Copper Alloy Casting JIS 5120

Copper Alloy Casting JIS 5120

Uploaded by

Janak MistryCopyright:

Available Formats

Copper Alloy Casting JIS 5120

Copper Alloy Casting JIS 5120

Uploaded by

Janak MistryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Copper Alloy Casting JIS 5120

Copper Alloy Casting JIS 5120

Uploaded by

Janak MistryCopyright:

Available Formats

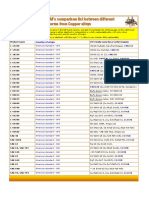

JIS H 5120 : 1997

Copper and copper alloy castings

Table 1 Classification and symbols

Classification

Copper

castings, class 1

Symbol

(old

symbol)

CAC101

(CuCl)

Alloy series

Copper

castings, class 2

CAC102

(CuC2)

Cu series

Copper

castings, class 3

CAC103

(CuC3)

Cu series

Of the copper castings, the

best in conductivity and

thermal conductivity.

Brass castings,

class 1

Brass castings,

class 2

Brass castings,

class 3

CAC201

(YBsC1)

CAC201

(YBsC1)

CAC203

(YBsC3)

Cu-Zn series

Easy to braze.

Cu-Zn series

Of the brass castings,

relatively easy in casting.

Better in mechanical

properties than CAC202.

High strength

brass castings,

class 1

CAC301

(HBsC1)

Cu-Zn-MnFe-Al series

High in strength and

hardness, and good in

corrosion resistance and

toughness.

High strength

brass castings,

class 2

CAC302

(HBsC3)

Cu-Zn-MnFe-Al series

High in strength and good

in abrasion resistance.

Higher in hardness than

CAC301 and having

stiffness.

High strength

brass castings,

class 3

CAC303

(HBsC3)

Cu-Zn-MnFe-Al series

High particular in strength

and hardness and good in

abrasion resistance

even in the case of high

load.

High strength

brass castings,

class 4

CAC304(

HBsC4)

Cu-Zn-AlMn-Fe series

Bronze castings,

class 1

CAC401

(BC1)

Cu-Zn-Pb-Sn

series

Of the high strength brass

castings, high particular in

strength and hardness, and

good in abrasion

resistance even in the case

of high load.

Good in liquidity and

machinability.

Cu series

Cu-Zn series

Division of

casting

methods

Sand mold

casting,

metal mold

casting,

centrifugal

casting and

precision

casting

Informative reference

Characteristics of alloys

Good in castability and

good in conductivity,

thermal conductivity and

mechanical properties.

Better in conductivity and

thermal conductivity than

CAC101.

Examples of uses

Tuyere, large tuyere, cold

plate, hot air valve,

electrode holder, general

machine parts, etc.

Tuyere, electrical

terminal, diverging sleeve,

contact, conductor,

general electric parts, etc.

Lance nozzle for

converter, electric

terminal, diverging sleeve,

current-carrying support,

conductor, general electric

parts, etc.

Flanges, electric parts,

general machine parts, etc.

Electric parts, meter parts,

general machine parts, etc.

Water-supply and drain

metal fittings, electric

parts, building metal

fittings, general machine

parts, domestic wares and

miscellaneous goods, etc.

Propeller for ship,

propeller bon-net, bearing,

valve seat, cage of

bearing, lever, arm, gear,

equipments for ship, etc.

Propeller for ship,

bearing, cage of bearing,

slipper, end plate, valve

seat, valve rod, special

cylinder, general machine

parts, etc.

Low speed and high load

moving parts, large-size

valve, stem, bushing,

worm gear, slipper, cam,

hydraulic cylinder parts,

etc.

Low speed and high load

moving parts, base plate

for bridge, bearing,

bushing, nut, worm gear,

abrasion resistant plate,

etc.

Bearing, identification

plate, general machine

parts, etc.

JIS H 5120 : 1997

Table 1 (continued)

Classification

Bronze castings,

class 2

Symbol

(old

symbol)

CAC402

(BC2)

Alloy series

Cu-Sn-Zn

series

Bronze castings,

class 3

CAC403(

BC3)

Cu-Sn-Zn

series

Bronze castings,

class 6

CAC406

(BC6)

Cu-Sn-Zn-Pb

series

Bronze castings,

class 7

CAC407

(BC7)

Cu-Sn-Zn-Pb

series

Phosphor

bronze castings,

class 2, A

CAC502A

(PBC2)

Cu-Sn-P

series

Phosphor

bronze castings,

class 2, B

CAC502B

(PBC2B)

Cu-Sn-P

series

Phosphor

bronze casting ,

class 3, A

CAC503A

Cu-Sn-P

series

Phosphor

bronze castings,

class 3, B

CAC503B

(PBC3B)

Cu-Sn-P

series

Lead bronze

castings, class 2

CAC602

(LBC2)

Cu-Sn-Pb

series

Lead bronze

castings, class 3

CAC603

(LBC3)

Cu-Sn-Pb

series

Lead bronze

castings, class 4

CAC604

(LBC4)

Cu-Sn-Pb

series

Division of

casting

methods

Sand mold

casting,

metal mold

casting,

centrifugal

casting and

precision

casting

Informative reference

Characteristics of alloys

Good in pressure

tightness, abrasion

resistance and corrosion

resistance and, moreover,

in mechanical properties.

Good in pressure

tightness, abrasion

resistance and mechanical

properties, and better I

corrosion resistance than

CAC402

Good in pressure

tightness, abrasion

resistance, machinability

and castability.

Better in mechanical

properties than CAC406.

Sand mold

casting,

centrifugal

casting and

precision

casting

Metal mold

casing and

centrifugal

casting

Sand mold

casting,

centrifugal

casting and

precision

casting

Metal mold

casting and

centrifugal

casting

Sand mold

casting,

metal mold

casting,

centrifugal

casting and

precision

casting

Good in corrosion

resistance and abrasion

resistance.

Examples of uses

Bearing, sleeve, bushing,

pump barrel, impeller

valve, gear, side scuttle for

ship, electric motor parts,

etc.

Bearing, sleeve, bushing,

pump barrel, impeller,

valve, gear, side scuttle for

ship, electric motor parts,

general machine parts, etc.

Valve, pump barrel,

impeller, water tap faucet,

bearing, sleeve, bushing,

general machine parts,

landscape castings, art

castings, etc.

Bearing, small-size pump

parts, valve fuel pump,

general machine parts, etc.

Gear, worm gear, bearing,

bushing, sleeve, impeller,

general machine parts, etc.

High in hardness and

good in abrasion

resistance

Moving parts, oil hydraulic

cylinder, sleeve, various

types of roller for paper

manufacturing, etc.

Good in pressure

tightness and abrasion

resistance.

Suitable for bearing of

high plate pressure and

good in conformability.

Middle and high speed and

high load use bearing,

cylinder, valve, etc.

Middle and high speed and

high load use bearing,

bearing for large size

engine, etc.

Middle and high speed and

middle load use bearing,

bearing for car, back plate

of white metal, etc.

Better in conformability

than CAC603

JIS H 5120 : 1997

Table 1 (concluded)

Classification

Symbol

(old

symbol)

CAC605

(LBC5)

Cu-Sn-Pb

series

Aluminium

bronze castings,

class 1

CAC701

(AlBC1)

Cu-Al-Fe

series

Aluminium

bronze castings,

class 2

CAC702

(AlBC2)

Cu-Al-Fe-NiMn series

Aluminium

bronze castings,

class 3

CAC703

(AlBC3)

Cu-Al-Fe-NiMn series

Suitable for large size

castings, high in

particular in strength and

good in corrosion

resistance and abrasion

resistance.

Aluminium

bronze castings,

class 4

CAC704

(AlBC4)

Cu-Al8MnFe-Ni series

Silzin bronze

castings, class 1

CAC801

(SzBC1)

Cu-Si-Zn

series

Silzin bronze

castings, class 2

CAC802

(SzBC2)

Cu-Si-Zn

series

Suitable for large-size

casings of simple shape,

high in particular in

strength and good in

corrosion resistance and

abrasion resistance.

Good in liquidity. High in

strength and good in

corrosion resistance.

Higher in strength than

CAC801.

Silzin bronze

castings, class 3

CAC803

(SzBC3)

Cu-Si-Zn

series

Lead bronze

castings, class 5

Alloy series

Division of

casting

methods

Sand mold

casting,

metal mold

casting,

centrifugal

casting and

precision

casting

Informative reference

Characteristics of alloys

Of the lead bronze

castings, good in

particular in

conformability and

baking proof.

High in strength and

toughness and strong

against bending. Good in

corrosion resistance, heat

resistance, abrasion

resistance and lowtemperature

characteristics.

High in strength, and

good in corrosion

resistance and abrasion

resistance.

Good in liquidity. Little

in annealing property.

High in strength and good

in corrosion resistance.

Examples of uses

Middle and high speed and

low load use bearing,

bearing for engine, etc.

Acid-proof pump, bearing,

bushing, gear, valve seat.

Plunger, roll for paper

manufacturing, etc.

Small size propeller for

ship, beaing, gear,

bushing, valve seat,

impeller, bolt, nut, safety

tool, bearing for stainless

steel, etc.

Propeller for ship,

impeller, valve, gear,

pump parts, chemical

industry, use instrument

parts, bearing for stainless

steel, food processing use

machine parts, etc.

Propeller for ship, sleeve,

gear, chemical use,

instrument parts, etc.

Equipments for ship,

bearing, gear, etc.

Equipments for ship,

bearing, gear, propeller for

boat, etc.

Equipments for ship,

hydraulic machine parts,

etc.

JIS H 5120 : 1997

Table 2 Chemical composition

Symbol

Symbol (old symbol)

CAC101 (CuC1)

CAC102 (CuC2)

CAC103 (CuC3)

CAC201 (YBsC1)

CAC202 (YBsC2)

CAC203 (YBsC3)

CAC301 (HBsC1)

CAC302 (HBsC2)

CAC303 (HBsC3)

CAC304 (HBsC4)

CAC401 (BC1)

CAC402 (BC2)

CAC403 (BC3)

CAC406 (BC6)

CAC407 (BC7)

CAC502A (PBC2)

CAC502B (PBC2B)

CAC503A

CAC502B (PBC3B)

CAC602 (LBC2)

CAC603 (LBC3)

CAC604 (LBC4)

CAC605 (LBC5)

CAC701 (AlBC1)

CAC702 (AlBC2)

CAC703 (AlBC3)

CAC704 (AlBC4)

CAC801 (SzBC1)

CAC802 (SzBC2)

CAC803 (SzBC3)

Main composition

Cu

99.5 min.

99.7 min.

99.9 min.

83.0 to

88.0

65.0 to

70.0

58.0 to

64.0

55.0 to

60.0

55.0 to

60.0

60.0 to

65.0

60.0 to

65.0

79.0 to

83.0

86.0 to

90.0

86.5 to

89.5

83.0 to

87.0

86.0 to

90.0

87.0 to

91.0

87.0 to

91.0

84.0 to

88.0

84.0 to

88.0

82.0 to

86.0

77.0 to

81.0

74.0 to

78.0

70.0 to

76.0

85.0 to

90.0

80.0 to

88.0

78.0 to

85.0

71.0 to

84.0

84.0 to

88.0

78.5 to

82.5

80.0 to

84.0

Sn

Ph

Zn

Fe

Ni

Al

Mn

Si

11.0 to

17.0

24.0 to

34.0

30.0 to

41.0

33.0 to

42.0

30.0 to

42.0

22.0 to

28.0

22.0 to

28.0

0.5 to 1.5

0.1 to 1.5

0.5 to 2.0

0.5 to 2.0

0.1 to 3.5

2.0 to 4.0

3.0 to 5.0

2.5 to 5.0

2.0 to 4.0

5.0 to 7.5

2.5 to 5.0

0.5 to 3.0

0.5 to 3.0

0.5 to 1.5

2.0 to 4.0

3.0 to 7.0

8.0 to 12.0

7.0 to 9.0

3.0 to 5.0

9.0 to 11.0

1.0 to 3.0

4.0 to 6.0

4.0 to 6.0

4.0 to 6.0

5.0 to 7.0

1.0 to 3.0

3.0 to 5.0

12.0 to

15.0

12.0 to

15.0

9.0 to 11.0

4.0 to 6.0

0.05 to

0.20

0.15 to

0.50

0.05 to

0.20

0.15 to

0.50

9.0 to 11.0

9.0 to 11.0

14.0 to

16.0

16.0 to

22.0

1.0 to 3.0

0.1 to 1.0

8.0 to 10.0

0.1 to 1.0

2.5 to 5.0

1.0 to 3.0

8.0 to 10.5

0.1 to 1.5

3.0 to 6.0

3.0 to 6.0

8.5 to 10.5

0.1 to 1.5

2.0 to 5.0

1.0 to 4.0

6.0 to 9.0

7.0 to 15.0

9.0 to 12.0

9.0 to 12.0

7.0 to 9.0

6.0 to 8.0

9.0 to 11.0

14.0 to

16.0

13.0 to

15.0

3.5 to 4.5

4.0 to5.0

3.2 to 4.2

JIS H 5120 : 1997

Table 3 Mechanical properties and electrical properties

Symbol (old

symbol)

CAC101 (CuC1)

CAC102 (CuC2)

CAC103 (CuC3)

CAC201 (YBsC1)

CAC202 (YBsC2)

CAC203 (YBsC3)

CAC301 (HBsC1)

CAC302 (HBsC2)

CAC303 (HBsC3)

CAC304 (HBsC4)

CAC401 (BC1)

CAC402 (BC2)

CAC403 (BC3)

CAC406 (BC6)

CAC407 (BC7)

CAC502A (PBC2)

CAC502B (PBC2B)

CAC503A

CAC502B (PBC3B)

CAC602 (LBC2)

CAC603 (LBC3)

CAC604 (LBC4)

CAC605 (LBC5)

CAC701 (AlBC1)

CAC702 (AlBC2)

CAC703 (AlBC3)

CAC704 (AlBC4)

CAC801 (SzBC1)

CAC802 (SzBC2)

CAC803 (SzBC3)

Conductance test

Conductance

%IACS

50 min.

60 min.

80 min.

Tensile test

Tensile

strength

N/Mmm

175 min.

155 min.

135 min.

145 min.

195 min.

245 min.

430 min.

490 min.

635 min.

755 min.

165 min.

245 min.

245 min.

195 min.

215 min.

195 min.

295 min.

195 min.

265 min.

195 min.

175 min.

165 min.

145 min.

440 min.

490 min.

590 min.

590 min.

345 min.

440 min.

390 min.

Hardness test

Elongation

%

Brinell hardness

HB

35 min.

35 min.

40 min.

25 min.

20 min.

20 min.

20 min.

18 min.

15 min.

12 min.

15 min.

20 min.

15 min.

15 min.

18 min.

5 min.

5 min.

1 min.

3 min.

10 min.

7 min.

5 min.

5 min.

25 min.

20min.

15 min.

15 min.

25 min.

12 min.

20 min.

35 min. (10 / 500)

33 min. (10 / 500)

30 min. (10/ 500)

165 min. (10/3 000)

200 min. (10/3 000)

60 min. (10/1 000)

80 min. (10/1 000)

80 min. (10/1 000)

90 min. (10/1 000)

65 min. (10/ 500)

60 min. (10/ 500)

55 min. (10/ 500)

45 min. (10/ 500)

80 min. (10/1 000)

120 min. (10/1 000)

150 min. (10/3 000)

160 min. (10/3 000)

Informative reference

Tensile test

Hardness test

0.2 % proof

Brinell hardness.

stress

HB

N/mm

140 min.

90 min. (10/1 000)

175 min.

100 min. (10/1 000)

305 min.

410 min.

120 min.

145 min.

135 min.

145 min.

100 min.

80 min.

80 min.

60 min.

245 min.

270 min.

Presented by

A unit of

Flow Control Engineering Co., Ltd.

5

You might also like

- Metco 16C 10-040Document8 pagesMetco 16C 10-040JSH100No ratings yet

- QC Piping Inspector Notes Part-IDocument39 pagesQC Piping Inspector Notes Part-Imanojballa100% (4)

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- A 480 - A 480MDocument24 pagesA 480 - A 480MRami GhorbelNo ratings yet

- ASTM B208 - Norma de Ensaio de Tensão Bronze PDFDocument11 pagesASTM B208 - Norma de Ensaio de Tensão Bronze PDFFred Duarte CaldeiraNo ratings yet

- Cu Ni V Mo CR MN C WT CE: - Page 1 of 3Document3 pagesCu Ni V Mo CR MN C WT CE: - Page 1 of 3Ainsworth Noriega RiosNo ratings yet

- Din 17440 1996Document24 pagesDin 17440 1996Janak MistryNo ratings yet

- Airbus Airbus: Deciphering The Codes Deciphering The CodesDocument4 pagesAirbus Airbus: Deciphering The Codes Deciphering The CodesKhaled ElmabroukNo ratings yet

- Creating The Lean Car DealerDocument52 pagesCreating The Lean Car DealerMahadiMohdDinNo ratings yet

- Aboveground Piping Installation Works 2016Document7 pagesAboveground Piping Installation Works 2016Aldrin75% (4)

- Schools - HSMS 20120509 Central RegisterDocument180 pagesSchools - HSMS 20120509 Central RegisterWilliam F. ZachmannNo ratings yet

- Alloy Cross Reference Table PDFDocument4 pagesAlloy Cross Reference Table PDFChad MitchellNo ratings yet

- Filler Metal Selection GuideDocument32 pagesFiller Metal Selection GuideSamuel Latumahina100% (1)

- 12Cr Stats WeldingDocument27 pages12Cr Stats WeldingMark JohnsonNo ratings yet

- Cast Iron StandardsDocument2 pagesCast Iron StandardsBao Duy NguyenNo ratings yet

- (Index - HTML) : Aluminium Alloy 6082, Aluminium 6082 He30, Aluminium 6082 He30 Sheets PlatesDocument2 pages(Index - HTML) : Aluminium Alloy 6082, Aluminium 6082 He30, Aluminium 6082 He30 Sheets PlatesSamrat OMS100% (1)

- A485 PDFDocument4 pagesA485 PDFProduction DepartmentNo ratings yet

- S235jr Carbon SteelDocument2 pagesS235jr Carbon Steelcheligp1981100% (1)

- High Tensile Steel 4340Document2 pagesHigh Tensile Steel 4340Arun KumarNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- GB STD Steel PDFDocument7 pagesGB STD Steel PDFBapu612345No ratings yet

- Pub 85 Welding Aluminium BronzeDocument12 pagesPub 85 Welding Aluminium BronzefranekzapaNo ratings yet

- ASTM steel 분류표Document30 pagesASTM steel 분류표Hyeong-Ho KimNo ratings yet

- Comp SA36, IS 2062, SA516 GR 60Document2 pagesComp SA36, IS 2062, SA516 GR 60RajendraNo ratings yet

- BS 970 PDFDocument5 pagesBS 970 PDFParvee K NakwalNo ratings yet

- Astm A297Document3 pagesAstm A297rams789No ratings yet

- ASTM A159 - Standard Specification For Automotive Gray Iron CastingsDocument2 pagesASTM A159 - Standard Specification For Automotive Gray Iron Castingsjaskaran singh100% (1)

- Manufacturing of FB2 Material For RotorDocument30 pagesManufacturing of FB2 Material For RotorEdwardt Sinaga100% (1)

- Is 2707Document6 pagesIs 2707RSP1234No ratings yet

- Equivalent Materials 2Document5 pagesEquivalent Materials 2lalitlbw91No ratings yet

- 17-7 PH Stainless SteelDocument2 pages17-7 PH Stainless Steelzain malikNo ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- Bisalloy's PlatesDocument16 pagesBisalloy's PlatesMarcoNo ratings yet

- AMS4930LDocument8 pagesAMS4930Lremaja1249No ratings yet

- AISI 1008 Steel: UNS G10080Document2 pagesAISI 1008 Steel: UNS G10080omneyaaNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document3 pagesAisi 4140 Alloy Steel (Uns g41400)diogolabegNo ratings yet

- Dec 2016finish ListDocument7 pagesDec 2016finish ListjmdrioindiaNo ratings yet

- Bearing Steel Material Specification Sheet SAE52100Document1 pageBearing Steel Material Specification Sheet SAE52100Christy Vijay Roy HenryNo ratings yet

- Astm A565-1Document4 pagesAstm A565-1MICHELNo ratings yet

- Spring Grade 52cr4mo2v ChemicalDocument1 pageSpring Grade 52cr4mo2v ChemicalSujin SujiNo ratings yet

- Bollhoff HeliCoil Plus ImperialDocument48 pagesBollhoff HeliCoil Plus ImperialAce Industrial SuppliesNo ratings yet

- Aisi 1008Document2 pagesAisi 1008GANESH GNo ratings yet

- Development of New Etchant For High Manganese Steel CastingDocument9 pagesDevelopment of New Etchant For High Manganese Steel CastingShankhaPathakNo ratings yet

- Comparison List Copper Bronze 2011 1Document7 pagesComparison List Copper Bronze 2011 1NaldoVicenteNo ratings yet

- Astm B849-02Document3 pagesAstm B849-02luiz.superv.valbrac100% (1)

- JIS G4103 SNCM420 Steel PlateDocument2 pagesJIS G4103 SNCM420 Steel Plateamit2688No ratings yet

- ASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Document2 pagesASTM A536 Grade 80-55-06 (2021 - 03 - 22 20 - 48 - 50 UTC)Milton Pereira JúniorNo ratings yet

- A488A488M Standard Practice For Steel Castings, Welding, Qualifications of Procedures and PersonnelDocument18 pagesA488A488M Standard Practice For Steel Castings, Welding, Qualifications of Procedures and Personnelbhavin178No ratings yet

- AÇO - DIN17100 St52-3Document1 pageAÇO - DIN17100 St52-3Paulo Henrique NascimentoNo ratings yet

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Tabel AISI ASTM (Selected)Document5 pagesTabel AISI ASTM (Selected)Dini Adilah PrabowoNo ratings yet

- Geared Motor: Product ManualDocument178 pagesGeared Motor: Product Manualsanjibkrjana100% (1)

- LIST TC JIS-Japanese-Standards-for-Steel-Materials PDFDocument2 pagesLIST TC JIS-Japanese-Standards-for-Steel-Materials PDFHongducBui0% (1)

- Is 3930Document19 pagesIs 3930IPSITNo ratings yet

- Company Profil KS Dan Data Dukungnya PDFDocument107 pagesCompany Profil KS Dan Data Dukungnya PDFRidwanda HimawanNo ratings yet

- Valve Material EquivalentsDocument8 pagesValve Material EquivalentsFabio Peres de LimaNo ratings yet

- Astm A532 A532m 10 2019Document2 pagesAstm A532 A532m 10 2019Milady OyuelaNo ratings yet

- Cast Steel GradesDocument5 pagesCast Steel Gradessohan_miyawala1906No ratings yet

- Metal Seated Ball ValveDocument12 pagesMetal Seated Ball Valvevaitheeswaran PNo ratings yet

- Barreto 2020Document11 pagesBarreto 2020Daniyar MaukenovNo ratings yet

- GK Catalogue - Updated 22 Sep 21Document10 pagesGK Catalogue - Updated 22 Sep 21mvb 012No ratings yet

- Nitronic60 MainDocument28 pagesNitronic60 MainAnonymous IpqcBBNo ratings yet

- Corrosion Prevention and ProtectionDocument9 pagesCorrosion Prevention and ProtectionKyaw Kyaw AungNo ratings yet

- Nitro Nic 60 BookDocument36 pagesNitro Nic 60 BookGerman ToledoNo ratings yet

- Copper and Copper Alloy Ingots and CastingsDocument2 pagesCopper and Copper Alloy Ingots and CastingspoopNo ratings yet

- Din en Iso 2338Document1 pageDin en Iso 2338Janak MistryNo ratings yet

- B14 Uni 1701Document1 pageB14 Uni 1701Janak MistryNo ratings yet

- Is 2708 - Manganize Steel CastingDocument6 pagesIs 2708 - Manganize Steel CastingJanak MistryNo ratings yet

- Casting ExerciseDocument5 pagesCasting ExerciseEdward MorganNo ratings yet

- Interview Guide On Street Vendors in ManilaDocument6 pagesInterview Guide On Street Vendors in ManilaShiela CoralesNo ratings yet

- Project Report in JSWDocument45 pagesProject Report in JSWJyant Khobragade0% (1)

- Fleet SizingDocument88 pagesFleet SizingGanesh SNo ratings yet

- Haryana RuralDocument3 pagesHaryana RuralRocky KaushikNo ratings yet

- Value Chain Seminar - Prof M Firdaus 5 April 2018Document13 pagesValue Chain Seminar - Prof M Firdaus 5 April 2018Budi SeptionoNo ratings yet

- ME324 Jeopardy2Document22 pagesME324 Jeopardy2Catherine AndersonNo ratings yet

- Rate AnalysisDocument20 pagesRate AnalysisKrishna Kadam83% (6)

- Business Success Is Dependent On A Variety of FactorsDocument9 pagesBusiness Success Is Dependent On A Variety of FactorsMasud RanaNo ratings yet

- Container TypeDocument3 pagesContainer TypeRedouane FirdaoussiNo ratings yet

- CH 14 CarbonandAlloySteelsDocument43 pagesCH 14 CarbonandAlloySteelsMohmmad ShaikhNo ratings yet

- Easa Aw119 TCDSDocument45 pagesEasa Aw119 TCDSAnonymous ucJM9AGda100% (1)

- TrafficDocument7 pagesTrafficJose Li ToNo ratings yet

- Aircraft Ref File in Model - Series Name SequenceDocument1,447 pagesAircraft Ref File in Model - Series Name SequenceJ HevesiNo ratings yet

- Bryan SavoyDocument3 pagesBryan SavoynormanwillowNo ratings yet

- Thai Air AccidentsDocument33 pagesThai Air AccidentsBobby Chipping100% (2)

- ATM 8 Fleet Planning A162Document11 pagesATM 8 Fleet Planning A162Muhriddin OripovNo ratings yet

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgeNo ratings yet

- Transportation Law OutlineDocument8 pagesTransportation Law OutlineMeet MeatNo ratings yet

- Lab 3 Road Skid ResistanceDocument9 pagesLab 3 Road Skid ResistanceAmar AizadNo ratings yet

- A321 Ams Issue 15 Amd 00 FinalDocument782 pagesA321 Ams Issue 15 Amd 00 FinalTony ThanhNo ratings yet

- Jindal Saw LimitedDocument41 pagesJindal Saw Limitedrinkal_143No ratings yet

- Flanges and Pipe Fitting ManufacturerDocument12 pagesFlanges and Pipe Fitting Manufacturer9823458877No ratings yet

- Gmail - Your IndiGo Itinerary - B86R2JDocument1 pageGmail - Your IndiGo Itinerary - B86R2JSukhamMichaelNo ratings yet

- 3 Application ARCDocument9 pages3 Application ARCHemantkumar TungNo ratings yet

- 3 Structural Steel Fabrication3Document28 pages3 Structural Steel Fabrication3yradwohc100% (2)