Effect of Carbonitiriding On Endurance Life of Ball Bearing Produced From Sae52100

Uploaded by

mans2014Copyright:

Available Formats

Effect of Carbonitiriding On Endurance Life of Ball Bearing Produced From Sae52100

Uploaded by

mans2014Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Effect of Carbonitiriding On Endurance Life of Ball Bearing Produced From Sae52100

Uploaded by

mans2014Copyright:

Available Formats

Journal of Surface Engineered Materials and Advanced Technology, 2013, 3, 172-177

http://dx.doi.org/10.4236/jsemat.2013.33023 Published Online July 2013 (http://www.scirp.org/journal/jsemat)

Effect of Carbonitriding on Endurance Life of Ball Bearing

Produced from SAE 52100 Bearing Steels

Karthikeyan Rajan, Vinod Joshi, Arindam Ghosh*

Research & Development, National Engineering Industries Ltd., Jaipur, India.

Email: *arindam.ghosh@nbcbearings.in

Received April 5th, 2013; revised May 6th, 2013; accepted June 1st, 2013

Copyright 2013 Karthikeyan Rajan et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ABSTRACT

The present paper reports the unusual enhancement of endurance life of ball bearings subjected to carbonitriding treatment. The microstructure was characterized by scanning electron microscopy and correlated with hardness and X-ray

diffraction analysis. Endurance tests at 90% reliability revealed that the carbonitrided bearings exhibit nearly ten times

more life than the non-carbonitrided bearings. This is attributed to synergic combination of retained austenitic, fine

martensitic microstructure and ultrafine carbide precipitates obtained by carbonitriding treatment.

Keywords: Carbonitriding; Retained Austenite; Martensite; Endurance Test; Bearing Steel

1. Introduction

Rolling bearings of 21st century are expected to deliver

superior performance for prolong duration while operating under most hostile (ultrahigh speed and load with

insignificant lubrication) conditions [1]. To meet these

exponentially increasing service demands, bearing tribologists have constantly been exploring newer avenues

to improve the performance. The SAE 52100 steel, in

hardened and tempered condition with a predominantly

tempered-martensitic microstructure and appropriate amount

of retained austenite (RA) is strenuously developed as a

promising rolling bearing material for many automotive

applications. Owing to this synergic combination of fine

martensitic microstructure and RA, sufficient wear

(abrasion) resistance and mechanical (fatigue and tensile)

strength at ambient temperature are obtained.

Majority of the failures in rolling bearings are due to

rolling contact fatigue (RCF) and are defined as the mechanism of crack propagation caused by the near surface

alternating load cycle within the rolling-contact bodies,

which eventually leads to material removal by cracking

or pitting/delamination [2]. Recently, there have been

lots of researches in SAE 52100 steel to understand and

improve the resistance to RCF [2]. It can be noted that

the surface characteristics of the bearings greatly affect

the RCF, for all the fatigue failure initiates at the surface.

Engineering the surface condition to achieve desired pro*

Corresponding author.

Copyright 2013 SciRes.

perties is an inevitable solution to avoid/postpone the

failure.

Various surface chemistry modifications and coating

techniques have been employed by technologist to enhance the life of the bearing by preventing/postponing

the RCF and other commonly occurring defects in the

bearing. Among the techniques, carbonitriding (CN)

seems to be quite cost effective [1]. Recently, CN has

been extensively used to enhance the surface hardness,

wear, fatigue characteristics of metal and alloys [1]. The

process involves in penetration of C and N2 into base metal lattice at interstitial spaces, generating significant crystallographic compressive stresses [3]. It can be noted

that surface chemistry and residual compressive stresses

greatly influence RCF strength [4]. The CN provides a

range of parameters which can be optimized suitably to

get properties of interest.

In this investigation, attempt has been made to develop

CN treatment on SAE 52100 steel and evaluate the conventional ball bearings endurance life. The above effects

on CN have opened new opportunities for developing

bearings with improved RCF resistance.

2. Experimental Procedure

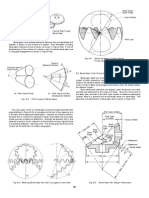

The average chemical composition of the steel was examined using optical emission spectroscopy-ARL FISONS 3460 Metal Analyzer (OES) analysis. The CN treatment is performed, which is, austenitization at temperaJSEMAT

Effect of Carbonitriding on Endurance Life of Ball Bearing Produced from SAE 52100 Bearing Steels

ture typically between 1073 - 1173 K (800C - 900C)

for 110 - 230 minutes followed by oil quenching at 333 353 K (60C - 80C) and tempering at 423 - 533 K

(150C - 250C). The schematic of temperature-time

cyclogram of employed CN treatment is shown in Figure

1. Following CN treatment metallographic examination

is conducted using scanning electron microscopy (SEM).

Specimens are etched with 2% nital for 20 - 60 s to obtain reliable metallographic images. Retained austenite

and phase analysis were conducted using X-ray diffracttion (XRD) PANalytical, Xpert Pro diffractometer with

a rotating Cu K radiation. The instrumental contribution

to peak broadening was subtracted before the RA analysis. Mitutoyo hardness tester-ARK-F1000 with load of

1000 g and a dwell time of 10 s was employed to determine the hardness and temper resistance characteristics

of the steel. The specimens for optical microscopy, SEM,

XRD and temper resistance were cut from outer (Figure

2(a)) and inner (Figure 2(b)) ring of the bearing after the

Figure 1. Illustration of various stages in temperature-time

cyclogram of the carbonitriding treatment with gas potential.

(a)

CN treatment. In endurance test, the bearings were subjected to high speed rotation (1000 - 11,000 rpm) under

heavy load (20% - 40% of dynamic load rating) with presence of oil lubrication. Vibrations and temperature are

the two important parameters that were monitored continuously during the test. ENKLO-68, HP oil is employed

as lubricant in endurance test.

3. Results and Discussion

3.1. Chemical Composition

The average chemical composition (in wt%) of steel

(from Spectra analysis) was found to be Fe: 95.91%, C:

1.12%, Mn: 0.43%, Si: 0.36%, Cr: 1.6%, S: 0.027%, P:

0.024%, Ni: 0.24%, Cu: 0.26%, Mo: 0.04%. It can be

seen that the compositions are reasonably close to the nominal composition of SAE 52100 steel [1].

3.2. X-Ray Diffraction Analysis

Figure 3 shows X-ray diffraction spectra of carbonitrided (plotted using black colour) and non-carbonitrided

(plotted using red colour) samples. It can be noted that

the carbonitriding treatment as resulted in formation of

nitrides and carbides based phases. In non-carbonitrided

sample the predominant phase is Fe (Cr, Mo) solid solution (PDF: 09-0050). Unidentified peaks are expected to

peaks of complex Fe-Cr based oxides. In carbonitrided

sample, Fe3C (PDF: 35-0772), -C3N4 (PDF: 50-0848)

and complex nitrides of Fe and Si were identified in addition to the matrix material. Formation of process-induced phases (Fe, Cr and Si based oxides) are also expected. It can also be seen the full width half maximum

(FWHM) appears to the reduced after the carbonitriding

treatment. This is attributed to the possible grain coarsening during the carbonitriding treatment. Process-induced phases (carbide, nitrides and oxide precipitates)

(b)

Figure 2. Schematic of bearing component: (a) Outer ring

and (b) Inner ring.

Copyright 2013 SciRes.

173

Figure 3. XRD Diffraction spectra of SAE 52100 steel: carbonitrided material, non-carbonitrided specimen.

JSEMAT

174

Effect of Carbonitriding on Endurance Life of Ball Bearing Produced from SAE 52100 Bearing Steels

behave as dispersoids in the matrix leading enhanced

mechanical properties.

3.3. Scanning Electron Microscopy

The SEM micrographs of outer ring after CN treatment

are shown in the Figure 4. Presences of two different

phases are evident from the micrographs: fine martensite

and retained austenite. The micrographs of outer ring

(Figures 4 (a) and (b)) shows that the retained austenite

grain size at surface (~4 - 5m) is significantly higher

compared to core (<1 m). EDS analysis (Figure 5) of

the retained austenite (marked in dotted circle 1 in the

Figure 4) indicated the presence of Fe, Mn, and Cr.

The microstructure prior to quenching consists of ferrite matrix and coarse carbides (M7C3/M23C6) in these

steels. The volume fraction and nature of the carbides

depends upon heat treatment conditions [5]. The 52100

steels are quenched and tempered before usage and their

material properties are significantly influenced by the

characteristics of the carbides. Studies have indicated

that the uniform dispersion and fineness of carbides

(M7C3/M23C6) are ideal for improved mechanical properties [5]. Carbides are prevents the grain boundary sliding

and migration by pinning/strengthening the boundaries

[5]. It is to be expected that this change will cause an

increase in the dispersion strengthening brought about by

the carbides. XRD analysis of carbonitrided sample

(Figure 3) indicated the presence of carbides and nitride

precipitates and this is consistent with the SEM results

obtained at core (Figure 6). It can be noted that dissolution of carbides are envisaged at higher austenitizing

temperatures, leading to depinning of grain boundaries.

Similarly, decreasing the austenite transformation temperature of the steel with given carbon content will lend

to smaller size of carbide precipitates besides increasing

the number density of the carbides [6,7]. In addition, dislocation density increases with decreasing transformation

temperature, primarily due to the greater strain accompanying the transformation and because there is very

possibility for the dislocations to be annealed out during

the shorter time of transformation. It can be noted that

fraction of dislocation density is directly proportional to

the strength of the steel.

3.4. Micro-Hardness Analysis

The micro-hardness on surface was determined at 10

different areas in the specimen with the interval of 5 x,

where x is the length of the diagonal of the indentation.

The average hardness of specimen was found to 63.6

Figure 4. SEM micrograph of CN ball bearing outer ring

fabricated from 52100 steel, (a) at surface and (b) at core.

Figure 5. The EDS spectrum is from globular RA marked 1

in the image Figure 4 (a).

Copyright 2013 SciRes.

Figure 6. High resolution SEM image of CN ball bearing

inner ring fabricated from 52100 steel showing fine globular cementite.

JSEMAT

Effect of Carbonitriding on Endurance Life of Ball Bearing Produced from SAE 52100 Bearing Steels

1.3 and 61.2 1.4 HRc for carbonitrided sample and

non-carbonitrided sample respectively. Figure 7 shows

the variation in hardness (in HRc) along cross section of

CN steel and non-CN steel tempered at 573 K for 180

min and at 623 K for 210 min. It can be seen that the

hardness of CN steel is higher than that of non-CN steel

at all tempering temperatures. This is possibly due to

presence of fine precipitates of carbides and nitrides uniformly aggregated in the fine martensitic microstructure,

which act as obstacles to the motion of dislocations. In

addition, at the surface, drop in hardness of non-CN samples after tempering is higher compared to CN samples.

This is possibly due to coarsening of the microstructure

of non-CN samples; whereas in the case of CN samples

presence of fine carbides and nitrides stabilize the microstructure by restricting coarsening of grain boundaries.

Presences of the fine carbides and nitrides in CN samples

are quite evident from XRD analysis.

Figure 8 shows the plot of ln (hardness) vs. distance

from surface for CN steel tempered at 573 K for 210 min

and 623 K for 180 min. It can be seen that there is a

gradual decrease in the hardness up to ~0.5 m from the

surface after which there is no appraisable decrease in the

hardness. Figure 8 also shows a drastic slope change in

hardness at a particular distance, which is referred to as

transition zone in these steels. The transition zone indicates the case depth of the CN layer. It can also be

noted the value of the slope is related to microstructural

stability.

3.5. Retained Austenite

The martensite () (body centered tetragonal) structure

has a larger volume than the austenite () (face centered

cubic). Owing to this, ~4% volumetric expansion is observed during to transformation. At room temperature, heavy mechanical stresses favor the to

transformation, leading to distortion, crack initiation and

propagation. For this reason, amount of RA on the surface (after quenching and tempering) has to be appropriately optimized. It can be noted that the percentage of

RA in the quenched condition is directly proportional to

austenitizing temperature [8]. In this study, our austenizing temperature is 1113-1173 K (840C - 900C).

The measurement condition with regard to XRD is that

the scanning speed is 2/min and measured planes are

(200) , (220) , (211) and (311) . The

amount of retained austenite is estimated using intensity

ratio of (martensite) and (austenite). The volume

fraction of all carbides is given by

n

r

Figure 7. Hardness profile of CNed steel and non-treated

steel annealed at 573 K for 180 min and 623 K for 210 min.

(filled symbols corresponding to CNed steel and unfilled

symbol corresponds to non-treated steel).

Figure 8. Plot of ln (hardness) vs. distance from surface for

CN steel.

Copyright 2013 SciRes.

175

1 n I

hkl

Rhkl

1

n

1 n Ihkl / Rhkl 1 / n Ihkl / Rhkl

1

(1)

where r is the volume fraction of all carbides in the material, Ihkl and Ihkl the integrated intensities of austenite and ferrite peaks, respectively, n and n the numbers

of (hkl) lines for which the integrated intensities have

been measured, and Rhkl and Rhkl are theoretical intensities [9]. Determination of phase volume fraction

using optical microscopy is unsuitable for phase

which do not exceed more than few microns. For accurate measurement, computer image analysis after colour

etching, neutron or X-ray diffraction and magnetic

methods are employed [9,10]. In Figure 9, the percentage of RA at the surface and core is shown as a function

of tempering temperature for the SAE 521000 steel. It is

observed in quenched condition ~55% and ~35% RA at

surface and core respectively and the rest is composed of

fine martensite formed during quenching. The increased

volume fraction of RA both at surface and core after

quenching to room temperature is attributed to the effect

JSEMAT

176

Effect of Carbonitriding on Endurance Life of Ball Bearing Produced from SAE 52100 Bearing Steels

Figure 9. Variation of percentage retained austenite at surface and core with tempering temperature, K.

of interstitial alloying element like nitrogen. It has been

shown in Figure 1 that the CN treatment has been done

with above A1 temperature in the presence of nitrogen

source (ammonia (NH3)), which greatly influence the

austenite stability at room temperature.

It can be noted that there is very minimal reduction in

the RA till ~400 K (~127C) above which reduction is

steep (Figure 9). It can be seen that saturation tread is

observed around 520 K (277C) at surface; however no

such saturation trend is seen at core. A distinct change in

the slope indicates strong temperature dependence of RA

(Figure 9). The value of slope indicate rate of RA to

martensite transformation. It is quite evident from the

values slope that RA at surface transforms faster compared to RA at core. It directly related to the poor thermal stability of RA at the surface compared to RA at core.

The goodness of the linear Recent investigation indicates

that the higher RA contents at the surface increase the

fatigue life of the bearing [11].

3.6. Endurance Testing

RCF life of bearings in dependent on many interacting

factors such as bearing materials, melting technique, material processing variables, lubricant system, elasto-hydrodynamic (EHD) film thickness, contact stress levels

and other environmental and operational effects [11]. Endurance testing is a global employed technique to evaluate RCF of the bearing. Figure 10 shows the comparson of endurance testing of non-carbonitriding and carbonitriding ball bearings. Five different sets bearing were

subjected to endurance testing. The target L10 life is denoted as x. It can be noted the all non-CN bearings

have failure due to fatigue after crossing the target L10

life. Surface roughness of the track (ball-path) is ~0.07

m. It is reduced to ~0.03 m after the endurance test. It

Copyright 2013 SciRes.

Figure 10. Comparison of endurance test of normal ball

bearing (non-carbonitrided) and carbonitrided ball bearing.

x-denoted the target L10 life.

is attributed to smoothening effect during the test. The

surface micro-asperities present in the ball-path gets flatten/smoothen owing to the high load in the presence of

lubricating oil. It can be seen the carbonitrided bearing

exhibit significant enhancement in the life (Figure 10). It

is attributed to the wear resistance characteristic of the

CN bearing surface. A presence of RA (>20% at surface)

aids in higher the RCF resistance by blunting the micro-crack and preventing the crack propagation. In addition, fine precipitates of carbides and nitrides increases

the stability of the microstructure, thereby increase the

wear resistance.

4. Conclusion

In summary, effect of carbonitriding on microstructure of

SAE 52100 steel revealed ultrafine carbides and nitrides

based precipitates. Case depth of ~0.5 m is observed

from temper resistance behaviour of carbonitrided steel

at 573 and 623 K. The dependence of the volume fraction

of retained austenite on the tempering temperature is demonstrated. The rate of transformation of retained austenite is faster in the surface of the component compared

to core. Endurance tests at 90% reliability revealed that

the carbonitrided bearings exhibit nearly ten times more

life than the non-carbonitrided bearings. This is attributed to synergic combination of retained austenitic, fine

martensitic microstructure and ultrafine carbide precipitates obtained by carbonitriding treatment.

5. Acknowledgements

Authors gratefully acknowledge the support of Ms.

Amathur Heat treatment Pvt. Ltd., Chennai in carbonitriding process. Karthik thankfully acknowledges Mr. N.

K. Gupta, Mr. Apoorv, Mr. Ayush Jain and Dr. Rajaram

for their support during characterization and discussion.

Authors gratefully acknowledge Mr. Anand Bapat, Mr.

JSEMAT

Effect of Carbonitriding on Endurance Life of Ball Bearing Produced from SAE 52100 Bearing Steels

Carburized Steel, Institute of Casting Problems, Metal

Science and Heat Treatment, Vol. 20, No. 11, 1978, pp.

927-930.

Srini Dumpur and Mr. Rohit Saboo for their encouragement and support throughout this research work.

REFERENCES

177

[7]

N. Luzginova, L. Zhao and J. Sietsma, Evolution and

Thermal Stability of Retained Austenite in SAE 52100

Bainitic Steel, Material Science and Engineering A, Vol.

448, No. 1-2, 2007, pp. 104-110.

doi:10.1016/j.msea.2006.10.014

[8]

M. Yaso, S. Hayashi, S. Morito, T. Ohba, K. Kubota and

K. Murakami Characteristics of Retained Austenite in

Quenched High C-High Cr Alloy Steels, Materials

Transactions, Vol. 50, No. 2, 2009, pp. 275-279.

doi:10.2320/matertrans.MRA2008161

B. D. Cullity, Elements of X-Ray Diffraction, Addison-Wesley, Reading, 1978.

[1]

H. K. D. H. Bhadeshia, Steels for Bearings, Progress in

materials Science, Vol. 57, No. 2, 2012, pp. 268-435.

doi:10.1016/j.pmatsci.2011.06.002

[2]

S. Stewart and R. Ahmed, Rolling Contact Fatigue of Surface CoatingsA Review, Wear, Vol. 253, No. 11-12,

2002, pp. 1132-1144.

doi:10.1016/S0043-1648(02)00234-X

[3]

W. Schilling, Self-Interstitial Atoms in Metals, Journal

of Nuclear Materials, Vol. 69-70, 1978, pp. 465-489.

[9]

[4]

R. C. Dommarco, K. J. Kozaczek, P. C. Bastias, G. T.

Hahn and C. A. Rubin, Residual Stresses and Retained

Austenite Evolution in SAE 52100 Steel under Non-Ideal

Rolling Contact Loading, Wear, Vol. 257, No. 11, 2004,

pp. 1081-1088. doi:10.1016/j.wear.2004.01.020

[10] J. D. Makinson, W. N. Weins and R. J. De Angelis, The

Substructure of Austenite and Martensite through a Carburized Surface, Advances in X-Ray Analysis, Vol. 34,

1990, pp. 483-491.

[5]

F. B. Pickering, The Structure and Properties of Bainite

in Steels, Symposium: Transformation and Hardenability in Steels, Michigan, 1967, pp. 109-129.

[6]

B. B. Vinokur, S. E. Kondratyuk, L. I. Markovskaya, R.

A. Khrunik, A. A. Gurmaza and V. B. Vainerman, Effect

of Retained Austenite on the Contact Fatigue Strength of

Copyright 2013 SciRes.

[11] J. J. C. Hoo, Rolling Contact Fatigue Testing of Bearings Steels, ASTM Special Technical Publication, Philadelphia, 1981, pp. 169-189.

JSEMAT

You might also like

- United Valve Comparison Awwa c515 Awwa c509100% (2)United Valve Comparison Awwa c515 Awwa c5092 pages

- Effect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentNo ratings yetEffect of Hardness and Wear Resistance On en 353 Steel by Heat Treatment4 pages

- Article - Experimental Characterization of Bending Fatigue Strength in GearNo ratings yetArticle - Experimental Characterization of Bending Fatigue Strength in Gear8 pages

- 007 Downloadable Resistor Color Code ChartNo ratings yet007 Downloadable Resistor Color Code Chart1 page

- Analysis of The Yokeless and Segmented Armature MachineNo ratings yetAnalysis of The Yokeless and Segmented Armature Machine7 pages

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannNo ratings yetFace Gears: Geometry and Strength: Ulrich Kissling and Stefan Beermann8 pages

- Grain Size and Mechanical Properties of Low Carbon Cast SteelNo ratings yetGrain Size and Mechanical Properties of Low Carbon Cast Steel7 pages

- Backlash Prediction of A Spur Gear Pair With Manufacturing Errors of Runouts, Span and Pitch DeviationsNo ratings yetBacklash Prediction of A Spur Gear Pair With Manufacturing Errors of Runouts, Span and Pitch Deviations18 pages

- A Kinematic Analysis of Meshing Polymer Gear TeethNo ratings yetA Kinematic Analysis of Meshing Polymer Gear Teeth16 pages

- Gregory A. Fett - Importance of Induction Hardened Case Depth in Torsional ApplicationsNo ratings yetGregory A. Fett - Importance of Induction Hardened Case Depth in Torsional Applications5 pages

- Gear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers EdgeNo ratings yetGear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers Edge3 pages

- Engine Mounts and Powertrain Mounting SystemsNo ratings yetEngine Mounts and Powertrain Mounting Systems22 pages

- Ball Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial AxialNo ratings yetBall Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial Axial6 pages

- Bossard White Paper Material Fatigue enNo ratings yetBossard White Paper Material Fatigue en16 pages

- Gear Trains: Qassim University Unayzah College of Engineering Mechanical Engineering DeptNo ratings yetGear Trains: Qassim University Unayzah College of Engineering Mechanical Engineering Dept42 pages

- AUC - 2004 - Finite Element Analysis of Rolls & Mill Housing in Cold Rolling MillNo ratings yetAUC - 2004 - Finite Element Analysis of Rolls & Mill Housing in Cold Rolling Mill11 pages

- Design of Machine Elements: Design Against Fluctuating LoadsNo ratings yetDesign of Machine Elements: Design Against Fluctuating Loads50 pages

- Solid Lubrication Fundamentals Amp Applications Materials Engineering PDFNo ratings yetSolid Lubrication Fundamentals Amp Applications Materials Engineering PDF415 pages

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFNo ratings yetCycloid Drive - Replaced by Planocentric Involute Gearing PDF6 pages

- Rolling Contact Fatigue in Ultra High Vacuum: Mike Danyluk and Anoop DhingraNo ratings yetRolling Contact Fatigue in Ultra High Vacuum: Mike Danyluk and Anoop Dhingra22 pages

- Further Understanding of Rolling Contact Fatigue in Rolling Element Bearings - A ReviewNo ratings yetFurther Understanding of Rolling Contact Fatigue in Rolling Element Bearings - A Review23 pages

- Metallurgy Unlocked Mastering Metallurgical Diploma Questions and AnswersFrom EverandMetallurgy Unlocked Mastering Metallurgical Diploma Questions and AnswersNo ratings yet

- Failure Analysis of Gas Turbine First Stage BladeNo ratings yetFailure Analysis of Gas Turbine First Stage Blade16 pages

- Effects of Heat Treatments On Steels For Bearing ApplicationsNo ratings yetEffects of Heat Treatments On Steels For Bearing Applications8 pages

- Time Management: A Practical Guide To Efficiently Prioritizing Your Time, Enabling You To Achieve Optimum ResultsNo ratings yetTime Management: A Practical Guide To Efficiently Prioritizing Your Time, Enabling You To Achieve Optimum Results3 pages

- Simplified Solution For Elliptical BodiesNo ratings yetSimplified Solution For Elliptical Bodies3 pages

- Bearing Life Optimization of Taper Roller BearingNo ratings yetBearing Life Optimization of Taper Roller Bearing3 pages

- Bearing Life Optimization of Taper Roller BearingNo ratings yetBearing Life Optimization of Taper Roller Bearing3 pages

- The Design of Rolling Bearing Mountings (FAG Bearing Co) WWNo ratings yetThe Design of Rolling Bearing Mountings (FAG Bearing Co) WW223 pages

- Reinforced Concrete Design - I: UET PeshawarNo ratings yetReinforced Concrete Design - I: UET Peshawar22 pages

- ANTEC 1999 - Investigation of Rhelogical Properties of Rotomolding ResinsNo ratings yetANTEC 1999 - Investigation of Rhelogical Properties of Rotomolding Resins5 pages

- Cold Weather Concrete A Review Paper On Concreting in Cold TemperatureNo ratings yetCold Weather Concrete A Review Paper On Concreting in Cold Temperature8 pages

- Use of Cement in Concrete According To European STNo ratings yetUse of Cement in Concrete According To European ST7 pages

- Manufacturing of Interlocking Brick With Cement-Lime Mortar and HyposludgeNo ratings yetManufacturing of Interlocking Brick With Cement-Lime Mortar and Hyposludge8 pages

- DT Breakout Fibre Optic Cable 4 24 Fibres Rev.1.0.3-3No ratings yetDT Breakout Fibre Optic Cable 4 24 Fibres Rev.1.0.3-33 pages

- Group 1 - Nature of Engineering MaterialsNo ratings yetGroup 1 - Nature of Engineering Materials67 pages

- BP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014No ratings yetBP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-201432 pages

- Effect of Hardness and Wear Resistance On en 353 Steel by Heat TreatmentEffect of Hardness and Wear Resistance On en 353 Steel by Heat Treatment

- Article - Experimental Characterization of Bending Fatigue Strength in GearArticle - Experimental Characterization of Bending Fatigue Strength in Gear

- Analysis of The Yokeless and Segmented Armature MachineAnalysis of The Yokeless and Segmented Armature Machine

- Face Gears: Geometry and Strength: Ulrich Kissling and Stefan BeermannFace Gears: Geometry and Strength: Ulrich Kissling and Stefan Beermann

- Grain Size and Mechanical Properties of Low Carbon Cast SteelGrain Size and Mechanical Properties of Low Carbon Cast Steel

- Backlash Prediction of A Spur Gear Pair With Manufacturing Errors of Runouts, Span and Pitch DeviationsBacklash Prediction of A Spur Gear Pair With Manufacturing Errors of Runouts, Span and Pitch Deviations

- A Kinematic Analysis of Meshing Polymer Gear TeethA Kinematic Analysis of Meshing Polymer Gear Teeth

- Gregory A. Fett - Importance of Induction Hardened Case Depth in Torsional ApplicationsGregory A. Fett - Importance of Induction Hardened Case Depth in Torsional Applications

- Gear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers EdgeGear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers Edge

- Ball Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial AxialBall Bearing: Ball (Bearing) Rolling-Element Bearing Balls Bearing Radial Axial

- Gear Trains: Qassim University Unayzah College of Engineering Mechanical Engineering DeptGear Trains: Qassim University Unayzah College of Engineering Mechanical Engineering Dept

- AUC - 2004 - Finite Element Analysis of Rolls & Mill Housing in Cold Rolling MillAUC - 2004 - Finite Element Analysis of Rolls & Mill Housing in Cold Rolling Mill

- Design of Machine Elements: Design Against Fluctuating LoadsDesign of Machine Elements: Design Against Fluctuating Loads

- Solid Lubrication Fundamentals Amp Applications Materials Engineering PDFSolid Lubrication Fundamentals Amp Applications Materials Engineering PDF

- Cycloid Drive - Replaced by Planocentric Involute Gearing PDFCycloid Drive - Replaced by Planocentric Involute Gearing PDF

- Rolling Contact Fatigue in Ultra High Vacuum: Mike Danyluk and Anoop DhingraRolling Contact Fatigue in Ultra High Vacuum: Mike Danyluk and Anoop Dhingra

- Further Understanding of Rolling Contact Fatigue in Rolling Element Bearings - A ReviewFurther Understanding of Rolling Contact Fatigue in Rolling Element Bearings - A Review

- Modelling, Simulation and Control of Two-Wheeled VehiclesFrom EverandModelling, Simulation and Control of Two-Wheeled Vehicles

- Metallurgy Unlocked Mastering Metallurgical Diploma Questions and AnswersFrom EverandMetallurgy Unlocked Mastering Metallurgical Diploma Questions and Answers

- Effects of Heat Treatments On Steels For Bearing ApplicationsEffects of Heat Treatments On Steels For Bearing Applications

- Time Management: A Practical Guide To Efficiently Prioritizing Your Time, Enabling You To Achieve Optimum ResultsTime Management: A Practical Guide To Efficiently Prioritizing Your Time, Enabling You To Achieve Optimum Results

- The Design of Rolling Bearing Mountings (FAG Bearing Co) WWThe Design of Rolling Bearing Mountings (FAG Bearing Co) WW

- ANTEC 1999 - Investigation of Rhelogical Properties of Rotomolding ResinsANTEC 1999 - Investigation of Rhelogical Properties of Rotomolding Resins

- Cold Weather Concrete A Review Paper On Concreting in Cold TemperatureCold Weather Concrete A Review Paper On Concreting in Cold Temperature

- Use of Cement in Concrete According To European STUse of Cement in Concrete According To European ST

- Manufacturing of Interlocking Brick With Cement-Lime Mortar and HyposludgeManufacturing of Interlocking Brick With Cement-Lime Mortar and Hyposludge

- DT Breakout Fibre Optic Cable 4 24 Fibres Rev.1.0.3-3DT Breakout Fibre Optic Cable 4 24 Fibres Rev.1.0.3-3

- BP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014BP Bitumen - Guide To Bituminous Binders in Asphalt and Sprayed Sealing Applications-2014