculation of A Cylindrical Spur Gear: Tooth Geometry and MaterialDocument4 pagesCalculation of A Cylindrical Spur Gear: Tooth Geometry and Materialepdsan3dNo ratings yet

- ReportDocument29 pagesReportvikasanandg6264No ratings yet

- Teague's ShaftDocument145 pagesTeague's ShaftBUDAPESNo ratings yet

- Gear2 02aDocument5 pagesGear2 02aΚυριάκος ΒαφειάδηςNo ratings yet

- Design and Calculation ShaftDocument115 pagesDesign and Calculation ShaftDavid Lambert100% (3)

- Gear 40nDocument10 pagesGear 40nSantosh Kumar ReddyNo ratings yet

- Important Hint: at Least One Warning Has Occurred During The CalculationDocument8 pagesImportant Hint: at Least One Warning Has Occurred During The CalculationS.DasguptaNo ratings yet

- Proračun 4.brzinaDocument11 pagesProračun 4.brzinaJurmanNo ratings yet

- Report_ShortDocument6 pagesReport_Shortvikasanandg6264No ratings yet

- Calculation of A Helical Gear Pair: 1. Tooth Geometry and MaterialDocument9 pagesCalculation of A Helical Gear Pair: 1. Tooth Geometry and Materialanush_swaminathanNo ratings yet

- f2 BP 2018 Cvikyr Martin Priloha I Kisssoft VysledkyDocument11 pagesf2 BP 2018 Cvikyr Martin Priloha I Kisssoft VysledkyKarthikeyan NatarajanNo ratings yet

- Planetry GearsDocument10 pagesPlanetry Gearsvinu1175No ratings yet

- 14-54 8m-Inetermediate-3Document10 pages14-54 8m-Inetermediate-3epdsan3dNo ratings yet

- Calculation of A Helical Gear Pair: 1. Tooth Geometry and MaterialDocument14 pagesCalculation of A Helical Gear Pair: 1. Tooth Geometry and Materialsumeetsaini88No ratings yet

- 13-55 4m-Inetermediate-1Document10 pages13-55 4m-Inetermediate-1epdsan3dNo ratings yet

- O.Groupbox - Gearpairconst1.Gearpairconst1 - Calc: Calculation of A Cylindrical Spur Gear PairDocument55 pagesO.Groupbox - Gearpairconst1.Gearpairconst1 - Calc: Calculation of A Cylindrical Spur Gear PairSunil AundhekarNo ratings yet

- Kissoft 15,69,0.4Document10 pagesKissoft 15,69,0.4Daggupati PraveenNo ratings yet

- Important Hint: at Least One Warning Has Occurred During The CalculationDocument8 pagesImportant Hint: at Least One Warning Has Occurred During The CalculationDemir HamzicNo ratings yet

- 2300rpm Max Output TorqueDocument8 pages2300rpm Max Output TorqueRavi Kiran MeesalaNo ratings yet

- 175 Own InputDocument8 pages175 Own Inputsantosh kumarNo ratings yet

- Ta 32 Api 613 Agma 6011 Geometry CalculationDocument9 pagesTa 32 Api 613 Agma 6011 Geometry Calculationahp2011No ratings yet

- Report of DesignDocument42 pagesReport of Designamir sadighiNo ratings yet

- Spur Gearing, Helical Gearing (mm/ISO)Document6 pagesSpur Gearing, Helical Gearing (mm/ISO)oman1148No ratings yet

- Calculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDocument9 pagesCalculation of A Cylindrical Spur Gear Pair: Important Hint: at Least One Warning Has Occurred During The CalculationDaggupati PraveenNo ratings yet

- Output Gear Avoid Under CutDocument10 pagesOutput Gear Avoid Under CutDaggupati PraveenNo ratings yet

- Tes 5Document11 pagesTes 5Nasim ZafariNo ratings yet

- Tes 2Document11 pagesTes 2Nasim ZafariNo ratings yet

- Important Hint: at Least One Warning Has Occurred During The CalculationDocument9 pagesImportant Hint: at Least One Warning Has Occurred During The CalculationS.DasguptaNo ratings yet

- Proračun Vratila 3.brzinaDocument17 pagesProračun Vratila 3.brzinaJurmanNo ratings yet

- Kiss SoftDocument10 pagesKiss SoftDaggupati PraveenNo ratings yet

- Calculo Flecha TerminadoDocument149 pagesCalculo Flecha TerminadoSebastián ValenciaNo ratings yet

- Proračun Vratila 2.brzinaDocument17 pagesProračun Vratila 2.brzinaJurmanNo ratings yet

- Output Gear Root SafetyDocument10 pagesOutput Gear Root SafetyDaggupati PraveenNo ratings yet

- Rolling Bearing Analysis Calculation Method: ISO 281:2007 Und Herstellerangaben - With Modified Bearing Service Life According To ISO 281:2007Document2 pagesRolling Bearing Analysis Calculation Method: ISO 281:2007 Und Herstellerangaben - With Modified Bearing Service Life According To ISO 281:2007Santosh Kumar ReddyNo ratings yet

- Calculation of A Helical-Toothed Cylindrical Gear Pair: Tooth Geometry and MaterialDocument6 pagesCalculation of A Helical-Toothed Cylindrical Gear Pair: Tooth Geometry and Materialepdsan3dNo ratings yet

- Sa Backlash DinDocument3 pagesSa Backlash Dinsantosh kumarNo ratings yet

- KISSsoft Release 03Document15 pagesKISSsoft Release 03ali.sayyady.zavoshteNo ratings yet

- Gear4 02Document101 pagesGear4 02pratapslairNo ratings yet

- FlenderDocument2 pagesFlenderpablo_stzNo ratings yet

- Aluminum-Bronze Sand Castings: Standard Specification ForDocument5 pagesAluminum-Bronze Sand Castings: Standard Specification Forpablo_stzNo ratings yet

- Influence of Gear Surface Roughness, Lubricant Viscosity and Quality Level On ISO 6336 Calculation of Surface DurabilityDocument25 pagesInfluence of Gear Surface Roughness, Lubricant Viscosity and Quality Level On ISO 6336 Calculation of Surface Durabilitypablo_stzNo ratings yet

- Agma 910-C90Document35 pagesAgma 910-C90pablo_stz100% (3)

- Des CatalogDocument4 pagesDes CatalogthinboyNo ratings yet

- Epx2032 - I 548 8Document135 pagesEpx2032 - I 548 8Eduardo GreinacherNo ratings yet

- D9R تنظیمات زنجیر بلدوزرDocument5 pagesD9R تنظیمات زنجیر بلدوزرmidalllllNo ratings yet

- Re98057 - 0802 ShemaDocument16 pagesRe98057 - 0802 ShemaHasse Hasib SejdinovićNo ratings yet

- Contoh Penawaran HargaDocument2 pagesContoh Penawaran HargaKurniawan FebryNo ratings yet

- Technical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsDocument6 pagesTechnical Data: Concentrate Control Valve Applications, Priming Connections, and TrimsAhmed ElbarbaryNo ratings yet

- TAL 044 LS 5674k - enDocument16 pagesTAL 044 LS 5674k - enJermaine PeñaNo ratings yet

- Experimental Investigation of Pedal Driven Hacksaw: Sreejith K., Aravind K., Danie Davis, Farish K.A., George JohnsonDocument5 pagesExperimental Investigation of Pedal Driven Hacksaw: Sreejith K., Aravind K., Danie Davis, Farish K.A., George JohnsonChandanSuriyaNo ratings yet

- Hex Key ChartDocument1 pageHex Key ChartMassimoNo ratings yet

- 01air Elect Feb2015Document27 pages01air Elect Feb2015juanNo ratings yet

- Gas Control & Regulation Products: Solenoid, Motorised & Pneumatic Control ValvesDocument2 pagesGas Control & Regulation Products: Solenoid, Motorised & Pneumatic Control ValvesPune Gas Service TeamNo ratings yet

- Combinacion Diales MecanicosDocument5 pagesCombinacion Diales MecanicosHo MeGaNo ratings yet

- Testing Adjusting GD 16 M UpdateDocument110 pagesTesting Adjusting GD 16 M UpdateAhmad NawawiNo ratings yet

- Industrial Visit Report To Shakurbasti and TRTCDocument46 pagesIndustrial Visit Report To Shakurbasti and TRTCRachit Goel0% (1)

- Manual Recambios 4008TAG2A DGB082339 PDFDocument141 pagesManual Recambios 4008TAG2A DGB082339 PDFsxturbo100% (1)

- Farm EquipmentsDocument8 pagesFarm EquipmentsJoey Ramirez Marasigan100% (2)

- Leitz - Lexicon - Edition - 7 - 07 - Prihvatni - I - Stezni - Dijelovi - EnglDocument71 pagesLeitz - Lexicon - Edition - 7 - 07 - Prihvatni - I - Stezni - Dijelovi - EnglJura OkrešaNo ratings yet

- Running Inspection Checklists - Modified (2789)Document19 pagesRunning Inspection Checklists - Modified (2789)Samir SavadogoNo ratings yet

- Perkins 2300 P/NDocument3 pagesPerkins 2300 P/NAdel ArosiNo ratings yet

- Motor Korando g20dfDocument36 pagesMotor Korando g20dfNicolas MendezNo ratings yet

- Hc-E102z New Next IiDocument9 pagesHc-E102z New Next IiLe Thanh SonNo ratings yet

- SteeringDocument52 pagesSteeringRamón Eduardo ColmenaresNo ratings yet

- Ford Telstar Mazda MX6 y 626Document6 pagesFord Telstar Mazda MX6 y 626rafael oswaldo lara rodriguezNo ratings yet

- Torque Density of PM MotorsDocument7 pagesTorque Density of PM MotorsDantam RaoNo ratings yet

- 14OBDG02 Engine DiagnosticsDocument502 pages14OBDG02 Engine DiagnosticsVASEK100% (1)

- EE-416 ProblemDocument2 pagesEE-416 ProblemImEngineeringCracklings0% (2)

- General Purpose Engine: GX35NTDocument61 pagesGeneral Purpose Engine: GX35NTwilber fletesNo ratings yet

- 17 Technical Maintenance: 17.1 Types of Maintenance and Maintenance IntervalsDocument16 pages17 Technical Maintenance: 17.1 Types of Maintenance and Maintenance Intervalsm.dumitraNo ratings yet