Technical Information For Carbon Monoxide Sensors

Technical Information For Carbon Monoxide Sensors

Uploaded by

sanchez_buenoCopyright:

Available Formats

Technical Information For Carbon Monoxide Sensors

Technical Information For Carbon Monoxide Sensors

Uploaded by

sanchez_buenoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Technical Information For Carbon Monoxide Sensors

Technical Information For Carbon Monoxide Sensors

Uploaded by

sanchez_buenoCopyright:

Available Formats

an ISO9001 company

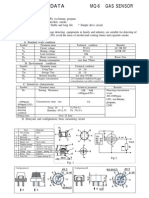

TECHNICAL INFORMATION FOR TGS5042

Technical Information for Carbon Monoxide Sensors

Figaros TGS5042 is a battery operable

electrochemical sensor which offer several

advantages over traditional electrochemical

sensors. Its electrolyte is environmentally

friendly, it poses no risk of electrolyte leakage,

can detect concentrations as high as 1% CO,

operates in a range from -40 and +70C, and it

has lower sensitivity to interference gases. With

a long life, good long term stability, and high

accuracy, this sensor is the ideal choice for CO

detectors with digital display. OEM customers

will find individual sensors data printed on each

sensor in bar code from, enabling users to skip

the costly gas calibration process and allowing

for individual sensor tracking. TGS5042 utilizes

a standard AA battery-sized package.

Specifications

Page

Features..................................................................................................2

Applications...............................................................................................2

Structure...........................................................................................2

Basic Measuring Circuit...........................................................................2

Operating Conditions & Specifications...................................................3

Mechanical Strength..............................................................................3

Dimensions...................................................................................................3

Operation Principle......................................................................................................4

Basic Sensitivity Characteristics

Sensitivity to Various Gases............................................................5

Temperature and Humidity Dependency.............................................5

Gas Response Pattern.................................................................................6

Repeatability.............................................................................6

Influence of Storage...................................................................................6

Normal Operation Test.....................................................................................7

Sensitivity Test...................................................................................7

Reliability

Interference Gas Test......................................................................................8

Long-Term Stability................................................................................9

Corrosion Test...........................................................................................9

Variable Ambient Temperature Test................................................................9

Humidity Test.............................................................................................10

Stability Tests..................................................................................................11

Sequential Test...........................................................................................11

Dust Test................................................................................................12

Water Loss Test.......................................................................................12

Marking..........................................................................................................................12

Cautions.......................................................................................................13

Appendix................................................................................................................14

IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED WILL VARY

WITH EACH CUSTOMERS SPECIFIC APPLICATIONS. FIGARO STRONGLY RECOMMENDS CONSULTING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO SENSORS IN YOUR APPLICATION AND,

IN PARTICULAR, WHEN CUSTOMERS TARGET GASES ARE NOT LISTED HEREIN. FIGARO CANNOT

ASSUME ANY RESPONSIBILITY FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR

WHICH SENSOR HAS NOT BEEN SPECIFICALLY TESTED BY FIGARO.

TGS5042 is a UL recognized component in accordance with the

requirements of UL2034. Please note that component recognition

testing has confirmed long term stability in 15ppm of carbon monoxide;

other characteristics shown in this brochure have not been confirmed by

UL as part of component recognition.

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

1. Specifications

* Battery operable

* High repeatability/selectivity to carbon monoxide

* Linear relationship between CO gas concentration

and sensor output

* Simple calibration

* Long life

* UL recognized component

* Meets UL2034, EN50291, and RoHS requirements

Cap /Working electrode

terminal

Active charcoal filter

1-1 Features

Gas inlet

Gas inlet

Gasket

Gas diffusion control film

Gas sensing layer

Washer

Water

Can /Counterelectrode

terminal

1-2 Applications

*

*

*

*

*

*

Residential and commercial CO detectors

CO monitors for industrial applications

Ventilation control for indoor parking garages

Recreational vehicle CO detectors

Marine CO detectors

Fire detection

Backing Layer

Catalyst layer

Separator

(immersed by liquid

alkaline electrolyte)

Gas sensing layer

Figure 1 - Sensor structure

1-3 Structure

Figure 1 shows the structure of TGS5042. The gas sensing

layer is sandwiched between a stainless steel washer

(counter electrode) and a stainless steel cap (working

electrode), together with gas diffusion control stainless

film and backing layers. This assembly is placed in the

compartment of the stainless steel can. Water is stored in

the bottom compartment and a charcoal filter is installed

inside the stainless steel cap.

C1

1F

R1

1M

Working

IC

TGS5042

1-4 Basic measuring circuit

Figure 2 shows the basic measuring circuit of TGS5042.

The sensor generates a minute electric current which is

converted into sensor output voltage (Vout) by an op-amp/

resistor (R1) combination.

Figaro recommends the following electrical parts:

R1 : 1M

C1 : 1F

IC : AD708

An additional resistor or FET is required to prevent

polarization of the sensor when circuit voltage if off.

NOTE: When voltage is applied to the sensor output

terminal, the sensor may be damaged. Voltage applied to

the sensor should be strictly limited to less than 10mV.

1-5 Operating conditions & specifications (Table 1)

Vout

Counter

Figure 2 - Basic measuring circuit

(Including equivalent circuit)

Item

Specification

Model number

TGS5042-A00 (pin version)

TGS5042-B00 (ribbon version)

Target gases

Carbon monoxide

Typical detection range

0 ~ 10,000ppm

Output current in CO

1.2~2.4nA/ppm

Baseline offset

<10ppm equivalent

Operating temperature

-10C ~ +60C (continuous)

-40C ~ +70C (intermittent)

Operating humidity

5 ~ 99%RH (no condensation)

Response time (T90)

within 60 seconds

Storage conditions

-10C ~ +60C (continuous)

-40C ~ +70C (intermittent)

Weight

approx. 12g

Standard test conditions

202C, 4010%RH

NOTE 1: Sensor output in air under operating conditions

Table 1 - Operating conditions and specifications

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

1-6 Mechanical strength

All sensor characteristics shown in this brochure

represent typical characteristics. Actual characteristics

vary from sensor to sensor and from production lot

to production lot. The only characteristics warranted

are those shown in the Specification.

The sensor shall have no abnormal findings in

its structure and shall satisfy the above electrical

specifications after the following performance tests:

Withstand force withstand force of 10kg (cap from metal can) along

a vertical axis

Vibration - frequency--10~500Hz (equiv. to 10G),

duration - 6 hours, x-y-z direction

Shock - acceleration-100G, repeat 5 times

1-7 Dimensions (see Fig. 3)

Gas inlet

Top view

Working electrode

49.71.0

1.250.25

0.200.12

8.50.3

Side view

Insulation tube

Counter electrode

0.

4.

Bottom view

unit: mm

NOTE: The sensor can be supplied with lead pins. Please refer to the Appendix for details

Figure 3 - Dimensions

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

2. Operation Principle

The electrolyte of TGS5042 is a very low concentration of mixed/prepared alkaline electrolyte

consisting of KOH, KHCO3, and K2CO3. The

mixed alkaline electrolyte acts as a buffer solution

with a pH value maintained between 7~10. When

CO passes through the backing layer and reaches

to the working electrode, electrons are generated

resulting from the reaction between CO and anions

in the electrolyte such as OH-, HCO3-, and CO32(see equations 1a~1c). By creating a short circuit

between the working and counter electrodes with

external wiring, electrons move to the counter

electrode through the external wiring. At that

point, the consumed anions in the electrolyte at

the working electrode are replenished and move to

the electrolyte by the reaction of CO2, water, and

electrons as shown in equations 2a~2c. The total

reaction is expressed as shown in equation 3.

A linear relationship exists between the sensor's

electric current and CO concentration (see equation

4). By calibrating the sensor with a known

concentration of CO gas, the output current of the

sensor can then be used to quantitatively determine

CO concentration.

Working electrode (Anodic reaction)

CO + 2OH- CO2 + H2O + 2e(equation 1a)

CO + 2HCO3- 3CO2 + H2O + 2e- (equation 1b)

CO + CO32- 2CO2 + 2e(equation 1c)

Counter electrode (Cathodic reaction)

1/2O2 + H2O + 2e- 2OH(equation 2a)

1/2O2 + 2CO2 + H2O + 2e- 2HCO3- (equation 2b)

1/2O2 + CO2 + 2e- CO32(equation 2c)

Total reaction

CO + 1/2 O2 CO2

(equation 3)

Theoretical output current value

I = F x (A/) x D x C x n

(equation 4)

where:

F : Faraday constant

A: Surface area of diffusion film

D: Gas diffusion co-efficient

C: Gas concentration

: Thickness of diffusion film

n: Number of reaction electrons

Figure 4 - Operation principle

Gas

Working electrode

Since, unlike conventional dry batteries, there is no

consumption of active materials or of the electrodes,

TGS5042 possesses excellent long-term stability

for its output signal and enables maintenance-free

operation. Furthermore, the sensor's self-generating

output current makes it ideal for usage in batteryoperated CO detectors.

Separator immersed

in liquid alkaline

electrolyte

e-

OH- ,HCO3- ,CO32-

Counter electrode

Air

Figure 5 - Schematic diagram of TGS5042

operating principle

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

3. Basic Sensitivity Characteristics

3-1 Sensitivity to various gases

Figure 6 shows the sensors sensitivity to various

gases. The Y-axis shows output current (Iout/A) in

each gas. The output current is linear to CO concentration, with a deviation of less than 5% in the range

of 0~500ppm. Cross sensitivity data for other gases

than those in Figure 6 are tabulated in Table Y.

Gas

Hydrogen

Methane

Butane

EtOH

HMDS (Si vapor)

Toluene

NO2

Benzene chloride

Formaldehye

Acetoaldeyde

CH3COOH

Heptane

IPA

Freon R22

Acetylene

Ethylene

Hexane

CO2

NH3

SO2

Ethyl acetate

Concentration

CO equivalent

1000ppm

<350ppm

Figure 6 - Sensitivity to various gases

1000ppm

<30ppm

200ppm

Note: The figures in this table are typical values and should not be used

as a basis for cross calibration. Cross sensitivity for various gases may

not be linear and should not be scaled. All data based on a 4 minute

exposure. For some gases, fliter saturation and gas breakthrough may

occur if gas is applied for a longer time period.

3-2 Temperature and humidity dependency

Figure 7a shows the temperature dependency of

TGS5042 under a constant humidity of 50%RH. The

Y-axis shows the ratio of output current in 400ppm of

CO at various temperatures (I) to the output current

in 400ppm of CO at 20C/50%RH (Io). Temperature

dependency is based on the difference in the

catalytic reaction rate on the electrodes, and it can be

simply compensated by utilizing a thermistor. The

data displays that even at -40C (where water in the

water reservoir is frozen), the sensor has sufficient

CO sensitivity. This linear relationship between I/

Io and CO concentration is constant regardless of

CO concentration range, according to the sensor's

operating principle.

Figure 7b shows the humidity dependency of

TGS5042 under constant temperatures of 20C and

50C. The Y-axis shows the ratio of output current

in 400ppm of CO at various relative humidities

(I) to the output current in 400ppm of CO at

20C/50%RH (Io). This data demonstrates that

humidity dependency is negligible as temperature

varies.

Revised 04/13

2.0

1.5

1.0

I/Io

0.5

0.0

-40

-20

20

40

60

Temperature (C)

Figure 7a - Temperature dependency at 400ppm CO/50%RH

(Io=sensor output current at 20C)

2.0

20C

50C

1.5

1.0

I/Io

0.5

0.0

0

20

40

60

80

100

Relative Humidity (%)

Figure 7b - Humidity dependency at 400ppm CO

(Io=sensor output current at 50%RH)

TECHNICAL INFORMATION FOR TGS5042

3-3 Gas response pattern

Figure 8 shows the gas response pattern of the

output signal when the sensor is placed into 30, 70,

150 and 400ppm of CO and then returned to normal

air. The response time to 90% of the saturated signal

level is within 60 seconds, and the recovery of the

signal back to 90% of the base level is within 120

seconds. This data demonstrates that TGS5042

possesses sufficient response speed for meeting UL

requirements for CO detectors.

1.0

CO 400ppm

0.8

0.6

Iout(A)

CO 150ppm

0.4

CO 70ppm

0.2

CO 30ppm

0.0

500

1000

1500

2000

Time (sec.)

Figure 8 - Response pattern

1.0

3-4 Repeatability

Figure 9 shows the pattern of the output signal

when the sensor is repeatedly exposed to 400ppm

of CO at a constant interval of 240 seconds. The data

demonstrates extremely high reproducibility of the

output signal, the deviation being less than 5%.

0.8

0.6

0.4

Iout(A)

0.2

0.0

-0.2

500

1000

1500

2000

Time (sec.)

Figure 9 - Repeatability (in 400ppm of CO)

3-5 Influence of storage

Figure 10 shows the initial action of the sensor's

output current signal in fresh air. For the purpose

of this test, sensors were stored for more than six

months under two separate conditions between the

working and counter electrodes: in short-circuited

condition, and in open-circuited condition. The

chart illustrates the behavior of sensor output

current for each group just after installation into

the operating circuit. The output current signal of

sensors stored in a short-circuited condition reaches

its saturated level quickly, while those stored with

an open-circuit exhibit much slower behavior.

Revised 04/13

Figure 10 - Influence of storage

(in fresh air)

TECHNICAL INFORMATION FOR TGS5042

3-6 Normal operation test

Figure 11a shows the result of the Normal Operation

Test required by UL2034, Sec. 35.3 where the

sensor is exposed to 600ppm of CO for 12 hours at

20C/40%RH. Stable output current signal can be

seen throughout the exposure.

1.5

CO 600ppm

1.0

Iout(A)

0.5

0.0

0

12

16

Time (hrs.)

Figure 11a - Normal operation test

(CO 60030ppm for 12 hours at 20C/40%RH)

In addition, Figure 11b shows the CO sensitivity

characteristics of the sensor before, during, and

after the Normal Operation Test, demonstrating that

TGS5042 is hardly influenced by exposure to high

concentrations of CO.

Figure 11b - Normal operation test

(20C/40%RH)

3-7 Sensitivity test

Figure 12a shows the results of the Sensitivity Test

as required by UL2034, Sec. 38. Under this test, the

sensor was exposed to 30, 70, 150 and 400ppm of CO

at 20C/40%RH. The period of exposure was varied

by concentration, corresponding with the maximum

time in which a CO detector should generate an

alarm for the subject concentration. Throughout the

test exposures, TGS5042 displayed a reasonable and

stable output current signal.

1

CO 400ppm

0.8

0.6

Iout(A)

0.4

CO 150ppm

0.2

CO 70ppm

CO 30ppm

0

0

200

400

600

800

1000

1200

1400

Time (min.)

Figure 12a - Sensitivity test

(20C/40%RH)

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

In addition, Figure 12b indicates the CO sensitivity

characteristics of the sensor before, during, and

after the Sensitivity Test, demonstrating the

excellent reproducibility of TGS5042's CO sensitivity characteristics.

4. Reliability

Tests conducted in this section demonstrate that TGS5042

can meet the requirements of various testing standards

without incurring adverse long term effects from such

tests.

Fig. 12b - Sensitivity test

(20C/40%RH)

0.08

4-1 Interference gas test

Figure 13a shows the results of testing the TGS5042

sensor for durability against various interference

gases as specified by UL2034, Sec. 39. The test

was conducted by exposing the sensor to each gas

shown in Figure 13a (starting with CO 30ppm) for

two hours, then removing the sensor to fresh air for

just one hour, and followed by inserting the sensor

into the next gas. This procedure was repeated for

the full range of gases shown in Figure 13a.

Because the sensor is exposed to each of the test

gases consecutively, to some small extent the effect

of the previous test gas may affect subsequent tests

for a short period. However, despite the short-term

effects of such gases remaining after exposure, the

sensor still shows significantly less sensitivity to

each test gas when compared to 30ppm of CO, and

CO sensitivity remains unaffected.

0.06

0.04

Iout(A)

0.02

-0.02

r

Ai ppm pm pm pm pm pm pm pm ppm pm pm ppm pm

p

p

p

p

p

p

p

p

p

p

30 500 300 500 200 200 000 100 200 200 200 200 30

CO ne ne ne ate IPA 2 5 H3 nol ne ne one CO

t

e

a

a

a

a

a

t

t

e

h

CO N Eth olu eth cet

et Bu Hep l ac

T ro

A

M

lo

hy

Et

ich

r

T

Ai

Figure 13a - Interference gas test

(20C/40%RH)

In addition, Figure 13b shows the CO sensitivity

characteristics of the sensor before and after this test,

further demonstrating the excellent reproducibility

of the CO sensitivity characteristics of TGS5042,

demonstrating its durability against the interference

gases listed in the requirements of UL2034, Sec. 39.

Figure 13b - Interference gas test

(20C/40%RH)

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

4-2 Long-term stability

Figure 14 shows long-term stability data for

TGS5042. Test samples were stored in natural clean

air under a short-circuit condition and measured at

various intervals as dictated by the standard test

conditions of UL2034, Sec. 38. The Y-axis shows the

ratio of output current in 300ppm of CO at any point

in time (I) over output current in 300ppm of CO on

the first day of the test (Io). This chart demonstrates

very stable characteristics with a variation of less

than 15% for more than 7 years.

3.0

ave.

min.

max.

2.5

2.0

N=10

I/Io

1.5

1.0

0.5

0.0

500

1000

1500

2000

2500

3000

Time (days)

4-3 Corrosion test

Figure 14 - Long term stability

To demonstrate the durability of TGS5042 against

corrosion, samples were subjected to test conditions

called for by UL2034, Sec.58-Corrosion Test. Over

a three-week period, a mixture of 100ppb of H2S,

20ppb of Cl2, and 200ppb of NO2 was supplied to the

sensors at a rate sufficient to achieve an air exchange

rate of five times per hour. Figure 15 shows the CO

sensitivity characteristics before and after exposure

in the above conditions, demonstrating that TGS5042

is hardly influenced by such corrosive gases. In

addition, the sensor's stainless steel housing did not

show any sign of corrosion as a result of this test.

4-4 Variable ambient temperature test

To demonstrate the ability of TGS5042 to withstand

the effects of high and low temperature, the

Variable Ambient Temperature Test of UL2034,

Sec. 45 was conducted.

Figure 15 - Durability against corrosion

(1) Operation in high and low temperature test

Figure 16a shows the results for the Operation in

High and Low Temperature Test of UL2034, Sec.

45.1. The sensor was exposed to environments of

0C/15%RH and 49C/40%RH for at least three

hours each, with measurements taken before and

during the exposure in accordance with the test

conditions of UL2034, Sec. 38. By plotting the output

current values from these test measurements atop

the data taken prior to this test at a constant 50%RH

(representing standard temperature dependency), it

can be seen that the test data are still in line with data

taken at a constant RH. The conclusion which can be

drawn is that, regardless of exposure to extremes of

temperature and humidity, the sensor's output is not

affected by humidity. As a result, TGS5042 can meet

the requirements of UL2034, Sec. 45.1 by utilizing a

simple temperature compensation method.

Figure 16a - Operation in high and low temperature

(all data at 50%RH except Sec. 45.1 test points)

(2) Effect of shipping and storage

Revised 04/13

TECHNICAL INFORMATION FOR TGS5042

To verify the effects of shipping and storage, the

sensor was tested under the conditions of UL2034,

Sec. 45.2. Test samples in a short-circuited condition

were subjected to 70C for 24 hours, allowed to cool

to room temperature for 1 hour, subjected to -40C

for 3 hours, and then allowed to warm up to room

temperature for 3 hours. Figure 16b shows the CO

sensitivity characteristics before and after the test,

demonstrating that TGS5042 meets the requirement

of UL2034, Sec. 45.2.

Figure 16b - Effects of shipping and storage

4-5 Humidity test

Figure 17a shows the results of testing the sensor

under UL2034, Sec. 46A. The sensor was exposed

in an atmosphere of 523C/954%RH for a

period of 168 hours, returned to normal air for

2 days, then followed by 168 hours exposure at

223C/103%RH. The data demonstrates the

stable characteristics in both low and high humidity

conditions.

Figure 17a - Humidity test

Figure 17b shows data taken prior to the above test

at a constant relative humidity of 50%. These curves

represent the typical temperature dependency of the

sensor. When plotting measurements taken at the

environmental extremes specified on UL2034, Sec.

46A (523C/954%RH and 223C/103%RH)

onto the temperature dependency curves, it can

be seen that measurements taken at these extreme

conditions still fall in line with the temperature

dependency curve derived prior to testing. The

conclusion which can be drawn is that, regardless of

exposure to extremes of temperature and humidity,

the sensor's output is not affected by humidity. As

a result, TGS5042 can meet the requirements of

UL2034, Sec. 46A by utilizing a simple temperature

compensation method.

Figure 17b - Humidity test

(all data at 50%RH except Sec. 46A test points))

4-6 Stability test

Revised 04/13

10

TECHNICAL INFORMATION FOR TGS5042

(1) False alarm test

To show the sensors behavior under continuous

low level exposure to CO, samples were tested

against the procedure detailed in UL2034, Sec.

41.1(c)-Stability Test. Test samples were exposed to

30ppm of CO continuously for a period of 30 days

under standard circuit conditions. Figure 18 shows

the CO sensitivity characteristics before and after

the exposure test, demonstrating that detectors

using TGS5042 will not give a false alarm as a result

of continuous low level CO exposure.

Figure 18 - False alarm test

(2) Temperature cycle test

In accordance with UL2034, Sec. 41.1(e)-Stability

Test, test samples were exposed to ten cycles

(<1 hour and >15 minutes) of temperature from

0C/100%RH to 49C/40%RH. Figure 19 shows

CO sensitivity characteristics before and after the

cycle test, demonstrating that TGS5042 is hardly

influenced by the extreme conditions of the

temperature cycle test.

Figure 19 - Temperature cycle test

4-7 Sequential test

In UL2034, Sec. 41.3, a single lot of sample detectors

are to be subjected to the following sequence of

tests: Section 38, Section 41.1, Section 39, Section

45, and Section 46A. While TGS5042 meets the

requirements of each of these test individually (as

shown elsewhere in this brochure), this test is designed

to demonstrate the sensor's ability to withstand all

of these test when conducted in sequence. Figure 20

shows the results of sequentially testing the same

lot of sensors. The good stability of the sensor's

output signal indicates that TGS5042 can satisfy the

requirements of UL2034, Sec. 41.3-Sequential Test.

4-8 Dust test

To judge the effect of dust contamination on TGS5042,

t

t

)

t

t

t

t

t

t

)

)

)

t

t

g

in tes tes tes tes tes 0C 9C tes 0C 0C tes tes t tes tes

l

st

p

t ( (4 ge -4 (7 st

st s

ia

te 38 .3 .1 39

e c. . 35 . 41 c. tem tes est ora st ( est y te y te ty te ent

r

t st

t

it

p

fo Se c ec Se nt

it di qu

te

Be ter r Se r S ter bie tem mp ing/ ge age mid mid umi se

Af fte Afte Af am ent nt te ipp tora stor hu hu w h fter

A

/

h

r.

A

e

/s

gh igh lo

bi

va am mbi .2 s ing ping hi

h

A

1

A 6A

5. ar. r. a . 45 hipp hip 46 46 c. 4

4

v va

ec 2 s .2 s ec. ec. Se

c. .1

S r S er

Se 45 5.1 e S 5. 45

re ec. c. 4 for c. 4 ec. fore fte Aft

o

e

f

e S

A

e

S

e

e

B

S

B

r

B ter r S

r

te Afte

Af Afte

Af

Figure 20 - Sequential test

Revised 04/13

11

TECHNICAL INFORMATION FOR TGS5042

approximately 2 ounces (0.06 kg) of cement dust, capable

of passing through a 200 mesh screen, was circulated for

1 hour by means of a blower, enveloping the sensor in the

test chamber. Air flow was maintained at an air velocity of

approximately 50 fpm (0.25 m/s) at 20C/40%RH.

Figure 21 shows the sensor's CO sensitivity characteristics

before and after the dust exposure test. This data

demonstrates that the dust test of UL2034, Sec. 53 has a

negligible effect on CO sensitivity.

4-9 Water loss test

For evaluating the life expectancy of TGS5042 from the

viewpoint of its water reservoir (which prevents the

electrolyte from drying up), the weight loss of TGS5042

was periodically measured when stored at 20C/40%RH

and 70C/5%RH respectively. Figure 22 demonstrates

that the sensors weight decreased linearly with time due

to evaporation of the water. The rate of water loss under

various temperature was related with the water vapor

pressure at each temperature. According to calculations

based on this rate of water loss and the differences in

water vapor pressure in 20C and 70C, the water (>4.5g

initially) will last more than 10 years under natural

residential conditions such as 20C/40%RH.

Figure 21 - Dust test

0.00

-0.02

20C

70C

-0.04

-0.06

Weight loss (g)

-0.08

-0.10

0

20

40

60

80

100

Time (days)

5. Marking

The TGS5042 comes with a sticker attached to the sensor

housing which contains important information. The one

dimensional bar code indicates the sensor's sensitivity

(slope) in numeric value as determined by measuring the

sensor's output in 300ppm of CO:

xxxx = x.xxx nA/ppm

In user readable format, the sensor's sensitivity per ppm

(nA) is printed below the one dimensional bar code

and the sensor's Lot Number is printed to the left of the

sensitivity data. Please note that three decimal places

should be added to the sensitivity reading (e.g. 1827

should be read as 1.827 nA/ppm).

Figure 22 - Water loss test

One dimensional bar code

FIGARO

TGS5042

041124

1827

Lot No.

Sensitivity to CO (nA/ppm)

(Ex.1827 = 1.827nA/ ppm)

Figure 23 - TGS5042 markings

(NOTE: UL Mark may appear on shrink tube)

6. Cautions

6-1 Situations which must be avoided

Revised 04/13

12

TECHNICAL INFORMATION FOR TGS5042

1) Disassembling the sensor

Under no circumstances should the sensor be disassembled, nor should the sensor can and/or cap be deformed.

2) Contamination by alkaline metals

Sensor characteristics may be significantly changed when

the sensor is contaminated by alkaline metals, especially

salt water spray.

3) Exposure to high concentration of basic (non-acidic) gases

Sensor characteristics may be irreversibly changed by the

exposure to high concentrations of basic gases such as

ammonia.

4) High temperature exposure

At temperatures of 80C or higher, the sensing membrane

may deteriorate, resulting in irreversible change of sensor

characteristics.

5) Contact with water

Sensor characteristics may be changed due to soaking or

splashing the sensor with water.

6) Application of excessive voltage

If higher than specified voltage is applied to the sensor,

breakage may occur or sensor characteristics may drift,

even if no physical damage or breakage occurs. Do not

use the sensor once excessive voltage is applied.

6-2 Situations to avoid whenever possible

1) Exposure to silicone vapors

Avoid exposure of sensor where silicone adhesives, hair

grooming materials, or silicone rubber/putty may be

present. Silicone vapors may cause clogging of the gas

diffusion route.

2) Dew condensation

If severe dew condensation occurs for a long period

inside of the sensor or on the sensor surface, it may cause

clogging of gas diffusion route or deterioration of the

sensing membrane. Mild dew condensation which occurs

in normal indoor air would not cause any significant

damage.

3) Storage in sealed container

Do not keep the sensor in a sealed containers such as

sealed bag. Due to ambient temperature change, dew

condensation may occur inside the sensor if the sensor is

stored in this manner.

4) Freezing

When subjected to temperatures below 0C, it is possible

that the water in the reservoir may freeze. Since water

volume will expand when freezing, the sensor can may

undergo some deformation. Care should be taken in

the design of the detector to ensure that the sensor is

not placed too close to other components or the circuit

pattern on a PCB, as such deformation may cause the

sensor to come in contact with these items. In addition,

if the freezing process were to occur very rapidly,

Revised 04/13

water leakage may occur inside the sensor, irreversibly

changing its characteristics. This risk greatly is increased

if the sensor is positioned with the cap facing down (for

more information, refer to Item 3-1 Position Dependency of

the Sensor in the document Application Notes for TGS5042).

5) Exposure to hydrogen sulfide or sulfuric acid gas

If the sensor is exposed to hydrogen sulfide or sulfuric acid

gas, sensor components such as the gas diffusion film, can,

and cap may be corroded, resulting in the sensor damage.

6) Vibration and shock

Vibration and shock may cause an open or short circuit

inside the sensor.

7) Dust and oil mist

Extremely high concentrations of dust or oil mist

may cause clogging of the sensor's internal structure.

When such conditions are expected to be encountered,

installation of an external air filter is recommended.

8) Flux for soldering

Manual soldering is recommended since high concentrations of flux may affect sensor characteristics when the

sensor is soldered by wave soldering. When wave soldering

is used, a test should be conducted before production

starts to see if there would be any influence to sensor

characteristics. Please refer to Item 5-3 of Application Notes

for TGS5042 for advice on manual soldering conditions.

9) Exposure to organic vapors

If the sensor is exposed to organic vapors such as alcohols,

acetone, or volatile oils, these gases may adsorb on the

sensor surface, resulting in temporary sensor drift.

6-3 Additional cautions for storage and installation

1) Store and ship in a short-circuited form.

2)This sensor requires the existence of oxygen in the

operating environment to function properly and to exhibit

the characteristics described in this brochure. The sensor

will not operate properly in a zero oxygen environment.

Figaro USA Inc. and the manufacturer, Figaro Engineering

Inc. (together referred to as Figaro) reserve the right to make

changes without notice to any products herein to improve

reliability, functioning or design. Information contained in

this document is believed to be reliable. However, Figaro

does not assume any liability arising out of the application

or use of any product or circuit described herein; neither

does it convey any license under its patent rights, nor the

rights of others.

Figaro's products are not authorized for use as critical

components in life support applications wherein a failure

or malfunction of the products may result in injury or

threat to life.

13

TECHNICAL INFORMATION FOR TGS5042

FIGARO GROUP

HEAD OFFICE

OVERSEAS

Figaro Engineering Inc.

1-5-11 Senba-nishi

Mino, Osaka 562-8505 JAPAN

Tel.: (81) 72-728-2561

Fax: (81) 72-728-0467

email: figaro@figaro.co.jp

www.figaro.co.jp

Figaro USA Inc.

121 S. Wilke Rd. Suite 300

Arlington Heights, IL 60005 USA

Tel.: (1) 847-832-1701

Fax.: (1) 847-832-1705

email: figarousa@figarosensor.com

APPENDIX

TGS5042 Lead Configurations

Leads are connected to sensor electrodes when of open-circuit storage in fresh air. Nevertheless,

the sensors are shipped. There are two lead the period to reset sensor polarization depends

configurations available:

on storage conditions which includes amount

of gases, temperature and humidity, storage

A00 : Stainless steel (SUS) pin version

period, and customers circuit. As a result,

B00 : Flexible nickel ribbon version

Figaro recommends measuring the required

When ordering, please be sure to specify the stabilization period of sensor output in air at the

lead configuration. Please refer to Figure 24 on customers actual production process.

Page 15 for sensor dimensions on each model.

TGS5042-B00

TGS5042-A00

Flexible nickel ribbon version

Stainless steel (SUS) pin version

For applications where there is insufficient

The solid SUS pins of the A00 version enable space for mounting TGS5042-A00, such as in

the sensor to be more easily mounted and/or portable CO monitors, the TGS5042-B00 is

directly soldered onto a PCB.

a suitable alternative. This model can also be

directly soldered onto a PCB.

Mechanical strength:

Withstand force - 6kg along a vertical axis (lead Mechanical strength:

from metal can)

Withstand force - 1.5kg along a vertical axis

Vibration - frequency--10~500Hz (equiv. to 10G) (metal ribbon from metal can)

duration--6 hours

Vibration - frequency--10~500Hz (equiv. to 10G)

direction--x - y - z

duration--6 hours

Shock - acceleration of 100G, repeat 5 times

direction--x - y - z

Shock - acceleration of 100G, repeat 5 times

NOTE: When the sensor is shipped, the

working electrode and counter electrode are NOTE: The nickel ribbon leads are provided for

not connected (i.e. open-circuited). To obtain the purpose of electrical connection and should

stable sensor output, the sensor should be short- not be used for affixing the sensor to a PCB. To

circuited by connecting to a measuring circuit. secure the sensor and prevent disconnection of

Figaro's tests have shown that one hour should be the leads, affix the sensor to a PCB using wire,

enough to stabilize sensor output after 6 months two-sided tape, or other appropriate measures.

Revised 04/13

14

TECHNICAL INFORMATION FOR TGS5042

APPENDIX (cont.)

TGS5042-A00

TGS5042-B00

3.01.5

4.150.8

Top view

2.01.0

4.01.0

8.30.05

0.80.05

20.90.05

4.00.1

904

Working electrode

1.250.25

0.200.12

8.50.3

(Ribbon thickness:

0.15 mmT)

Side view

49.71.0

50.21.5

49.71.0

Ribbon*1

Cutting point

14.10.6

14.10.6

Insulation tube

20.90.05

4.00.1

0.80.05

904

3.01.5

2.01.0

4.01.0

7.50.1

8.30.05

0.80.05

4.150.8

Counter electrode

Bottom view

unit: mm

Figure 24 - TGS5042 Dimensions

(lead configurations)

When the sensor is shipped, the working

electrode and counter electrode are connected

(i.e. short circuited) by a metal ribbon in order to

avoid polarization of the electrodes. To measure

Revised 04/13

the sensor output, the ribbon should be cut and

the sensor connected to a measuring circuit. The

cutting point as indicated can be used to cut the

ribbon easily.

15

You might also like

- For The Detection of Carbon Monoxide: Applications: FeaturesDocument2 pagesFor The Detection of Carbon Monoxide: Applications: FeaturesAdib PriatamaNo ratings yet

- Nap 505 ManualDocument30 pagesNap 505 ManualAngelNo ratings yet

- Technical Data Mq-2 Gas Sensor: H L H HDocument3 pagesTechnical Data Mq-2 Gas Sensor: H L H HsksachinNo ratings yet

- MQ 3 DatasheetDocument8 pagesMQ 3 DatasheetelvinguitarNo ratings yet

- Xgard Bright: Addressable Fixed Point Gas Detector With DisplayDocument4 pagesXgard Bright: Addressable Fixed Point Gas Detector With DisplayPunyawich FungthongjaroenNo ratings yet

- TGS5042 Product Infomation Rev01Document2 pagesTGS5042 Product Infomation Rev01Sahil ChadhaNo ratings yet

- For The Detection of Carbon Monoxide: Applications: FeaturesDocument2 pagesFor The Detection of Carbon Monoxide: Applications: FeaturesFito PaezNo ratings yet

- Bulletin11M12A01 01EDocument13 pagesBulletin11M12A01 01ECristian Branada MacayaNo ratings yet

- Lampiran 1Document2 pagesLampiran 1hme_unismaNo ratings yet

- TGS8100 Product InfomationDocument10 pagesTGS8100 Product Infomationbemxgm-1No ratings yet

- 2620 Datasheet SensorDocument12 pages2620 Datasheet SensorFachrizal MuhammadNo ratings yet

- Gasboard 3000plusDocument8 pagesGasboard 3000plusSabar PrasetyoNo ratings yet

- 4160 PDFDocument2 pages4160 PDFratonitoNo ratings yet

- Datasheet Sensor MQ9Document3 pagesDatasheet Sensor MQ9Harold CaraballoNo ratings yet

- TGS 842Document2 pagesTGS 842Cesar TemocheNo ratings yet

- 821 PDFDocument2 pages821 PDFemrenormNo ratings yet

- Ptical Oxygen Sensor: ATA HeetDocument14 pagesPtical Oxygen Sensor: ATA HeetZoran ConstantinescuNo ratings yet

- Figaro: For The Detection of Air ContaminantsDocument2 pagesFigaro: For The Detection of Air ContaminantsarfiarfiNo ratings yet

- Analog Gas Transmitters Polygard 2 At6: DescriptionDocument6 pagesAnalog Gas Transmitters Polygard 2 At6: DescriptionVasil StoyanovNo ratings yet

- SG800GDocument26 pagesSG800GRodrigo CorintoNo ratings yet

- AstroUV Turbo - HACH New ProductDocument4 pagesAstroUV Turbo - HACH New ProductprannoyNo ratings yet

- Data Sheet AO 02 Oxygen SensorDocument5 pagesData Sheet AO 02 Oxygen SensorKaio QueirozNo ratings yet

- Tgs2600 Product Information Rev02 EkoDocument2 pagesTgs2600 Product Information Rev02 EkoNurry EkoNo ratings yet

- Hornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetDocument2 pagesHornet Hot Cathode Miniature-Ionization Vacuum Gauge With Dual Convection Data SheetInstruTech, Inc.No ratings yet

- Technical Data Mq-7 Gas Sensor: FeaturesDocument3 pagesTechnical Data Mq-7 Gas Sensor: FeaturesCatur Mei RadhickaNo ratings yet

- Technical Data Mq-5 Gas Sensor: H L H HDocument2 pagesTechnical Data Mq-5 Gas Sensor: H L H HLucho Yupanqui SantosNo ratings yet

- Model 1000 Analyzers CG, TCD, EC SensorsDocument4 pagesModel 1000 Analyzers CG, TCD, EC SensorsDr. John " Jack" driscollNo ratings yet

- Cromatografo de Gas NaturalDocument8 pagesCromatografo de Gas NaturalJinhichi Molero RodriguezNo ratings yet

- TGS2106Document2 pagesTGS2106RyanSardanaNo ratings yet

- Asg 2001Document12 pagesAsg 2001Luiza OcheanaNo ratings yet

- GTD-2000Ex Manual (Eng)Document26 pagesGTD-2000Ex Manual (Eng)Justice KNo ratings yet

- LPG Detection AlarmDocument26 pagesLPG Detection AlarmsravanNo ratings yet

- Model 112 VOC or EC Analyzers 4 PG 807 3 GasDocument4 pagesModel 112 VOC or EC Analyzers 4 PG 807 3 GasDr. John " Jack" driscollNo ratings yet

- BW GasPoint DSDocument2 pagesBW GasPoint DSgreggherbigNo ratings yet

- MQ 2 PDFDocument2 pagesMQ 2 PDFSanjana SinghNo ratings yet

- NDIR Sensor CheckDocument36 pagesNDIR Sensor CheckCNNo ratings yet

- EL3020 Data PDFDocument24 pagesEL3020 Data PDFichrakNo ratings yet

- Journal Paper - Chlorine Leakage Detection-Revised On 241123Document8 pagesJournal Paper - Chlorine Leakage Detection-Revised On 241123Sunsets.nNo ratings yet

- Doc024 52 93026Document28 pagesDoc024 52 93026Long Nguyễn VănNo ratings yet

- Journal Paper-Elseviere - Chlorine Leakage Detectioncorrected On 9-11-23Document8 pagesJournal Paper-Elseviere - Chlorine Leakage Detectioncorrected On 9-11-23Sunsets.nNo ratings yet

- POLYMETRON 8398 Inductive Probe Manual-221 183 098Document28 pagesPOLYMETRON 8398 Inductive Probe Manual-221 183 098Long Nguyễn VănNo ratings yet

- JW01 V2.2 3IN1datasheeetsDocument5 pagesJW01 V2.2 3IN1datasheeetsmhumer438No ratings yet

- Technical Data Mq-2 Gas Sensor: H L H HDocument2 pagesTechnical Data Mq-2 Gas Sensor: H L H HMhmmd Agus HidayatNo ratings yet

- Technical Data Lambda Transmitter LT2 KS1D Lt2 Ks1D-K Combination Probe KS1D KS1D-KDocument28 pagesTechnical Data Lambda Transmitter LT2 KS1D Lt2 Ks1D-K Combination Probe KS1D KS1D-KEdgardoNo ratings yet

- 1 Gasboard-3000PlusDocument8 pages1 Gasboard-3000PlusSabar PrasetyoNo ratings yet

- TGS 244Document2 pagesTGS 244Tugino GinoNo ratings yet

- S Guard Manual PDFDocument25 pagesS Guard Manual PDFRomanPochinkovNo ratings yet

- Carbon Monoxide Sensor Mq7Document4 pagesCarbon Monoxide Sensor Mq7Primas EmeraldiNo ratings yet

- O2 Mox 4 Medicel V2 1Document4 pagesO2 Mox 4 Medicel V2 1Chaphidzun NakMadridista SejaetieNo ratings yet

- Technical Data Mq-135 Gas Sensor: H L H HDocument2 pagesTechnical Data Mq-135 Gas Sensor: H L H HSiddharthRawatNo ratings yet

- Technical Data Mq-6 Gas Sensor: H L H HDocument2 pagesTechnical Data Mq-6 Gas Sensor: H L H Hmd4760No ratings yet

- High Temperature Zirconia Oxygen Probe: ZGP2 SeriesDocument12 pagesHigh Temperature Zirconia Oxygen Probe: ZGP2 SeriesjoymotiNo ratings yet

- Xgard_Bright_Data_Sheet_en_24Document2 pagesXgard_Bright_Data_Sheet_en_24shanto2024.zenithNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- No Residue™ Flux IF 2005MDocument4 pagesNo Residue™ Flux IF 2005MBéla BődiNo ratings yet

- Catalogo UTPDocument483 pagesCatalogo UTPcbmcartagenaNo ratings yet

- Norma IPC-T-50G-cuprinsDocument2 pagesNorma IPC-T-50G-cuprinsJoan EspinozaNo ratings yet

- Chemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of Elements PDFDocument14 pagesChemistry Notes For Class 12 Chapter 6 General Principles and Processes of Isolation of Elements PDFbharatarora0106No ratings yet

- Defaults Wave SolderingDocument8 pagesDefaults Wave SolderingTANNo ratings yet

- Mil C 14550BDocument4 pagesMil C 14550BKris PathinatherNo ratings yet

- Heareus RTD ApplicationNotesDocument2 pagesHeareus RTD ApplicationNotesAshish GuptaNo ratings yet

- Section 5. Welding and BrazingDocument27 pagesSection 5. Welding and BrazingrobinyNo ratings yet

- Galvanizing Defects RectificationsDocument19 pagesGalvanizing Defects RectificationskumarNo ratings yet

- Brazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessDocument23 pagesBrazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessAd Man GeTigNo ratings yet

- 16.3 Filler Metal SpecificationsDocument2 pages16.3 Filler Metal Specificationsedgar zamoranNo ratings yet

- Soldering Thermometer & TesterDocument12 pagesSoldering Thermometer & TesterFerdinand EstanislaoNo ratings yet

- HVAC Welding and Cutting 1202Document14 pagesHVAC Welding and Cutting 1202deangel1701No ratings yet

- Welding Processes and TechniqueDocument49 pagesWelding Processes and TechniqueRanendraNo ratings yet

- Lab Manual IpeDocument700 pagesLab Manual IpeMominul Islam OpuNo ratings yet

- Solid and Flux Cored Welding WiresDocument29 pagesSolid and Flux Cored Welding WiresAli TalebiNo ratings yet

- 12th Saiveera Academy Reduced Chemistry Guide Vol 1Document102 pages12th Saiveera Academy Reduced Chemistry Guide Vol 1꧁ꌚꐇꌅꐞꁲ ꧂100% (1)

- Sir Ecm Testing Soldering Materials SmtaDocument4 pagesSir Ecm Testing Soldering Materials SmtaAdair NettoNo ratings yet

- Car Parking SensorDocument39 pagesCar Parking SensorSubarna Poddar100% (10)

- Processing of Copper Anode-Slimes For Extraction of Metal ValuesDocument12 pagesProcessing of Copper Anode-Slimes For Extraction of Metal ValuesUli ArthaNo ratings yet

- Welding, Brazing and Soldering PDFDocument103 pagesWelding, Brazing and Soldering PDFAtul Kumar100% (1)

- Reaction of Iron With Molten TinDocument8 pagesReaction of Iron With Molten TinGabriel TaberneroNo ratings yet

- Aluminium Vacuum BrazingDocument9 pagesAluminium Vacuum BrazingsinanNo ratings yet

- Diffusible Hydrogen TestDocument11 pagesDiffusible Hydrogen Testvijaya kumarNo ratings yet

- Manual Soldering/desoldering - Electrical/electronic ComponentsDocument6 pagesManual Soldering/desoldering - Electrical/electronic ComponentsRudi FajardoNo ratings yet

- CZ XGZP6857a100kpg 0001Document7 pagesCZ XGZP6857a100kpg 0001RolandoIgorLeivaNo ratings yet

- Brazing EnglishDocument36 pagesBrazing EnglishgeorgiosaguNo ratings yet

- P-Series 0.5W White SPMWHT366EA3: Middle Power LED PLCC SeriesDocument19 pagesP-Series 0.5W White SPMWHT366EA3: Middle Power LED PLCC SeriesRivera FernandoNo ratings yet

- Marathon 543: Classifi CationsDocument1 pageMarathon 543: Classifi CationsBranko FerenčakNo ratings yet

- FusionDocument3 pagesFusionMuhammad Robby Firmansyah100% (1)