Catalogue Xrba Xr2 Xf9 en

Catalogue Xrba Xr2 Xf9 en

Uploaded by

vili75Copyright:

Available Formats

Catalogue Xrba Xr2 Xf9 en

Catalogue Xrba Xr2 Xf9 en

Uploaded by

vili75Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Catalogue Xrba Xr2 Xf9 en

Catalogue Xrba Xr2 Xf9 en

Uploaded by

vili75Copyright:

Available Formats

Screw limit switches XRBA and XR2

Overtravel limit switches XF9

Catalogue

Simply easy!

TM

Contents

Screw limit switches XRB4 and XR2

Overtravel limit switches XF9

Screw limit switches XRBA and XR2

Selection guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . pages 2 and 3

Screw limit switches for standard duty XRBA

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Order form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Screw limit switch selection example . . . . . . . . . . . . . . . . . . . . . . pages 8 and 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Screw limit switches for heavy duty XR2

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential drive units

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

page 10

page 11

page 13

page 18

page 17

page 17

page 19

Overtravel limit switches XF9

Overtravel limit switches for power cicuits

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

page 20

page 21

page 22

page 23

10

Selection guide

Screw limit switches

Applications

Standard duty a or c (Ithe = 10 A)

Heavy duty a or c (Ithe = 10 A)

Number of contacts

4 or 6

3, 4, 6, 10, 14, 20, 24 or 28

Conventional thermal current (Ithe)

10 A

10 A

Type of contacts

Single-pole C/O, snap action

Single-pole C/O, snap action

Reduction gear ratio

For 1 revolution of cams: 13/1, 17/1, 46/1,

60/1, 78/1, 210/1, 274/1 or 960/1

For 6 turns of threaded shaft: 0.4/6, 0.8/6,

1.6/6, 3/6, 6/6, 10/6, 20/6, 40/6, 80/6, 150/6,

300/6, 560/6 or 1100/6

Adaptation for potentiometer

Conformity to standards

IEC/EN 60947-5-1

IEC/EN 60947-5-1

Degree of protection

XRBA4: IP 55 conforming to IEC/EN 60529,

IP 557 conforming to NF C 20-010

XRBA6: IP 55 conforming to IEC/EN 60529,

IP 555 conforming to NF C 20-010

IP 54 conforming to IEC/EN 60529

Cable entry

1 tapped entry for n 9 cable gland

Clamping capacity 5 to 8 mm

1 tapped entry for n 16 cable gland

Clamping capacity 10 to 14 mm

2 tapped entries for n 13 cable gland

Clamping capacity 9 to 12 mm

Materials

Stainless steel input drive shaft

Aluminium alloy body housing

XRBA4: aluminium alloy cover

XRBA6: polyphenylene oxide cover

Aluminium alloy body housing,

insulated cover

Type reference

XRBA

XR2AA

Pages

13

Heavy duty a or c (Ithe = 10 A)

Heavy duty a or c (Ithe = 20 A)

3, 4, 6, 10, 14, 20, 24 or 28

3, 5, 9, 13, 19, 23 or 27

10 A

20 A

Single-pole C/O, snap action

Single-pole N/C or N/O, with snap action mechanism

For 6 turns of threaded shaft: 0.4/6, 0.8/6, 1.6/6, 3/6, 6/6, 10/6, 20/6, 40/6,

80/6, 150/6, 300/6, 560/6 or 1100/6

For 6 turns of threaded shaft: 0.4/6, 0.8/6, 1.6/6, 3/6, 6/6, 10/6, 20/6, 40/6,

80/6, 150/6, 300/6, 560/6 or 1100/6

IEC/EN 60947-5-1

IEC/EN 60947-5-1

IP 54 conforming to IEC/EN 60529

IP 54 conforming to IEC/EN 60529

Removable gland plate

Removable gland plate

Sheet steel enclosure

Sheet steel enclosure

XR2AB

XR2B

13

13

Presentation

Screw limit switches

Standard duty, XRBA

Functions

These switches are designed to monitor the movement of an object via an input drive

shaft coupled to the actuator. Detection of position is ensured by a system of

independently adjustable cams which actuate the electrical contact blocks.

They are usually used for applications where it is either impossible or impractical to

mount standard type position sensors that are actuated directly by the moving object.

Main applications:

b position control of moving parts of hoisting or materials handling equipment

(winches, travelling cranes, gantries, cranes, rotary excavators, etc.).

b liquid level control in pumping systems.

Description

3

5

1

2

3

4

5

Input drive shaft

Reduction gear

Cams

Contact blocks

Potentiometer (option)

Operation

The input drive shaft, which is coupled to the machine part being controlled, is

normally fitted on the right-hand side. This transmits the movement by means of a

worm screw and reduction gear to a set of 4 or 6 independent cams which, in turn,

operate the contact blocks.

A choice of 3 cam types (20, 50 and 80) enables a wide range of cam

arrangements to be achieved.

The cams are easily accessible and individual adjustment of the cams is a simple

operation, without risk of affecting the setting of adjacent cams.

As an option, a potentiometer can be fitted in order to provide an analogue output.

Screw limit switches

Characteristics

Standard duty, XRBA

Environment

Conformity to standards

IEC/EN 60947-5-1

Protective treatment

Standard version

Special version

Ambient air temperature

For storage

For operation

TC

TH on request

C

C

- 40+ 70

- 25+ 70

Shock resistance

80 gn (11 ms)

Vibration resistance

> 5 gn (1060 Hz)

Degree of protection

XRBA4pppp: IP 55 conforming to IEC/EN 60529, IP 557 conforming to NF C 20-010

XRBA6pppp: IP 55 conforming to IEC/EN 60529, IP 555 conforming to NF C 20-010

Stainless steel input shaft. Aluminium alloy body housing.

Aluminium alloy cover for XRBA4pppp

Polyphenylene oxide cover for XRBA6pppp

1 tapped entry for n 9 cable gland (clamping capacity 5 to 8 mm) and 1 tapped entry

for n 16 cable gland (clamping capacity 10 to 14 mm)

Materials

Cable entry

Mechanical characteristics

Reduction gear ratio

For 1 revolution of cams

Average drive torque

At 20C

Maximum speed of input drive shaft

13/1, 17/1, 46/1, 60/1, 78/1, 210/1, 274/1 or 960/1

N.cm

rpm

1000

Mechanical durability

15 x 106 drive shaft revolutions

Electrical characteristics of contacts

Type of contacts

Single-pole C/O, snap action

Rated operational

Conforming to IEC/EN 60947-5-1

characteristics

Conventional thermal current

a AC-15, A300 (Ue = 240 V, Ie = 3 A), c DC-13, Q300 (Ue = 250 V, Ie = 0.27 A)

A

Ithe = 10

Rated insulation voltage

Conforming to IEC/EN 60947-1

Ui = 250

Rated impulse withstand

voltage

Resistance across terminals

Conforming to IEC/EN 60947-1

kV

Uimp = 6

mW

y 25

Short-circuit protection

10 A cartridge fuse type gG

Connection

Screw and captive cable clamp terminals.

Clamping capacity: 2 x 1.5 mm2 with cable end

Clips or solder tags available on request

Electrical durability

Conforming to IEC/EN 60947-5-1

Utilisation categories: AC-15 and DC-13

Operating rate: 3600 operating cycles/hour

Load factor: 0.5

a.c. supply a 50/60 Hz

Power broken in VA for 0.5 million operating

cycles

d.c. supply c

Power broken in W for 0.5 million operating

cycles

Voltage (V)

o

8

Voltage (V)

o

8

12

18

65

24

48

127 220

35

700 165 220

108 216 450 530

12

27

55

24

39

84

48

50

110

110 220

65

67

130 135

Optional potentiometer characteristics (analogue output)

Rotation ratio between cams and potentiometer

1, 1.5 (1.333) or 2 (1.933)

Maximum rotation angle of potentiometer

350

Potentiometer type

Type SI, size 15, ball bearing mounted

Power: 3 W

Withstand voltage: 1500 V

Ohmic value: 10 000 (other values available on request)

References:

page 6

Dimensions:

page 18

Screw limit switches

References

Standard duty, XRBA

534926

Screw limit switches

Description

Screw limit switches

(with bare drive shaft)

Number of

contacts

4

Basic reference,

to be completed

(1)

XRBA4pppp

XRBA6pppp

Weight

kg

1.500

1.350

XRBA901

XRBA902

XRBA903

Contact block

Short roller lever actuator

1 C/O snap action contact

XEPA10801D64

XRBA901

50 (2)

XRBA902

0.002

80 (2)

XRBA903

0.002

XEPA1081D64

0.011

N 16 plastic, clamping

capacity 10 to 14 mm

DE9PL116044

0.008

Chain sprockets

12.7 mm pitch, for switch

input drive shaft

12 teeth

XRBZ912

0.080

14 teeth

XRBZ914

0.090

16 teeth

XRBZ916

0.100

L = 2 metres

XR2AZ302

0.600

L = 5 metres

XR2AZ305

1.500

L = 10 metres

XR2AZ310

3.000

10 000

XRBZ9100

0.060

Potentiometer

Type SI, size 15, 3 W

XRBZ91p

20 (2)

Weight

kg

0.002

Cable glands

Chains (12.7 mm pitch)

conforming to standard

NF E 26-101, chromium plated,

with joining link (3)

DE9PL116044

Reference

Cams

Type

Description

Separate components and replacement parts

XRBA4pppp

Other Ohmic values: please consult our Customer Care

Centre.

(1) For completion of the basic reference, please refer to Order form on page 7.

(2) Average values.

(3) For liquid level control applications, the length of the chain should at least be equal to the

difference between the upper and lower liquid levels + 0.50 m.

XRBZ9pp

Characteristics:

page 5

Dimensions:

page 18

Screw limit switches

Order form

Standard duty, XRBA

(specimen suitable for

photocopying)

Customer

Company

Order N

Delivery date

Schneider Electric

Sales Office - Subsidiary Co.

Order N

To use this order form:

b State the number of identical screw limit switches required

b Complete the basic reference with the 9 or 11 digits indicating the various switch options

b Mark the required cam arrangement on the drawing below.

For examples showing completion of the basic reference, refer to pages 8 and 9.

Number of

identical switches

Basic

reference,

to be

completed

Number Reducof

tion

contacts gear

ratio

Drive

Adaptation

shaft

for 10 k

position potentiometer

Option cam

N1

N2

N3

N4

N5

(1)

N6

(1)

2

5

8

2

5

8

2

5

8

2

5

8

2 (1)

5 (1)

8 (1)

2 (1)

5 (1)

8 (1)

XRBA

Number of contacts

Switch with 4 contacts

4

Switch with 6 contacts

6

Reduction gear ratio (for 1 revolution of cams)

13/1

1

17/1

2

46/1

3

60/1

4

78/1

5

210/1

6

274/1

7

960/1

8

Drive shaft position

Right-hand side (standard model)

1

Left-hand side

2

Adaptation for 10 k potentiometer

Without adaptation

With adaptation, ratio 1

With adaptation, ratio 1.5 (1.333)

With adaptation, ratio 2 (1.933)

Choice of cams (3 different angles, 4 or 6 positions)

To select a cam, add 4 digits for XRBA4 switches or 6 digits for XRBA6 switches.

20 cam

50 cam

80 cam

00

13

23

33

Required cam arrangement

The cam positioned nearest to the

plate is considered as cam n 1

Marking guide for cam

arrangement diagram

Mark the required cam arrangement

Cam

1 2 3 4 5 6

20 cam

50 cam

(average values)

n 1 n 2 n 3 n 4 n 5 n6

20

20

50

50

80

80

80 cam

(1) Do not add these digits for XRB4 switches (with 4 contacts).

Note: If the above cam arrangement is left blank, the cams will be factory-mounted as standard as shown below:

Cam n

1

2

3

4

5

6

_

_

XRBA4pppp

20

50

80

20

XRBA6pppp

20

20

50

50

80

80

Example of a standard product: reference XRBA45100 corresponds to a switch with 4 contacts, a reduction gear ratio of 78/1, a right-hand side shaft input and no

potentiometer. The cams are positioned in the following order: 20, 50, 80 and 20.

Screw limit switches

Screw limit switch

selection example

Standard duty, XRBA

Application: monitoring the movement of a machine part

Example:

Monitoring the movement of a machine part from A to F (AF = 7.5 m) with potentiometer linked display.

Chain sprocket on switch input drive shaft: 16 teeth on 12.7 mm pitch.

Point A

Point B

Points C and D

Point E

Point F

7,5 m

Stop position, direction F V A

Slow-down position, direction F V A

Specific points

Slow-down position, direction A V F

Stop position, direction A V F

0,9 m

4,3 m

A B

0,9 m

Selection of switch and completion of basic reference

b Number of contacts: 6 positions to monitor, therefore, 6 contacts.

E F

1st digit of reference:

7.5

= 37

16 0.0127

b Reduction gear ratio: Distance AF = 7.5 m, therefore, number of turns of input drive shaft:

b Select a reduction ratio whereby the number of turns of the input drive shaft is greater than 37

Reduction ratio between

number of turns of drive

shaft and 1 revolution of

cams

Rotation ratio between

cams and the

potentiometer (actual

value)

Maximum rotation of

cams for 37 turns of

switch input drive shaft

Maximum rotation of

potentiometer

360 37

360 37

1 = 269

= 289

46

46

360 37

360 37

1 .333 = 296

2nd solution

60/1

1.5 (1,333)

= 222

60

60

360 37

360 37

1 .933 = 330

3rd solution

78/1

2 (1.933)

= 171

78

78

Assume the 3rd solution is best suited for the application, which offers a wide potentiometer operating angle (330) whilst maintaining cam

setting flexibility (171 operating angle).

1st solution

46/1

b Reduction gear ratio: 78/1

2nd digit of reference:

b Input drive shaft position: Right-hand side preferred

3rd digit of reference:

b Adaptation for potentiometer: Value of 10 k and a ratio of 2

4th and 5th digits of reference:

XRBA

Reference of screw limit switch to be entered on Order form on page 7

Selection of cams, marking cam arrangement diagram

b Point A - cam n 1: 20 cam (stop cam).

b Point B - cam n 2: The selection of cam n 2 is determined by the distance BA (0.90 m), giving:

171 0.90

A 20 cam could be used, but a 50 cam is more suitable in order to ensure an overlap with the

20

stop cam.

7.5

b Points C and D - cams n 3 and 4: The distance CD = 4.30 m, giving:

171 4.30

2 overlapping cams are required, for example: cam n 3 = 50,

98

cam n 4 = 80.

7.5

b Point E - cam n 5: The selection of cam n 5 is determined by the distance EF (0.9 m), giving:

171 0.90

A 50 cam is therefore selected, for the same reasons as the cam for point B.

20

7.5

b Point F - cam n 6: 20 cam (stop cam).

7,5 m

0,9 m

Cams

n 1 n 2 n 3

20

50

80

A B

n 4 n 5 n 6

Cam n 1

Cam n 2

Cam n 3

Cam n 4

Cam n 5

Cam n 6

20

50

50

80

50

20

4,3 m

0,9 m

E F

5

1

33

33

Screw limit switches

Screw limit switch

selection example

Standard duty, XRBA

Specific application: liquid level control (1)

Selection guide table for reduction ratio between number of turns of switch input drive shaft and 1 revolution of the cams and chain sprocket

size to be fitted to switch input drive shaft.

Change in level Screw limit switches without potentiometer

to be controlled Reduction

Chain sprocket Cam rotation

(in metres)

gear ratio

Number of

angle

teeth (12.7 mm

pitch)

0.5

13/1

12

91

1

13/1

12

182

1.5

13/1

12

273

2

13/1

14

311

2.5

17/1

12

347

3

17/1

16

313

3.5

46/1

12

180

4

46/1

12

205

4.5

46/1

12

231

5

46/1

12

257

5.5

46/1

12

282

6

46/1

12

308

6.5

46/1

12

334

7

46/1

14

308

7.5

60/1

12

295

8

60/1

12

315

8.5

60/1

12

335

9

46/1

16

347

9.5

60/1

14

321

10

60/1

14

337

10.5

78/1

12

318

11

78/1

12

333

11.5

78/1

12

348

12

78/1

14

311

12.5

78/1

14

324

13

78/1

14

337

13.5

78/1

16

307

14

78/1

16

318

14.5

78/1

16

329

15

78/1

16

341

Screw limit switches with potentiometer

Reduction

Chain sprocket Adaptation for

gear ratio

Number of

potentiometer

teeth (12.7 mm Ratio

pitch)

13/1

12

2

13/1

14

2

13/1

14

1.5

17/1

16

1.5

46/1

12

2

46/1

12

2

46/1

14

2

46/1

16

2

46/1

12

1.5

60/1

14

2

78/1

12

2

60/1

14

1.5

78/1

14

2

78/1

16

2

78/1

12

1.5

78/1

14

1.5

78/1

14

1.5

78/1

16

1.5

78/1

16

1.5

78/1

16

1.5

78/1

12

1

78/1

12

1

78/1

12

1

78/1

14

1

78/1

14

1

78/1

14

1

78/1

16

1

78/1

16

1

78/1

16

1

78/1

16

1

Cam rotation

angle

Potentiometer

rotation angle

91

156

233

208

128

154

154

154

231

169

167

202

169

159

227

208

221

204

216

227

318

333

348

311

324

337

307

318

329

341

182

312

350

312

256

308

308

308

347

338

334

303

339

318

341

312

331

306

324

341

318

333

348

311

324

337

307

318

329

341

Example: Controlling a change in liquid level of 5.30 m

Selection of reduction gear ratio

From the above table, select the value immediately superior to 5.30 m, i.e. 5.50 m

b Case n 1: without potentiometer. Recommended solution:

v Reduction gear ratio: 46/1, chain sprocket with 12 teeth on 12.7 mm (0.0127 m) pitch.

v Cam rotation angle:

5.30

360

282 5.30

12 0.0127

using above table:

or,

by

calculation:

= 272

= 272

5.50

46

3

00

2nd digit of reference:

v Completion of basic switch reference:

4th and 5th digits of reference:

b

v

v

v

Case n 2: with potentiometer. Recommended solution:

Reduction gear ratio: 78/1, chain sprocket with 12 teeth on 12.7 mm (0.0127 m) pitch.

Ratio of potentiometer adaptation: 2

Cam rotation angle:

5.30

360

12 0.0127

167 5.30

using above table:

or, by calculation:

= 161

= 161

78

5.50

v Potentiometer rotation angle:

using above table:

334 5.30

= 322

5.50

5.30

360

or, by calculation: 2 12 0.0127

78

v Completion of basic switch reference:

2nd digit of reference:

4th and 5th digits of reference:

(10 k potentiometer)

= 322

5

33

(1) Accessories for liquid level control: see page 16.

Presentation

Screw limit switches

Heavy duty, XR2

Functions

These switches are designed to monitor the movement of an object via an input drive

shaft coupled to the actuator. Detection of position is ensured by a system of

adjustable fingers which actuate the electrical contact blocks.

They are usually used for applications where it is either impossible or impractical to

mount standard type position sensors that are actuated directly by the moving object.

Main applications:

b position control of moving parts of hoisting or materials handling equipment

(winches, travelling cranes, gantries, cranes, rotary excavators, etc.),

b liquid level control in pumping systems.

Description

1 Input drive shaft, with

facilities for attaching chain

sprocket.

2 2-pinion primary gearbox,

with choice of reduction

ratio.

3 Internally threaded shaft,

driven via gearbox, fitted

with adjustable fingers

which actuate the electrical

contact blocks.

4 Fixed lead screw, along

which threaded shaft

travels.

5 Snap action contact blocks,

actuated by fingers.

Operation

Due to the variable composition 2-pinion primary gearbox, multiple choices of

reduction ratio between the input drive shaft and the threaded shaft, which operates

the finger actuators, are possible.

The finger actuators, clamped to the rotating threaded shaft, describe a helical path

and operate the contacts as and when they are engaged along its length of travel

(6 turns maximum).

To avoid damage at the end of travel of the threaded shaft, a clutch is incorporated

in the drive mechanism (patented feature).

10

Screw limit switches

Characteristics

Heavy duty, XR2

Environment

Conformity to standards

IEC/EN 60947-5-1

Protective treatment

Standard version

Special version

Ambient air temperature

For storage

For operation

TC

TH on request

C

C

- 40+ 70

- 25+ 70

Shock resistance

50 gn (11 ms)

Vibration resistance

> 5 gn (1055 Hz)

Degree of protection

IP 54 conforming to IEC/EN 60529

Materials

XR2AA: Aluminium alloy body housing, insulated cover

XR2AB and XR2BB: Sheet steel enclosure

XR2AA: 2 tapped entries for n 13 cable gland

(clamping capacity 9 to 12 mm)

XR2AB and XR2BB: Removable gland plate

Cable entry

Mechanical characteristics

Maximum number of turns of threaded shaft

Threaded shaft screw pitch

mm

Operating finger radius

mm

40

Length of developed helical travel

mm

Contact actuators differential snap-over angle

(measured at finger)

Tripping point repeat accuracy

30

Number of turns of input drive shaft

For 6 turns of threaded shaft: 0.4, 0.8, 1.6, 3, 6, 10, 20, 40 or 80

Mechanical durability

10 x 106 drive shaft revolutions

0.02% between 2 successive operations

Electrical characteristics of contacts

Type of contacts

Conventional thermal current

Rated insulation voltage

Rated impulse withstand voltage

kV

XR2A: single-pole C/O, snap action

XR2B: single-pole N/C or N/O, with snap action mechanism

a AC-15, A300 (Ue = 240 V, Ie = 3 A), c DC-13, Q300 (Ue = 250 V, Ie = 0.27 A),

conforming to IEC/EN 60947-5-1

XR2A: Ithe = 10

XR2B: Ithe = 20

Ui = 500, conforming to IEC/EN 60947-1

Ui = c 600, conforming to CSA C 22-2 n 14

Uimp = 6, conforming to IEC/EN 60947-1

Resistance across terminals

mW

y 25

Rated operational characteristics

Short-circuit protection

XR2A: 10 A cartridge fuse type gG

XR2B: 20 A cartridge fuse type gG

Screw clamp terminals.

Clamping capacity: 2 x 1.5 mm2 with or without cable end, 2 x 2.5 mm2 without cable

end

Connection

Electrical durability

Conforming to IEC/EN 60947-5-1

Utilisation categories: AC-15 and DC-13

Operating rate: 3600 operating cycles/hour

Load factor: 0.5

References:

page 13

For 3 million

operating

cycles

XR2A

For 10 million

operating

cycles

XR2A

XR2B

XR2B

a.c. supply a 50/60 Hz

Power broken in VA

Voltage (V) 12

24

48

127

o

100 200 400 700

8

100 220 480 1050

o

240 450 800 1300

8

240 450 800 1900

o

45

75

120 180

8

70

120 180 270

o

220 350 450 500

8

220 440 600 740

220

750

1150

1500

2200

200

290

500

750

380

800

1150

1500

2200

200

300

520

750

500

800

1200

1500

2200

200

300

520

750

d.c. supply c

Power broken in W

12

24

48

100 120 110

100 140 130

135 115 105

220 450 400

45

40

35

100 90

85

55

45

38

220 450 400

110

95

110

95

330

30

80

35

330

220

80

95

90

280

20

60

32

280

440

45

65

85

240

7.5

33

30

240

Dimensions:

page 18

11

Screw limit switches

Characteristics (continued)

Heavy duty, XR2

Variable composition primary gearbox characteristics

Primary gearbox reference code (1) (2)

04

08

16

10

20

40

80

Primary gearbox type

Single-stage

Theoretical number of turns of input drive shaft K

Number of teeth per pinion

A

0.4

59

0.8

59

1.6

49

3

59

6

Direct

drive

10

49

20

26

40

26

80

16

16

16

26

16

26

49

49

59

59

49

49

26

16

26

16

16

16

26

26

49

59

49

59

59

Number of turns of threaded shaft

Actual number of turns of input drive shaft

0.441

0.863

1.689

3.066

11.739

21.3

41.697

81.586

Maximum speed of input drive shaft in rpm

12

25

50

75

150

200

250

300

350

Primary gearbox arrangement (for references of the gearbox only, see page 14)

1 Input drive shaft

2 Threaded shaft (6 turns) and contact side

3 Casing

(1) Code required to complete the basic reference of the screw limit switch.

(2) For ratios greater than 80 turns, please consult our Customer Care Centre.

Average drive torque

Operating torque required at input drive shaft

cm.daN

200

XR2Apppppp

4

100

50

0,

XR2Bpppppp

0,8

=13,6

KK=

3

K=

20

10

K=

KN ==

K=

K = 40

1100

20

0

=8

0,5

12

1 Clutch torque (at front mechanical

stop/end of travel)

2 Nominal torque required to drive

switch

3 Torque required to operate 1

contact

4 Torque required to operate 2

contacts simultaneously

5 Torque required to operate 3

contacts simultaneously

6 Torque required to operate 4

contacts simultaneously

7 Torque required to operate 6

contacts simultaneously

8 Torque required to operate 8

contacts simultaneously

9 Clutch torque (at rear mechanical

stop/end of travel)

Screw limit switches

References

Heavy duty, XR2

534911

Switches with C/O contacts (Ithe = 10 A) (ZC1ZB211)

Presentation

Number of

contacts

Aluminium alloy body

housing, plastic cover

Sprocket key and

washer (2)

Basic reference, to

be completed by

adding primary

gearbox code (1)

XR2AA03Kpp

Sheet steel enclosure

Sprocket key and

washer (2)

XR2AB04Kpp

10.000

XR2AB06Kpp

12.000

10

XR2AB10Kpp

15.000

14

XR2AB14Kpp

18.000

20

XR2AB20Kpp

23.000

24

XR2AB24Kpp

28.000

28

XR2AB28Kpp

35.000

534912

XR2AA03Kpp

Weight

kg

Drive shaft end

fittings

6.000

Switches with N/C contacts (Ithe = 20 A) (ZC4CB2) (3)

Presentation

Sheet steel enclosure

534913

XR2AB06Kpp

Number of

contacts

3

Reference (1)

XR2BB03Kpp

Weight

kg

10.000

XR2BB05Kpp

12.000

XR2BB09Kpp

15.000

13

XR2BB13Kpp

18.000

19

XR2BB19Kpp

23.000

23

XR2BB23Kpp

28.000

27

XR2BB27Kpp

35.000

(1) Code corresponding to the required primary gearbox, selected according to number of turns

of the switch input drive shaft.

See page 12.

Example: for a screw limit switch with 3 C/O contacts and a theoretical number of input shaft

turns K = 0.4, the reference becomes: XR2AA03K04.

(2) Switches supplied without input drive shaft chain sprocket. For suitable sprockets and chains,

see page 14.

(3) For switches fitted with N/O contacts, please consult your Regional Sales Office.

XR2BB03Kpp

Characteristics:

pages 11 and 12

Drive shaft end

fittings

Sprocket key and

washer (2)

Dimensions:

page 18

13

Screw limit switches

References

Heavy duty, XR2

Separate components and replacement parts

Description

Chain sprockets, 12.7 mm pitch,

for switch input drive shaft

Type

Reference

Flat sprocket 12 teeth

with fixing hub

16 teeth

XR2AZ212

Weight

kg

0.180

XR2AZ216

0.200

24 teeth

XR2AZ224

0.230

36 teeth

XR2AZ236

0.450

48 teeth

XR2AZ248

0.770

56 teeth

XR2AZ256

1.130

XR2AZ001

0.030

C/O (for XR2A)

ZC1ZB211

0.120

N/C (for XR2B)

ZC4CB2

0.140

XR2AZ302

0.600

XR2AZ305

1.500

L = 10 metres

XR2AZ310

3.000

Single-stage K04

XR2AZ804

1.520

K08

XR2AZ808

1.520

K16

XR2AZ816

1.520

K3

XR2AZ83

1.470

K6

XR2AZ86

1.470

K10

XR2AZ810

1.470

K20

XR2AZ820

1.520

K40

XR2AZ840

1.470

K80

XR2AZ880

1.520

XR2AZ2pp

XR2AZ001

Operating finger

Contact blocks with snap-over

actuator

ZC1ZB211

Chains (12.7 mm pitch) conforming L = 2 metres

to standard NF E 26-101, chromium

plated, with joining link (1)

L = 5 metres

Replacement primary gearbox kit

comprising:

- casing with input drive shaft

(fitted with sprocket key, washer and

screw)

- steel pinions

534927

ZC4CB2

XR2AZppp

(1) For liquid level control applications, the length of the chain should at least be equal to the

difference between the upper and lower liquid levels + 0.50 m.

Characteristics:

pages 11 and 12

14

Dimensions:

page 19

References

Screw limit switches

Winch shaft chain sprockets,

conforming to standard NF E 23-111,

12.7 mm pitch

Monobloc sprockets with through hub

Number

of teeth

32

35

XR2AZ3ppp5

A (bore in mm)

Reference

12

57

025

B

50

2635

B

XR2AZ31225

0.386

16

73

50

55

XR2AZ31625

0.424

24

105

50

XR2AZ32425

0.632

55

XR2AZ32435

0.500

50

55

XR2AZ34825

1.000

48

202

Weight

kg

Monobloc sprockets with keyed through hub

Number

of teeth

32

35

A (bore in mm)

Reference

Masse

kg

16

73

025

B

50

2635

B

55

XR2AZ41625

0.421

24

105

50

XR2AZ42425

0.580

55

XR2AZ42435

0.600

50

55

XR2AZ43625

0.750

XR2AZ4ppp5

36

153

Split sprockets with through hub

Number

of teeth

105

2150

B

64.5 80

Reference

XR2AZ52450

Masse

kg

0.680

24

A (bore in mm)

57

60

XR2AZ52450

15

References

Screw limit switches

Accessories for liquid level control using float (1)

Accessories

Description

XL1DB0111

Type

Material

Reference

Weight

kg

5.900

Ballast float, 270 mm

for change in level

less than 4.50 m

Without guide

lugs

Stainless

steel

XL1DB0111

Counterweights

For 270 mm

float

XR2AZ002

2.540

For 350 mm

float

XR2AZ003

7.500

Pulley assembly

XL1DB04

1.050

Cable, 37 mm,

length 6 m (with attachment

clamp)

Stainless

steel

XL1DB05

0.250

XR2AZ002

XL1DB04

(1) For mounting example, see page 19.

Dimensions:

page 19

16

Screw limit switches

Presentation,

references

Differential drive units

Functions

534928

This unit enables the monitoring of any speed difference between 2 movements

which, under normal circumstances, should be identical. Any difference in speed is

transmitted to an XR2 screw limit switch which, in turn, re-establishes correct

operation.

Main applications:

b Controlling movement of grabs on cranes and travelling cranes.

b Liquid level control in decantation tanks.

b Monitoring relative difference between 2 moving parts.

ZR2FAp

Operation

M1

M2

The difference in rotational speeds of shafts M1 and M2, which are connected to

motors or capstans, is transferred to a set of internal pinions which, in turn, control

the rotation of shaft S which is connected to one or more screw limit switches.

Differential

Screw limit

switch

S

Figure 1

Figure 2

M1M2

M1M2

ZR2FA1: same direction

ZR2FA2: opposing directions

Schematic representation

M1

S

M2

Relationship between rotational directions

If the rotation of shafts M1 and M2 is synchronised, shaft S does not turn.

If the rotation of shafts M1 and M2 is out of synchronisation, shaft S turns.

This relationship is indicated either by white arrows or black arrows (each shaft

having 2 possible directions of rotation).

The rotational direction of shaft S is indicated by the arrow on shaft S immediately

below the arrow on shaft M which represents the highest rotational speed (see

figures 1 and 2).

M1 = M2: S does not turn

M1 M2: S turns

Note

In both cases, the rotational speed ratio between shafts M and S is 2/1. It is important

to know the maximum number of turns or differential travel that the screw limit switch

must control (if necessary, both sides of its initial setting).

References

The differential units are supplied with bare shafts fitted with keyed discs, ready for

the attachment of numerous types of coupling. They are dust and damp-proof and

the internal mechanism is maintenance free. All 3 shafts are steel and are needle

roller bearing mounted. A set of duplicate cast steel pinions ensure the accuracy of

the differential. The cover is both glued and screwed to the housing.

Description

Type

Reference

For input shafts turning in

the same direction

ZR2FA1

Weight

kg

6.510

For input shafts turning in

opposing directions

ZR2FA2

6.510

Flexible coupling

ZR2FA005

0.120

Winch shaft chain sprockets

See page 15

Differential units

ZR2FA005

Dimensions:

page 19

17

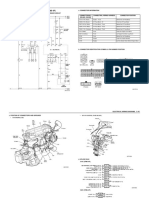

Screw limit switches

Dimensions

Screw limit switches

XRBA4pppp

XRBA6pppp

57,5

(2)

36,5

(1)

57,5

(2)

24,5

50

46

140

24,5

(3)

77

130

166

140

46

(3)

166

24,5

24,5

151,5

(1) 1 tapped entry for n 9 cable gland.

(2) 4 tapped fixing holes for M5 screws, depth 20.

(3) 1 tapped entry for n 16 cable gland.

50

36,5

(1)

77

(1) 1 tapped entry for n 9 cable gland.

(2) 4 tapped fixing holes for M5 screws, depth 20.

(3) 1 tapped entry for n 16 cable gland.

XR2AAppppp with chain sprocket XR2AZ2pp fitted

(4)

35

71

71

30

60 (2)

59

(5)

74

155

130

(3)

20

(1)

160

90

246 (6)

270

300

(1) 2 elongated fixing holes 9 x 11.

(2) Alternative fixings: 2 x M8 threaded holes on same axis as cable glands.

(3) 2 tapped entries for n 13 cable gland.

(4) E of chain sprocket XR2AZ2pp (see next page).

(5) Bore of chain sprocket XR2AZ2pp: 16, 2 x 5 keyway.

(6) + 125 mm for removal of cover.

XR2ABppppp, XR2BBppppp with chain sprocket XR2AZ2pp fitted

20

(3)

115

Reference

(4)

36 100x70

240

326

(2)

132

G

c1

50

18

c1

200

260

440

560

800

980

1100

310

370

550

670

910

1090

1210

100

160

340

460

700

880

1000

c1

200

260

440

560

800

980

1100

310

370

550

670

910

1090

1210

100

160

340

460

700

800

1000

(1)

150

Reference

180

(1) 4 elongated fixing holes 9 x 11.

(2) Removable plate for connections or for mounting cable glands.

(3) E of chain sprocket XR2AZ2pp (see next page).

(4) Bore of chain sprocket XR2AZ2pp: 16, 2 x 5 keyway.

References:

pages 6 and 13

XR2AB04Kpp

XR2AB06Kpp

XR2AB10Kpp

XR2AB14Kpp

XR2AB20Kpp

XR2AB24Kpp

XR2AB28Kpp

Number of

contacts

4

6

10

14

20

24

28

XR2BB03Kpp

XR2BB05Kpp

XR2BB09Kpp

XR2BB13Kpp

XR2BB19Kpp

XR2BB23Kpp

XR2BB27Kpp

Number of

contacts

3

5

9

13

19

23

27

Screw limit switches

Dimensions,

mounting

Chain sprockets (1) for switch input drive shaft

Differential units

XR2AZ2pp

ZR2FAp

91

91

20

140

18

89

(1)

18

(2)

40

(2)

8

20

208

73,5

20

35

Reference

Number of teeth

XR2AZ212

12

XR2AZ216

16

XR2AZ224

24

XR2AZ236

36

XR2AZ248

48

XR2AZ256

56

(1) Chain pitch: 12.7 mm.

(2) Keyway: 2 x 5 mm.

E

57

73

105

153

202

234

111

270

111

300

235

(1) Removable circlips.

(2) 2 elongated fixing holes 9 x 11 for 8 screws.

Application: liquid level control

113

Mounting details using an XR2pBppppp screw limit switch

240

(3)

(1)

b1

(2)

55

60

36

33

a1

132

55

45

Change in liquid level up to 4.5 m

(using XL1DB01p1 and XR2AZ002)

a

270

Change in liquid level greater than 4.5 m 350

(using XL1DB02p1 and XR2AZ003)

a1

60

b

200

b1

160

148

245

110

(1) Guide rods.

(2) Guide rod lugs.

(3) Pulley, internal 65 mm.

References:

pages 14, 16 and 17

19

Overtravel limit switches

Presentation

For power circuits, XF9

Functions

The overtravel limit switches for power circuit switching are specifically designed to

ensure the safety of hoisting equipment.

They directly break the power supply to the hoist motor if the load being handled

accidentally exceeds the operating limits of the equipment.

Their mechanism is designed to ensure breakage of the power supply in the event

of a malfunction and therefore, an overtravel limit switch cannot be used in place of

an end of travel limit switch. It must only be used as a back-up device in the event of

failure of the latter, or any other component forming part of an automated control

circuit monitoring for excessive overtravel.

Description

XF9Dppp overtravel limit switches are housed in an aluminium alloy case.

XF9Fppp overtravel limit switches are housed in a sheet steel enclosure.

They are equipped with power contacts from Schneider Electric contactors.

Operation

Mounting and operating precautions

It is recommended that the overtravel limit switch be connected as near as possible

to the motor, in order to minimise the risk of shunting.

The switch must be positioned in such a manner so as to avoid any damage in the

event of the load exceeding the end of travel limits.

In order to ensure positive operation, the operating lever of the overtravel limit

switch must be actuated directly by the moving part being monitored. It is essential

that the use of any flexible or deformable intermediate actuators be avoided.

Manual reset switches - resetting after tripping

b Before resetting the overtravel limit switch ensure that the cause of its tripping is

located and rectified.

b Rotate and hold lever up against end stop.

b Simultaneously press the reset button (XF9D), using accessory included with

switch, or operate the reset lever (XF9F) and turn the control station switch away

from the trip position.

b Rotate lever back to its initial position.

10

Characteristics:

page 21

20

References:

page 22

Dimensions:

page 23

Overtravel limit switches

Characteristics

For power circuits, XF9

Environment

Overtravel limit switch type

XF9D251

XF9F1151

XF9F1851

XF9F1152

XF9F1852

IEC 60158-1, NF C 63-110, VDE 0660, IEC 60947-1, IEC 60947-4

Conformity to standards

Product certification

3-phase

Ambient air temperature

Degree of protection

XF9F2651

XF9F2652

CSA

Single-phase, 2-pole

Protective treatment

XF9D651

20 HP

40 A, 600 V

20 HP

80 A, 600 V

100 HP

175 A, 600 V

150 HP40 A,

200 A, 600 V

200 HP

428 A, 600 V

3 HP

40 A, 230 V

10 HP

80 A, 230 V

Standard version

TC

Special version

TH on request

For storage

- 40+ 70

For operation

- 25+ 70

Conforming to

IEC/EN 60529

IP 54

IP 43

Housing

Aluminium alloy case

Sheet steel enclosure

Cable entry

2 tapped entries

for n 21 cable

gland

2 entries incorporating n 36 plastic cable gland

3 tapped entries

for n 29 cable

gland

Contact block characteristics

Number of poles

Rated operational current (le)

For 2-pole scheme

50

130

For 3-pole scheme on AC-3 A

25

65

115

185

265

Conventional thermal current (Ithe) For 2-pole scheme

at y40 C

For 3-pole scheme

80

160

40

80

200

275

350

Rated insulation voltage (Ui)

500

600

400

1000

1100

1600

2200

180

630

900

1200

1750

Flexible wiring, 1 conductor

without cable

end

2 conductors

mm2

1.5/10

2.5/25

mm2

1.5/6

2.5/16

Flexible wiring, 1 conductor

with cable end

2 conductors

mm2

1/6

2.5/16

mm2

1/4

2.5/6

Solid wiring,

without cable

end

1 conductor

mm2

1.5/6

2.5/25

2 conductors

mm2

1.5/6

4/16

Cable

1 conductor

mm2

95

150

240

2 conductors

mm2

95

150

240

Rated breaking capacity (I rms)

Connection

Min./max. cable

c.s.a.

Conforming to

IEC 60158-1, IEC 947-4,

VDE 0110 Group C

Conforming to

CSA 22-2 n 14

Conforming to

500 V

IEC 60158-1

For 2-pole scheme 660 V

660

10

Presentation:

page 20

References:

page 22

Dimensions:

page 23

21

Overtravel limit switches

References

For power circuits, XF9

References

Switches without auxiliary contact block

Description

Rated

operational

current

A

25

With manual latching and

resetting restricted by a

or

padlockable device

Snap action opening mechanism

50

Maximum travel: 75 in each

direction

65

4

XF9Fppp2

Disconnection

Reference

Weight

3-pole or 4-pole

XF9D251

kg

2.200

XF9D651

5.000

or

2-pole

80

80

3-pole or 4-pole

or

or

130

160

115

With manual latching and

resetting

Horizontal or vertical actuation

Snap action opening mechanism 185

200

3-pole

XF9F1151

25.500

275

3-pole

XF9F1851

26.000

265

350

3-pole

XF9F2651

27.500

With counterweights and

115

automatic resetting

Horizontal or vertical actuation

Slow break opening mechanism 185

Minimum actuation speed:

2.5m/s

200

3-pole

XF9F1152

28.500

275

3-pole

XF9F1852

29.000

265

350

3-pole

XF9F2652

32.500

For use with switches

Reference

XF9Dppp and XF9Fppp

LADN11

Weight

kg

0.030

For use with

switches

XF9F115p

Reference

LA5FF431

Weight

kg

0.270

XF9F185p

LA5FG431

0.350

XF9F265p

LA5FH431

0.660

XF9F115p

LA511550

0.490

XF9F185p

LA518550

0.670

XF9F265p

LA526550

0.920

2-pole

XF9D651

Conventional

thermal

current

A

40

5

3 mm

8,5 mm

Auxiliary contact blocks

Description

N/C + N/O instantaneous

LADN11

Replacement parts

Description

Contact set

comprising per pole:

- 2 fixed contacts,

- 1 moving contact,

- 2 deflectors,

- 1 backplate,

clamping screw and washers

8

Arc chambers

LA5FG431

9

Contacts closed

Contacts open

10

Presentation:

page 20

22

Characteristics:

page 21

Dimensions:

page 23

Overtravel limit switches

Dimensions

For power circuits, XF9

Dimensions

XF9D651

58

10

66

87,5

46

129,5

28

=

10

95

127

232

28

184

10

=

10

55

71

(3)

55

71

10

27

10

(3)

128,5

112,5

252

187

119

103

(3)

(3)

113

99

(3)

(2)

52

28

(2)

207

(1)

69,5

122,5

(1)

67

10

XF9D251

10

3

(1) 2 elongated holes 6 x 8.5 (removable fixing lugs).

(2) 6 mm square rod, length 200 (can be mounted at 90).

(3) 3 plain entries for n 29 cable gland.

13 = contact actuation, 75 = maximum travel.

(1) 2 elongated holes 6 x 8.5 (removable fixing lugs).

(2) 6 mm square rod, length 200 (can be mounted at 90).

(3) 2 tapped entries for n 21 cable gland.

13 = contact actuation, 75 = maximum travel.

XF9Fppp1

Manual resetting

XF9Fppp2

Automatic resetting

122

32

75

32

23

282

(1)

90

370

70

97

124

70

282

372

400

(1)

110

405

92

370

435

465

405

665

465

43

435

600

(2)

386

308

170

100

(1)

34

70

28

82

34

(1) 2 entries incorporating n 36 plastic cable gland.

(2) 4 holes 8.5 to be drilled by user (for attaching fixing lugs to enclosure base).

372

(1)

(1)

70

59

308

170

100

(1)

364

(2)

(1) 2 entries incorporating n 36 plastic cable gland.

(2) 4 holes 8.5 to be drilled by user (for attaching fixing lugs to enclosure base).

10

Presentation:

page 20

Characteristics:

page 21

References:

page 22

23

Schneider Electric Industries SAS

Head Office

35, rue Joseph Monier

F-92500 Rueil-Malmaison

France

www.tesensors.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein.

Design: Schneider Electric

Photos: Schneider Electric

You might also like

- Powerpack 2 System Installation Manual: July 28, 2017 Rev. 1.04Document59 pagesPowerpack 2 System Installation Manual: July 28, 2017 Rev. 1.04David Garcia100% (5)

- MTR Bump Test ProcedureDocument1 pageMTR Bump Test ProcedureMac BoothNo ratings yet

- Nu Flow Powerpoint PresentationDocument47 pagesNu Flow Powerpoint PresentationNu FlowNo ratings yet

- Conmaco 385 Winch ManualDocument44 pagesConmaco 385 Winch ManualdarioNo ratings yet

- DIN 17100 Steels For General Structural Purposes (DIN17100)Document7 pagesDIN 17100 Steels For General Structural Purposes (DIN17100)tiwariNo ratings yet

- Strip Weld OverlayDocument24 pagesStrip Weld OverlaymayataNo ratings yet

- Stresses and Displacements On The Boundaries of Circular Rings Diametrically Loaded PDFDocument7 pagesStresses and Displacements On The Boundaries of Circular Rings Diametrically Loaded PDFjuanjogtr1719No ratings yet

- Bulletin DTB145PM63BDocument2 pagesBulletin DTB145PM63BDanielAlejandroRamosQuero100% (1)

- Fuse Application Chart For PEUGEOT 306 From DAM 7147 TO 7447Document3 pagesFuse Application Chart For PEUGEOT 306 From DAM 7147 TO 7447dedi kurniawanNo ratings yet

- BT 50 2012Document269 pagesBT 50 2012Phạm An Bình100% (5)

- Audi A8 Fuses LocationDocument42 pagesAudi A8 Fuses Locationestonie12No ratings yet

- R 92 05Document41 pagesR 92 05Anmol GuptaNo ratings yet

- Tainter Gate Operation and MaintenanceDocument14 pagesTainter Gate Operation and Maintenancechutton681No ratings yet

- Hydraulic and Mechanical Equipment: Design Standards No. 6Document27 pagesHydraulic and Mechanical Equipment: Design Standards No. 6Adelmo FilhoNo ratings yet

- 20160323110112-Sae 1215Document1 page20160323110112-Sae 1215awesome_600No ratings yet

- Parker High Pressure Hyd FlangesDocument96 pagesParker High Pressure Hyd Flangesgoranm-mnflexNo ratings yet

- Bolt ConnectionDocument24 pagesBolt ConnectionXzk MallaboNo ratings yet

- SSPC PA 2 Measurement DFTDocument8 pagesSSPC PA 2 Measurement DFTBayu TirtaNo ratings yet

- Ics 8 2012 Ready To Publish WatermarkedDocument111 pagesIcs 8 2012 Ready To Publish WatermarkedJesus SalazarNo ratings yet

- 1.4 - Precipitation HardeningSteelDocument1 page1.4 - Precipitation HardeningSteelMuhammad Khizer KhanNo ratings yet

- 2013 Wright Specifications CatalogDocument189 pages2013 Wright Specifications CatalogcenicercNo ratings yet

- Ship LaddersDocument5 pagesShip LaddersPatrick GuoNo ratings yet

- Durapac Gatos HidraulicosDocument108 pagesDurapac Gatos Hidraulicosgechaves1No ratings yet

- 05.40.00 Cold-Formed Metal Framing Specification Updated June 2015Document26 pages05.40.00 Cold-Formed Metal Framing Specification Updated June 2015mishikhanNo ratings yet

- Hoisting Grips For Coaxial Cable and Elliptical WaveguideDocument9 pagesHoisting Grips For Coaxial Cable and Elliptical WaveguideRv SalazarNo ratings yet

- ANSYS Release Notes 190 PDFDocument146 pagesANSYS Release Notes 190 PDFAle100% (1)

- The Ow Pattern and Entropy Generation in An Axial Inlet Cyclone With Re Ux Cone and Gaps in The Vortex FinderDocument12 pagesThe Ow Pattern and Entropy Generation in An Axial Inlet Cyclone With Re Ux Cone and Gaps in The Vortex FinderdadNo ratings yet

- NBC1990 1st Revision Errata PDFDocument220 pagesNBC1990 1st Revision Errata PDFeuleringNo ratings yet

- External PressureDocument3 pagesExternal PressureKingston RivingtonNo ratings yet

- Snt-Tc-1a 2011 - 0001Document40 pagesSnt-Tc-1a 2011 - 0001Julian David Rodriguez CuervoNo ratings yet

- En1991.1-Forklift LoadsDocument2 pagesEn1991.1-Forklift LoadsColin TanNo ratings yet

- Clip Spacing PDFDocument2 pagesClip Spacing PDFBang OchimNo ratings yet

- NozzlePRO 14.1NewFeatures-2019ReleaseDocument13 pagesNozzlePRO 14.1NewFeatures-2019ReleasedelitesoftNo ratings yet

- CCME EngDocument68 pagesCCME EngTamer ElNo ratings yet

- Fixed Ladders: Michigan Occupational Safety & Health Administration Consultation Education & Training DivisionDocument9 pagesFixed Ladders: Michigan Occupational Safety & Health Administration Consultation Education & Training DivisionleodegarioporralNo ratings yet

- DNV RP C201Document33 pagesDNV RP C201Miguel CardosoNo ratings yet

- Examples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyDocument4 pagesExamples - Shafts: B. Free Body Diagram of Forces A. Chain Drive AssemblyHarish Mohankrishnan NairNo ratings yet

- Design and Analysis of Structural Members of The Jib CraneDocument4 pagesDesign and Analysis of Structural Members of The Jib CraneInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Elastic Stability of Thin - Walled Cylindrical and Conical Shells Under Axial CompressionDocument10 pagesElastic Stability of Thin - Walled Cylindrical and Conical Shells Under Axial CompressionChandra PrakashNo ratings yet

- Ansi b36 10 1979Document23 pagesAnsi b36 10 1979Roberto Wallis100% (1)

- Standards of Tubular Exc - Hanger Manufacturers Association: Fifth EditionDocument15 pagesStandards of Tubular Exc - Hanger Manufacturers Association: Fifth EditionAgung Dewandaru MahatmantoNo ratings yet

- Csa-G40 350WLRDocument2 pagesCsa-G40 350WLRMario VenturaNo ratings yet

- Engineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe RacksDocument8 pagesEngineering Journal - 4th Quarter 2010 - Design of Structural Steel Pipe Racksger80No ratings yet

- Canadian Prescriptive-Residential-Exterior-Wood-Deck-Span-GuideDocument17 pagesCanadian Prescriptive-Residential-Exterior-Wood-Deck-Span-GuideElli VarodoraNo ratings yet

- Hoisting Rigging ManualDocument564 pagesHoisting Rigging ManualBCosmeNo ratings yet

- HSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHDocument10 pagesHSL-3 Heavy Duty Anchor: Basic Loading Data (For A Single Anchor) : HSL-3/HSL-3-SHAlexandru OlaruNo ratings yet

- Elevated Water TankDocument16 pagesElevated Water TankRANJITH PULIKESHINo ratings yet

- Utilities - 2019 - : PreambleDocument110 pagesUtilities - 2019 - : PreambleHARINo ratings yet

- Tools Threading MachineDocument20 pagesTools Threading MachinedayglisNo ratings yet

- Scaffolder: Construction Job Description 5Document1 pageScaffolder: Construction Job Description 5bacabacabacaNo ratings yet

- 152 - HARDOX - 500 - UK - Data Sheet PDFDocument2 pages152 - HARDOX - 500 - UK - Data Sheet PDFneto-portoNo ratings yet

- Problem 1-015 PDFDocument3 pagesProblem 1-015 PDFOscar SanchezNo ratings yet

- BRIDON BAC TechnicalDocument25 pagesBRIDON BAC TechnicalMohamed SidateNo ratings yet

- Cabloc Vertical Fall Arrest PDFDocument10 pagesCabloc Vertical Fall Arrest PDFTunaru GabrielNo ratings yet

- Sail Hook Standard1-08-009-18Document5 pagesSail Hook Standard1-08-009-18PRATHU SINGHNo ratings yet

- Maintenance and Inspection of BTH LiftersDocument8 pagesMaintenance and Inspection of BTH Liftersrpatel12No ratings yet

- Hillman RollersDocument16 pagesHillman RollersLuis LuperdiNo ratings yet

- GRT8100 Product Guide ImperialDocument32 pagesGRT8100 Product Guide ImperialMahfuja HoqueNo ratings yet

- Att - Frict - Capstan EquationDocument16 pagesAtt - Frict - Capstan Equationarrtfiend2131No ratings yet

- Hands-On Simulation Modeling with Python,: Develop simulation models for improved efficiency and precision in the decision-making processFrom EverandHands-On Simulation Modeling with Python,: Develop simulation models for improved efficiency and precision in the decision-making processNo ratings yet

- Harvesting Freedom: The Life of a Migrant Worker in CanadaFrom EverandHarvesting Freedom: The Life of a Migrant Worker in CanadaNo ratings yet

- Wave and Tidal EnergyFrom EverandWave and Tidal EnergyDeborah GreavesNo ratings yet

- OsiSense - XR - Screw Limit Switch - EN PDFDocument22 pagesOsiSense - XR - Screw Limit Switch - EN PDFHellen MontañaNo ratings yet

- Rab SimpleDocument23 pagesRab Simpleboba bajingNo ratings yet

- Amc 600 Installation Instructions 4189341325 UkDocument43 pagesAmc 600 Installation Instructions 4189341325 UkSebastian VasquezNo ratings yet

- Parameter Settings For The Electrical Protection Ae1172 Setting Report Protection Unit71 00Document270 pagesParameter Settings For The Electrical Protection Ae1172 Setting Report Protection Unit71 00MayurNo ratings yet

- Wipers/Washer Systems: Section 9DDocument24 pagesWipers/Washer Systems: Section 9DJarry PotterNo ratings yet

- ĐINH PHÚ 0337999937: 23. Electric SystemDocument39 pagesĐINH PHÚ 0337999937: 23. Electric SystemQuốc Phú ĐinhNo ratings yet

- Tyristor Power Regulator User ManualDocument2 pagesTyristor Power Regulator User ManualJorge ReyesNo ratings yet

- VC (HD120) 07MY General PDFDocument131 pagesVC (HD120) 07MY General PDFVăn Hòa100% (1)

- Ats22 User Manual en Bbv51330 02Document85 pagesAts22 User Manual en Bbv51330 02Catalin PelinNo ratings yet

- JBSYSTEM - Beglec - Control 5.2 Mixer - ManualDocument20 pagesJBSYSTEM - Beglec - Control 5.2 Mixer - ManualFranzzNo ratings yet

- Fereri Final Designdocx DspmNei20VDocument101 pagesFereri Final Designdocx DspmNei20VhasanNo ratings yet

- Danby Dpac 11010 User ManualDocument22 pagesDanby Dpac 11010 User ManualElla MariaNo ratings yet

- Bomag BMP8500Document132 pagesBomag BMP8500George Plishko100% (4)

- Manual T1873LewmarUKTTThruster140 300500100issue3Document28 pagesManual T1873LewmarUKTTThruster140 300500100issue3Jason WilliamNo ratings yet

- Megatronics V3.0 Quick Start GuideDocument8 pagesMegatronics V3.0 Quick Start GuideAndres MesaNo ratings yet

- Circuit Breaker, Relay, and Switch: Solutions GuideDocument68 pagesCircuit Breaker, Relay, and Switch: Solutions GuideRajiv ChaudhariNo ratings yet

- Commissioning Checklist V6.0Document5 pagesCommissioning Checklist V6.0HashemAliHashemNo ratings yet

- Abb IsolatorDocument84 pagesAbb IsolatorSanjay LohodasanNo ratings yet

- X4020126-301 IncomingDocument35 pagesX4020126-301 Incomingbobb djNo ratings yet

- !indx PipDocument18 pages!indx PipCharles JacobNo ratings yet

- PDS S-Series Electronic Marshalling PDFDocument43 pagesPDS S-Series Electronic Marshalling PDFJesse GambleNo ratings yet

- IGCSE Physics MCQ 6 Mains ElectricityDocument6 pagesIGCSE Physics MCQ 6 Mains ElectricityTessa KNo ratings yet

- 0PS1020.0 Powersupply, 1phase, 24VDC, 2A - EnG - V2.11Document14 pages0PS1020.0 Powersupply, 1phase, 24VDC, 2A - EnG - V2.11Edson VargasNo ratings yet

- SECTION 16340 Medium Voltage Switch Gear - Part 1 - GeneralDocument319 pagesSECTION 16340 Medium Voltage Switch Gear - Part 1 - Generalm.abdelsalam772570No ratings yet

- 220kv Line Control & Protection Scheme PDFDocument121 pages220kv Line Control & Protection Scheme PDFYasserali Hasnine100% (1)

- Diagramas Harley Dyna 2011Document156 pagesDiagramas Harley Dyna 2011HerramientasDeMotocicletasRiveraNo ratings yet

- Ecm (Engine Control Module) - 2.0D (Itms-6F)Document12 pagesEcm (Engine Control Module) - 2.0D (Itms-6F)Men PanhaNo ratings yet