Machinist 12812 7

Machinist 12812 7

Uploaded by

Raya DuraiCopyright:

Available Formats

Machinist 12812 7

Machinist 12812 7

Uploaded by

Raya DuraiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Machinist 12812 7

Machinist 12812 7

Uploaded by

Raya DuraiCopyright:

Available Formats

MICHIGAN CIVIL SERVICE COMMISSION

JOB SPECIFICATION

MACHINIST

JOB DESCRIPTION

Employees in this job perform and oversee maintenance, repair, and fabrication work

requiring the skillful use of a variety of metal machining tools and precision measuring

devices to cut, grind, or otherwise shape metal and plastic parts into conformance with

specified dimensions.

There are two classifications in this job.

Position Code Title Machinist-E

Machinist E9

This is the experienced level. The employee performs a full range of machinist

assignments using independent judgement to make decisions requiring the application

of procedures and practices to specific work situations.

Position Code Title Machinist-A

Machinist 10

This is the advanced level. The employee functions as a crew leader, overseeing the

work of lower-level Machinists and others, and performs journey-level machinist

assignments; or, as a senior worker performing duties which have been recognized by

Civil Service as having greater complexity than those assigned at the experienced level.

JOB DUTIES

NOTE: The job duties listed are typical examples of the work performed by

positions in this job classification. Not all duties assigned to every

position are included, nor is it expected that all positions will be assigned

every duty.

Studies specifications, blueprints, or damaged tools and machine parts to determine

nature and dimension of parts to be fabricated.

Selects metallic and nonmetallic materials to be machined and measures, marks, or

scribes dimensions and reference points on to stock preparatory to machining

operations.

Sets up and operates lathes, milling machines, precision grinders, drill presses, band

saws, shapers and other powered metal-working tools to machine parts to specified

dimensions.

MACHINIST

PAGE NO. 2

Uses precision measuring devices such as height gauges, micrometers, vernier calipers

and dial indicators to verify conformance of machinist pieces to specifications.

Uses mechanics hand tools such as files, scrapers, mallets, wrenches, screwdrivers,

and riveters to fit and assemble parts and assemblies.

Operates machines and other mechanisms to observe operation and diagnose

malfunctions or to test repaired equipment.

Keeps inventory of stock and orders new materials as needed.

Keeps records and reports use of equipment.

Develops specifications from general description of parts or assemblies to be fabricated

and draws or sketches device to be made.

Operates bench grinder to sharpen cutting tools.

Operates gas or electric welders to install finished assemblies or to join or build up

metal surfaces of parts to be machined or repaired.

Performs routine or preventive maintenance and repair, lubrication and cleaning of

machine tools, equipment and mechanical, electrical, and hydraulic systems such as

laundry, bakery, kitchen, automotive, farm and power plant equipment.

Designs and constructs jigs and special tools to facilitate the machining, assembly, or

disassembly of parts and assemblies.

Makes estimates of time and materials required to complete an assignment.

May assist in the training of Trades Helpers and others.

Performs related work as assigned.

Additional Job Duties

Machinist 10 (Lead Worker)

Coordinates work by scheduling assignments and overseeing the work of others.

Provides instruction and training in the proper methods and processes to carry out

assignments.

Oversees and assures the work quality and flow by directing the strict adherence to

methods and procedures.

Explains work instructions and adapts, if necessary, pertinent general methods and

procedures in order to meet the needs of special projects.

MACHINIST

PAGE NO. 3

Machinist 10 (Senior Worker)

Develops, modifies, designs and tests prototypes.

Creates complex or non-routine Computer Numerically Controlled (CNC) milling

machine programs.

Selects and machines exotic materials (i.e. aluminum, abrasion resistant steel)

emphasizing efficient operation and minimal cutting, tool wear and/or breakage.

Performs non-routine machine shop maintenance and repair, lubrication and cleaning of

machine tools, equipment and mechanical, electrical and hydraulic systems.

Develops, designs or performs complex repairs on various tools, machines or

equipment, of a specialized nature for state and/or non state entities.

Serve as a subject matter expert when reviewing and recommending equipment

usability, life expectancy and salvage potential.

Provides guidance and instruction on agency specialized equipment and machining

processes.

JOB QUALIFICATIONS

Knowledge, Skills, and Abilities

NOTE: Considerable knowledge is required at the experienced level and

thorough knowledge is required at the advanced level.

Knowledge of the methods, practices, tools and equipment of the machinist trade.

Knowledge of the machining qualities, properties and uses of various metals such as

aluminum, brass, steel, cast iron and stainless steel.

Skill in the operation of machine tools and the use of precision measuring devices.

Ability to apply machinist craft techniques, processes and principles.

Ability to apply shop mathematics to practical problems such as computing dimensions,

laying out work, and setting up machine tools.

Ability to read and work from sketches, specifications, and blueprints.

Additional Knowledge, Skills, and Abilities

Machinist 10 (Lead Worker)

Ability to train and instruct others in the work.

MACHINIST

PAGE NO. 4

Ability to assign work to employees.

Ability to prioritize and evaluate the work of others.

Ability to organize and coordinate the work of the unit.

Machinist 10 (Senior Worker)

Ability to perform the most complex machining assignments.

Ability to program and operate complex computerized machining equipment.

Working Conditions

Some jobs require an employee to be exposed to a hazardous work environment.

Physical Requirements

The job duties require an employee to move heavy objects.

Education

No specific amount is required.

Experience

Machinist E9

Four years of experience assisting a skilled machinist in a general machine shop.

Machinist 10

Five years of experience in the machine trade, including one year equivalent to a

Machinist E9.

Special Requirements, Licenses, and Certifications

None.

NOTE: Equivalent combinations of education and experience that provide

the required knowledge, skills, and abilities will be evaluated on an

individual basis.

MACHINIST

PAGE NO. 5

JOB CODE, POSITION TITLES AND CODES, AND COMPENSATION INFORMATION

Job Code Job Code Description

MACHINIST Machinist

Position Title Position Code Pay Schedule

Machinist-E MACHNSTE A31-010

Machinist-A MACHNSTA A31-012

ECP Group 1

Revised 07/13/10

LP/MF

You might also like

- Mechanical FitterDocument9 pagesMechanical Fitterjayaarnav50% (2)

- Beyond Greed and FearDocument279 pagesBeyond Greed and Fearreviur100% (13)

- The Complete Guide To Day TradingDocument295 pagesThe Complete Guide To Day Tradingholtla95% (77)

- Astm A480-A480m (2022)Document25 pagesAstm A480-A480m (2022)faruk öztürk100% (3)

- J S Office Machines Repairer: M D C SDocument3 pagesJ S Office Machines Repairer: M D C SYeron GelayeNo ratings yet

- Job Class - Senior Mechanical Maintenance TechnicianDocument7 pagesJob Class - Senior Mechanical Maintenance TechnicianAvina NigNo ratings yet

- Arshad CVDocument4 pagesArshad CVAli BaseejiNo ratings yet

- Millwright ResumeDocument6 pagesMillwright Resumeafiwgzsdf100% (2)

- Resume For MaintenanceDocument7 pagesResume For Maintenanceaqquwuekg100% (1)

- Job Description of MachinistDocument2 pagesJob Description of MachinistBalram JiNo ratings yet

- Mechanical Maintenance Technician - 2412Document3 pagesMechanical Maintenance Technician - 2412HASSAIN NAWAZNo ratings yet

- Mechanical Technician ResumeDocument4 pagesMechanical Technician Resumetazyz0vod1l3100% (1)

- Trades HelperDocument3 pagesTrades Helperjokelo2429No ratings yet

- Mechanic SupervisorDocument3 pagesMechanic SupervisorFharishPutraNo ratings yet

- Masood Jaffri CVDocument3 pagesMasood Jaffri CVmonkey000No ratings yet

- JD FabricatorDocument8 pagesJD Fabricatorkrishna73566256No ratings yet

- CNC Lathe Operator Resume SampleDocument4 pagesCNC Lathe Operator Resume Sampleuyyjcvvcf100% (2)

- Maintenance Tech ResumeDocument8 pagesMaintenance Tech Resumeafazakemb100% (2)

- English Advert - HME Machinist JDDocument2 pagesEnglish Advert - HME Machinist JDBarry MurphyNo ratings yet

- MechanicDocument3 pagesMechanicJacob LeysonNo ratings yet

- Plumber Resume ExamplesDocument6 pagesPlumber Resume Examplesapuanzzgf100% (1)

- Industrial Electrician ResumeDocument5 pagesIndustrial Electrician Resumee768938t100% (1)

- Resume For Welder JobDocument5 pagesResume For Welder Jobbetevopelah3100% (2)

- Executive Operation (Factory)Document2 pagesExecutive Operation (Factory)Ketan VadorNo ratings yet

- Metal Fabricator WelderDocument2 pagesMetal Fabricator WelderPravin VisputeNo ratings yet

- Machine Shop SupervisorsDocument16 pagesMachine Shop Supervisorsphutthawongdanchai041215No ratings yet

- Mahesha P K Resume 2023Document18 pagesMahesha P K Resume 2023JohnCarterNo ratings yet

- Power Plant Engineer Ii 529Document2 pagesPower Plant Engineer Ii 529Rico HutasoitNo ratings yet

- Advert - RubberlinerDocument4 pagesAdvert - RubberlinerJoseph buluguNo ratings yet

- Echanical Ngineer: Tasks Basic Educational RequirementDocument1 pageEchanical Ngineer: Tasks Basic Educational RequirementNinoy C CarranzaNo ratings yet

- Mechanic Resume SkillsDocument5 pagesMechanic Resume Skillsg1hulikewes2100% (2)

- Building Maintenance ResumeDocument6 pagesBuilding Maintenance Resumeafjwdudgyodbef100% (2)

- MECHANICAL ENGINEER MAINTENANCE Asset Maintenance 1718787962Document2 pagesMECHANICAL ENGINEER MAINTENANCE Asset Maintenance 1718787962Halliday Gerald DabokikaNo ratings yet

- Heavy Equipment Mechanic Resume Cover LetterDocument7 pagesHeavy Equipment Mechanic Resume Cover Letterafmrgjwjcowaov100% (1)

- Machine Operator ResumeDocument5 pagesMachine Operator Resumemklfhaegf100% (1)

- Daniel Magana: Cell: 918-808-6229 Email: DOB: 8/18 SSN#: 25096 SummaryDocument4 pagesDaniel Magana: Cell: 918-808-6229 Email: DOB: 8/18 SSN#: 25096 SummaryKishan DabhiNo ratings yet

- Heavy Duty Equipment MechanicDocument13 pagesHeavy Duty Equipment Mechanic69v29snjcmNo ratings yet

- Cameron Job Descriptions 8 16 13Document10 pagesCameron Job Descriptions 8 16 13Khan FaizanNo ratings yet

- Craftsmen Training Scheme (CTS) NSQF Level - 5Document12 pagesCraftsmen Training Scheme (CTS) NSQF Level - 5St. Stephen ITI KattanamNo ratings yet

- Process Engineer Manufacturing EngineerDocument4 pagesProcess Engineer Manufacturing Engineerapi-121388837No ratings yet

- Welding Skills ResumeDocument7 pagesWelding Skills Resumeafdlxeqbk100% (1)

- Resume Examples For Maintenance TechnicianDocument5 pagesResume Examples For Maintenance Technicianbcqv1trr100% (2)

- Assembler ResumeDocument6 pagesAssembler Resumebcr1xd5a100% (2)

- Mechanical Engineering Technician - 312512 - SampleDocument8 pagesMechanical Engineering Technician - 312512 - Samplebhavesh11563No ratings yet

- CV Rahul K - MH2 A - 035417Document4 pagesCV Rahul K - MH2 A - 035417Rahul KumarNo ratings yet

- Shahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Document7 pagesShahid.A.siddiqui Rotating Equipment Engineer (Maintenance & Installation) Mobile: +919934975939 (India) Skype Id: Shahidsiddiqui1984Sikander GirgoukarNo ratings yet

- DutyDocument19 pagesDutyRahmar ullah suzanNo ratings yet

- Design DutiesDocument5 pagesDesign DutiesKailas NimbalkarNo ratings yet

- Methods Research Jobs RequirementsDocument11 pagesMethods Research Jobs RequirementsJherel BerinNo ratings yet

- Electrical Supervisor Resume SampleDocument5 pagesElectrical Supervisor Resume Sampleafiwiaufk100% (2)

- Position Summary:: Winnipeg, MBDocument10 pagesPosition Summary:: Winnipeg, MBZaman Bhuiyan100% (1)

- Ernani D. Ubalde: ObjectiveDocument4 pagesErnani D. Ubalde: Objectiveernani ubaldeNo ratings yet

- Mechanical Engineering 2013 PDFDocument24 pagesMechanical Engineering 2013 PDFsarosathishcNo ratings yet

- Resume For WelderDocument7 pagesResume For Welderfsva0jkd100% (1)

- Chief Building Engineer ResumeDocument6 pagesChief Building Engineer Resumee7648d37100% (1)

- CNC Machine Operator ResumeDocument6 pagesCNC Machine Operator Resumebzmf6nm1100% (1)

- Industrial Training Report - I: Wickramanayake HMKSK E/96/307Document44 pagesIndustrial Training Report - I: Wickramanayake HMKSK E/96/307Ahmad BukhariNo ratings yet

- Resume EngineDocument8 pagesResume Engineafiwiafoc100% (2)

- Heavy Equipment Mechanic SupervisorDocument3 pagesHeavy Equipment Mechanic SupervisorMaha ManiNo ratings yet

- Welding - Instructor: Job RequirementsDocument5 pagesWelding - Instructor: Job RequirementsKentDemeterioNo ratings yet

- Airframe and Powerplant Resume ExamplesDocument6 pagesAirframe and Powerplant Resume Examplesgt58x6w9100% (1)

- Mechanical Engineer - Static & Rotry - ThanzeelDocument5 pagesMechanical Engineer - Static & Rotry - ThanzeelMuhammed ThanzeelNo ratings yet

- Savings Account De-Linkage FormDocument1 pageSavings Account De-Linkage FormRaya DuraiNo ratings yet

- Airtel USSD CodeDocument7 pagesAirtel USSD CodeRaya Durai100% (1)

- FnowebclnDocument1 pageFnowebclnRaya DuraiNo ratings yet

- Demat Account De-Linkage FormDocument1 pageDemat Account De-Linkage FormRaya DuraiNo ratings yet

- Revised List of Charges 4 Dec 12Document1 pageRevised List of Charges 4 Dec 12Raya DuraiNo ratings yet

- StudyGuide MachinistDocument30 pagesStudyGuide MachinistRaya Durai100% (1)

- Weekly View:: Nifty Likely To Trade in Range of 6600-6800Document14 pagesWeekly View:: Nifty Likely To Trade in Range of 6600-6800Raya DuraiNo ratings yet

- Tata Steel: CMP: INR452 TP: INR496 BuyDocument10 pagesTata Steel: CMP: INR452 TP: INR496 BuyRaya DuraiNo ratings yet

- Regd. Office: Exchange Plaza, Bandra Kurla Complex, Bandra (E), Mumbai - 400 051 Page 1 of 1Document1 pageRegd. Office: Exchange Plaza, Bandra Kurla Complex, Bandra (E), Mumbai - 400 051 Page 1 of 1Raya DuraiNo ratings yet

- Job Description CNC Machinist (Advanced) : Key Skills and CompetenciesDocument2 pagesJob Description CNC Machinist (Advanced) : Key Skills and CompetenciesRaya DuraiNo ratings yet

- Technidex: Stock Futures IndexDocument3 pagesTechnidex: Stock Futures IndexRaya DuraiNo ratings yet

- Tele Register July'13 AbinayaDocument1 pageTele Register July'13 AbinayaRaya DuraiNo ratings yet

- Index Analysis: Technical Outlook - 3 March'14Document3 pagesIndex Analysis: Technical Outlook - 3 March'14Raya DuraiNo ratings yet

- Daily Technical Report: Sensex (21120) / Nifty (6277)Document4 pagesDaily Technical Report: Sensex (21120) / Nifty (6277)Raya Durai100% (1)

- Weekly View:: Nifty Likely To Trade in Range of 6600-6800Document14 pagesWeekly View:: Nifty Likely To Trade in Range of 6600-6800Raya DuraiNo ratings yet

- Enq Analysis of Sept 2013 - BiDocument3 pagesEnq Analysis of Sept 2013 - BiRaya DuraiNo ratings yet

- Abinaya DSMR - Report 2013Document54 pagesAbinaya DSMR - Report 2013Raya DuraiNo ratings yet

- Daily Activity Report - TejasreDocument53 pagesDaily Activity Report - TejasreRaya Durai100% (1)

- Oct Nov Dec Date Attendance Date Attendance Date AttendanceDocument2 pagesOct Nov Dec Date Attendance Date Attendance Date AttendanceRaya DuraiNo ratings yet

- Rigid Link. Turning Pair. Self-Closed. Constrained With 1 DOFDocument8 pagesRigid Link. Turning Pair. Self-Closed. Constrained With 1 DOFRafiaNo ratings yet

- CNC Technology and CNC Programming: Integrated Manufacturing SystemsDocument137 pagesCNC Technology and CNC Programming: Integrated Manufacturing SystemsDavid RodriguezNo ratings yet

- Yanmar Shop - Fig 11. Engine Mount SchematicDocument3 pagesYanmar Shop - Fig 11. Engine Mount SchematicAUNG NAINGNo ratings yet

- CNC Guide Book PDFDocument256 pagesCNC Guide Book PDFYounes Elhamri100% (1)

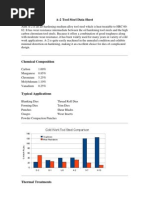

- A2 - Data SheetDocument3 pagesA2 - Data SheetferrerarmfNo ratings yet

- How To Use The Right FastenerDocument4 pagesHow To Use The Right FastenerMatt ChauvelNo ratings yet

- Welding Prosedur Specification Wps Pre QualifiedDocument8 pagesWelding Prosedur Specification Wps Pre QualifiedryanonedNo ratings yet

- CAT CAT CAT CAT: Guideline For Reusable Parts and Salvage OperationsDocument10 pagesCAT CAT CAT CAT: Guideline For Reusable Parts and Salvage OperationsJavier Hector CayaNo ratings yet

- Trouble Shooting Guide HobbingDocument3 pagesTrouble Shooting Guide HobbingShashindra DhopeshwarNo ratings yet

- PG Navoj - DIN 40430Document1 pagePG Navoj - DIN 40430Janez PartNo ratings yet

- Planing and Slotting OperationsDocument4 pagesPlaning and Slotting Operationsmanish kumarNo ratings yet

- Jig & Fixture DesignDocument22 pagesJig & Fixture Designmagi017No ratings yet

- Industrial Training ReportDocument45 pagesIndustrial Training ReportBishnu BhowmikNo ratings yet

- Foundry Tools and Equipment'sDocument18 pagesFoundry Tools and Equipment'sbereket gNo ratings yet

- Bolts, Screw, Nut - Terminology and Nomenclature. ISO1891 - 1979 (E - F - R)Document66 pagesBolts, Screw, Nut - Terminology and Nomenclature. ISO1891 - 1979 (E - F - R)tkcn tvNo ratings yet

- Asshnment For J@T 2Document23 pagesAsshnment For J@T 2wabdushukurNo ratings yet

- Asme B18.11-1961 (2000)Document13 pagesAsme B18.11-1961 (2000)IliyaNo ratings yet

- Thread DataDocument3 pagesThread DataenricoNo ratings yet

- Stellram MillingDocument44 pagesStellram Millingdhiraj_forNo ratings yet

- Work in Process in April: SL No. Ybf No. Product Lot No. Grade Weight in KGDocument3 pagesWork in Process in April: SL No. Ybf No. Product Lot No. Grade Weight in KGSangram ManeNo ratings yet

- Blanking and PiercingDocument5 pagesBlanking and Piercingm9966822100% (1)

- 1730 - Steel Plates Sheets Strips & FlatsDocument11 pages1730 - Steel Plates Sheets Strips & FlatsKaushik SenguptaNo ratings yet

- Z-Carb Original End Mills: Revolutionizes MillingDocument4 pagesZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNo ratings yet

- Thread and Thread CuttingDocument9 pagesThread and Thread Cuttinglyk zNo ratings yet

- What Is Hole Punching? What Is Drilling?Document6 pagesWhat Is Hole Punching? What Is Drilling?Krisha Ann RosalesNo ratings yet

- Adp 6Document3 pagesAdp 6mohd_azhar_51No ratings yet

- Amarendra Kancharla - 17BME0828 - School of Mechanical EngineeringDocument1 pageAmarendra Kancharla - 17BME0828 - School of Mechanical EngineeringGoutham ReddyNo ratings yet

- Hand Tools Hand SawDocument5 pagesHand Tools Hand SawSherwin D. SungcalangNo ratings yet

- 5 DrillingDocument25 pages5 DrillingOmar Mohammed IbrahimNo ratings yet