Welding Habitat

Welding Habitat

Uploaded by

Desmond ChangCopyright:

Available Formats

Welding Habitat

Welding Habitat

Uploaded by

Desmond ChangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Welding Habitat

Welding Habitat

Uploaded by

Desmond ChangCopyright:

Available Formats

Working Together for Safety Recommendation 036N/2012

Use of habitats

Use of habitats

Working Together for Safety Recommendation 036N/2012

Prepared by the Working Together

for Safety Working Group:

15 May 2012

Revision:

Working Together for Safety Project

Manager:

Rev 00

Hugo Halvorsen

Applies from:

Next revision:

1 July 2012

June 2015

Approved by the Working Together

for Safety Board, Chairman:

yvind Norheim

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Contents

Introduction .......................................................................................................... 3

Objective ................................................................................................................ 3

Definitions .............................................................................................................. 3

Best practice ......................................................................................................... 4

Planning ................................................................................................................. 4

Design construction of the habitat ............................................................... 4

Inspection prior to use ....................................................................................... 5

Operation of the habitat ..................................................................................... 6

Working environment ......................................................................................... 6

Maintenance of the habitat ................................................................................ 7

Removal of the habitat ....................................................................................... 7

Risk management ............................................................................................... 8

Appendix A: Checklist for approval of habitats ....................................... 9

Appendix B: Checklist for daily inspection of habitats ........................11

Appendix C: Duties of the habitat responsible .......................................12

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Introduction

Within the petroleum industry, the term habitat is used to describe an enclosed area with

overpressure. Habitats are constructed from flame retardant materials. The overpressure prevents

flammable gas from reaching hot work (e.g. welding) inside the habitat and igniting. With an

associated control and shutdown system, a habitat is able to ensure the safe execution of hot

work in classified areas under normal operating and production conditions. Conditions in

unclassified areas can also make it necessary to use a habitat.

This recommendation assumes that a risk assessment has already been carried out, including an

assessment of alternative methods (cold work, shutdown, etc.), and it has been decided that a

habitat shall be used.

Objective

This best practice (method) describes how a habitat should be planned, designed, inspected,

operated, maintained and removed if it is to constitute a safety barrier.

Definitions

Habitat: A temporarily enclosed area with overpressure and associated control and shutdown

systems.

Classified area: Classified area refers to Zones 0, 1 and 2.

Safe area: Safe area refers to an area, generally unclassified, where there is the lowest possible

risk of the presence of gas in the air intake.

Reference

In this context, the ignition source control system and other habit equipment are defined as

temporary equipment in accordance with Norsok Standard Z-015N.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Best practice

Planning

Thorough planning prior to the use of a habitat is important in order to ensure safe execution of the

work. Planning forms the basis for being able to manage the risks associated with all sub-tasks

involved in establishing a habitat.

Best practice in planning a habitat includes:

Reviewing area classification drawings and undertaking an inspection to ensure that the

drawings match the actual conditions. This includes a review of the physical conditions, such

as electrical connections, air supply to the habitat, the size of the job (with regard to potential

heat and air flow) and special conditions at the installation/facility.

Identifying risks associated with the planning, design, control, operation, use, maintenance

and removal of the habitat. The identification of risks may involve an assessment of

HAZID/HAZOP needs, including an assessment of the activity level at the installation,

operating conditions, concurrent operations, etc.

Clarifying how compensatory measures should be implemented.

Design construction of the habitat

It should be verified that the necessary resources (scaffolding, electricity, air, etc.) identified

through the planning work are available at the location where the habitat shall be constructed.

The construction of the habitat must be managed by a competent habitat installer. Common

competence requirements for habitat installers do not currently exist, but work is being

carried out to establish a norm. Until such a norm is in place, the individual supplier must set

internal competence requirements and document these. The requirements must also be

approved by the individual operator.

The habitat, including its door, must be constructed from flame retardant materials, be

adequately stiffened, and constructed so that heat and sparks from the planned activity do

not constitute an ignition source risk outside the habitat.

The habitat must be equipped with a window so that the habitat responsible can monitor the

work inside the habitat. The window should be positioned so that flame detectors can remain

operational.

The habitat must be equipped with a manual emergency stop device, which cuts off the

electricity supply to equipment within the habitat.

A habitat must be constructed so that potential hydrocarbon leakage points are not located

inside the habitat. However, if it is decided that, for example, a flanged joint must be built in,

compensatory measures must be implemented.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Welding and heat treatment equipment must be placed inside the habitat, or in a separate

habitat if necessary.

The construction of the habitat and strength of the fabric must be able to withstand the

relevant wind stresses in the area in which the habitat is placed. Habitats are normally

designed to be able to withstand wind speeds of up to 30 m/s.

A habitat should be equipped with a self-closing door (a habitat can lose overpressure after

just a few seconds of the door being open). Creating good, labelled evacuation routes from

the habitat to a safe area should be prioritized. If necessary, alternative evacuation routes

should be constructed there must always be another escape route in addition to the door

of the habitat.

For work in the habitat which represents an ignition source (for example heat), even after the

electricity or gas supply to the habitat has been cut off, the fan unit and damper must be

independent of the working electrical current to ensure continued overpressure in such

situations. Electrical and pneumatic fans shall be EX approved for Zone 1. Fans must be

shut down and dampers closed automatically if gas is detected in the air intake. The air inlet

for fans should be placed in a safe area (well away from classified areas), in order to ensure

sufficient air supply to the habitat.

The habitat must be equipped with at least three external gas detectors. If gas is detected

(over 10% LEL) by one of these detectors, all equipment within the habitat shall be isolated

(trip) automatically. If overpressure within the habitat is lost, all equipment within the habitat

must also be isolated (trip) automatically or by the habitat guard. EX certified lights must be

set up inside the habitat. EX certified flashlights should be available in the habitat as a backup in the event of a loss of power.

Communication must be established with the central control room, and the habitat system

must be equipped with both audible and visual alarms.

If gases are used (propane oxygen/acetylene) the gas bottles must be placed outside the

habitat and the supply physically removed/disconnected before any hot work starts. One of

the gas detectors must also be connected to the automatic disconnection system for ignition

sources and gas sources (e.g. solenoid valves on propane bottles) and placed at the lowest

possible level in the habitat together with a hand-held O2 meter. Gas equipment, including

hoses, shall be tested for leaks and found to be in order.

The habitat must be constructed so that an overpressure of a minimum of 50 Pascals (Pa)

can be established. If the job requires it (e.g. during string bead welding), the overpressure

can be reduced for a short period (but to no lower than 15 Pa). This must be risk

assessed/documented in each individual instance.

Inspection prior to use

The area responsible/area technician, together with the habitat installer, HSE function and

executing worker, should carry out a checklist-based final inspection (ref. Appendix A). This

is done in order to verify that the habitat is constructed in accordance with requirements. A

copy of the checklist must be placed in a folder hung on the outside of the habitat.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

A visual inspection is carried out in the form of a self-inspection, and the safety functions

inside the habitat are checked in accordance with Appendix B.

Operation of the habitat

The habitat installer should be available while the habitat is in use, unless other personnel

with competence in ensuring the habitats integrity are present during this period.

The detection of gas at the installation/facility shall automatically shut down ignition sources

inside the habitat.

Use of the habitat requires a dedicated habitat guard, whose main task is to monitor the

work site. A complete list of the habitat guards tasks can be found in Appendix C.

Working environment

Ergonomics

The habitat should be constructed in a way that facilitates good working conditions. Good

communication with the executing personnel should therefore be maintained while the

habitat is constructed.

Noise

Work in the habitat often generates noise, in addition to other sources of noise in the area.

This must be taken into consideration when selecting equipment, assessing whether hearing

protection should be used, and evaluating how long personnel should be permitted to work

in the area.

Dust Chemicals

Work in overpressure habitats creates turbulent air conditions, and overpressure respirators

should therefore be used.

Fire

The habitat should be equipped with a zinc bucket for used welding electrodes, appropriate

fire extinguishing equipment (water or foam), flashlights, a knife, and water bottles/water

tanks for cooling the workpiece.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

The need for extra personnel to monitor the work (in addition to the habitat guard) must be

assessed.

The area around the work site inside the habitat must be covered with fire retardant material

so that no sparks or hot work can damage equipment or the habitat.

Maintenance of the habitat

During continual use, the habitat should be checked daily by the executing personnel in

accordance with the relevant checklist (Appendix B).

When the habitat is not in use, it should be opened to allow air to flow through it.

The supplier/owner of the habitat equipment must have a system for the maintenance and

inspection of all the elements included in the habitat system. Any need for help from the

operator, such as for routine checks of gas detectors and electrical equipment, should be

clarified at the individual installation/facility.

Removal of the habitat

After use, the habitat and other temporary equipment should be removed as quickly as possible

so that the installation/facilitys operations can be returned to normal.

There is often dust, etc. inside the habitat after use, so appropriate personal protective

equipment must be used when removing this.

The control room should be contacted to return any temporary safety measures (for use of the

habitat) to normal operation.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

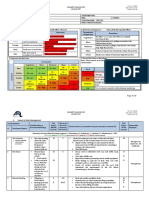

Risk management

The identification of risks should be based on single activities associated with the planning, design,

inspections, operation and maintenance, and removal of the habitat as described above. It can be

helpful to divide the individual activities into requirements, best practice, assessment by the

executing team and the actual execution of the activities as follows:

Requirements

Identify requirements relating to the activity in order to ensure an understanding of what shall be

achieved.

Method (procedure)

Identify best practice and ensure the understanding and use of this.

Assessment by the executing work team

The planning must ensure involvement from the executing team. This is in order to ensure that

the best practice (method) is sufficient to manage the risks and meet the requirements.

Execution

In the event of changes/any stop in the work, a new risk assessment should be carried out

before the work is resumed.

Appendices

A: Checklist for approval of habitats

B: Daily checklist for habitats

C: Duties of the habitat guard

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Appendix A: Checklist for approval of habitats

No.

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

Contents:

Responsible:

The habitat, including its door, is constructed from flame retardant

materials, adequately stiffened, and constructed so that heat and sparks

from the planned activity do not constitute an ignition source risk outside

the habitat.

The habitat is equipped with a window for visibility and constructed so

that the fire watcher outside the habitat can monitor the activity inside the

habitat.

A self-closing door is fastened to the frame and the closing mechanism

functions correctly. The seal around the door is checked and OK.

The habitat fabric is secured against leaks around pipes and structures

with straps or tape.

The air inlet to the habitat is located in a safe area.

Habitat

installer

Overpressure inside the habitat is tested to at least 50 Pa (5mm VS).

Electrical contacts and valves for air that is used to run the fans are

labelled: For habitat, must not be closed/switched off and secured in

the open position.

The executing worker, area technician and habitat guard are familiar with

the automatic shutdown system and checklists.

The escape routes are checked and cleared also with respect to how a

stretcher can be evacuated. Alternative escape routes are labelled inside

the habitat.

A pressurised fire hose is positioned outside the habitat. The fire water

valve is labelled For habitat, must not be closed and secured in the

open position.

A function test of the control unit(s), including testing with gas, has been

carried out.

The habitat has been evaluated for HC leaks/sweating in the vicinity of

the habitat, e.g. plug leaks.

Exposed flame detectors are shielded or set to bypass.

(If in doubt, this must be tested in collaboration with the CCR).

Gas detectors are in position, connected to the control unit and the

placement is approved by the area technician.

The method of communication between the executing worker and habitat

responsible has been agreed upon, e.g. for opening the door of the

habitat, and the habitat responsible is familiar with the task to be carried

out.

For welding: There is a zinc bucket for used electrodes inside the habitat,

as well as water for cooling the workpiece.

Sufficient welding/emery cloths are hung up to protect the fabric of the

habitat. There are no flammable materials inside the habitat.

EX certified lights that do not shut off when the electricity supply for

welding is disconnected are installed.

All electrical equipment that is used inside the habitat, with the exception

of EX certified emergency lighting, is connected to a control unit. Welding

equipment and heat treatment transformers are placed inside the habitat.

Preventive maintenance has been carried out on the electrical

equipment.

Heat from the planned activity does not constitute an ignition source risk

outside the habitat.

When the habitat is used with any gas sources (propane

oxygen/acetylene) inside the habitat itself: One of the gas detectors

connected to the automatic disconnection system for ignition sources is

placed at the lowest possible level inside the habitat together with a

hand-held O2 meter. Gas bottles are placed outside the habitat and the

control valves on these are physically disconnected before welding

starts. Gas equipment, including hoses, is tested for leaks and found to

Habitat

installer

Habitat

installer

Habitat

installer

Habitat

installer

Habitat

installer

Habitat

installer

Habitat

installer

Area

technician

Area

technician

Area

technician

Area

technician

Area

technician

Area

technician

Executing

worker

Executing

worker

Executing

worker

Executing

worker

Executing

worker

Executing

skilled

worker

Signature:

Verified:

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

21

be in order.

The need for fresh air has been assessed, and online meters for

fresh/breathing air have been function tested and approved.

22

An Approved sign is installed when the habitat has been approved. The

habitat must be re-approved in the event of changes.

Executing

worker

Executing

worker

Habitat No.: _________Approved Date:________ Area/ Module: __________SJA No.:_________

Area Technician:

Operational system responsible:

Habitat expert:

Completed checklists shall be stored together with the active work permit.

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Appendix B: Checklist for daily inspection of habitats

No.

Contents:

Responsible:

A pressurised fire hose is positioned outside the habitat. The fire

water valve is labelled For habitat, valve must not be closed and

secured in the open position. (If there is a risk of frost, the hose

should be positioned while dry and the valve labelled For habitat,

must not be disconnected).

The escape routes are checked and cleared also with respect to

how a stretcher can be evacuated.

Sufficient welding/emery cloths are hung up to protect the fabric of

the habitat, and there are no flammable materials inside the habitat.

None of the components of the habitats door are flammable.

Gas detectors are in position.

Executing

worker

2

3

4

5

6

7

All electrical equipment that is used inside the habitat, with the

exception of EX certified emergency lighting, is connected to a

control unit. Welding equipment and heat treatment transformers

are placed inside the habitat. Normal preventive maintenance (PM)

has been carried out on the electrical equipment.

EX certified lights that do not shut off when the electricity supply for

welding is disconnected are installed.

Heat from the planned activity does not constitute an ignition source

risk outside the habitat. The need for protection under the floor, in

the ceiling or around pipes has been assessed.

When the habitat is used with any gas sources (propane

oxygen/acetylene) inside the habitat itself: One of the gas detectors

connected to the automatic disconnection system for ignition

sources is placed at the lowest possible level inside the habitat

together with a hand-held O2 meter. Gas bottles are placed outside

the habitat and the control valves on these are physically

disconnected before welding starts. Gas equipment, including

hoses, is tested for leaks and found to be in order.

Habitat No.: _________

Date:________

Executing

worker

Executing

skilled worker

Executing

skilled worker

Executing

worker

Executing

worker

Executing

worker

Executing

worker

Area/ Module: ___________

Executing worker:

Completed checklists shall be stored together with the active work permit.

Signature:

Working Together for Safety Recommendation 036N/2012

Use of habitats

Rev 00

Appendix C: Duties of the habitat responsible

The Habitat guard shall be clearly identifiable from clothing featuring the words Habitat guard (Habitatvakt) or

Fire watcher (Brannvakt)

Duties of the habitat responsible when using habitats in process areas

Before the work starts,

the habitat responsible

shall:

- Review all the habitats safety functions together with the person responsible for work

in the habitat

- Become familiar with the requirements for overpressure, breathing air and extra

meters when using gas or propane

- Become familiar with the use and operation of the gas meters

- Agree upon stop signals with the personnel who shall work inside the habitat

- Participate in Safe Job Analysis

- Establish and maintain radio communication with the central control room (CCR)

- Inform involved personnel of escape routes

- Ensure that all lighting and other equipment is in accordance with instructions for

equipment used inside welding habitats

- Position the following equipment at the habitat and make it ready for immediate use:

EX certified flashlight

Pressurised fire hose

Foam/water fire extinguisher. Remember that CO2 should never be used on

fires in enclosed areas/habitats

Compressed air breathing apparatus with buddy mask or equivalent, if

necessary

Other rescue equipment as required by the work permit.

Before work starts, the

habitat responsible

shall become familiar

with:

- The nearest trigger for the sprinkler/deluge system

- The circuit breaker for welding equipment/electrical equipment

- The location of the nearest telephone/fire alarm

During the work, the

habitat responsible

shall:

- Not participate in work that may disturb the task at hand

- Remain at the entrance to the habitat and visually monitor the work and surroundings

at all times

- Stop the work if incidents occur that may affect the safety of personnel or the work

that is being carried out

When the work is

interrupted or

completed, the habitat

responsible shall:

- Secure the equipment/work site

- Turn off electrical equipment and shut off any gas bottles

- Gas bottles shall be physically disconnected when personnel leave the habitat

- Notify the area technician/CCR

In the event of an

undesirable incident in

the entry area, the

habitat responsible

shall:

- Notify work colleagues, the CCR, and sound the alarm

- Administer life-saving first aid if this is possible without exposing oneself to danger

- Secure the work site and shut off any gas bottles

In an alarm situation,

the habitat responsible

shall:

- Notify work colleagues and stop the work

- Secure the work site, and shut off any electrical equipment and gas bottles

You might also like

- Muscle Fitness Magazine 12 Weekrock Hard Challenge 2008Document7 pagesMuscle Fitness Magazine 12 Weekrock Hard Challenge 2008campbenc100% (2)

- Process Operations Task No. Description: Work ProcedureDocument6 pagesProcess Operations Task No. Description: Work Proceduregururaj100% (1)

- Flange Management ProcedureDocument15 pagesFlange Management Proceduremahi1437100% (5)

- Simultaneous Operations (SIMOPS)Document19 pagesSimultaneous Operations (SIMOPS)Desmond Chang80% (10)

- Module One Dry NeedlingDocument56 pagesModule One Dry NeedlingAndrei R Lupu100% (3)

- Industrial Industrial Rope Access Division Method Statement Method StatementDocument22 pagesIndustrial Industrial Rope Access Division Method Statement Method StatementAli Sadiqin0% (1)

- Work Method Statement Template - May 2020Document4 pagesWork Method Statement Template - May 2020Anson Chew Wai Yin100% (1)

- 4 - Hydro Jetting and Sludge RemovalDocument18 pages4 - Hydro Jetting and Sludge RemovalPerwez21100% (2)

- H99-0008 - 02 - A - Flange ManagementDocument19 pagesH99-0008 - 02 - A - Flange Managementadam100% (3)

- Confine Space Entry Procedure New - OptDocument23 pagesConfine Space Entry Procedure New - OptAizat Najib100% (4)

- TFA Course For Foremen & QC TechnDocument39 pagesTFA Course For Foremen & QC TechnPrabhu Rajalingam100% (1)

- JSA - Shut Down and Tie in WorkDocument6 pagesJSA - Shut Down and Tie in WorkNurul Hidayah67% (6)

- Drop Object Prevention PlanDocument8 pagesDrop Object Prevention PlanAui Piando100% (1)

- 15.tube Bundle Puller.Document3 pages15.tube Bundle Puller.Mohammad Fazal Khan100% (1)

- Hot Work ProcedureDocument30 pagesHot Work ProcedureOws Anish100% (3)

- Chevron SOP 45 Scaffolding PDFDocument40 pagesChevron SOP 45 Scaffolding PDFmohammedkaustNo ratings yet

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 pageManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Sec.2-61 Sky Climbers & Suspended Power PlatformsDocument6 pagesSec.2-61 Sky Climbers & Suspended Power Platformsbravo2uniform2736100% (1)

- JSA006 - Vacuum Box TestingDocument5 pagesJSA006 - Vacuum Box TestingLaohan LiuNo ratings yet

- LIMA-Z-PRC-1013 Rev 1 Habitat Operation N Dismantling ProcedureDocument45 pagesLIMA-Z-PRC-1013 Rev 1 Habitat Operation N Dismantling ProcedureCahya Adi Yefta100% (3)

- JSA UT Thickness PVDocument3 pagesJSA UT Thickness PVMuhammadHudanulHakim67% (3)

- Abbrasive Blasting ProceduresDocument4 pagesAbbrasive Blasting Proceduresdanielpospited100% (1)

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Industy Code of Practice For Safe Working in A Confined Space 2010Document80 pagesIndusty Code of Practice For Safe Working in A Confined Space 2010Abd Rahim100% (2)

- Welding ProcedureDocument7 pagesWelding Proceduredương_thành_28No ratings yet

- Abrasive Blasting Safe Work PDFDocument2 pagesAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- Installation of Pipe SpoolsDocument3 pagesInstallation of Pipe SpoolsAbdul Hakam Mohamed Yusof100% (2)

- Welding and Cutting ProcedureDocument5 pagesWelding and Cutting ProcedureRoger SimbhooNo ratings yet

- JSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityDocument7 pagesJSA-RSS-HSE-005 Bristle Blasting, Needle Gun and Painting ActivityRaditya PramudyaNo ratings yet

- Confined Space CSE Air Supply CalculationDocument9 pagesConfined Space CSE Air Supply Calculationasep saefulloh100% (1)

- P1 Group Pipe Purging ProcedureDocument2 pagesP1 Group Pipe Purging Procedurembrush810100% (1)

- Nitrogen PurgingDocument4 pagesNitrogen PurgingKatamaneni KoteswararaoNo ratings yet

- Valve ReplacementDocument7 pagesValve ReplacementKamarularifin Kamel100% (2)

- SWP06 MSW WorkatHeight ChevronDocument34 pagesSWP06 MSW WorkatHeight Chevronpriyanta100% (1)

- H2S ManagementDocument4 pagesH2S Managementmailisaf100% (1)

- Catalog Intipratama Global TeknikDocument34 pagesCatalog Intipratama Global TeknikToto SusantoNo ratings yet

- Flange Management ProcedureDocument15 pagesFlange Management Proceduremahi1437100% (3)

- Retrieval of Stuck Pig PDFDocument1 pageRetrieval of Stuck Pig PDFyasir_anjumNo ratings yet

- 206B-FF Flange Facer ManualDocument22 pages206B-FF Flange Facer ManualKmelt39No ratings yet

- Flange Bolt Tightening ProceduresDocument11 pagesFlange Bolt Tightening Proceduresjerrymcfly0% (1)

- JSA Hot TapingDocument3 pagesJSA Hot TapingHeris Sitompul0% (1)

- Flange Management Procedure FixDocument13 pagesFlange Management Procedure FixNaza Gavaputri100% (2)

- 022 Procedure Hand ToolsDocument14 pages022 Procedure Hand ToolsHSE CERINo ratings yet

- Job Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCDocument4 pagesJob Safety Analysis Form: Law M. Mechanical Supervisor Alex A./ Egbejimi Adebayo PSCChukwuma Emmanuel Onwufuju0% (1)

- Assembling Flanged Joints Procedure1Document34 pagesAssembling Flanged Joints Procedure1Ndomadu100% (3)

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- 7 JSA WrappingDocument3 pages7 JSA WrappingYosua Situmorang100% (1)

- Flange Management Procedure FixDocument13 pagesFlange Management Procedure FixGalih Prianggodo100% (3)

- Lifting Plan of SpoolDocument1 pageLifting Plan of SpoolhazopengineerNo ratings yet

- 011.TBSHE JSA 005 Pipelaying WorkDocument8 pages011.TBSHE JSA 005 Pipelaying Worknellaika puspa dewi100% (1)

- JSA UT TestDocument1 pageJSA UT TestIksan Adityo MulyoNo ratings yet

- JHA Valve Leak Test and RepairDocument16 pagesJHA Valve Leak Test and Repairrosevelvet100% (1)

- Rope Access IntroDocument21 pagesRope Access IntroWan Rozaidi100% (1)

- Line Breaking, Blinding & De-Blinding ProcedureDocument39 pagesLine Breaking, Blinding & De-Blinding Procedureaimanshirin5No ratings yet

- Job Procedure For RadiographyDocument12 pagesJob Procedure For RadiographyMecon HyderabadNo ratings yet

- 03-Procedure For WeldingDocument8 pages03-Procedure For WeldingAyush AgarwalNo ratings yet

- API RP 2D Rigger Safety (2 Day) (API-U Approved)Document1 pageAPI RP 2D Rigger Safety (2 Day) (API-U Approved)idris100% (1)

- Pipeline RepairsDocument44 pagesPipeline RepairsMohamad PizulNo ratings yet

- 364 Pre Job Check List High Pressure Hydro Jetting Rev 000Document2 pages364 Pre Job Check List High Pressure Hydro Jetting Rev 000asan100% (1)

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Use of Habitats-NorskDocument12 pagesUse of Habitats-NorskmashanghNo ratings yet

- Working Together For Safety Recommendation 036N/2012 Use of HabitatsDocument12 pagesWorking Together For Safety Recommendation 036N/2012 Use of HabitatsgopuNo ratings yet

- Recommendation 036E HabitatDocument11 pagesRecommendation 036E HabitatcweilietNo ratings yet

- Markl SIFs & Asme ViiiDocument3 pagesMarkl SIFs & Asme ViiiDesmond ChangNo ratings yet

- Induction BendsDocument16 pagesInduction BendsDesmond Chang100% (1)

- Stressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Document4 pagesStressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Desmond ChangNo ratings yet

- SIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDocument2 pagesSIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDesmond ChangNo ratings yet

- Lopa Workbook Sept 2005Document12 pagesLopa Workbook Sept 2005Desmond Chang100% (1)

- Stressman Engineering - Study - Stresses in Branch Connections at Different AnglesDocument7 pagesStressman Engineering - Study - Stresses in Branch Connections at Different AnglesDesmond ChangNo ratings yet

- PFD Calculation Program: #Value! #Value! #Value!Document4 pagesPFD Calculation Program: #Value! #Value! #Value!Desmond ChangNo ratings yet

- Standards IndexDocument32 pagesStandards IndexDesmond Chang100% (1)

- Weld End Preparation at Unequal Wall ThicknessesDocument4 pagesWeld End Preparation at Unequal Wall ThicknessesDesmond ChangNo ratings yet

- Piping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDocument52 pagesPiping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDesmond Chang100% (1)

- Ansys - DynamicsDocument13 pagesAnsys - DynamicsNono_geotecNo ratings yet

- PDMS Update AvevaDocument21 pagesPDMS Update AvevaDesmond ChangNo ratings yet

- ANSYS Modal AnalysisDocument40 pagesANSYS Modal AnalysisDesmond Chang100% (1)

- Permit To Work Flow ChartDocument2 pagesPermit To Work Flow ChartDesmond ChangNo ratings yet

- The Basics of Arc WeldingDocument35 pagesThe Basics of Arc WeldingDesmond ChangNo ratings yet

- 第1章 牙合(英文)Document73 pages第1章 牙合(英文)pete6514100% (1)

- NCPDocument4 pagesNCPAndrea BroccoliNo ratings yet

- Pneumonia GuidelinesDocument4 pagesPneumonia GuidelinesFatkhul Ali ImronNo ratings yet

- C E C T Steel Penstocks PDFDocument80 pagesC E C T Steel Penstocks PDFtecnidibujosNo ratings yet

- Amarta Hills Club House Capacity: Dimensi (m2) On FunctionDocument1 pageAmarta Hills Club House Capacity: Dimensi (m2) On Functiontaufiq baskoroNo ratings yet

- Unit Test 3 - Group A: ListeningDocument3 pagesUnit Test 3 - Group A: ListeningMen BlysNo ratings yet

- Fibrodysplasia Ossificans ProgressivaDocument13 pagesFibrodysplasia Ossificans ProgressivaCharles IppolitoNo ratings yet

- Sports and Performance NutritionDocument18 pagesSports and Performance Nutritionuser-100722No ratings yet

- Teacher Biology Careers Lesson PresentationDocument22 pagesTeacher Biology Careers Lesson PresentationalimeeroNo ratings yet

- The Plant Food Factory: Background KnowledgeDocument2 pagesThe Plant Food Factory: Background Knowledgeapi-254428474No ratings yet

- SHS PE MODULE 1 - RemovedDocument21 pagesSHS PE MODULE 1 - RemovedXypher NNo ratings yet

- QOSDocument40 pagesQOSravindraNo ratings yet

- Homeopathic Proving of Titanium Metallicum: Materials and MethodsDocument3 pagesHomeopathic Proving of Titanium Metallicum: Materials and MethodsAditya RajNo ratings yet

- Broqueza, Jonnel Regoris: Philippine Children's Medical CenterDocument1 pageBroqueza, Jonnel Regoris: Philippine Children's Medical CenterRica RegorisNo ratings yet

- A Histoarchitectural Approach To Skeletat Muscle InjurieDocument9 pagesA Histoarchitectural Approach To Skeletat Muscle InjurieJesúsNo ratings yet

- Kimia Jawaban Tugas Kimia IntiDocument24 pagesKimia Jawaban Tugas Kimia IntiMonica Puspita SariNo ratings yet

- Mango Malformation ReviewDocument6 pagesMango Malformation ReviewBhanu DangiNo ratings yet

- NGT PresentationDocument23 pagesNGT PresentationniyigokNo ratings yet

- Chang v. Orgain Inc. ComplaintDocument33 pagesChang v. Orgain Inc. Complaintyumyum9No ratings yet

- Cro in SingaporeDocument41 pagesCro in SingaporeSan EeshNo ratings yet

- Incepta Intern PaperDocument83 pagesIncepta Intern PaperSoikotNo ratings yet

- Handling of Safety Information From Social MediaDocument14 pagesHandling of Safety Information From Social MediaYash DevrukhkarNo ratings yet

- 15-Sensory OrgansDocument23 pages15-Sensory OrgansMilad HabibiNo ratings yet

- Books ListDocument51 pagesBooks ListManoj PeddintiNo ratings yet

- Food SafetyDocument6 pagesFood SafetyRafid HassanNo ratings yet

- Reproductive and Child Health ProgrammeDocument37 pagesReproductive and Child Health ProgrammeVeena JV100% (3)

- Format Iii: Examination Results (Annual and Supplementary) OF The UniversityDocument16 pagesFormat Iii: Examination Results (Annual and Supplementary) OF The UniversityArun KumarNo ratings yet

- Essential - Health - Packages - Docx Filename - UTF-8''essential Health PackagesDocument10 pagesEssential - Health - Packages - Docx Filename - UTF-8''essential Health PackagesYvonne Carmel Aguilar SunigaNo ratings yet