1070 PDF

1070 PDF

Uploaded by

mbhadelCopyright:

Available Formats

1070 PDF

1070 PDF

Uploaded by

mbhadelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1070 PDF

1070 PDF

Uploaded by

mbhadelCopyright:

Available Formats

O n e C o m p a n y U n l i m i t e d S o l u t i o n s

O n e C o m p a n y U n l i m i t e d S o l u t i o n s

S

e

r

i

e

s

7

0

S

h

o

r

t

C

a

t

c

h

O

v

e

r

s

h

o

t

s

SERIES 70 OVERSHOTS

Instruction Manual 1070

1070.pmd 11/22/2005, 10:48 PM 1

Series 70 Short Catch Overshots

General Description ...................................................... 3

Use ............................................................................... 3

Construction .................................................................. 3

Operation....................................................................... 3

To Engage and Pull the Fish ................................. 3

To Release from the Fish ....................................... 3

Precautions.................................................................... 3

Explanation of Mechanism ........................................... 4

Maintenance .................................................................. 4

Specifications and Replacement Parts .................. 5 6

Table of Calcuated Strengths........................................ 7

The designs and specifications for the tools described in this

instruction manual were in effect at the time this manual was

approved for printing. National Oilwell Varco, whose policy is

one of continuous improvement, reserves the right to discon-

tinue models at any time, or to change designs and specifica-

tions without notice or without incurring obligation.

Seventeeth Printing, September 2005

I

N

D

E

X

S e r i e s 7 0 O v e r s h o t s

3

General Description

Bowen Series 70 Short Catch Over-

shots are especially designed to engage

the exposed portion of a fish too short

to be engaged with conventional catch

overshots. Designed and developed upon

the same principle as other Bowen

Overshots, they are the most effective

means for the recovery of a fish whose

exposed upper end is very short.

Use

Each Bowen Series 70 Short Catch

Overshot is designed to engage a spe-

cific maximum outside diameter. (See

the Specifications tables on pages 5 and 6).

Each Overshot can be dressed to engage

any smaller diameter by instal-ling the

desired size of Basket Grapple.

Construction

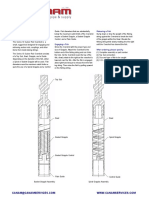

A Series 70 Short Catch Overshot

consists of a Top Sub, a Bowl, a Basket

Grapple Control, and a Basket Grapple. In

this Overshot, the Basket Grapple is

inserted into the Bowl from the top and the

finger of the Basket Grapple Control fits

into the top of the Basket Grapple. The

Bowl is designed to allow the Basket

Grapple to be located at its extreme lower

end.

Bowen Series 70

Short Catch Overshot

Operation

First determine that the Overshot is

properly assembled, dressed with the

proper size Grapple, and that all of its

parts are in good working order. Refer

to the Specification Tables for the list

of parts.

Make up the Overshot on the fishing

string and run into the well.

To Engage and Pull the Fish

As the top of the fish is reached, slowly

rotate the fishing string to the right and

gradually lower the Overshot over the

fish. Combined rotating and lowering is

important.

Allow the right-hand torque to slack out

of the fishing string and then pull on the

fish by elevating the fishing string.

To Release from the Fish

Bump down.Then simultaneously rotate

to the right and slowly elevate the fishing

string until the Overshot is clear of the

fish.Combined rotating and elevating is

important.

To release from a recovered fish, follow

the same procedure while holding the

fish below the Overshot.

Precautions

Unless an upward strain is maintained,

never rotate the fishing string to the left

while the Overshot is engaged with the

fish.

Always bump down the full weight of the

fishing string before starting releasing

operations.

Basket

Grapple

Top Sub

Bowl

Basket

Grapple

Control

1070.pmd 11/22/2005, 10:48 PM 3

4

Explanation of Mechanism

After the Overshot has reached the top

of the fish, combined rotation and lower-

ing results in the following:

1. The bottom of the Bowl serves as a

guide to direct the fish into the Basket

Grapple.

2. The Grapple will expand and the fish

will pass into it to be halted by the

lower end of the top sub.

3. The fish is now properly located in the

Overshot and thereafter, when upward

pull is exerted, the Grapple is con-

tracted by the tapers of the Bowl and

the hold is secure.

When releasing, the sharp downward

bump breaks the freeze between Bowl

and Grapple, and places the largest

portion of the Bowl tapers opposite the

largest portion of the Grapple Spirals.

Elevation of the Fishing String and right-

hand rotation of the overshot causes the

left hand wickers in the Grapple to feed

the overshot (Grapple) off the fish.

Maintenance

To guard against misruns and to prolong

the life of the tool, the Overshot should

be disassembled after use, cleaned

and all parts oiled or lubricated before

reassembling. Grapple wickers should

be checked for dullness, and replaced

if necessary.

Reference to the illustrations will indicate

that little instruction is needed to dis-

mantle or assemble this tool. To prevent

rust or deterioration, either paint or

grease the exterior of the Overshot.

Bowl

Grapple

Control

Basket

Grapple

1070.pmd 11/22/2005, 10:48 PM 4

5

How to Order

Specify:

(1) Name and number of assembly or part

(2) Top connection desired

(3) Size of fish to be caught

(4) OD, if other than standard

RECOMMENDED SPARE PARTS:

(1) 2 Basket Grapples for each catch size

(2) 1 Basket Grapple Control

SPECIAL NOTES:

FS (Full Strength) ................. Engineered to withstand all pulling, torsional, and jarring strain.

SH (Slim Hole) ..................... Engineered to withstand heavy pulling strain only.

Series 70 Short Catch Overshot Specifications

Maximum Catch 1-5/8 2-1/2 2-5/8 3-1/16 3-1/16 3-1/16 3-1/8 3-3/8 3-21/32

Standard O.D. 2-5/16 3-5/8 3-3/4 3-15/16 4-1/8 4-5/8 4-1/8 4-3/8 4-11/16

Standard Connection 7/8 2-1/2 2-3/8 2-3/8 2-7/8 2-1/2 2-7/8 2-7/8 2-7/8

SR EUE API EUE REG EUE REG REG REG

PIN REG

Type SH SH SH SH SH FS SH SH SH

Complete Assembly Part No. 38506 17615 13535 63892 10434 11290 68550 C-11023 10543

Weight 8 30 36 39 59 57 59 87 100

Replacement Parts

Top Sub Part No. 38507 17616 13536 63893 10435 11295 68551 A-11024 10544

Weight 4 14 15 16 20 23 20 35 35

Bowl Part No. 38508 17617 13537 63894 10436 11291 68552 B-11025 10545

Weight 2 11 14 15 25 21 25 33 54

Basket Grapple Part No. 38509 17618 13538 63895 10437 11292 68553 B-11026 10546

Weight 1-1/2 3 4-1/2 5-1/2 11 10 11 15 8

Basket Grapple Control Part No. 38510 17619 13539 63896 10438 11294 68554 A-11027 10547

Weight 1/2 1 2-1/4 2-1/2 2-3/4 3 2-3/4 4 3

Series 70 Short Catch Overshot Specifications

Maximum Catch 3-21/32 3-3/4 3-3/4 4-1/8 4-1/4 4-3/4 4-3/4 5-1/4 6

Standard O.D. 5-5/8 4-3/4 5-1/2 5-1/4 5-25/32 5-7/8 6-5/8 6-1/4 7-5/8

Standard Connection 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 4-1/2 4-1/2 4-1/2

FH FH FH IF FH IF FH REG FH

Type FS SH FS FS FS SH FS SH FS

Complete Assembly Part No. 11297 12645 12785 53186 13065 10560 11303 14805 11630

Weight 87 59 123 87 116 129 153 158 165

Replacement Parts

Top Sub Part No. 11298 10544 12786 53187 13066 10561 11304 14806 11631

Weight 35 35 58 35 65 55 80 89 91

Bowl Part No. 11299 12646 12787 53188 13067 10562 11305 14807 11632

Weight 33 13 41 33 24 49 39 32 34

Basket Grapple Part No. 11300 12647 12788 53189 13068 10563 11306 14808 11633

Weight 15 6 19 15 16 21 19 32 34

Basket Grapple Control Part No. 11301 12648 12789 53190 13069 10564 11307 14809 11634

Weight 4 4-1/2 5-1/4 4 5 3-3/4 5 5 7-1/2

1070.pmd 11/22/2005, 10:48 PM 5

6

How to Order

Specify:

(1) Name and number of assembly or part

(2) Top connection desired

(3) Size of fish to be caught

(4) OD, if other than standard

RECOMMENDED SPARE PARTS:

(1) 2 Basket Grapples for each catch size

(2) 1 Basket Grapple Control

SPECIAL NOTES:

FS (Full Strength) ................. Engineered to withstand all pulling, torsional, and jarring strain.

SH (Slim Hole) ..................... Engineered to withstand heavy pulling strain only.

Series 70 Short Catch Overshot Specifications

Maximum Catch 6-1/4 6-3/8 6-1/2 7 7 7-3/4 8 8-1/4 9

Standard OD 7-7/8 8 8-1/4 8-3/8 8-1/2 9-1/4 9-3/4 10 11-1/4

Standard Connection 4-1/2 8-5/8 5-1/2 8-5/8 4-1/2 4-1/2 6-5/8 8-5/8 7-5/8

IF REG REG REG FH IF REG REG REG

Type FS FS FS SH FS FS FS FS FS

Complete Assembly Part No. 16975 46673 38939 151454 20050 25030 20060 46102 33878

Weight 230 229 245 236 243 288 356 378 429

Replacement Parts

Top Sub Part No. 16976 46674 38940 20051 20051 25031 20061 46679 38879

Weight 140 145 145 148 150 200 210 224 225

Bowl Part No. 16977 46675 38941 20052 20052 25032 20062 46680 33880

Weight 45 38 46 39 28 45 48 62 110

Basket Grapple Part No. 16978 46676 38942 151455 20053 25033 20063 46681 33881

Weight 36 38 45 39 55 32 80 78 78

Basket Grapple Control Part No. 16979 46677 38943 151456 20054 25034 20064 46682 33882

Weight 7-1/2 8 8 10 8-1/2 9 16 12 13

1070.pmd 11/22/2005, 10:48 PM 6

7

Series 70 Short Catch Overshot Table of Calculated Strengths

Load Capacity at Yield Point Maximum

Basket Grapple (lb) Recommended

Complete Assembly No. Bowl Number O.D. (in) Max. Catch Size (in) Without Stop With Stop Makeup Torque (ft lb)

10434 10436 4-11/16 3-1/16 697,300 571,300 5,250

10434* 10436 4-1/8 3-1/16 212,700 212,700 2,700

10543 10545 5-7/8 3-21/32 1,283,600 1,011,300 7,400

10543* 10545 4-11/16 3-21/32 197,600 197,600 2,900

10560 10562 6-5/8 4-3/4 915,200 693,600 18,600

10560* 10562 5-7/8 4-3/4 348,200 306,200 6,750

C-11023 B-11025 4-3/8 3-3/8 250,300 3,400

11290 11291 4-5/8 3-1/16 398,100 398,100 5,650

11297 11299 5-5/8 3-21/32 790,500 635,700 13,700

11303 11305 6-5/8 4-3/4 720,600 579,400 19,800

11630 11632 7-5/8 6 445,300 358,000 14,200

12645 12646 4-3/4 3-3/4 267,100 267,100 3,950

12785 12785 5-7/8 3-3/4 907,000 729,300 15,700

12785* 12787 5-1/2 3-3/4 558,100 504,500 9,900

13065 13067 5-25/32 4-1/4 575,600 467,400 7,300

13535 13537 3-3/4 2-5/8 239,800 239,800 2,700

14805 14807 6-1/4 5-1/4 319,700 6,500

16975 16977 7-7/8 6-1/4 445,700 349,200 13,200

17615 17617 3-5/8 2-1/2 263,600 2,900

20050 20052 8-1/2 7 373,700 285,100 12,400

20060 20062 9-3/4 8 445,100 22,200

25030 25032 9-1/4 7-3/4 391,700 16,800

33878 33880 11-1/4 9 874,800 46,800

36239 36241 15 12-1/4 934,800 120,000

38506 38508 2-5/16 1-5/8 85,200 600

38939 38941 8-1/2 6-1/2 445,100 17,100

46102 46680 10 8-1/4 445,100 18,000

46673 46675 8 6-3/8 445,700 14,700

53186 53188 5-1/4 4-1/8 339,500 339,500 5,750

63892 63894 3-15/16 3-1/16 224,600 2,750

68550 68552 4-1/8 3-1/8 254,700 1,900

151454 20052 8-3/8 7 226,400 6,150

* Standard OD

NOTE:

1) All strengths listed are calculated theoretical yield points and accurate within 20%. It should be noted, however,

that all strengths assume a straight, steady pull and full grapple engagement of a roundfish. Anything less than

full engagement or straight pulling will reduce the listed strength substantially. Tong marks and other surface

damage to the bowl will also reduce the strength. Jarring may amplify the pull load by a factor of 3 to 10.

2) Maximum Recommended Makeup Torque is at 50% of yield. No tong marks should be applied to the Bowl. This

is the maximum torque. Much less torque may be used depending upon the situation.

1070.pmd 11/22/2005, 10:48 PM 7

NATIONAL OILWELL VARCO

2005 National Oilwell Varco

MANUAL NO. 1070 R4

1070.pmd 12/8/2005, 8:33 PM 8

Well Service and Completion Solutions

You might also like

- NSK MegatorqueDocument52 pagesNSK MegatorquegoldprocessNo ratings yet

- Punch and DieDocument16 pagesPunch and DieNani DatrikaNo ratings yet

- Itco Spear Bull Noze Make Up PDFDocument1 pageItco Spear Bull Noze Make Up PDFmbhadelNo ratings yet

- Clay Bricks ManufacturingDocument15 pagesClay Bricks ManufacturingSabhaya ChiragNo ratings yet

- Allrounder 420 C: Golden EditionDocument6 pagesAllrounder 420 C: Golden EditionEdwinQuintiNo ratings yet

- Yamaha FZ1 06 Service ManualDocument450 pagesYamaha FZ1 06 Service ManualVirginiaIonela100% (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- RollerLatch UndergroundHeadAssembly Brochure EnglishDocument4 pagesRollerLatch UndergroundHeadAssembly Brochure EnglishCarlos Antonio Chavez EgoavilNo ratings yet

- ArtificialDocument47 pagesArtificialShihabsirNo ratings yet

- Swage Lok Pocket Installer GuideDocument80 pagesSwage Lok Pocket Installer Guidefogler833No ratings yet

- Customer Guide Vol18.1Document378 pagesCustomer Guide Vol18.1Arunan SivakumarNo ratings yet

- Series 70 Overshot Strength DataDocument1 pageSeries 70 Overshot Strength DataRazvan RaduNo ratings yet

- Chap 1-Dwg TerminologyDocument32 pagesChap 1-Dwg TerminologyZhafri SyazwiNo ratings yet

- Hose&Braid Catalog FlexicraftDocument24 pagesHose&Braid Catalog Flexicraftkutts76No ratings yet

- Using Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationDocument2 pagesUsing Two eRED Valves As Shallow-Set Barriers During A Completion Deployment OperationLoganBohannonNo ratings yet

- Cam Design PDFDocument54 pagesCam Design PDFroshanijazNo ratings yet

- Two-Way Swivel Redress Kit Assembly InstructionsDocument10 pagesTwo-Way Swivel Redress Kit Assembly InstructionsEvolution Oil ToolsNo ratings yet

- Well Head 10 3/4" Casing: and AccessoriesDocument2 pagesWell Head 10 3/4" Casing: and AccessoriesHendra JurbonNo ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- MZ Alternate Path Multizone Packer: ApplicationsDocument3 pagesMZ Alternate Path Multizone Packer: ApplicationsRodolfo RiderNo ratings yet

- Contactless Electromechanical Actuator With Coupled Electronic Motor Commutation and Output Position SensorsDocument18 pagesContactless Electromechanical Actuator With Coupled Electronic Motor Commutation and Output Position SensorsHassanNo ratings yet

- The Accelerator Tool Gives You Up To Twice The Impact From Your Hydra-JarDocument4 pagesThe Accelerator Tool Gives You Up To Twice The Impact From Your Hydra-JarAlexander KlmNo ratings yet

- Screw and BoltDocument31 pagesScrew and Boltyashar2500No ratings yet

- Ferraz Shawmut FusesDocument68 pagesFerraz Shawmut FusesMk BhatNo ratings yet

- Drill Stem Testing RD Sampler: SmartstarDocument1 pageDrill Stem Testing RD Sampler: SmartstarDenier RubianoNo ratings yet

- Iron Roughnecks: Cost-Effective, Compact Designs With User-Intuitive Control SystemsDocument2 pagesIron Roughnecks: Cost-Effective, Compact Designs With User-Intuitive Control SystemschenNo ratings yet

- Rupture Disk FUL-FLO Sampler: HalliburtonDocument2 pagesRupture Disk FUL-FLO Sampler: Halliburtonsaeed65No ratings yet

- 32A Tension Set Packet Rev.E0 27 Jul 12Document2 pages32A Tension Set Packet Rev.E0 27 Jul 12digger1833No ratings yet

- Product BrochureDocument29 pagesProduct BrochureWahiba EnergyNo ratings yet

- Teknik Sondaj Rig#4 BrochureDocument10 pagesTeknik Sondaj Rig#4 BrochureBaris UnalNo ratings yet

- Tesco Casing Drive System™Document5 pagesTesco Casing Drive System™Citra FerdyanNo ratings yet

- WCT Cast Iron Bridge Plug Technical DatasheetDocument3 pagesWCT Cast Iron Bridge Plug Technical DatasheetEvolution Oil ToolsNo ratings yet

- Flexible Couplings 2010Document32 pagesFlexible Couplings 2010amekhzoumiNo ratings yet

- HoningDocument6 pagesHoningAnonymous 5AmJ13mLkNo ratings yet

- Valvula Piloto 1.5 inDocument10 pagesValvula Piloto 1.5 inDurvis Joel Romero LopezNo ratings yet

- SS Gauge CarriersDocument2 pagesSS Gauge CarriersGonza PfNo ratings yet

- Top Drive2Document2 pagesTop Drive2Fabian Edison VeraNo ratings yet

- X Treme WindowMaster Whipstock System SLSHDocument2 pagesX Treme WindowMaster Whipstock System SLSHfetorrezeNo ratings yet

- Permanent PKR Eline/Hydraulic Setting Tool Signature: AdvantagesDocument18 pagesPermanent PKR Eline/Hydraulic Setting Tool Signature: Advantagesjulio RDLRNo ratings yet

- Shear Force For SBRDocument14 pagesShear Force For SBRnjava1978No ratings yet

- Abstract Awes Dig RPDocument4 pagesAbstract Awes Dig RPabinadi1230% (1)

- PCK para Limpiar PunzadosDocument19 pagesPCK para Limpiar PunzadosRodolfo RiderNo ratings yet

- SKF Linear Ball BearingsDocument55 pagesSKF Linear Ball BearingsLLNo ratings yet

- FA25i FA5i FA5Ti Parts Information AirToolProDocument48 pagesFA25i FA5i FA5Ti Parts Information AirToolProEslam Saeed100% (1)

- Elite Magna-Range Bridge PlugDocument2 pagesElite Magna-Range Bridge PlugJohanes GigihNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- Directional Control ValveDocument27 pagesDirectional Control ValveRajib ChhataitNo ratings yet

- Series 10 Sucker Rod Overshots: Releasing A FishDocument4 pagesSeries 10 Sucker Rod Overshots: Releasing A Fishfelipe100% (1)

- Mud Pumps 1Document2 pagesMud Pumps 1John RongNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- Mi Swaco MD-3Document12 pagesMi Swaco MD-3solnyshko28110705100% (1)

- ReLineMNS Omega PDFDocument3 pagesReLineMNS Omega PDFJuan Manuel Rojas AcuñaNo ratings yet

- PFF Manula Gate ValveDocument11 pagesPFF Manula Gate ValveEizeldin KhalilNo ratings yet

- SH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockDocument7 pagesSH Shandong Kerui Petroleum Equipment Co., LTD.: 1, Crown BlockCleevh MabialaNo ratings yet

- Bimbar Inflatable PDFDocument36 pagesBimbar Inflatable PDFcarlosdh_03No ratings yet

- GR - WRDSP - Tech LiteratureDocument7 pagesGR - WRDSP - Tech LiteratureDigger Downhole ToolsNo ratings yet

- ELDER IX 5 5 X 2 375Document8 pagesELDER IX 5 5 X 2 375crni rokoNo ratings yet

- Arrow-Pak Retrievable Seal Bore Packer: Specifications GuideDocument7 pagesArrow-Pak Retrievable Seal Bore Packer: Specifications GuideTech AlfaNo ratings yet

- MHD55148 BOP Catalog 052008Document20 pagesMHD55148 BOP Catalog 052008jlmunozv100% (4)

- Flywheel DesignDocument9 pagesFlywheel DesignTessema ShbruNo ratings yet

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocument20 pages6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezNo ratings yet

- BJ S C, USA: Doug LehrDocument12 pagesBJ S C, USA: Doug LehrBalkis FatihaNo ratings yet

- E04 Using Kalsi Seals in Washpipe AssembliesDocument17 pagesE04 Using Kalsi Seals in Washpipe AssembliesSuresh Kumar MittapalliNo ratings yet

- SLRN Landing Nipple Technical DatasheetDocument3 pagesSLRN Landing Nipple Technical DatasheetEvolution Oil ToolsNo ratings yet

- App Chap 12Document19 pagesApp Chap 12mbhadelNo ratings yet

- 5456 de Filter PressDocument6 pages5456 de Filter PressmbhadelNo ratings yet

- Roller Reamer PresentationDocument18 pagesRoller Reamer Presentationmbhadel50% (2)

- Baker Filtration EquipDocument5 pagesBaker Filtration EquipmbhadelNo ratings yet

- P1R8789A Well Completion & Workover Manual Volume1Document416 pagesP1R8789A Well Completion & Workover Manual Volume1mbhadel50% (2)

- Drilling and Workover Best PracticesDocument430 pagesDrilling and Workover Best Practicesmbhadel86% (14)

- Reamer Running and Drillout Protocol Wft005188Document1 pageReamer Running and Drillout Protocol Wft005188mbhadelNo ratings yet

- PRE9053 Well Test ReportDocument7 pagesPRE9053 Well Test ReportmbhadelNo ratings yet

- Drilling and Workover Best PracticesDocument430 pagesDrilling and Workover Best Practicesmbhadel86% (14)

- BJ Services Company Completion Tools - LocationsDocument1 pageBJ Services Company Completion Tools - LocationsmbhadelNo ratings yet

- Drill Pipe Spec's SheetDocument10 pagesDrill Pipe Spec's SheetAhmed BakrNo ratings yet

- Stuck Pipe1 PDFDocument16 pagesStuck Pipe1 PDFqwerty_qwerty_2009No ratings yet

- PFI Catalog 2011 JUL-DEC MotionDocument848 pagesPFI Catalog 2011 JUL-DEC Motioncraig9257No ratings yet

- Cook N ChillDocument6 pagesCook N ChillDheerajNo ratings yet

- Pipe Size CalculationDocument42 pagesPipe Size CalculationfelipeNo ratings yet

- Bucket ElevatorsDocument36 pagesBucket ElevatorsuseforfreelanceworkNo ratings yet

- Motor Cat C9-AcertDocument4 pagesMotor Cat C9-Acertcarlucido247970100% (1)

- RT 24 VhsDocument13 pagesRT 24 VhsNinoslav ArsićNo ratings yet

- UPenn Ethanol To Ethyl Acetate PDFDocument403 pagesUPenn Ethanol To Ethyl Acetate PDFAlan TeeNo ratings yet

- Abs HaldexDocument2 pagesAbs HaldexBom_Jovi_681No ratings yet

- KPI Full BrochureDocument10 pagesKPI Full BrochureOrlando Melipillan100% (1)

- User Manual HYCD-282-282ADocument16 pagesUser Manual HYCD-282-282ALuis GutierrezNo ratings yet

- LG Cm1530-AuDocument49 pagesLG Cm1530-Aualejandro ittermannNo ratings yet

- Busch Mink MM 1104-1142 BP Manual enDocument20 pagesBusch Mink MM 1104-1142 BP Manual enmakremNo ratings yet

- 1 Ungrounded SystemDocument31 pages1 Ungrounded SystemRaymond MarquesesNo ratings yet

- ScribduploadDocument3 pagesScribduploadKen SuNo ratings yet

- Lab Class 9Document2 pagesLab Class 9fahadm12No ratings yet

- Electric Chain HoistDocument91 pagesElectric Chain Hoisthanner90100% (1)

- NC Spot DrillsDocument2 pagesNC Spot DrillsFelipe Vásquez MinayaNo ratings yet

- Blocks and TacklesDocument19 pagesBlocks and TacklessbdmanNo ratings yet

- Jurnal Skripsi JulDocument22 pagesJurnal Skripsi JulGogelNo ratings yet

- Path Old J Ce GlobalDocument11 pagesPath Old J Ce GlobalShishan AhmadNo ratings yet

- Operational Aspect LATEST (Repaired)Document8 pagesOperational Aspect LATEST (Repaired)Michael Jan N MalaNo ratings yet

- Chemical Tanker OperationsDocument12 pagesChemical Tanker OperationsJeet Singh80% (5)

- Unit18 Surface Finish MeasurementDocument14 pagesUnit18 Surface Finish Measurementirfanajai100% (1)

- Transient Speed Vibration Analysis: Insights Into Machinery BehaviorDocument47 pagesTransient Speed Vibration Analysis: Insights Into Machinery Behaviorpeach5No ratings yet

- NC Tool StorageDocument6 pagesNC Tool StorageabhayiimcNo ratings yet

- 400215-Sicomin SR 1125 SD 3303Document4 pages400215-Sicomin SR 1125 SD 3303McFlyNo ratings yet