SAIC-P-3301 Rev 4

SAIC-P-3301 Rev 4

Uploaded by

sikandar1234Copyright:

Available Formats

SAIC-P-3301 Rev 4

SAIC-P-3301 Rev 4

Uploaded by

sikandar1234Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SAIC-P-3301 Rev 4

SAIC-P-3301 Rev 4

Uploaded by

sikandar1234Copyright:

Available Formats

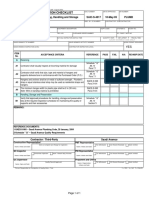

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAIC NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Cable Tray and Accessories - Storage, Handling and

Preservation

PROJECT TITLE

SAIC-P-3301

WBS / BI / JO NUMBER

EQUIPMENT ID NUMBER(S)

EQUIPMENT DESCRIPTION

LAYOUT DRAWING NUMBER

REV. NO.

SCHEDULED INSPECTION DATE & TIME

ACTUAL INSPECTION DATE & TIME

31-Mar-10

DATE APPROVED

31-Aug-11

QR NUMBER

ELECT

CONTRACTOR / SUBCONTRACTOR

EQPT CODE

SYSTEM ID.

PURCHASE ORDER NUMBER

PLANT NO.

EC / PMCC / MCC NO.

QUANTITY INSP.

MH's SPENT

TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER

SAUDI ARAMCO ACTIVITY NUMBER

SAUDI ARAMCO INSPECTION LEVEL

CONTRACTOR INSPECTION LEVEL

ITEM

No.

ACCEPTANCE CRITERIA

REFERENCE

A. General Requirements

A1

Electrical materials shall be new and unused.

Schedule G

Sec. 2

A2

Electrical materials shall be in accordance with the Saudi

Aramco-approved project-specific design drawings, diagrams,

schedules, lists, databases, and associated documents.

Schedule G

Sec. 2

A3

Electrical materials shall be free of damage.

Schedule Q

Att. lV

A4

Electrical materials shall conform to all applicable requirements,

standards, and specifications prior to release to be used as part of the

work.

Schedule Q

Att. lV

A5

Electrical materials shall be identified by using tags, stamps, color

coding, stencils or labels. The location and method of identification shall

not affect the function or quality of the materials.

Schedule Q

Att. lV

A6

Electrical materials shall be traceable from the manufacturer and

supplier through delivery, storage, fabrication, erection, installation,

repair, modification and use.

Schedule Q

Att. lV

B. Storage, Handling, and Preservation

B1

Shipments shall be hand unloaded unless provisions have been made

with the cable tray manufacturer for forklift unloading.

(NEC 110.3, NEMA VE-2 Sec. 2)

SAES-P-104

Sec.4.1

B2

To prevent damage to cable tray:

1) Never pull cable tray from truck trailer by chaining to bottom rung and

dragging out of trailer

2) Special care must be exercised using slings so cable tray is not

crushed from the improper location and lifting by sling

(NEC 110.3, NEMA VE-2 Sec. 2)

SAES-P-104

Sec.4.1

B3

Cable tray can be stored outside without cover, but shall be:

1) Loosely stacked

2) Elevated off the ground

3) Ventilated to prevent storage stain

4) Protected from scratching and marring of finish

5) Small accessories should be stored to prevent loss

6) Stored away from high traffic areas

7) Stacked by width and type

(NEC 110.3, NEMA VE-2 Sec. 3)

SAES-P-104

Sec.4.1

B4

Cable tray systems shall not be subjected to physical damage. Cable

tray shall be free from burrs or other sharp projections that could cause

damage to the cable jacket during installation.

[NEC 392.4, 392.5 (B)]

SAES-P-104

Sec. 4.1

Page 1 of 2

WORK PERMIT REQUIRED?

PASS

FAIL

N/A

RE-INSP DATE

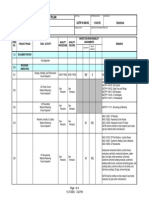

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - March 2010)

Rev 4

SAUDI ARAMCO INSPECTION CHECKLIST

Cable Tray and Accessories - Storage, Handling and

Preservation

DATE APPROVED

SAIC-P-3301

PROJECT TITLE

ITEM

No.

31-Mar-10

SAIC NUMBER

31-Aug-11

WBS / BI / JO NUMBER

ACCEPTANCE CRITERIA

REFERENCE

QR NUMBER

ELECT

CONTRACTOR / SUBCONTRACTOR

PASS

FAIL

N/A

RE-INSP DATE

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G - Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), March 2006

2. Schedule Q - Quality Requirements (Pro Forma Contract), November 2003 and February 2008

3. SAES-P-104 - Wiring Methods and Materials, November 2008

4. NEMA VE 2-2006 - National Electrical Manufacturers Association, Cable Tray Installation Guidelines

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified

purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party

Construction Representative*

Saudi Aramco

PMT Representative

Work is Complete and Ready for Inspection:

Name, Initials and Date:

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

T&I Witnessed

QC Record Reviewed

Work Verified

Name, Initials and Date:

QC Inspector

PID Representative

Performed Inspection

Work / Rework May Proceed

Name, Initials and Date:

Name, Initials and Date:

QC Supervisor

Proponent and Others

Quality Record Approved:

Name, Sign and Date:

Name, Organization,

Initials and Date:

*Person Responsible for Completion of Quality Work / Test

Y = YES

Page 2 of 2

N = NO F = FAILED

You might also like

- SAIC-X-3001 Rev 2Document2 pagesSAIC-X-3001 Rev 2josephjohn2No ratings yet

- Saudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Level - Magnetic Gauges / Switches-Material Receiving. SAIC-J-6302 1-Oct-05 InstAdel KlkNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstDocument2 pagesSaudi Aramco Inspection Checklist: Flow - Integral Orifice - Material Receiving. SAIC-J-6106 1-Oct-05 InstAdel KlkNo ratings yet

- SATR-J-6912 Rev 0 PDFDocument4 pagesSATR-J-6912 Rev 0 PDFAdel KlkNo ratings yet

- SATR-J-6911Rev 0 PDFDocument6 pagesSATR-J-6911Rev 0 PDFAdel KlkNo ratings yet

- SAIC-J-6401 - Rev 0Document4 pagesSAIC-J-6401 - Rev 0Adel KlkNo ratings yet

- SAIC-X-3002 Rev 5Document3 pagesSAIC-X-3002 Rev 5aamirapiNo ratings yet

- Saudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbDocument1 pageSaudi Aramco Inspection Checklist: Hangers and Supports Receiving, Handling and Storage SAIC-S-4017 18-May-05 PlumbUzair AhmadNo ratings yet

- SATR-J-6602 Rev 0 PDFDocument9 pagesSATR-J-6602 Rev 0 PDFAdel KlkNo ratings yet

- SAIC-P-3009 Rev 3Document16 pagesSAIC-P-3009 Rev 3YaserNo ratings yet

- SAIC-P-3010 Rev 3Document30 pagesSAIC-P-3010 Rev 3YaserNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 pagesSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNo ratings yet

- AGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Document49 pagesAGC-TR-414 (Revised Tie-In Package For 4'' - KALCIP-TR-510)Dilshad Ahemad100% (2)

- SAIC-P-3015 Rev 3Document24 pagesSAIC-P-3015 Rev 3YaserNo ratings yet

- SAIC-M-1018 Leak Proof Testing-Final InspectionDocument1 pageSAIC-M-1018 Leak Proof Testing-Final InspectionLegend AnbuNo ratings yet

- Saudi Aramco Inspection ChecklistDocument20 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- SAIC-P-3014 Rev 3Document14 pagesSAIC-P-3014 Rev 3YaserNo ratings yet

- SAIC-W-2XXX-11 Control of Welding ConsumablesDocument5 pagesSAIC-W-2XXX-11 Control of Welding ConsumablesAnsuman KalidasNo ratings yet

- SATR-J-6601 Rev 0 PDFDocument4 pagesSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapNo ratings yet

- SAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingDocument3 pagesSAIC-P-3005 Rev 3 General - Channel, Strut, and Support Materials - Material ReceivingShaikh Mohd QaisarNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade ProtectionDocument1 pageSaudi Aramco Inspection Checklist: SAIC-D-2018 1-Dec-06 Mech-Insp of Under-Tank Leak Detection, Sub-Grade Protectionரமேஷ் பாலக்காடுNo ratings yet

- SAIC & SATR - InstrumentationDocument4 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- Saic P 3315Document2 pagesSaic P 3315Arshad ImamNo ratings yet

- Signal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For RailwaysDocument14 pagesSignal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For Railwaysanon_485351313No ratings yet

- SATR-J-6503 - Rev 0 PDFDocument5 pagesSATR-J-6503 - Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Ogdcl Rig Tor Rm-4573Document8 pagesOgdcl Rig Tor Rm-4573Ahmed Imtiaz RaoNo ratings yet

- Saudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechDocument1 pageSaudi Aramco Inspection Checklist: Storage & Preservation of Fireclay Bricks & Mortar SAIC-N-2038 15-Dec-09 MechaamirapiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistphilipyap100% (1)

- Saudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechDocument5 pagesSaudi Aramco Inspection Checklist: Post-Application Inspection of Fireclay Brick Installation SAIC-N-2041 15-Dec-09 MechaamirapiNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 pageSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapNo ratings yet

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDocument4 pagesSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinNo ratings yet

- Saic K 4001Document2 pagesSaic K 4001BilalNo ratings yet

- Saic N 2037Document5 pagesSaic N 2037aamirapiNo ratings yet

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiNo ratings yet

- Saic - K-4015Document3 pagesSaic - K-4015Bander Al–kouhlaniNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saic P 3314Document4 pagesSaic P 3314Arshad ImamNo ratings yet

- Sample SAT Procedure (Only For Reference)Document3 pagesSample SAT Procedure (Only For Reference)Mohammed SinanNo ratings yet

- Satip-X-600-02 Rev 1 For CP SystemDocument4 pagesSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedNo ratings yet

- SAIC-J-6007 Rev 3Document9 pagesSAIC-J-6007 Rev 3mujjamilNo ratings yet

- SAIC-N-2020 Rev 0Document4 pagesSAIC-N-2020 Rev 0philipyapNo ratings yet

- Saep 20 PDFDocument25 pagesSaep 20 PDFbrecht1980100% (1)

- SAIC-P-3017 Rev 7 FinalDocument14 pagesSAIC-P-3017 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistDilshad AhemadNo ratings yet

- SATIP S 070 03 ThermoplasticDocument2 pagesSATIP S 070 03 ThermoplasticMuhammad Farukh Manzoor100% (1)

- SATIP-N-001-02 Rev. 4Document2 pagesSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- Saic N 2030Document6 pagesSaic N 2030aamirapi100% (1)

- Saic P 3002Document1 pageSaic P 3002aneeshjokay0% (1)

- SAIC-L-2092 Rev 7Document12 pagesSAIC-L-2092 Rev 7Jaseel KanhirathingalNo ratings yet

- Delivery of ConcreteDocument5 pagesDelivery of Concretesikandar1234No ratings yet

- 012 Ladder InspectionDocument1 page012 Ladder Inspectionsikandar1234No ratings yet

- Required HSE Documents Typiacally at Construction SiteDocument4 pagesRequired HSE Documents Typiacally at Construction Sitesikandar1234No ratings yet

- Training Attendance SheetDocument8 pagesTraining Attendance Sheetsikandar1234No ratings yet

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- ? Lesson 22 Companions of The Prophet ( )Document4 pages? Lesson 22 Companions of The Prophet ( )Thierno AbdoulayeNo ratings yet

- Gad Accomplishment Report: To Improve The Facilities of Hand Washing AreaDocument2 pagesGad Accomplishment Report: To Improve The Facilities of Hand Washing AreaCYNTHIA CUSTODIONo ratings yet

- 18th - Moot ProblemDocument13 pages18th - Moot ProblemAngela ConejeroNo ratings yet

- Framework For The Provision of Pro Bono Legal Services 1Document32 pagesFramework For The Provision of Pro Bono Legal Services 1maliandrew2004No ratings yet

- Loadstar Shipping vs. CA (G.R. No. 131621Document2 pagesLoadstar Shipping vs. CA (G.R. No. 131621Rhea CalabinesNo ratings yet

- Minutes of The Barangay Disaster Reduction Council Quarterly Meeting of Barangay AriosaDocument2 pagesMinutes of The Barangay Disaster Reduction Council Quarterly Meeting of Barangay AriosaJoselito M. BaborNo ratings yet

- Terms & Conditions of Use V6.0Document3 pagesTerms & Conditions of Use V6.0erika985No ratings yet

- REYES Angelo Ss IndictmentDocument7 pagesREYES Angelo Ss IndictmentEditor, Hartford CourantNo ratings yet

- Insurance Need AnalysisDocument8 pagesInsurance Need AnalysisRajesh Chowdary ChintamaneniNo ratings yet

- NTRUHS Admission For NursingDocument2 pagesNTRUHS Admission For NursingSushiv SuraparajuNo ratings yet

- Foreign Exchange Operations of Janata Bank LTDDocument81 pagesForeign Exchange Operations of Janata Bank LTDMd Alimur Razee Real71% (7)

- Relationship ContractDocument3 pagesRelationship ContractSuper Fly100% (1)

- MCQ S Question Bank - Law: Company Basic ConceptsDocument31 pagesMCQ S Question Bank - Law: Company Basic Conceptssanjib chakrabortty100% (1)

- History of Abar 1st Elem. SchoolDocument15 pagesHistory of Abar 1st Elem. SchoolArnold Onia50% (2)

- Answers - Chapter 2 Vol 2 RvsedDocument13 pagesAnswers - Chapter 2 Vol 2 Rvsedjamflox100% (3)

- History and Culture of The Argobba: Recent Investigations: Tesfaye HailuDocument21 pagesHistory and Culture of The Argobba: Recent Investigations: Tesfaye HailuGnizla GnizlaNo ratings yet

- Addis Abeba Science and Technology UniversityDocument11 pagesAddis Abeba Science and Technology UniversityYonas BelaynehNo ratings yet

- O Dia Do Chacal - Frederick ForsythDocument104 pagesO Dia Do Chacal - Frederick ForsythPaulo Rafael GonçalvesNo ratings yet

- E-Way Bill: Government of IndiaDocument1 pageE-Way Bill: Government of IndiaShefali MandowaraNo ratings yet

- CHAPTER 12 US Reconstruction NotesDocument2 pagesCHAPTER 12 US Reconstruction Notesexamplelive100% (1)

- Alabama Association of Realtors Vs HHSDocument13 pagesAlabama Association of Realtors Vs HHSstreiff at redstateNo ratings yet

- Catholic Encyclopedia - Bosnia and Herzegovina 1895Document4 pagesCatholic Encyclopedia - Bosnia and Herzegovina 1895RodrigoMenozaNo ratings yet

- CRN-SPC-CVL-713026361-377 - Boundary Fences PDFDocument17 pagesCRN-SPC-CVL-713026361-377 - Boundary Fences PDFPaulNo ratings yet

- Property Law Project Avinash TiwariDocument31 pagesProperty Law Project Avinash TiwariAvinash TiwariNo ratings yet

- Exercise - Institutional Investors - CompletedDocument7 pagesExercise - Institutional Investors - CompletedAgustín Alberto RosalesNo ratings yet

- Questionnaire of Behavioral FinanceDocument9 pagesQuestionnaire of Behavioral Financebikash_sharma19880% (1)

- CEngr 2130Document2 pagesCEngr 2130Mr. DummyNo ratings yet

- Joint Ventures in IndiaDocument41 pagesJoint Ventures in IndiavinodNo ratings yet

- (Series) Macmillan Campaign Military 1 2 3 - FULL Ebook + Audio CD - Bonnhara ChunDocument1 page(Series) Macmillan Campaign Military 1 2 3 - FULL Ebook + Audio CD - Bonnhara ChunFekadu Ayalkbet100% (2)

- Dilg Writeshop BasisDocument3 pagesDilg Writeshop BasisDutchsMoin MohammadNo ratings yet