Sae J 417 Fragment

Uploaded by

simo96Sae J 417 Fragment

Uploaded by

simo96TECHNICAL DATA

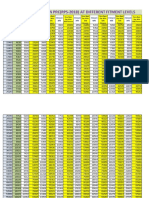

CONVERSION TABLE OF HARDNESS

EXCERPT FROM SAE J 417

(1983)

(1)

Conversion table for approximate values for steel according to Rockwell hardness C scale

Rockwell

hardness

C scale

Vickers

hardness

(HRC) (HV)

Brinell hardnes(HB)

(3)

Standard ball

Tungsten

carbide

ball

A scale(HRA)

Load:60kgf

Diamond conical

penetrator

B scale

(HRB)

Load:100kgf

Ball of 1.6mm

(1/16")

dia.

Rockwell superficial hardness

Diamond conical penetrator

Tensile strength Rockwell

Shore (Approximate value)hardness

hardness

MPa

C scale(3)

D scale(HRD)

15-N Scale 30-N Scale 45-N Scale

2

Load:100kgf

)

(kgf/mm

Diamond conical

Load:15kgf Load:30kgf Load:45kgf (Hs)

(2)

penetrator

Rockwell hardness

Ball:10mm in

diameter/Load:3000kgf

68

67

66

65

64

940

900

865

832

800

(739)

(722)

85.6

85.0

84.5

83.9

83.4

76.9

76.1

75.4

74.5

73.8

93.2

92.9

92.5

92.2

91.8

84.4

83.6

82.8

81.9

81.1

75.4

74.2

73.3

72.0

71.0

97

95

92

91

88

68

67

66

65

64

63

62

61

60

59

772

746

720

697

674

(705)

(688)

(670)

(654)

(634)

82.8

82.3

81.8

81.2

80.7

73.0

72.2

71.5

70.7

69.9

91.4

91.1

90.7

90.2

89.8

80.1

79.3

78.4

77.5

76.6

69.9

68.8

67.7

66.6

65.5

87

85

83

81

80

63

62

61

60

59

58

57

56

55

54

653

633

613

595

577

615

595

577

560

543

80.1

79.6

79.0

78.5

78.0

69.2

68.5

67.7

66.9

66.1

89.3

88.9

88.3

87.9

87.4

75.7

74.8

73.9

73.0

72.0

64.3

63.2

62.0

60.9

59.8

78

76

75

74

72

2075 (212)

2015 (205)

58

57

56

55

54

53

52

51

50

49

560

544

528

513

498

(500)

(487)

(475)

(464)

525

512

496

481

469

77.4

76.8

76.3

75.9

75.2

65.4

64.6

63.8

63.1

62.1

86.9

86.4

85.9

85.5

85.0

71.2

70.2

69.4

68.5

67.6

58.5

57.4

56.1

55.0

53.8

71

69

68

67

66

1950 (199)

1880 (192)

1820 (186)

1760 (179)

1695 (173)

53

52

51

50

49

48

47

46

45

44

484

471

458

446

434

451

442

432

421

409

455

443

432

421

409

74.7

74.1

73.6

73.1

72.5

61.4

60.8

60.0

59.2

58.5

84.5

83.9

83.5

83.0

82.5

66.7

65.8

64.8

64.0

63.1

52.5

51.4

50.3

49.0

47.8

64

63

62

60

58

1635 (167)

1580 (161)

1530 (156)

1480 (151)

1435 (146)

48

47

46

45

44

43

42

41

40

39

423

412

402

392

382

400

390

381

371

362

400

390

381

371

362

72.0

71.5

70.9

70.4

69.9

57.7

56.9

56.2

55.4

54.6

82.0

81.5

80.9

80.4

79.9

62.2

61.3

60.4

59.5

58.6

46.7

45.5

44.3

43.1

41.9

57

56

55

54

52

1385 (141)

1340 (136)

1295 (132)

1250 (127)

1215 (124)

43

42

41

40

39

38

37

36

35

34

372

363

354

345

336

353

344

336

327

319

353

344

336

327

319

69.4

68.9

68.4

67.9

67.4

(109.0)

(108.5)

(108.0)

53.8

53.1

52.3

51.5

50.8

79.4

78.8

78.3

77.7

77.2

57.7

56.8

55.9

55.0

54.2

40.8

39.6

38.4

37.2

36.1

51

50

49

48

47

1180 (120)

1160 (118)

1115 (114)

1080 (110)

1055 (108)

38

37

36

35

34

33

32

31

30

29

327

318

310

302

294

311

301

294

286

279

311

301

294

286

279

66.8

66.3

65.8

65.3

64.7

(107.5)

(107.0)

(106.0)

(105.5)

(104.5)

50.0

49.2

48.4

47.7

47.0

76.6

76.1

75.6

75.0

74.5

53.3

52.1

51.3

50.4

49.5

34.9

33.7

32.7

31.3

30.1

46

44

43

42

41

1025 (105)

1000 (102)

980 (100)

950 ( 97)

930 ( 95)

33

32

31

30

29

28

27

26

25

24

286

279

272

266

260

271

264

258

253

247

271

264

258

253

247

64.3

63.8

63.3

62.8

62.4

(104.0)

(103.0)

(102.5)

(101.5)

(101.0)

46.1

45.2

44.6

43.8

43.1

73.9

73.3

72.8

72.2

71.6

48.6

47.7

46.8

45.9

45.0

28.9

27.8

26.7

25.5

24.3

41

40

38

38

37

910 (

880 (

860 (

840 (

825 (

93)

90)

88)

86)

84)

23

22

21

20

(18)

254

248

243

238

230

243

237

231

226

219

243

237

231

226

219

62.0

61.5

61.0

60.5

-

100.0

99.0

98.5

97.8

96.7

42.1

41.6

40.9

40.1

-

71.0

70.5

69.9

69.4

-

44.0

43.2

42.3

41.5

-

23.1

22.0

20.7

19.6

-

36

35

35

34

33

805 (

785 (

770 (

760 (

730 (

82)

23

80)

22

79)

21

77)

20

75) (18)

(16)

(14)

(12)

(10)

( 8)

222

213

204

196

188

212

203

194

187

179

212

203

194

187

179

95.5

93.9

92.3

90.7

89.5

32

31

29

28

27

705 (

675 (

650 (

620 (

600 (

72)

69)

66)

63)

61)

(

(

(

(

180

173

166

160

171

165

158

152

171

165

158

152

87.1

85.5

83.5

81.7

26

25

24

24

580 (

550 (

530 (

515 (

59) (

56) (

54) (

53) (

6)

4)

2)

0)

Notes:(1) The figures in blue are based on Table 1 of ASTM E 140

(adjusted by SAE, ASM and ASTM in collaboration).

(2)

The values and units in parentheses have been converted from psi based on conversion tables of JIS Z 8413 and Z 8438.

2

1MPa=1N/mm

(3)

The figures in parentheses are less frequently used values and are for reference only.

28

27

26

25

24

(16)

(14)

(12)

(10)

( 8)

6)

4)

2)

0)

TECHNICAL DATA

INDICATIONS OF GEOMETRICAL TOLERANCE ON DRAWINGS

EXCERPT FROM

JIS B 0021

(1984)

Kinds and Symbols of Geometrical Tolerances

Definition of tolerance zone

Examples of diagrammatical indication and its interpretation

Where symbol F is attached before the numerical

value indicating a tolerance zone, this tolerance

zone is a zone in a cylinder of diameter t.

F0.08

Straightness

tolerance

Symbol

Ft

Kind of tolerance

The tolerance zone is a zone held

between two parallel planes a

distance t apart.

This surface shall be contained

between two parallel planes

0.08mm apart.

0.08

Flatness

tolerance

Where a tolerance frame is connected to

the dimension showing the diameter of a

cylinder, the axis of the cylinder shall be

contained a cylinder of 0.08mm diameter.

The tolerance zone in the considered

plane is a zone between two concentric

circles a distance t apart.

Circularity

tolerance

t

Form

tolerance

The tolerance zone is a zone

contained between two coaxial

cylinder surfaces a distance t apart.

Cylindricity

tolerance

Profile tolerance

of surface

In any cross-section parallel to the projection

plane the considered profile shall be contained

between two lines enveloping circles of 0.04mm

in diameter, the centers of which are situated on

a line having the theoretically exact profile.

0.04

The tolerance zone is a zone held

between the two surfaces enveloping

the spheres of diameter t, the centers

of which are situated on a theoretically

exact profile surface.

The considered surface shall be contained

between two surfaces enveloping the

spheres of diameter 0.02mm, the centers

of which are situated on a surface having

the theoretically exact profile.

0.02

The tolerance zone is a zone held

between two parallel planes parallel

to the datum plane and a distance t

apart from each other.

Parallelism

tolerance

SF t

The considered surface shall be

contained between two coaxial

cylinder surfaces 0.1mm apart.

0.1

The tolerance zone is a zone held

between two lines enveloping circles of

diameter t, the centers of

which are situated on a theoretically

exact profile line.

Profile tolerance

of line

The circumference in any section

normal to the axis shall be contained

between two concentric circles

0.1mm apart on the same plane.

0.1

The surface shown by the arrow of the leader

line shall be contained between two planes

parallel to the datum plane A and 0.01mm

apart from each other in the direction of the

arrow of the leader line.

0.01 A

A

Where symbol Fis attached before the numerical

value indicating the tolerance, the tolerance zone

is a zone within a cylinder of diameter t

perpendicular to the datum plane.

Ft

Orientation Perpendicularity

tolerance

tolerance

t

Angularity

tolerance

A

The tolerance zone is a zone held between

0.08 A

two parallel planes inclined at the specified

angle to the datum plane and a distance t 40B

apart from each other.

The surface shown by the arrow of the leader line

shall be contained between two parallel planes

which are inclined at 40Bwith theoretical exactness

to the datum plane A and which are

0.08mm apart from each other in the direction

of the arrow of the leader line.

Total run-out

tolerance

The tolerance zone is a zone between two

coaxial cylinders having axes agreeing with

the datum axial straight line and a distance

t apart from each other in the radial direction.

0.08 A

0.1 A-B

The tolerance is a zone between two concentric

circles whose centers agree

with the datum axial straight line on any

measuring plane normal to the datum axial

Toleranced straight line and which are a distance t apart

surface from each other in the radial direction.

B

0.1 A-B

The point shown by the arrow of the leader

line shall be contained within a circle of

0.03mm diameter having its center at the

true location 60mm and 100mm apart,

respectively,from the datum straight line

A and from the datum straight line B.

F0.01 A The axis shown by the arrow of the

leader line shall be contained within

a cylinder of 0.01mm diameter

whose axis agrees with the

datum axial straight line A.

Run-out

tolerance

Measuring plane

The tolerance zone is a zone held between

two parallel planes a distance t apart from

each other and arranged symmetrically about

the datum median plane.

Symmetry

tolerance

Circular run-out

tolerance

100

Where symbol F is attached before the numerical

value indicating the tolerance, the tolerance zone

is a zone within a cylinder of diameter t whose

axis agrees with the datum axial straight line.

Ft

Location

tolerance

Coaxiality

tolerance

or

concentricity

tolerance

True

location

F0.03 AB

Positional

tolerance

B

60

A

The tolerance zone is a zone within a circle or

sphere of diameter t having its center at the

theoretically exact location, hereinafter referred to

as thetrue location".

The axis of the cylinder shown by

the arrow of the leader line shall

be contained within a cylinder of

diameter 0.01mm perpendicular

to the datum plane A.

F0.01 A

The median surface shown by the arrow of

the leader line shall be contained between

two parallel planes 0.08mm apart from

each other and arranged symmetrically

about the datum median plane A.

The run-out in the radial direction of the cylinder

surface shown by the arrow of the leader line

shall not exceed 0.1mm on any measuring plane

normal to the datum axial straight line when the

cylinder is rotated by one rotation about the

datum axial straight line A-B.

The total radial run-out of the cylinder surface

shown by the arrow of the leader line shall not

exceed 0.1mm at any point on the cylinder

surface when the cylinder part is rotated about

the datum axial straight line A-B with a relative

movement in the axial direction.

Lines used in the drawings in the column ofdefinition of tolerance zone"indicate the following meanings:

Thick solid line or broken line:Feature

Thin alternate long and short dash line:Center line

Thick alternate long and short dash line:Datum

Thin alternate long and two short dashes line:Supplementary projection plane or sectional plane

Thin solid line or broken line:Tolerance zone

Thick alternate long and two short dashes line:Projection of a feature to supplementary Projection plane or sectional plane

You might also like

- Is 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless SteelNo ratings yetIs 11169-2 (1989) - Steels Forcold Heading - Cold Extrusion, Part 2 - Stainless Steel11 pages

- IS Materail Specification For General Application100% (1)IS Materail Specification For General Application1 page

- Technical Properties of 30khgsa Steel Rods (Gost 4543-71 / 2590-88)No ratings yetTechnical Properties of 30khgsa Steel Rods (Gost 4543-71 / 2590-88)2 pages

- Part Requirment in Prod.: Physical Properties Chemical CompositionNo ratings yetPart Requirment in Prod.: Physical Properties Chemical Composition3 pages

- Part Requirment in Prod.: Physical Properties Chemical CompositionNo ratings yetPart Requirment in Prod.: Physical Properties Chemical Composition3 pages

- Hot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)No ratings yetHot Rolled Carbon Steel Strip and Sheet (IS: 1079-1968)1 page

- ST0000.00.345.FCI.000 Revision 0 International Comparison of SteelsNo ratings yetST0000.00.345.FCI.000 Revision 0 International Comparison of Steels8 pages

- Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method For100% (1)Evaluating The Microstructure of Graphite in Iron Castings: Standard Test Method For13 pages

- Chemical Composition % of Steel C15 (1.0401) : EN 10277-2-2008No ratings yetChemical Composition % of Steel C15 (1.0401) : EN 10277-2-20081 page

- DIN 17135 - 1964 - Alterungsbeständige Stähle - Gütevorschriften PDFNo ratings yetDIN 17135 - 1964 - Alterungsbeständige Stähle - Gütevorschriften PDF6 pages

- Material Specification: Specification: Revision Date: Revision Level100% (1)Material Specification: Specification: Revision Date: Revision Level2 pages

- 1570 (Part II Sec I) Revised - Wrought Steeks For Plates67% (3)1570 (Part II Sec I) Revised - Wrought Steeks For Plates20 pages

- Austempered Ductile Iron Castings: Standard Specification For0% (1)Austempered Ductile Iron Castings: Standard Specification For9 pages

- EN 10247-2007 Micrographic Examination of The Non-Metallic Inclusion Content PDF100% (3)EN 10247-2007 Micrographic Examination of The Non-Metallic Inclusion Content PDF84 pages

- Comparison of Dx54d+Za255 (En 10143) and Jis G 3314 Sa1d, Sa1eNo ratings yetComparison of Dx54d+Za255 (En 10143) and Jis G 3314 Sa1d, Sa1e3 pages

- DIN 17022-5 - Heat Treating of Ferrous Materials PDF100% (1)DIN 17022-5 - Heat Treating of Ferrous Materials PDF13 pages

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1No ratings yetDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 15 pages

- Calculation of Hardenability in The Jominy End QuenchtestNo ratings yetCalculation of Hardenability in The Jominy End Quenchtest2 pages

- PCFICH Consideration While Planning PCI For 10MHz BandwidthNo ratings yetPCFICH Consideration While Planning PCI For 10MHz Bandwidth11 pages

- Expected Basic Pay in PRC (Rps-2018) at Different Fitment LevelsNo ratings yetExpected Basic Pay in PRC (Rps-2018) at Different Fitment Levels3 pages

- Hilcoe School of Computer Science and Technology: Meron Teshome / Am9943No ratings yetHilcoe School of Computer Science and Technology: Meron Teshome / Am994314 pages

- A Programmer Guid On Unidata and UnibasicNo ratings yetA Programmer Guid On Unidata and Unibasic54 pages

- Precalculus mathematics for calculus student solutions manual 6th edition Edition Bulman-Fleming all chapter instant download100% (1)Precalculus mathematics for calculus student solutions manual 6th edition Edition Bulman-Fleming all chapter instant download67 pages

- Addendum a- Answer Sheet Grade 8 November Exam CA FinalNo ratings yetAddendum a- Answer Sheet Grade 8 November Exam CA Final2 pages

- 75 Days Study Plan SSC CGL 1537957545 14No ratings yet75 Days Study Plan SSC CGL 1537957545 1411 pages

- Real Conditional Sentences With "If" ClausesNo ratings yetReal Conditional Sentences With "If" Clauses2 pages

- 1) Create A Simple Webpage With A Heading and A Body Text. 2) Create A Calendar Using Javascript With Notepad. Source CodeNo ratings yet1) Create A Simple Webpage With A Heading and A Body Text. 2) Create A Calendar Using Javascript With Notepad. Source Code2 pages

- zCEE Customization Security and CICS PDFNo ratings yetzCEE Customization Security and CICS PDF26 pages

- 12 How To Run A Non-Boring Prayer MeetingNo ratings yet12 How To Run A Non-Boring Prayer Meeting4 pages

- n5 Page 4 +4 Until Deshou N4 From Shi Until Page 9 n3 11-17 Tsumori n2 To 23No ratings yetn5 Page 4 +4 Until Deshou N4 From Shi Until Page 9 n3 11-17 Tsumori n2 To 2340 pages

- A Beginner's Guide To Programming Logic and Design: Seventh EditionNo ratings yetA Beginner's Guide To Programming Logic and Design: Seventh Edition37 pages